The proper functioning of the fireplace depends not only on the installation of the firebox, but also on the competent design and installation of the chimney. Everything is important: from calculations of the pipe cross-section to the nuances of thermal insulation. Only a high-quality chimney will best suit its purpose.

Do you want to build a chimney duct, but don’t know which pipe to choose and how to install it? We will help you deal with this problem - in the article we looked in detail at how to make a chimney for a fireplace, paying attention to the pros and cons of pipes made of various materials.

They also provided important requirements for arranging fireplaces and drawing up a project. The article material was supplemented with detailed instructions for installing a chimney, providing it with step-by-step photos.

Chimney pipe height.

Here we can do without complex calculations.

Yes, of course, there are rather cumbersome formulas that can be used to calculate the optimal height of the chimney with great accuracy. But they become really relevant when designing boiler houses or other industrial installations, where they operate with completely different power levels, volumes of fuel consumed, pipe heights and diameters. Moreover, these formulas also include an environmental component regarding the emission of combustion products to a certain height.

There is no point in presenting these formulas here. Practice shows, and this, by the way, is also stipulated in building codes, that for any of the theoretically possible solid fuel devices or structures in a private house, a chimney pipe (with natural draft) with a height of at least five meters will be sufficient. You can still find recommendations to focus on the figure of six meters.

This means exactly the height difference between the outlet of the device (for stoves it is often considered from the grate) to the upper edge of the pipe, without taking into account the attached umbrella, weather vane or deflector

This is important for those chimneys that have horizontal or inclined sections. We repeat - not the total length of the pipe used, but only the height difference

The height of the chimney is precisely the difference in height between its inlet and outlet, and not the total length of the pipe, which may have horizontal or inclined sections. By the way, you should always strive to minimize the number and length of such sections.

So, the minimum length is clear - five meters. Less is impossible! What about more? Of course, it is possible, and sometimes even necessary, since additional factors may intervene due to the specifics of the building (commonly the height of the house) and the location of the pipe head relative to the roof or neighboring objects.

This is due to both fire safety rules and the fact that the pipe head should not fall into the so-called wind pressure zone. If these rules are neglected, the chimney will become extremely dependent on the presence, direction and speed of the wind, and in some cases the natural draft through it may disappear altogether or change to the opposite (“capsize”).

These rules are not so complicated, and taking them into account it is already possible to accurately determine the height of the chimney pipe.

Chimney pipe prices

chimney pipe Basic rules for the location of chimneys relative to the roof elements of the building

First of all, no matter what roof the chimney passes through, the edge of the pipe cannot be closer than 500 mm from the roof (pitched or flat - it doesn’t matter). On roofs of complex configuration, or on a roof adjacent to a wall or other object (say, the edge of the roof of another building, an extension, etc.), the wind support zone is determined by a line drawn at an angle of 45 degrees. The edge of the chimney must be at least 500 mm above this conditional line (in the top picture - the left fragment).. The same rule, by the way, also applies when there is a tall third-party object next to the house - a building or even a tree

The figure below shows how the graphical plotting is done in this case.

Tall trees near the house can also create a zone of dense wind pressure.

On a pitched roof, the height of the section of pipe protruding above the roof depends on the distance from the ridge (left fragment of the upper diagram).

— A pipe located at a distance of up to 1500 mm from the ridge must, with its edge, rise above it by at least 500 mm.

— At a distance of 1500 to 3000 mm, the upper edge of the pipe should not be lower than the level of the ridge.

— If the distance to the ridge is more than 3000 mm, the minimum permissible position of the pipe edge is determined by a line passing through the top of the ridge, drawn at an angle of -10 degrees from the horizontal.

To reduce the dependence of draft on wind, special caps, deflectors, and wind vanes are used. In some cases, the use of a spark arrester is also required - this is especially true for solid fuel devices.

All that remains is to sit down with a drawing of your house (existing or planned), determine the location of the pipe and then finally settle on some height - from 5 meters or more.

What is better - to make it yourself or order it?

It’s easier to order, but more expensive - these works are performed by highly qualified workers, design also has its price.

Building a chimney from solid red brick requires certain skills - building a multi-meter structure with perfectly vertically straight walls is not so easy, and may not be possible for a novice home craftsman. Ceramic ones are also quite difficult to install. Concrete is usually not used in private houses. But the installation of steel structures is quite affordable - and they usually install them on their own.

Working at heights requires certain skills and assistants are required. Therefore, it is worth weighing the pros and cons and deciding whether it is worth trying to do the installation yourself.

Internal section of the chimney

Fireplace chimney.

There is nothing better than the usual cylindrical shape for constructing a chimney. Considering the uneven upward movement of combustion products, which move in a circle along the axis of the chimney, a cylinder seems to be the most acceptable shape, which is capable of providing the strongest draft. In a rectangular pipe, turbulence will form at the corner parts, which will prevent the normal level of draft. However, it is noted that a rectangular pipe can be successfully used with thermal devices that do not require high draft.

These fireplaces and stoves include options that heat rooms with wood. If, for example, the cross-section of the chimney is rectangular and the smoke circulation in it is properly arranged, then this will allow maintaining the temperature to which the heating device was heated. In comparison with pipes with a round cross-section, this looks ideal, since all the heat will evaporate from a cylindrical chimney quite quickly. New generation fireplaces are increasingly equipped with cylindrical chimneys. They operate using a fast heating system - when the system heats up to the set temperature, the boiler will automatically turn off and go into standby mode, thus saving energy.

Main nuances

Note that the chimney of a fireplace and stove is practically no different structurally. The only difference is that the fireplace has an open firebox, while the stove has a closed firebox. Incorrect calculation of the fireplace chimney can lead to smoke in the room

Therefore, it is important to correctly calculate the dimensions of the firebox, determine what diameter the channel will have and what height the structure will have

In this case, the chimney should be as simple as possible; the best option is straight and vertical. If a more complex configuration is used, it is necessary to provide bends with an angle of more than 45 degrees.

To regulate air exchange, do not forget to use a damper, and to clean the fireplace, you must provide a tee to make cleaning the heating equipment easier.

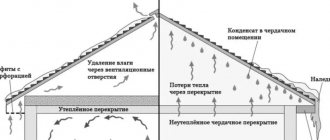

An important condition for the effective and safe operation of heating equipment of this type is reliable thermal insulation. The chimney heats up, so it is necessary to reliably protect the ceiling and walls from fire (mineral basalt wool is used for this)

It is also necessary to think about protection from the cold if the channel is located in an external wall or on the street, which is highly undesirable. From above, the chimney is protected from precipitation by a weather vane or fungus.

We also note that a modern fireplace can have different configurations; structures made of refractory brick or stone with an open firebox are used less and less; they have been replaced by fireplaces with a cast-iron closed firebox (the front panel is made of special fire-resistant glass).

The calculation for a fireplace with a closed firebox is almost the same as the calculation for a stove chimney. But we’ll talk below about how the calculation is performed if the fireplace has an open firebox.

Determining the dimensions of a structure using a specific example

It is very difficult to calculate a fireplace chimney yourself. To do this, you need to have knowledge and practical experience in such a complex field as heating engineering. Therefore, use those methodological materials that were developed by specialists, thanks to which the dimensions, including the diameter of the chimney, are determined very easily.

One of the classic tables is the ratio of the open combustion space to the total effective height of the chimney, which allows you to determine the channel cross-section

The open combustion space is measured in square meters; for this, it is enough to multiply the height of the firebox by its length.

The parameters of the total height of the chimney are measured in meters; in this case, it is simply necessary to make a calculation in which to determine the total height of the structure.

Let's take a specific example and dimensions.

The height of the firebox is 0.5 meters, and the length is 1.1 meters. In this case, the firebox area is 0.55 m2. The effective height at which the chimney extends beyond the ridge is 8.00 meters. We take the table and determine that the point of intersection of the vertical and horizontal lines is located directly in the sector where the diameter is 25 cm2. Thus, we determined that an open fireplace insert should have a chimney with an internal channel cross-section of 25 centimeters.

You should pay attention to another point. The fireplace must have fresh ventilation

In its absence, a vacuum is created in the room, which in turn leads to the formation of reverse draft and the release of smoke into the room. The fireplace is smoking. Therefore, it is also necessary to calculate the diameter of the supply air channel at which the heating equipment will operate correctly.

To do this, use the table of the ratio of the open combustion space (the area that the open firebox has) to the volume of the room in cubic meters.

The volume of the room is determined by multiplying the height by the length and width of the room.

This is how simple calculations are performed to answer the question: “What kind of chimney should a fireplace with an open firebox have?” Everything is in a simplified version. More complex options involve the use of complex formulas, which are fundamental in heating engineering. But more on this in the following materials.

List of the most dangerous errors

The procedure for laying a brick chimney.

These errors include:

- Insufficient thermal insulation of the chimney, which leads to fire and charring of adjacent materials.

- Using unifying protection of two or more channels with one fungus. As a result, the ventilation system is destroyed and smoke enters the house.

- Unauthorized repairs and modifications without special preliminary calculations.

Installing a correct and technically safe brick chimney is quite a difficult task. Each case is unique and has its own nuances. Therefore, it is necessary to consult with specialists at least when drawing up a chimney design for a fireplace.

Fireplace chimney valve

As we have already found out, the “sandwich” does not generate heat. It only acts as a “fur coat” that retains heat. But for this it is necessary that warm air constantly circulates through the chimney. The cross-sectional diameter of the chimney depends on the size of the firebox. Usually it is 180 mm., 200 mm..

Sometimes you come across larger chimneys. In any case, even the smallest chimney for a fireplace is quite an impressive channel through which a decent amount of heat can escape. I think that you will agree with me that it is very unwise to literally throw away precious heat into the street during the cold season. And if so, then on the chimney, in case the fireplace is down, a valve (gate) is provided. That is, when the valve is closed, heat does not escape into the chimney, while the “sandwich” instantly cools down.

The standard fireplace damper cannot heat the chimney

But that's not all. Ready-made fireplace inserts have a standard damper, which the fireplace manufacturer deliberately makes loose, with cracks. The air that goes into the chimney through these low densities in the standard damper is sorely not enough to warm up the “sandwich”. The metal pipe cools down very quickly and the draft in it overturns. Metal has very little thermal inertia and, because of this, is not able to retain heat for a long time under the influence of cold outside air.

In addition, due to the constantly flowing warm air, condensation forms in the iron pipe, which, when combined with combustion products deposited in the pipe, forms an acid that can completely destroy the metal pipe. At my dacha, because of this, a rather thick metal pipe coming from the stove rusted.

Components

The brick pipe is simple in design. The outer flue is protected by a metal cap, which prevents moisture, dust, debris and other unnecessary elements from penetrating inside. The head of the chimney must be placed wider than the main body of the chimney. This will protect the structure from the negative effects of precipitation. Chimney seals prevent sedimentary moisture from penetrating into the gap between the chimney and roofing materials.

Fluffing reduces the likelihood of rafters catching fire.

To prevent rafters and sheathing from catching fire due to high temperatures, it is recommended to use a thermal insulator to protect these elements. In the attic there is a section of the flue called the riser, and its lower part is protected by fluff. The fluff walls prevent the wooden floor beams from catching fire, between which a chimney is often erected. The end of the gas duct is called the neck. An iron valve is installed in this section, which regulates the boiler draft.

Chimney material

In modern heating systems running on gas and liquid fuel, the temperature of the exhaust gases has decreased significantly. Under such conditions, a brick chimney cannot warm up quickly, and when the heating system starts, this leads to the appearance of a large amount of condensate in the chimney. This, in turn, collects on the walls of the smoke ducts and mixes with the combustion products of natural gas, forming a liquid with acidic properties that destroys the brick.

Modular chimneys do not have problems with condensation. These are structures assembled from individual elements. Various materials are used for their manufacture: carbon and polished high-alloy stainless steel, aluminum alloy and ceramics. Such devices can be installed inside existing brick pipes during their reconstruction or represent independent systems operating inside or outside the building.

When assembling a steel chimney, it is important that the modules are assembled with the socket facing up, the joints are coated with sealant, and a condensate collector is installed at the bottom. The main features of a good chimney are high-quality fuel combustion, ideal draft, rapid heating of the walls and rapid overcoming of the dew point threshold

The second condition is met if the smoke exhaust system is well insulated. To do this, when installing a steel liner inside a brick channel, it is recommended to wrap it with special mineral wool, or leave an air gap around it. Do not fill the space between the insert and the brick with mortar. In this case, in addition to the steel liner, it will also be necessary to warm up the solution, which, moreover, when heated, the concrete will expand and press on the wall from the inside

The main features of a good chimney are high-quality fuel combustion, ideal draft, rapid heating of the walls and rapid overcoming of the dew point threshold. The second condition is met if the smoke exhaust system is well insulated. To do this, when installing a steel liner inside a brick channel, it is recommended to wrap it with special mineral wool, or leave an air gap around it. Do not fill the space between the insert and the brick with mortar. In this case, in addition to the steel liner, it will also be necessary to warm the solution, which, moreover, when heated, the concrete will expand and put pressure on the wall from the inside.

Before installing a chimney yourself, carefully read the recommendations. The operating parameters of your heating system are the basis from which to base your calculations. If desired, you can use specialized programs. But the best option is to trust competent specialists.

Waterproofing the passage

After completing the laying of the cap, you can install the umbrella and begin waterproofing the pipe passage through the roof.

Approximate diagram of chimney waterproofing

Waterproofing is a very important point in the design of a chimney, and the durability and efficiency of its operation depend on it.

The distance created between the pipe and the roof must be covered with an apron. Most often, roofing material is used for these purposes, which is fixed to a sealant.

On top of this layer of waterproofing is an “apron”, which is made from a wall profile or from a special waterproofing tape. It is also attached to the roofing material using sealant, and fixed to the pipe with a strip designed for this purpose.

"Apron" for the chimney pipe

Serious engineering solution

Calculating chimneys for a house or bathhouse is a complex engineering task. If you are not a specialist and you have a question about how to calculate a chimney for your home, use special programs that make it easier for you to make the correct calculation - be it the height, cross-section or length of the chimney.

In order to make correct calculations, it is necessary to know the structure and physical properties of materials, thermodynamics, and aerodynamics.

If you do not plan to further connect your life with the construction and design of chimneys, contact specialists. After all, the comfort of your home, safety and, most importantly, health, and sometimes life - yours and your loved ones - depend on the correct operation of the chimney.

Old school stove makers considered the ratio of the dimensions of the fireplace portal to the chimney to be 1:10 or 1:13. Depending on the operating conditions of the fireplace and weather conditions. Tabular fireplace calculation data are considered more accurate.

Table 6.1. Correlation of fireplace parameters (according to Sh. K. Afanasyev)

Pipes for fireplaces (three types of sections)

Flow section in bricks No.tr

Flow section in bricks No. tr

How to use table 6.1.

A is the width of the firebox,

B – height of the fireplace firebox,

column 3 – round standard chimney pipes, 4 – height of chimney pipes, 5 – dimensions of the firebox of the fireplace, 6 – height of the chimney pipes, 7 – dimensions of the firebox, 8 – height of the chimney pipes.

The ratio of the mirror of the fireplace portal, the cross-section and height of the chimney are directly dependent. Suppose you need to calculate a chimney based on the mirror of the fireplace portal with sides 1020x770. We search according to the table and find: diameter 300 mm, pipe height 9.5 meters.

Diagram 1.

Rice. 6.5 (A). Diagram for calculating the fireplace portal and pipe cross-section, where H is the height of the pipe in meters, F is the area of the fireplace portal (dimensions A and B in cm2; f is the cross-sectional area of the pipe (flow area in cm2; (f/ F) X100 is the percentage of area f from area F.

The configuration of the pipe sections is shown above.

How to use the diagram. Rice. 6.5(A). The horizontal numbers indicate (as a percentage) the area of the chimney pipe (f) to the area of the fireplace portal (F).

For example. The fireplace portal is 77 cm x 63 cm, therefore, the portal area is F = 4851 cm2. The dimensions of the square chimney pipe are 25cm x 25cm, therefore the cross-sectional area of the pipe is f = 625 cm2.

(f/ F) X100= 625/4851x100=12.8%.

Using a horizontal scale, we find the straight line until it intersects with the curve of the diagram (the middle line of a square chimney) and find the height of the chimney. The height of the chimney is 5 meters.

Let's consider other options for the ratios and dimensions of the fireplace. If you compare these tables, they are all approximately the same. There are small adjustments for: the roughness and cleanliness of the surface of the chimney walls, the angle of inclination of the outlet, the height of the pipe, the presence of nearby trees and buildings.

To determine the parameters and dimensions of the portal and chimney pipe of the fireplace, various factors are taken into account: the temperature of the flue gases, the speed of the exhaust gas-air mixtures (0.25 m/sec), the cleanliness of the channels, air pressure, etc. A round cross-section is considered better than a square cross-section, and a square cross-section is considered better than a rectangular cross-section. The air supply to the firebox of the fireplace is the main criterion in ensuring reliable operation of the fireplace. Most often, this is achieved by balanced supply and exhaust ventilation in a cottage, where the windows and doors are made of sealed double-glazed windows. Ventilation should be excessive with air pressure of 12-14%. If there is no supply and exhaust ventilation in the room, then sometimes it is enough to open the window, or slightly open the transom of the window.

Rice. 6.6. Facade, section and plan of the fireplace with letter designation for calculating various fireplace options according to table 6.2

Table 6.2. The ratio of the cross-section of the fireplace portal and the chimney.

Fig.6.6(A). The ratio of the cross-section of the fireplace portal and the chimney.

Errors or even the slightest inaccuracies made at the chimney construction stage will ultimately lead to serious consequences

In view of this, it is extremely important to do everything in accordance with the requirements and standards. An incorrectly designed chimney for a fireplace with your own hands can cause serious financial losses, which will manifest itself along with the need to redo everything

Among the consequences may be fire or poisoning of people in the room by products of improper combustion. Correct calculation of the chimney for the fireplace will allow you to avoid these accidents and enjoy a pleasant pastime in a cozy home.

Diagram of an English fireplace with a straight chimney.

Installation features

The construction and installation of a smoke exhaust structure, its installation, and then assembly and fastening are considered individually for each chimney.

For a brick chimney - this is the foundation, the correct location of the rows of masonry, the composition of the mortar for the masonry, mopping, the head and, if necessary, the chimney; for a ceramic chimney - foundation, fastening of modular elements, as well as an inspection with a tee for connection; for a stainless steel chimney - fastenings and brackets, internal pipes “for condensate” or external “for smoke”, the use of bends to divert the channel from the vertical, the arrangement of passages through the ceilings and roof, plus a head and a chimney.

The construction and installation of the chimney is carried out taking into account the thermal expansion of the material during operation. It is necessary to exclude the possibility of violating the tightness of the smoke duct and adhere to fire safety rules, especially in cases where the chimney is located in close proximity to flammable structures. The height and cross-section of the chimney, the compliance of the component elements, as well as the order of its installation are calculated at the design stage of the fireplace structure.

How to calculate the cross-sectional area of a chimney?

There are several methods for calculating the optimal cross-section. For example, on the size of the combustion chamber of the hearth or on the area of the furnace blower window

But in this publication, attention will be focused on the methodology, which is based on assessing the volume of flue gases generated during the combustion process

The combustion of wood and other solid fuels is always accompanied by very significant smoke formation. And the chimney pipe must be able to discharge these volumes outside in a timely manner.

Based on calculations and experiments, experts have long compiled tables from which information can be obtained on specific smoke production for different types of solid fuel. That is, what volume of combustion products is formed when burning, say, one kilogram of firewood, coal, peat, etc.

We will also present such a table (in an abbreviated version). In addition to the specific smoke formation, it shows the calorie content of the fuel (the amount of heat released when burning one kilogram) and the approximate temperature of the combustion products at the exit from the chimney. The first of these characteristics does not particularly interest us at a given moment - it simply gives a general idea of fuel efficiency. But the temperature, yes, will be needed for calculations.

| Fuel type | Specific caloric content of fuel, kcal/kg, average | Specific volume of combustion products released from combustion 1 kg, m³ | Recommended temperature at the chimney outlet, °C |

| Firewood with an average humidity level - 25% | 3300 | 10 | 150 |

| Lump peat (in bulk), air-dried, with an average moisture level of no higher than 30% | 3000 | 10 | 130 |

| Peat - briquettes | 4000 | 11 | 130 |

| Brown coal | 4700 | 12 | 120 |

| Coal | 5200 | 17 | 110 |

| Anthracite | 7000 | 17 | 110 |

| Pellets or wood briquettes | 4800 | 9 | 150 |

As you can see, the volumes are impressive. Even types of fuel that produce minimal smoke are already about 10 cubic meters for every kilogram burned. This means, simply for reasons of physics and geometry, the cross-section of the chimney duct must be able to constantly drain these considerable volumes out.

This is why we “dance” when calculating.

Chimney prices

chimney

The volume of combustion products released when burning solid fuel for an hour can be determined by the following formula (taking into account the thermal expansion of gases).

Vgch = Vud × Mch × (1 + Td/273))

Vgch is the volume of combustion products formed within an hour.

Vsp is the specific volume of combustion products generated for the selected type of fuel, m³/kg (from the table).

Mtch is the mass of the fuel charge burned within one hour. It is usually found by the ratio of the full fuel load to the time of its complete burnout. For example, 12 kg of firewood is loaded into the stove at once, and it burns out in 3 hours. This means Mtch = 12 / 3 = 4 kg/hour.

Td - gas temperature (℃) at the outlet of the chimney pipe (from the table).

273 is a constant for bringing temperature parameters to the Kelvin scale, used in thermodynamic calculations.

Since the unit of time in our calculation system is a second, it is not difficult to find out the volume obtained per second - the result is simply divided by 3600:

Vgc = Vgch / 3600

To find out the cross-sectional area of a channel that is guaranteed to pass this volume through itself at a certain speed of gas movement, it is necessary to find their ratio

Sc = Vgс / Fд

Sc is the cross-sectional area of the chimney channel, m².

Fd - gas flow speed in the chimney pipe, m/s

A few words about this speed. For heating appliances and household-grade structures, they usually aim to stay in the range from 1.5 to 2.5 m/s. With such a low speed, on the one hand, there is no significant resistance to the flow, and no strong turbulences arise that slow down the movement of gases. Heat losses are minimized, the temperature of gases at the outlet of the pipe is reduced to normal values. At the same time, the speed is sufficiently high to reduce the formation of condensation and the deposition of ash on the inner walls of the channel.

If the cross-section is found (and this is its minimum value), then using known geometric formulas you can find either the diameter for a pipe with a round cross-section, or the side length for a square cross-section, or select the lengths of the sides for a rectangular one.

Below is a calculator that will greatly simplify these calculations. It must indicate the type of fuel, its approximate consumption (more precisely, the mass and burning time of a full load) and the expected flow rate of gases in the chimney. The program will do the rest itself.

The final result is shown in three views:

— minimum diameter for a round section;

— minimum side length for a square section;

- cross-sectional area, according to which you can, for example, select the dimensions of the sides for a rectangular section.

Chimney inspection and cleaning

According to the rules for the operation of chimneys for fireplaces, they must be periodically inspected and technically inspected. This work is carried out by specialists to check the functionality of the smoke exhaust system. Cleaning fireplaces and chimneys involves removing contaminants from the ducts. To ensure fire safety, the tightness of the structure, the accumulation of soot in it, and the level of pipe destruction are checked (read: “How to clean a chimney - means and proven methods, prevention”). When carrying out a chimney inspection, the presence of draft, soot accumulation, the tightness of the channels, and the condition of the head are checked.

The special attention that fireplace smoke exhaust ducts require is due to the fact that they are considered fire hazardous sources. For this reason, increased demands are placed on them.

Regular cleaning of the chimney, elimination of contaminants in the ventilation ducts and blockages formed in them helps to prevent unpleasant consequences, maintain the home fireplace in proper condition and significantly extend its service life.