When faced with the need to install a chimney for their own needs for the first time, a person may ask a reasonable question: which chimney is better?

Choosing the best chimney

To choose the best chimneys, you first need to decide which heating unit will be used. Since the best chimneys for a wood stove and fireplace are completely unsuitable for a gas boiler.

Buy pipes and chimneys for a bath in Moscow in the VashiBani online store

Ours is one of the largest Russian suppliers of bath and sauna products. One of the main principles of our work is honesty. Honesty to our customers, honesty in pricing. We sell products whose quality we have no doubt about. The VashiBani assortment consists of certified products that are recognized internationally. In our store you will buy a heat-resistant stove pipe for a boiler in a bathhouse. The catalog contains fireproof smoke models of different heights and diameters. You will buy both single-circuit and double-circuit chimney units for stove boilers. The outer casings of some models are made of stainless steel, or galvanized or enameled.

In addition, you will order from us the construction of a turnkey sauna, hammam, installation of a chimney and stove. To find out the cost of the work, simply leave a request on our website.

General requirements for installation of structures

The regulations for gas boilers differ depending on the type of burner. The following standards and regulations apply to chimney systems installed on open-type boilers:

- the pipe has no more than 3 bends (45-90°);

- only non-flammable material is used;

- pipes must be protected with thermal insulation;

- a hole with a damper is provided through which the chimney is cleaned;

- the height and cross-sectional parameters of the chimney comply with the requirements recommended by the boiler manufacturer;

- there is another hole in the pipe to collect condensate;

- To protect the chimney from dirt, leaves, etc., a special umbrella is provided.

Requirements for chimneys on boilers with closed air exchange:

- the diameter of the outlet pipe is less than the diameter of the pipe itself;

- the minimum distance of the horizontal chimney from the ground surface is 2 m;

- the chimney pipe is located at least 2 meters from windows, doors, ventilation holes;

- the minimum vertical distance from the pipe to the window openings is 1 m;

- there should be no walls, fences or other obstacles closer than 1.5 m near the pipe;

- When installing, you should maintain a pipe inclination angle of 6-12° for natural removal of condensate.

It may be useful for many to know the requirements regarding chimneys for solid fuel boilers:

- it is allowed to use one outlet channel for two heating devices if the distance between them is at least 750 mm;

- pipes must be completely sealed;

- the optimal type of section is round;

- perfectly smooth inner walls (finished with galvanized or stainless steel).

It's time to move directly to the calculations themselves.

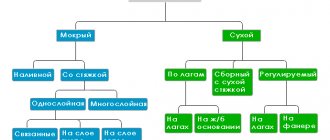

Sandwich chimney installation diagram.

How to choose pipes and chimneys for a stove in a bathhouse

Most experts recommend installing stainless, heat-resistant pipes for baths and chimneys for stoves - “sandwiches”, which got their name because of their multi-layer structure. Several rules for choosing a chimney for a sauna stove:

- The percentage of chromium content in steel should not be less than 13%. This protects the furnace body from corrosion.

- The minimum wall thickness of a heat-resistant chimney pipe for a stove is 80 millimeters.

- The most practical, airtight and durable welding seams are laser ones.

The choice of a chimney unit for the boiler and stove is also influenced by the size of your bathhouse. For example, one-story small baths and saunas always require a stainless steel “sandwich” chimney. For two-story buildings, ceramic stove pipes are better suited. Brick chimneys are recommended only if your bathhouse has a brick stove.

Purpose of the element

A heat exchanger is used to collect thermal energy passing through the chimney. The source is heated air. The design features of the unit depend on:

- pipe shape and diameter;

- material of manufacture;

- power of the carrier and the device generating heat.

There are air and liquid modifications. The first has a more primitive device, but is not considered the most effective. It requires high-quality material.

The liquid heat exchanger has the shape of a metal coil. It contrasts with the inner plane of the chimney and has a high thermal conductivity. The coil is housed in a metal housing for safety of use and optimal heat transfer. It is insulated on the inside with non-flammable insulation. Most often it is basalt wool.

Heat exchangers differ in the material from which they are made

The structure is installed on the chimney. The edges of the coil are passed through the body and connected to the heating system. An expansion tank is installed in the upper area. Copper tube is best suited for making a coil. In addition, this element is characterized by high efficiency, and therefore its dimensions are several times smaller than those of steel products.

First, the liquid is heated and then expands. After this, it moves along the coil and is sent to the radiator. Here, warm water displaces cool coolant, which is reheated in the coil. There is a constant circulation of coolant in the system.

In order for this process to take place as accurately as possible, it is necessary to calculate the diameter and length of the element, and also accurately determine the angle of inclination of the return and feed. It is important to take into account all these features not so much for the sake of the device to continue to work, but for the sake of preventing water hammer, the consequences of which can be unfavorable. At the same time, the described type of heat exchanger has certain disadvantages:

- Problems in arranging and carrying out calculations.

- Constant control of temperature and pressure indicators.

- Significant coolant consumption. It is caused by the evaporation of moisture from the expansion tank. In winter, when using a water system, the liquid must be drained.

- A significant decrease in the temperature of the exhaust gases, due to which the fuel may not burn completely with a simultaneous decrease in thrust.

Despite all these disadvantages, this heat exchanger can be made by anyone who knows how to handle the tool and has knowledge of physics.

Such a unit has disadvantages

What chimneys for a bath can be found in our catalog

The VashiBani catalog contains fireproof chimneys for stoves from companies (Russia), Schiedel (Germany), Ferrum (Russia), Sferra (Russia). Let's consider the features of iron, steel, cast iron and ceramic chimneys for stoves produced by the listed enterprises.

Iron

Galvanized iron chimney models for stoves are practically not subject to rust and are inexpensive. However, heat-resistant smoke units made of iron begin to emit toxic fumes at temperatures above 400 degrees. Therefore, it is allowed to buy iron pipes for sauna boilers only for systems with an operating temperature of no higher than 350 degrees.

However, if galvanized iron is only the outer layer of the “sandwich”, and the inside of the heat-resistant chimney is lined with stainless steel, there are no temperature contraindications.

Steel

Pipes for sauna boilers are made of stainless steel and are made of three layers: an inner layer, insulation, and an outer layer (the so-called “sandwich”). Their advantages are as follows:

Steel “sandwiches” for furnaces and boilers are dangerous only if installed and used incorrectly. Otherwise, this is one of the best options you can buy. They are not afraid of interaction with combustion products of wood and coal (nitric and sulfuric acid, creosote, etc.). Steel models for boilers are installed in baths and saunas of any size.

Cast iron chimneys for baths

Features of cast iron units for sauna stoves are:

- Low thermal conductivity, i.e. It won't be possible to heat it red hot. The heat capacity of cast iron is much higher than that of stainless steel. This means that heat-resistant cast iron chimneys for stoves will last much longer than others and will withstand any heat load.

- Cast iron chimneys are resistant to any microclimate that has formed in a bathhouse or sauna. In particular, cast iron is not afraid of temperature changes, thermal shock, and water hammer (water ingress during vaping).

- The use of cast iron fireproof models for the stove will protect against infrared radiation, especially during bathing procedures in winter.

Ceramic

Ceramic heat-resistant pipes are single-channel and multi-channel. Ceramic models cannot be installed directly on a sauna stove. They are mounted on the floor. They weigh almost ten times more than stainless steel models. If the unit is long and heavy enough, you need to build a foundation.

The advantages of ceramic fireproof models for sauna boilers and stoves are almost complete fire safety and aesthetics.

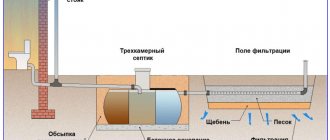

Types of gas boilers

The type of chimney selected, as well as its performance indicators, directly depends on the heating device. All gas boilers are divided into two large groups by design:

- With open burners

. Quite bulky boilers, comparable in size to a fireplace and installed on the floor. A working device consumes oxygen from the room. For stable operation you need constant high-quality air exchange. If not enough air enters the room, carbon dioxide released during combustion leaks into the house from the boiler.For boilers with an open burner, it is recommended to use a vertical chimney. Such a system is brought out at right angles to the section of the roof under which the boiler room is located.

- With closed type burners

. Such devices are installed on compact low-power boilers (up to 40 kW). Fuel combustion occurs in a sealed chamber. A coaxial type chimney is optimal for such a boiler. The chimney is mounted in a horizontal plane.

Now it’s time to study the requirements of GOSTs and SNiPs regarding heating equipment. With them, the algorithm for calculating chimneys for solid fuel boilers, as well as for gas boilers, will become a little more understandable.

Delivery of orders in Moscow and Russia

At VashiBani you will buy a cast iron chimney for a bathhouse with prompt delivery to any address. We deliver orders to Moscow, Moscow region and other regions of the country. The delivery price depends on your location, cargo weight, and additional services. Approximate prices are as follows:

- Within Moscow – 700 rubles. If the cargo is large - 1000 rubles;

- In the Moscow region – 700 rubles. with an additional payment of 30 rubles for each kilometer from the Moscow Ring Road. If the cargo is large - 1000 rubles. with an additional payment of 30 rubles for each km. from MKAD;

- If delivery to another region of Russia is required, we deliver the order to the warehouse of a transport company located in Moscow. Cost – 700 rub. (large orders - 1000 rubles).

If unloading, carrying or lifting of a large order is required, the cost of additional services will be discussed separately.

Power calculations

Independently calculate the power of the recuperator in the absence of initial data (furnace power, temperature and amount of exhaust gases per unit of time, contact area of the heat exchanger and the metal of the chimney, speed of passage of air or water through the device). You can measure the power of an already installed heat exchanger.

Roughly, you should expect that the heat exchanger on the chimney of a solid fuel stove or fireplace will warm up a couple of small radiators, increase the temperature in the garage, or make a room in the attic or a dressing room in a bathhouse warmer.

Is it worth buying inexpensive pipes and chimneys for a bathhouse?

No. Cheap heat-resistant oven units do not do their job. Indeed, in an attempt to save money on the production of heat-resistant equipment, unscrupulous companies use steel of inappropriate thickness, i.e. overly thin. In addition, such steel contains a low percentage of chromium, which makes it susceptible to corrosion. In less than a year, the chimney on the stove will become unusable under the influence of seasonal rains, snowfalls and other atmospheric phenomena. The price of a fire-resistant pipe for a furnace made of high-quality stainless materials cannot be low.

Once you have found suitable heat-resistant equipment for the stove in the VashiBani catalog, load it into the online shopping cart. You can pay for your order in cash, through an electronic payment system or by bank transfer. If you have questions about the purchase and delivery of goods, please call our operators.

Work specifics

Today, heat exchangers of various types are produced. In general, the features of their operation, as well as the design characteristics, are similar. The structural properties of such an element:

- Full body available.

- Presence of outlet and outlet pipes.

- Braking mechanism for combustion products. Its role is played by valves with cutouts that are installed on the axles.

The flaps can be turned. A zigzag chimney of varying lengths is formed. The valves can be adjusted to ensure the ratio of draft and heat transfer is as efficient as possible. Safety standards are met.

Simple modifications are also available that are not equipped with an adjustable valve system.

In this video you will learn how to make a heat exchanger:

Expert advice

It is necessary to choose pipes in which the thickness of the outer metal layer is 1 mm (not 0.5 mm). It’s very easy to check - for a product with a thin wall, the wall bends if you squeeze it with your hands.

When installing sandwich structures, it is necessary to use a special sealant for high operating temperatures (automotive sealant with an operating temperature of 500° is not suitable).

If the pipe rises more than one meter above the roof, it should be reinforced with guy wires.

The places where the sandwich passes through the roof and ceiling must be additionally insulated.

The main characteristics that a chimney should have

Regardless of what material the chimney is made of and what design it has, this product must comply with the basic parameters of fire and operational safety. So, the chimney must:

- Be made of non-flammable materials

- Be suitable for the specific type of heating equipment used

- Maintain the temperatures provided by the equipment - both operating and peak

- Withstand temperature changes and climatic influences

- Features simple installation

- Have a long service life

- Be completely sealed

- Have insulation at points of passage through walls, ceilings, and roofs

Let's take a closer look at each type of chimney pipe.