How to cut chipboard

Laminated chipboard can be sawed with a hand saw with a fine tooth, a jigsaw, or a circular saw.

The cut area is taped with masking tape and cut along the cut line with a sharp knife. The knife cuts through the laminate and the top grain of the wood underneath. Further, when passing the saw, the chipboard will not chip. Finishing the end under a C-shaped overlay edging when making furniture, this method is quite suitable. And under melamine self-adhesive tape it is better to use another method. Using a jigsaw or circular saw, we cut the chipboard with a margin of 2-3 mm. from the cutting line. I sawed along the guide with a jigsaw. You can use any smooth strip or rule as a guide. In my case, fiberglass lath is 150 mm wide. thickness 4 mm. As described above, chips formed on the chipboard. Next, we set the guide exactly along the cutting line and remove these 2-3 mm with a hand router and edge cutter. which we kept in reserve. The design of the edge cutter has a bearing on the shank equal to the diameter of the cutter itself. As a result, we get a perfectly smooth edge, to which you can easily glue self-adhesive melamine tape. Also, when cutting curved cuts, you cannot do without using a router. Using a jigsaw, we make a guide with the required radii and also go through the end with an edge cutter. The method of cutting chipboard without chipping is also suitable for cutting laminated plywood and MDF.

If you have at least once tried to cut chipboard at home, then you know for sure that this work is by no means easy and requires not only skill, but also the availability of a good tool. Laminated chipboard is especially difficult to process; when cutting it, many chips often form. That is why many craftsmen, faced with such a problem, come to the conclusion that it is better to cut chipboard when purchasing, especially since many trading organizations provide similar services and the price is quite reasonable.

Chipboard sawing is carried out using precise format-cutting machines, which will help obtain workpieces of a given size and shape.

In addition to cutting sheets, they will help you calculate and provide in the form of a visual video file several options for competent and economical cutting of sheet material (using special computer programs) and, if necessary, perform edging. However, if for some reason you prefer to do this work yourself, you will have to do some preparatory work before cutting the chipboard.

Figure cutting

It is even more difficult to obtain curved surfaces of a given configuration on your own; here you will have to spend additional money on purchasing a router that will help you get rid of chips

no nicks created when you have to cut chipboard.

The price of a hand router can vary significantly depending on the manufacturer, power, and the presence of additional functions. If you do not plan to produce furniture professionally, then it is advisable to purchase an inexpensive model.

To cut chipboard you need to follow these steps:

- Having marked the contours of the required part on a sheet of chipboard, we cut it out with a jigsaw, trying to cut away a couple of millimeters from the intended cutting line

- We make templates of the design radius from fiberboard or plywood; we do not thoroughly sand the ends with sandpaper.

- Having attached the template to the part to be finished, we clamp it with clamps and process it with a hand-held copying cutter with a bearing, removing excess material exactly to the intended line.

In this case, it does not matter which cutter (with two or four knives is used). The only condition is that the knives must be able to grasp the thickness of the cut being processed at its entire height. After processing, all that remains is to glue the edge onto the part. Watch the video to see how this is done:

What affects the quality of chipboard cutting?

In this case, we will be sawing chipboard; this is the most capricious material for sawing, because it has longitudinal and transverse layers, and a rather delicate and thin veneer. But on the other hand, it has a hard adhesive base, which will also interfere with us.

Saw blade. How to choose it?

When cutting chipboard, the saw blade must simultaneously cut cleanly and be durable, because the properties of the glue are very close to glass and dull the tool itself quite quickly. Therefore, in the process of cutting chipboard, you need to choose disks that are good enough to cut with them without loss of quality for a long time.

What is the difficulty of sawing with a circular saw with discs?

If we look at the cut of the workpiece, we will see that it is full of burrs, because “by hand” it is practically impossible to guide the saw straight through the cut.

On the saw blade there is a difference in height between the body of the saw itself and the sawing part - the tooth. Due to this distance, the disc has the ability to direct its position in the cut. Accordingly, as soon as it changes its geometry, the rear teeth begin to hit the chipboard workpiece and leave marks on it.

It is important to place the workpiece face down. Why?. The disk rotates from bottom to top, it cuts the pile of the workpiece upward onto the base

Thus, below, on the front side, we always have a clean surface. Problems begin to form at the top, where the teeth exit the workpiece. This is how explosions, chips, piles happen

The disk rotates from bottom to top; it cuts the pile of the workpiece upward onto the base. Thus, below, on the front side, we always have a clean surface. Problems begin to form at the top, where the teeth exit the workpiece. This is how explosions, chips, and piles happen.

How to minimize them, or avoid them altogether? There are several simple tricks and we will tell you about them now.

Trimming sawing method

This method also involves using a circular saw, but a plunge-cut saw is more suitable. You will need a double ruler: it is fixed to the workpiece with clamps. The principle of operation is the same as that of a format-cutting machine: two cuts are made along the same line.

This is what the ruler-bus is used for. It is installed along the marking line, the laminate is lightly cut without disturbing its texture. Then the material is sawed along the marked trace.

By the way! Thanks to the cut on the laminate, no chips will form during the second deep cut.

The cut area can be sealed with an edge.

Using this method, you can cut the tabletop into one or more parts. Minimal chips are possible, but they can be easily removed by regular sanding or hidden with a decorative overlay.

Round cuts can also be masked.

Disadvantage: This method can only make straight cuts.

Tools and materials

If possible, it is best to cut chipboard with a hand router using homemade guides. This method is not very convenient when cutting large sheets, because when working with this tool you need a table. In addition, with this method it is necessary to change cutters frequently. But as a result, you will get cleanly processed, “trimmed” edges.

An electric jigsaw is the most popular tool for cutting chipboard.

Some craftsmen use a jigsaw in their work, however, in the absence of skill, it is difficult to make an even cut, and chips may form.

You can try installing a bimetallic blade with teeth pointed inward, designed for laminate, on a jigsaw. When cutting with a jigsaw, you should increase the speed, with a small feed, so that breaks do not form.

If such methods do not suit you, then to cut chipboard at home, we will prepare for work:

- a hacksaw with fine teeth (the one designed for metal work is best). In this case, the teeth must be set apart by 1/2 the thickness of the blade and be hardened;

- paper adhesive tape;

- file for roughing the cut line;

- sandpaper to finish the cut line.

Rating of the best jigsaw files for wood

For sawing wood, you can choose high-quality, but inexpensive blades. They cope especially well with soft materials, but can also successfully cut hard rocks.

Practice 035-837

Electric jigsaw blades are made of durable carbon steel and are highly resistant to damage. Suitable for wood and plywood, provide fast cutting.

You can buy the Practice 035-837 set from 190 rubles Pros

- universal shank;

- quickly cuts wood and plywood;

- quality material.

Minuses

- Only two files are supplied in the kit;

- Products are not suitable for precise cutting.

GMT JT234X-5

Italian-made products are made according to international standards from high-strength alloy. They have a proprietary coating that increases their service life. The working length is 90 cm - blades of this size are sufficient to solve most problems.

Attention! GMT electric jigsaw files are only suitable for clean, neat cuts.

The price of files for a GMT electric jigsaw starts from 700 rubles

Pros

- five pieces in a set;

- good working length;

- universal tail section.

Minuses

- high price;

- Suitable for wood only.

VIRA T111C552025

Budget jigsaw blades are 75 mm long and are suitable for sawing workpieces of medium thickness. The products can be used for cutting plywood, wood and plastic. The files are certified according to the German DIM standard and meet the requirements of the Russian GOST. Made from high carbon steel, resistant to breakage.

You can buy saw blades for the VIRA electric jigsaw from 60 rubles

pros

- cheap;

- T-tail;

- comfortable length.

Minuses

- only two pieces in the set;

- Only suitable for quick cutting with an electric jigsaw.

Handy tools

You can cut chipboard with a jigsaw, but this will be a rough cut. The edges may turn out not straight, but sinusoidal, and in the worst case, the edge will not be perpendicular to the front surface.

When cutting, you must be prepared for the fact that the jigsaw file will begin to “walk” due to the bend. You need to cut with a margin of 4 mm, and then level the edge.

Cutting laminated chipboard at home using a jigsaw reduces the formation of chips. When cutting, you need to increase the speed and reduce the feed, setting the pumping to 0. Only sharp saw blades designed for special cutting of chipboard should be used. Only by following these rules can you achieve a good result. After cutting, the end that will be visible can be sanded down. Additionally, before cutting, as already mentioned, you need to cut a line along which the cut will take place. But we do not move the file along this line, but near it - then the chips will not touch the limits you need. In the end, all that remains is to finish the edges with sandpaper.

Indents from the contour can be up to 4 mm. Then these few millimeters are removed with a cylindrical cutter using a hand-held electric router with a bearing. The bearing is guided along a long level fixed to the back of the sheet.

To avoid problems with chipping, it is recommended to use (where possible) a flexible overhead U-profile. It covers chips well.

In addition, if the chips are in a non-working, low-visibility area, they can be disguised with a marker or felt-tip pen matched to their color.

The most undesirable way to cut chipboard is with a file (oddly enough, in old textbooks a lot of material is devoted to this method). You can use a plane, but preferably an electric one with carbide knives. But here we must take into account that dust from under the plane will scatter throughout the room.

And the most comfortable way is using a manual router along a guide. The end should be smooth and at 90 degrees, there will be no chips, and when the vacuum cleaner is turned on, there will be almost no dust.

https://youtube.com/watch?v=tG0elOFcRS8

Types and operational parameters

Like almost all construction equipment, circular saws are divided into professional and household. These two types differ in terms of service life and quality, and, as a consequence, in their cost.

For example, a professional tool is designed for long-term and intensive work, while the frequency of use of a household tool is often limited, since a circular saw can be used less often.

The second thing you need to pay attention to is the length of the intended cut of the board. The standard parameters of this criterion are 50-60 millimeters, which provides greater maneuverability of the saw.

But there are also exceptions. For example, to work with thin material, a tool with a disk of 30-40 millimeters is used, and, on the contrary, for thick boards, large saws in wood of 90-100 millimeters or more have been developed.

If you need a tool that combines different sizes of disks, then you can purchase a device with the possibility of permanent installation. It has the advantage of being lighter than devices with the same 100 millimeters.

The size of the hand saw blade also dictates its power – low, medium or high power. Professionals, in the case of household work, recommend giving preference to the second category, in which overheating and failure of sometimes quite expensive equipment are unlikely.

Do it yourself or order it?

A custom cut will be smoother

High-quality sawing of chipboard is difficult to do manually due to the large size of the sheets. The dimensions of a standard slab are 2440x1200, and this is not the limit. However, if you work with chipboard or MDF quite often, it makes sense to get an expensive tool and work for your own pleasure. If you only need to cut a few sheets, you can go two ways:

- Cut the slabs yourself using available hand tools;

- Order cutting of chipboard in a specialized workshop.

What to choose is up to you, and we will consider each of these options.

Ways to minimize chipping

An additional reason for the formation of chips may be misalignment of the saw teeth. Therefore, the first thing you need to do is purchase a tool with a straight cut (often Bosh files). However, it should be taken into account that during prolonged use, such files overheat and may even bend during the cutting process. Therefore, it is necessary to take breaks from work to cool the cutting tool.

However, just replacing the saw blade is not enough and in order to cut laminated chipboard (laminate) with a jigsaw without chipping, you need to make minor modifications to the power tool. Namely, make sure that when the saw moves against the inclination of the tooth, the material does not pull out. For this purpose it is enough to make a persistent platform. You can come to this conclusion by trying to cut two sheets of chipboard at the same time. So there will be practically no chips on the lower element.

In order to make a stop pad for a jigsaw, it is enough to cut out a rectangle from any dense material (for example, laminate) with dimensions identical to the dimensions of the sole of the power tool.

Then, along the larger center line, you should make a notch and secure the resulting equipment to the sole of the jigsaw using insulating tape or double-sided tape. All modifications are ready and finishing work can be carried out in compliance with certain recommendations.

Firstly, as mentioned above, you should use a jigsaw file with a straight cut.

Secondly, in order to better control the cutting process, it is justified to apply a marking line on both sides of the chipboard and check the accuracy of the processing from above and below.

And thirdly, take constant breaks from work to cool the cutting equipment.

Sometimes the solution to this issue can be simply cutting through the laminated layer of material using a mounting knife, and subsequent work with a jigsaw will no longer cause large defects in the form of chips. However, this work requires the performer to have some experience and accuracy.

Zero gap technique

Carpentry craftsmen most often use the principle of modifying the sole of a cutting tool, which consists in reducing the gap between the working tool and the pressure pad. This is almost guaranteed to eliminate the effect of “breaking” the crust in the top layer of the material.

Zero clearance is achieved by securing the cover plate to the tool base. The pad has only one narrow hole (or slot) that fits tightly to the cutting organ. Because of this, even with a high feed force, the teeth are guaranteed to cut off small chips and not turn out the chips in the upper layer of the part.

When using overlays, it is extremely important that they do not scratch or damage the surface of the part. Therefore, they are most often made from a material that is inferior in hardness to the material being processed, for example MDF or plasterboard. Unfortunately, such an overlay does not last long, which is why it has to be changed every 4–5 meters of the cut.

More durable linings can be made from sheet plastic (PVC, fluoroplastic), fiberglass or metal. In the latter case, the surface of the lining must be carefully polished and soft metals such as aluminum or duralumin must be used to reduce vibration.

How to cut chipboard

Laminated chipboard can be sawed with a hand saw with a fine tooth, a jigsaw, or a circular saw. The cut area is taped with masking tape and cut along the cut line with a sharp knife. The knife cuts through the laminate and the top grain of the wood underneath. Further, when passing the saw, the chipboard will not chip. Finishing the end under a C-shaped overlay edging when making furniture, this method is quite suitable. And under melamine self-adhesive tape it is better to use another method.

Using a jigsaw or circular saw, we cut the chipboard with a margin of 2-3 mm. from the cutting line. I sawed along the guide with a jigsaw. You can use any smooth strip or rule as a guide. In my case, fiberglass lath is 150 mm wide. thickness 4 mm. As described above, chips formed on the chipboard. Next, we set the guide exactly along the cutting line and remove these 2-3 mm with a hand router and edge cutter. which we kept in reserve. The design of the edge cutter has a bearing on the shank equal to the diameter of the cutter itself. As a result, we get a perfectly smooth edge, to which you can easily glue self-adhesive melamine tape. Also, when cutting curved cuts, you cannot do without using a router. Using a jigsaw, we make a guide with the required radii and also go through the end with an edge cutter. The method of cutting chipboard without chipping is also suitable for cutting laminated plywood and MDF.

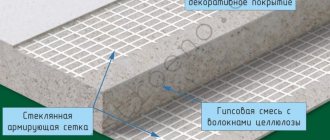

Everyone knows that laminated chipboard is our chipboard, which is covered with a paper-resin film. The lamination process takes place under special conditions: pressure 25-28 MPa, temperature 140-210 °C. The surface is durable, smooth, and beautiful. The laminated chipboard coating is very resistant to mechanical stress and thermal stress. Because of these qualities, laminated chipboard has become simply necessary for furniture production and for interior decoration.

Some craftsmen like to make furniture themselves. They purchase good quality laminated chipboards from manufacturers or in special construction stores. Since the color range of laminated chipboard is very rich, you can easily select the right material. The surface of laminated chipboard also has the most varied structure, since it can be smooth, imitate wood of different species or stone.

In order to make special furniture or a unique interior with your own hands, it is not enough just to buy laminated chipboard and draw it into details. The laminated chipboard coating is very thin, its structure is fragile. If you cut laminated chipboard roughly and incorrectly, the cut will turn out ugly, torn, and cavities will form on the edges. To be able to cut laminated chipboard correctly and not get chips and cracks, you need to know some little “tricks” of the job.

Rating of the best jigsaw files for laminate

Although theoretically any wood saw can be used for laminate, the most accurate results are achieved with special blades. They provide an even cut without defects and do not damage the front surface of the floor covering.

Practice 035-844

Products for cutting laminate with an electric unit have a working length of 75 mm with a total size of 100 mm. Made from high-strength bimetallic alloy. The sharp teeth of the blades are directed in the opposite direction, which allows you to saw the laminate as accurately as possible and without snags.

You can purchase Practice 035-844 from 200 rubles

pros

- high quality and reliable;

- reverse direction of teeth;

- Also suitable for sawing plywood and chipboard.

Minuses

- The set contains only two blades;

- cannot be used for rough cutting.

Bison 15591-2.5

The blades for the electric unit have a thickened working part and are especially resistant to kinks and breaks. They are distinguished by high-quality sharpening and polishing, serve for a long time and reliably. Provide clean and precise cuts of laminated boards and plywood.

The price of a set for an electric jigsaw Zubr starts from 100 rubles

pros

- rarely break even when heated;

- good sharpening;

- affordable price.

Minuses

- the set consists of two canvases;

- not suitable for metal.

Gross 78294

Files made of high-quality chrome vanadium steel are suitable for use with professional tools. They have high wear resistance and special hardness. In production, the method of laser profile cutting is used; sharpening and grinding are fully automated.

Attention! Gross products are suitable not only for laminate, but also for aluminum, stainless steel, plastic and wood.

You can buy files for a Gross electric jigsaw from 900 rubles.

Pros

- The set includes ten canvases;

- high-quality chrome vanadium alloy;

- Suitable for all types of cutting.

Minuses

- high price;

- no spare parts are provided.

Rules for sawing laminated chipboards

To cut laminated chipboard at home, use a hand saw with fine teeth, a circular saw or an electric jigsaw. To complete the job without any problems, you need to do the following:

- Secure the adhesive tape tightly exactly along the cut line. The tape will prevent the saw teeth from damaging the coating film.

- Use a sharp knife to cut through the coating and the layer underneath along the cutting line. In this case, the saw will only cut the inner layer of chipboard and touch the coating only tangentially.

- The hand saw, when working with it, should be placed at an angle (very sharp) to the surface of the slab.

- When cutting with a power tool, you need to use a minimum feed.

- When the part is cut out, you need to cut the edge of the coating at an angle of 45° with a sharp knife.

- The cut is polished using a fine file, the cut is processed towards the center from the edges.

The edge of the sawn laminated chipboard should be covered with a special overlay to prevent any chips or cracks on it in the future. To protect the cut, you can use self-adhesive melamine tape, or a C-shaped edge, or a T-shaped edge.

It is extremely rare that when carrying out repairs using chipboards, it is possible to do without cutting the material. Unfortunately, owners often cannot cut chipboard so smoothly that there are no chips or other damage. But with a competent approach to carrying out such an event, it is still possible to get quite a good result. To do this, you need to perform the following steps.

Cutting panels at home

It is quite possible to saw a sheet of chipboard or laminated chipboard by hand. True, in this case you are unlikely to be able to avoid the appearance of chips and burrs, but you can try to reduce their number and size.

There are several rules that should be followed when cutting chipboard panels:

- Sheets must be cut on a flat, hard surface. For sawing large panels, you can adapt two large tables (their height should be the same!);

- in order to prevent chipping, stick adhesive tape or good masking tape along the cut line, which will hold the edges of the laminated layer;

- For sawing with a hand saw, select a blade with a grinding tooth. The saw teeth should be sharpened well. You need to drive the saw with slight pressure, at an acute angle to the surface, constantly monitoring its position;

- To cut chipboards and laminated chipboards using a jigsaw, the cut line should be scratched or even cut through. It is best to use a sharp knife to cut through the durable laminate layer;

- install a file with fine reverse teeth;

- select the maximum speed of the jigsaw, turn off the “pendulum”;

- fasten an even strip along the cut line and move the jigsaw strictly along it;

- The jigsaw should be pressed firmly against the surface being cut.

All these recommendations help to correctly saw and cut chipboard, but chipping, nevertheless, cannot be completely avoided. Therefore, if it is so important to get a perfectly smooth, even cut line, without chips or saw marks, you should contact specialized workshops where they will cut out any shape from a sheet of chipboard for a reasonable fee.

Professional and household circular saws

Circular saws allow you to make cuts with maximum angular accuracy and a smooth edge. But when working with some materials, guides may be required. By the way, only professional tools are equipped with guide bars. There are models in which the guides are integrated into the design of the saws themselves.

Circular saws for professionals are equipped with a powerful motor that allows the blade with teeth to rotate at high speed.

An important characteristic of such saws is considered to be the depth of cut. Depending on it, saws are divided into small, medium, large and professional

For domestic use, it is recommended to choose small and medium-sized circular saws with a maximum cutting depth of up to 55 mm. Only large saws should be used for production purposes. Their cutting depth can reach 70 mm. In addition, large saws allow you to cut through both thin and thick materials. Woodworking industry enterprises usually use professional saws with a cutting depth of up to 140 mm.

Cutting pipe at an angle of 45 and 90 degrees

If you need to cut a pipe at an angle of 45 degrees, which is often required when laying water and heating pipes. Often steel and cast iron pipes that have a cylindrical shape are used. In installation work, rectangular or profile pipes are used. However, you should cut the pipe correctly with a grinder so that you can easily connect it later. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the cutting area using a tape measure, but we warn you that the result will most likely be negative. And for a positive result, consider the following recommendation from professionals.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to make an even cut. The edges of the paper must be absolutely aligned with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark a cutting line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape. Wrap it around the pipe so that the ends match. Make an even mark and saw off.

How to cut a profile pipe evenly?

Craftsmen advise using a square when cutting a profile pipe. To do this, apply the square to the sides one by one, and turn and apply marks with smooth movements. After the steps, secure the pipe and cut. Prepare yourself a template that will be useful in the future and will save time. It is better to carry out the action with a grinder, so the cut will be smoother.

How to cut a cast iron pipe?

When working with cast iron pipe, keep in mind that it is a fragile material. Therefore, we will find a way to cut such metal without damage.

Before starting work, make notes for the cut, as you would when working with steel pipes. Place a wooden beam for support. Run a grinder around the circumference of the pipe, making small cuts. Then take the chisels, insert them into the groove and hit them hard with a hammer. Please note that Bakelite-based cutting discs are used to cut cast iron pipes.

If you don’t have a grinder at hand to cut a cast-iron sewer pipe or other purposes, use a hacksaw, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting a gas pipe is a dangerous action, so it is best to leave it to professionals. But if you are confident in your abilities, then use a grinder, welding, hacksaw, or gas welding to cut metal.

Trimming instructions:

- Before work, turn off the gas supply riser. Then release the rest of the gas from the pipe. To do this, light the gas in the burners and wait for it to go out.

- After these steps, cut. Using a welding method, the metal base burns when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

Methods for cutting large diameter pipes

For cutting large diameter pipes, such as sewer pipes, there are a number of reliable tools available. Next, let's look at some of them in detail:

The grinder is an inexpensive and accessible option, but it is considered not the safest when working with such materials. If you decide to use this method, be careful and use protective equipment. A roller machine (pipe cutter) is a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted using mechanical devices

It is important to note that machine models differ in shape, so before use, consider the size relationship with the pipe. Gas cutting is the most popular option for cutting larger diameter pipes and sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut area with a gas flow

This method is convenient and effective.

How to cut a pipe lengthwise correctly?

A quick way to cut a pipe lengthwise using a grinder:

Pay main attention to the markings. For this case, use painting thread, which is widely used when marking walls. Before starting work, secure the pipe and, using small movements, carefully saw the pipe. It’s better not to rush, but delicately and slowly process the parts of the pipe, so that the cutting disc does not jump off the marking lines. Remember safety precautions... How to cut thin-walled pipes?

How to cut thin-walled pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper.

Rules for the safe operation of an electric circular saw

When purchasing this power tool, you should also pay attention to safety criteria. Absolutely all conscientious manufacturers of such equipment “swaddle” the cutting disc with a protective casing, which can protect fingers, parts of gloves or other materials from getting under the cutting device, preserving the health of its owner

The casing always covers the upper part of the disk, facing the face of the person working with the circular saw, and the lower part is “exposed” only during direct cutting.

The first quality of protection can also protect the face, body and other parts of a person’s face from chips.

Another safety measure is to protect the device from accidental activation. Only after pressing the start button and disabling this option will the saw begin to work.

You should not be afraid of a circular saw jamming, since almost all modern manufacturers have provided a similar possibility in their equipment, when the cutting disk stops rotating, but the engine does not turn off, after which the saw can be removed from the problem area of the cut and start working again.

How to cut laminated chipboard with a jigsaw without chipping

Such work should be done delicately, as there is a high probability of deformation of the material. For cutting, fillers such as sand are used. Actions can be carried out using a grinder or a special machine.

To summarize, we emphasize

that cutting metal pipes is a complex process, but every willing master can improve it. Using the advice of professionals, you can easily cope with cutting pipes of various sizes and materials. Also, do not forget to process the edges of the pipes after cutting with a file or sandpaper. And the most important thing to remember when starting such actions is safety precautions. When starting work, wear a special suit (casing), mask or closed-type glasses. Your hands should also be reliably protected from sparks, so use thick gloves.

What not to cut chipboard

If the volume of work is large enough and the quality requirements are low, some craftsmen advise sawing chipboard at home using a grinder (angle grinder, commonly called an “grinder”). In doing so, they use a disk designed for working with wood. To make cutting easier, a guide bar is secured along the cutting line using clamps. Cutting chipboard using a grinder can sometimes be seen in the video.

The easiest way to mark is to draw straight lines along the sides of the slab using stretched threads, a square, a ruler and (or) a measuring tape. If there are a large number of parts to be cut, it is difficult to choose the optimal sheet cutting scheme that can reduce losses due to the remaining scraps. To outline smooth curves, you need to use patterns that allow you to reproduce numerous fragments of the same type.

Special programs help improve the quality of cutting, in which the dimensions of products are specified, calculations are made and a diagram of the optimal arrangement of cutting lines is displayed. Such programs include “Cutting 2”, “Master 2” and others.

An example of using the software is shown in the video:

When cutting material with your own hands, you need to pay special attention to the straightness of the corners and maintaining straight lines. Marking large sheets should be done on the floor, working in pairs

Drawing dimensions by one person is fraught with distortion of parameters caused by the displacement of measuring instruments during work.

Using adhesive tapes

Using the same principle, you can protect the back side of the material being cut. A tape should be placed along the cutting line to protect against large fragments being torn out. Pasting surfaces is one of the few ways to ensure the cleanliness of a curved cut with a jigsaw. Unfortunately, masking tape is not the best choice for this due to its low strength.

The best quality cut can be obtained by covering the part with aluminum or fiberglass-reinforced tape. It should be wide enough to cover 15–20 mm on each side of the cutting line. The density of the sticker is also important: the tape must be pressed down well with a dry cloth swab and the formation of folds must be prevented by any means.

You should avoid tapes with very tenacious adhesive. During the tearing process, they can carry along small fibers and fragments of the laminated surface, dissected by microcracks that form during cutting. Also pay attention to how easily traces of glue are removed and whether the adhesive adheres well enough to work with rough materials such as unsanded plywood or OSB.