The minimum thickness of the screed is standardized by several official documents. SP 29.13330 (Floors) specifies a size of 2 cm for concrete floors, 4 cm when using acoustic materials in its pie. When embedding the contours of a water-heated floor into the structure, the height of the screed should be 4.5 cm greater than the diameter of the pipes used.

On the other hand, if there is no warm floor, sound insulation and insulation in the screed, and the leveling is done with a self-leveling floor, then this characteristic can be reduced to 5 - 10 mm and is set to “zero”, according to the recommendations of a particular manufacturer.

Height of the self-leveling floor layer.

Requirements for screed foundations

The screed has many functions. It not only protects the base located underneath from destruction, but also distributes the load on it evenly over the entire area. And for the top coating, it serves as a solid foundation, ensuring its stability and leveling out differences and defects in the underlying layers.

Even the minimum thickness of the screed must have certain characteristics:

- high strength, ability to withstand mechanical loads from furniture, equipment and people walking on the floor;

- homogeneity and equal density throughout the entire mass, without internal voids, cracks, chips;

- flat horizontal surface with a maximum slope of 2 mm per 1 running meter.

Compliance with the horizon is checked using a bubble level Source kvartirapedia.ru

On a note! The slope may be greater if this is provided for by the design and purpose of the screed. For example, when installing a shower floor to drain water to the drain hole.

In some cases, requirements for heat and sound insulation, surface quality, chemical resistance, etc. may be imposed on the rough coating. Therefore, the thickness of the floor screed is always calculated individually based on the totality of the requirements for it and the initial state of the foundation.

See also: Catalog of companies that specialize in finishing materials and related work

Protective layer of concrete for reinforcement

The protective layer in reinforced concrete building elements is a layer of concrete whose thickness is equal to the distance from the edge of the reinforcing frame to the surface of the monolith.

Its minimum value is determined by regulatory documents and should provide reliable protection of the metal from corrosion in the event of possible mechanical damage to the edge. Improperly laid mesh or reinforcement cage entails a decrease in the thickness of the protection and active exposure to chemical and electrochemical corrosion. In the most difficult cases, the presence of exposed steel reinforcement can lead to a violation of the integrity of reinforced concrete structures and their subsequent destruction.

Accurate adherence to the technology for installing reinforcing elements allows:

- ensure reliable fastening of steel rods in the concrete body;

- distribute the accepted loads evenly throughout the entire monolith structure;

- protect the metal from adverse external factors.

Therefore, the correct installation of reinforcement is one of the most important issues in the manufacture of reinforced concrete products and pouring monoliths on a construction site.

How to choose the thickness of the screed

Concrete mortars are used to level foundations in different rooms - ordinary rooms and bathrooms, garages and balconies. They are laid on the ground, wooden flooring, or reinforced concrete floor slab. At the same time, they try to solve related problems, for example, providing waterproofing or underfloor heating. It is clear that the structure and thickness of the screed must be different in each case in order to fulfill all the functions assigned to it.

Subfloor on the terrace Source rovny-pol.by

Based on the layer height, the following types of screeds can be distinguished:

- thick;

- normal;

- thin.

Thick screed

Thick screeds include reinforced screeds with a height of more than 15 cm. They are installed in those rare cases when a large load is expected on the floor - in garages, warehouses. A greater thickness of pouring is often done when screeding the floor on the ground, in order to raise it to the level of the foundation.

Rough screed inside a strip foundation Source stroybrigada.by

It is not recommended to install it in houses due to the excessive load on the floors and the risk of deformation of the walls due to the thermal expansion of concrete. The degree of this risk increases when a heated floor system is built into the screed. A large mass of a thick layer of concrete presses on the lower part of vertical structures, causing destruction and deformation. But they can be prevented by laying damper tapes along the perimeter of the walls to the entire height of the fill.

There are situations when the normal or minimum thickness of the concrete layer is not able to level out the slope of the base or cover all differences, and a decision is made to pour a thick screed. You should not do this without evaluating other ways to fix the problem.

- You can use special tools and remove the layer of old screed or cut off the most protruding areas.

- Perform preliminary leveling with expanded clay, thereby reducing the load, providing better thermal insulation of the floor and reducing the cost of concrete mixture.

Screed over a layer of expanded clay Source laminatepol.ru

Application of ready-made fixing parts

For quick and accurate installation of reinforcement inside the formwork, building material manufacturers produce inexpensive plastic clamps. You can see several types of such products. But, in fact, there are only two of them - vertical posts (supports, “chairs”) and round ones (“stars”). All other models are derived from these two types.

Vertical posts are used to install a reinforcing mesh or spatial structure in a position raised above the support. Their height and support recess may vary depending on the diameter of the reinforcement and the design height of the installation.

Round “stars” are put on using a special latch-lock on the upper horizontal rows and vertical ones. The calculated radius prevents the rods from getting closer to the formwork and ensures the required thickness of the protective layer. Available in various outer and inner diameters.

The use of plastic clamps for mounting steel reinforcement allows you to:

- ensure high accuracy of the thickness of the protective layer;

- reduce work completion time while ensuring high quality structures;

- reduce the cost of manufacturing reinforced concrete elements of buildings and structures.

The determining factor for use is the simple design of the clamps and their low cost.

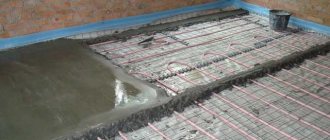

Screeds with heating system

Other standards apply when screeding a heated floor. In this case, it is subject to one more additional requirement: the layer of concrete above the heating elements must be such that it warms up quickly enough over the entire surface, without temperature changes.

Practical observations have shown that the optimal height of the concrete layer above the pipes is about 4 cm. With a standard pipe diameter of 25 mm, the overall minimum screed layer is 6-7 cm. It is not recommended to do it more or less for the following reasons:

- with a smaller thickness, the height of the layer above the pipes and reinforcing mesh is insufficient to ensure the required strength;

- a thin screed is heated in strips, only in the area of the heating elements, and the space between them remains cold;

- A thick screed requires more time and a higher temperature for heat to reach the surface.

Types of coatings

Cement mortar

A cement screed is the layer above a concrete slab; it is prepared from sand and cement. This is the basic structure of the floor to prepare the base for the floor covering. Cement screed requires special attention to preparation.

Mixing cement mortar yourself consists of combining cement, sand and water. But it’s quickest and most convenient to work with dry mixes that are sold in the store.

Cement screed stabilizes the temperature in the house, regulates humidity, and creates additional comfort. A heated floor system is usually installed on it. Due to the large thermal inertia, such a heating system cannot be single. It is necessary to install additional heat sources. But a comfortable internal climate is regulated by an even screed.

Dry backfill

Leveling the floor occurs by dry backfilling onto the surface of a clean, level concrete base. Depending on the purpose, dry screed can be classified into the following types:

- Designed for laying on flat surfaces.

- It is laid on a flat floor on top of a heat-insulating porous-fiber material.

- The floor is made using dry backfill.

- Installation is carried out on a combined substrate.

Dry screeding is easiest to do in dry weather conditions. Suitable for apartments where the level of condensation is high, for example, when living on the ground floor. More moisture accumulates there, and additional surface protection from liquid ingress is required. The dry method is suitable for humid environments, but it can also be used in other climatic conditions.

Using dry technology is convenient: after just a few days, other materials can be applied on top of it. When it gets stronger and becomes uniform, it will withstand any permissible load.

Ground screed

When installing the floor of a basement or first floor, the base for the screed is often the soil, which makes adjustments to its design and affects the thickness. If there is a large difference between the zero level and the ground level, the cost of concrete is unreasonably high, so the foundation must be prepared first.

- The soil is compacted.

- First, a layer of sand is poured onto it, then a layer of crushed stone to the desired level.

- All bulk layers are thoroughly compacted.

- Cover with a layer of waterproofing.

- Cover with a layer of thermal insulation (if necessary and desired).

- The fittings are laid.

- Beacons are placed for the screed.

Scheme of layers for a floor on the ground Source pol-exp.com

The minimum thickness of a concrete screed with reinforcement on the ground for such preparation is 5 cm. You cannot do less, since the underlying layers, despite compaction, still have some mobility and are influenced by seasonal ground movements. In addition, it is recommended to add plasticizers to such solutions when mixing for greater resistance to cracking under mechanical stress.

As in the case of very uneven bases, the method of preliminary leveling and raising the level with bulk materials allows you to reduce the amount of concrete and reinforcement for the screed. Thus, reducing financial expenses, saving effort and time for carrying out work and drying the concrete layer.

Repair in case of damage

During the operation of reinforced concrete elements, cracks, chips and other defects may appear on their surface, violating the integrity of the protective layer. The reasons for such formations can be:

- loads on structures exceeding the design value;

- ill-conceived use of special construction equipment;

- construction of additional floors without changing the foundation design;

- pressure of heaving and moving soils.

Violation of construction rules and technologies almost always leads to damage. Restoring the integrity of the protection is possible, but will require additional costs.

The full range of repair work should include:

- strengthening the concrete structure;

- installation of additional transverse elements;

- sealing all existing cracks;

- restoration of chipped and crumbled areas.

The work is carried out using concrete mixtures and high grade cement mortar. For strengthening, formwork is installed and reinforced concrete is added with preliminary driving of steel anchors into the old structure.

Restoration should not be performed more than 2-3 times. In these cases, it is not the repair of individual elements that is required, but the complete restoration of the building.

Briefly about the main thing

Concrete floor screed can have different thicknesses ranging from 2 to 15 cm. Usually, average values are chosen for it, trying to obtain the optimal combination of coating strength and the cost of its creation. The minimum layer thickness can be achieved subject to many conditions, the main ones being a strong and level base and the use of special solutions reinforced with fiber additives. But these conditions are not sufficient when installing screeds on the ground and underfloor heating. In the above cases, the concrete layer cannot be less than 5-7 cm.

Ratings 0

What tools are needed?

It is most convenient to install beacons for leveling bedding using a laser level, preferably with a range of 360 degrees.

If there is a lot of work to be done on cutting “dusty” materials (such as gypsum fiber board), then it is advisable to connect the cutting tool to a construction vacuum cleaner.

To screw the sheets of the first and second layers, you will need to use a screwdriver.

If the amount of work to be done is large, then a mixer can be useful for mixing glue, primer and mastic.

It is convenient to use a grinder to clean putty joints.

We will need hand and measuring tools: a tape measure, a plane for cleaning cut edges, knives, a rule 2 meters long, spatulas, a stapler, bubble levels, special beacon slats...

Installation of beacons

As a material for formwork, it is fashionable to use any good flat material that has one smooth side. Such material, for example, could be:

- boards;

- flat slate;

- chipboard (chipboard);

- plywood.

It is very convenient to use sheet plastic to fill curved paths. If your stock of materials does not contain anything similar, you can rent standard metal formwork from any construction organization. This is practiced quite often today.

The structure is installed along the edge of the marked or excavated area, defining the contour of the future concrete structure. Fastening is done with stakes driven in on both sides. It is allowed to push apart the formwork elements located opposite each other in the trench.

As beacons, if we concrete the yard with our own hands, it is best to use a metal profile, which is used for installing drywall. Their cost is quite affordable and they can provide the necessary rigidity without breaking under the pressure of the concrete mass.

To prevent rain and melt water from accumulating on the site and paths, their surface should have a slight slope. This should be taken into account when installing beacons. To do this, they are placed not along, but across the site. First, using a level, install two beacons along the edges, securing them in slides made of cement-sand mortar. Plaster solutions cannot be used to secure beacons.

After the solution has set, stretch 2-3 cords between these two beacons, and install the remaining beacons along them. As a result, they will all be on the same level. On paths, given their small width, beacon slats can be installed lengthwise, two at a time.

Concreting the site and paths

Pouring concrete itself is a fairly simple, but labor-intensive and very responsible process. The appearance of the entire concrete structure and overall quality depend on its precise implementation. Work must be carried out at an outside temperature of 5°C to 25°C.

In order to concrete the yard, you can order the delivery of ready-made concrete, which will significantly reduce the amount of work performed. Or, in order to save money, prepare the concrete mixture yourself.

If the size of the site is not very large, then the mixture can be prepared independently. To do this you will need:

- concrete mixer;

- shovel;

- buckets and a wheelbarrow for moving sand, crushed stone and ready-mixed concrete.

Concreting process.

Waterproofing

The waterproofing device is necessary in order to prevent the penetration of moisture from the soil into the concrete, as well as to prevent the premature loss of liquid into the soil from the concrete mixture after it is poured. In addition, in the future, the waterproofing layer will prevent grass from growing through the concrete layer.

After this stage of work is completed, reinforcement begins. It needs to be done so that the concrete structure becomes stronger and more durable.

Scope of work

In order to fill the yard with concrete, you will need to perform the following steps sequentially:

- excavation;

- installation of a drainage system;

- installation of formwork;

- waterproofing;

- reinforcement;

- installation of beacons;

- pouring concrete;

- processing during concrete hardening.

Each step is important and cannot be skipped. Since it is possible to fill the yard with concrete only if the work technology is fully followed, which will ensure a high-quality, durable and beautiful coating.

The main stages of concreting a path or yard.

These works have some specific nuances, since they directly depend on the topography of your site and the type of soil. If the soil in the yard is not fertile and you still have to import black soil, then all excavation work comes down to marking the yard with your own hands, leveling the surface and adding a thin layer of crushed stone.

It is necessary to remove the layer of earth so that the surface of the concrete is at the same level as the surface of the earth, i.e. by 20-25 cm.

And if the base is clay, then you don’t have to add crushed stone. It is best to remove a good fertile layer and transfer it to flower beds and beds, where it will be completely useful.