The presence of a greenhouse on a summer cottage is a common occurrence. Using different materials, you can build greenhouses of a wide variety of shapes and sizes. Work in them begins in early spring and ends in autumn. Having your own vegetables is not only economical, but also safe, since you can be confident in their quality. That is why many people have a desire to equip a winter greenhouse. You can grow vegetables and fruits in it all year round, even if it’s frosty outside.

Can an amateur summer resident build such a structure? In fact, the construction and arrangement of a winter greenhouse does not require much time and money, so you can handle the tasks yourself. In this article we will tell you how to build a winter greenhouse with your own hands, demonstrate the necessary drawings, as well as photo and video instructions.

Features and differences from a summer greenhouse

Features and differences

During the construction of a winter greenhouse, unlike a summer greenhouse, a strong and reliable structure is made. It stands on the foundation. In addition, the winter greenhouse has a heating system. The quality and consistency of the temperature inside will depend on the latter. Every winter greenhouse must contain:

- lighting;

- heating;

- ventilation;

- watering.

The size of the greenhouse must be selected in accordance with the number of crops that will be grown. The coating material must be reliable. A simple film will not protect crops from frost and snow. It is also important to provide for the possibility of additional wall insulation.

When developing a winter greenhouse, several conditions must be met for good plant growth: light and temperature conditions, as well as air humidity.

Drawing up diagrams and drawings

On the diagram you need to indicate the length, width and height that were calculated earlier.

A competent drawing is based on the shape and dimensions of the structure, and the construction diagram should be based on the requirements for this structure and the purpose of its use. It is recommended to take photos and dimensions of finished greenhouse frames as a basis or draw up a greenhouse project yourself.

An example of a competent drawing

Ready-made structures, which are manufactured at the factory, imply full compliance of the material and frame used with the main load and conditions of use. The design of a product that is built by hand should be based on similar rules.

The technology for drawing up a design diagram implies compliance with the following features:

- The frame in most cases is made of pipes or metal profiles. This is the best option for such structures.

- Lumber absorbs moisture, so it is not recommended to use it for making frames.

- If for some reason it was decided to use wood, then it is necessary to treat it with an antiseptic and apply a layer of varnish, which can extend the service life of the structure.

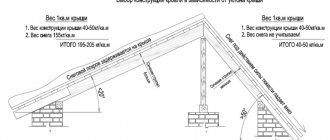

- The product diagram must be drawn up in accordance with the calculation of the characteristics of possible loads on the frame structure and coating. It is important to take into account the loads from wind and snow.

- If the design does not involve the manufacture of a durable frame, then the product must be cleared of snow from time to time in winter. Such a frame structure is cheaper, but it is less practical.

The frame of the building can be made of the following materials:

- aluminum;

- steel;

- wood;

- plastic.

Frame diagram of a small greenhouse

It is important to carefully consider how the heating system will be placed.

Greenhouse water heating scheme

Most often, modern greenhouses use water heating, which involves heating the plants being grown during the cold period by means of hot water that circulates in pipes.

If the greenhouse is installed near a private house, then you can connect it to the building’s heating system. In this case, the heating diagram will make it possible to correctly correlate the heating system of the greenhouse with a similar system in a private house. However, in most cases, an independent system is built for a greenhouse.

Main types of winter greenhouses

Main types

A modern winter greenhouse can be built from various materials. Today, the construction market is filled with innovative materials. They are distinguished by increased strength, lightness and affordable price. This allows you to choose everything you need within even a small planned budget. At the preparatory stage it is necessary to plan the design. Her choice will depend solely on the plants that are planned to be grown.

The types of winter greenhouses are distinguished not only by the materials used, but also by their external forms.

- Single-pitched - wall-mounted and with an earthen fill.

- Gable - with main walls and a glazed roof.

- Polycarbonate arched.

Foundation

The greenhouse building has a heavy structure and requires laying a foundation for strength. There are 4 ways to base it:

- tape;

- brick;

- squared;

- stone foundation.

Practice shows that the most common is a strip foundation.

Work order:

- Construction site marking;

- digging a ditch about a meter deep;

- covering the bottom of the pit with waterproofing;

- production of reinforcement to strengthen the foundation;

- filling the ditch with cement mortar;

- coating of thermal insulation material on a completely hardened foundation.

Next, bolts are attached to the prepared foundation to construct the frame. When deciding how to build a winter greenhouse, some craftsmen lay one layer of brick on the foundation. With this method, the bolts must pass through the brickwork and penetrate the fabricated foundation.

Criteria for choosing a greenhouse type

- First of all, the parameters are calculated, since further calculations will depend on this.

- It is also necessary to take into account functionality, that is, to know in advance the features of growing crops. In modern and modernized winter greenhouses, you can grow not only vegetables and fruits, but also mushrooms, herbs, and flowers.

- The microclimate inside the structure will depend on the correct location of the greenhouse at ground level. If desired, the structure can be deepened inside and get the effect of a thermos, or construction can begin on the surface. Some people prefer to set up greenhouses in old buildings (garage or barn).

- A wide variety of architectural solutions allows you to realize any ideas and plans. You can build the structure yourself or buy a ready-made structure. You can also seek help from specialists.

Many people grow flowers of various crops for sale. When choosing exotic plants, it is necessary to calculate all costs, as well as study the requirements for the structure.

Assembling the base

The strongest and most durable material for creating the skeleton of a greenhouse is metal.

Wood is susceptible to environmental influences and deteriorates over time, while plastic is not strong enough and can collapse under the weight of snow cover.

Step-by-step construction of the foundation:

- the lower part of the frame is attached to the foundation using anchors;

- vertical posts are welded or screwed to the bottom of the frame;

- a horizontal profile connects the vertical posts at the top;

- erection of the foundation for the roof.

The strength of the entire structure directly depends on the accuracy and correct installation of the frame. To do this, it is recommended to build it strictly according to the drawings and instructions. Drawings and photos of a winter greenhouse can be found on the World Wide Web.

Properly selected material is the key to protection from the cold

When developing a project, it is necessary to take into account the material with which the frame will be sheathed. The winter greenhouse must be durable and airtight, so for arranging the frame choose:

- tree;

- metal.

Both materials are very durable, so it is quite difficult to choose one or the other. Metal is strong and reliable, but wood is much easier to work with. In addition, the wood will not heat up in high summer temperatures. To support the weight of the entire structure, as well as the load of snow on the roof, it is necessary to use strong and thick racks.

Frame covering material:

- film;

- glass;

- cellular polycarbonate.

When choosing a film, it is necessary to sheathe the frame not in one layer, but in several. In addition, you should not use it to arrange the entire structure. Glass also has many disadvantages: heavy weight, fragility and difficulty in installation. The most suitable material for a winter greenhouse is cellular polycarbonate. The advantages include: light weight, light transmission, and ease of installation.

According to experts, the microclimate in a greenhouse made of wood is several times better than one made of metal. When choosing a tree, it must be treated with modern antiseptics and protective agents.

Introduction:

To be honest, a greenhouse has never been a priority for us, and the cultivation of the main vegetable crops (cucumbers, tomatoes) on our plot was carried out in open ground, using the simplest greenhouses made of covering material in the early stages of plant growth. The harvest was always quite satisfactory for a small family; there was always enough for a daily fresh summer salad. And all this was fine until we had to deal with the complete loss of the tomato crop (blackening) and the unsatisfactory quality of the “cucumber” products due to very unstable weather last summer. It becomes a pity to spend time and labor on preparing the soil, planting seedlings, watering, caring - and as a result you end up with a pile of tops that is unsuitable even for a composter. In this regard, it was decided to build a full-fledged greenhouse, with high beds, where there would be no restrictions on the types of crops grown (due to small greenhouses, it was necessary to choose low-growing varieties, and the peppers did not have time to ripen at all). The greenhouse design according to Mittleider was chosen. This design worked successfully for gardeners I knew. The frame of the greenhouse was designed from pine lumber with the bottom frame supported by concrete pillars. A simple greenhouse project was developed in SketchUp. The dimensions of the greenhouse in plan are 8000 mm x 3400 mm. The height from the base (ground) to the lower chord of the truss is 1800 mm, you can move freely to your full height. The greenhouse was planned to be divided into two sections, for different vegetable crops. By the way, the project is missing a very important detail; more on that later).

Selecting a location for a winter greenhouse

When choosing a site for the construction of a winter greenhouse, it is necessary to take into account three main factors:

- Light. The winter greenhouse should receive the maximum amount of sunlight. The greenhouse is best placed lengthwise from west to east.

- Wind. If the chosen location often experiences gusty and cold winds, it is necessary to consider protection. This will save on heating costs and constantly maintain an acceptable temperature and microclimate.

- Convenience. Access or passage to the greenhouse should be wide and convenient. Thanks to this, it will be very convenient to use the greenhouse for its intended purpose.

When organizing protection from strong winds, you can plant a hedge. It must be remembered that the fence must be placed at a distance of at least 10 m. The distance is calculated depending on the height of the ridge.

Application of polycarbonate to the base

The material is adjusted to the dimensions of the base. Cut into sheets and bolted to the frame, starting from the bottom of the structure. Laying occurs without gaps or overlapping of sheets on top of each other.

From the inside of the structure, the joints of the sheets are treated with sealants to protect against the penetration of moisture from the external environment.

Selecting a heating system

The most important thing in a winter greenhouse is heating. This process is the most labor-intensive and complex. To organize it, the help of specialists is required. But you can do everything yourself. It is necessary to choose the right type of heating, on which the productivity of the greenhouse will depend. Today there are many ways to heat even a large area. Each of them has its own advantages and disadvantages:

- Sun. Affordable and cheap option. But it is not suitable for winter, since the sun's rays are not so strong and will not be able to heat. It can be combined with other heat sources.

- Biological heating. Biologically active substances decompose, resulting in the release of heat. The simplest biological substance is manure. As with the sun, this method will not be able to completely heat even a small area.

- Electricity. An affordable and popular heating method. It can be installed in any area away from home. You can use different electrical appliances for it: convectors, air heaters, infrared radiation, cable heating, heat pump and water heating.

- Air heating. It is organized at the initial stage of construction of a winter greenhouse, in particular, when pouring the foundation. With the help of heating and ventilation units, warm air is supplied to the middle and upper part of the greenhouse.

- Gas. Gas heaters are installed in the greenhouse, in which direct combustion occurs. To avoid oxygen burnout, it is necessary to provide a good ventilation system.

- Bake. An affordable and economical option involves installing a stove and heating the entire area of the winter greenhouse. Gas, wood and coal can be used as fuel. Among the disadvantages is the heating of the walls, so planting plants next to the stove is not recommended.

It is necessary to choose the type of heating individually for each specific case. You must be guided by such criteria as local climate, planned budget and plant type.

Heating

Heating options may vary. The cheapest option is to install a stove with several pipes through which heated smoke moves. As a result, hot pipes warm up the room.

The main disadvantage of this heating option is that you have to constantly add fuel to the stove and monitor the temperature inside the room.

It is much easier to use water heating. The water is heated in a gas boiler, which can be installed either in a greenhouse or in a house, connecting it to the greenhouse with a pipe.

The air is heated by radiators located along the walls, or thin tubes are laid underground to warm the root system of plants.

The combined type of heating deserves special attention.

Composition of combined heating:

- infrared lighting lamps;

- polypropylene tubes buried in the ground.

The lamps heat the air from above, and the tubes from below. The main advantage is the automated control of the heating system.

Stages of construction of a winter greenhouse

Brick foundation of a greenhouse

Since the stages of construction and technology completely depend on the materials and design, there is no need to talk about standards. Using an example, we will look at the construction of a winter greenhouse, which is adjacent to the house. A brick is selected for the foundation. The frame is erected from wooden beams or profile pipes. The entire structure will be covered with polycarbonate.

To create the effect of a thermos, you don’t have to go deep into the ground, but only raise the base. The depth of the foundation is 50 cm, the width is 40 cm. For convenience, it is better to make a strip foundation. Do not forget about the sand cushion or use fine gravel. The execution steps are standard and do not require any professional skills or equipment. After pouring, it is recommended to keep the foundation for a week. On hot days, the surface is moistened with water. A layer of waterproofing should be laid between the foundation and the plinth.

You can use used bricks to build the basement. If the financial side allows, then a new brick is selected. The height of the wall should be about 1 m. The thickness of the walls can be half a brick or a brick, at your own discretion. The frame is constructed from durable and pre-treated wooden beams. Anchors and dowels act as fasteners. Thus, a skeleton is installed that will be a reliable support for heavy loads. The frame for the roof must be made at an angle of 30° from the horizon.

The frame should be sheathed with polycarbonate according to the standard scheme and technology. For a good result, several conditions must be met:

- marking;

- precision cutting;

- accuracy of installation;

- use of special fasteners;

- sealing polycarbonate seams for tightness.

Wall greenhouse

Several vents installed around the entire perimeter can serve as ventilation.

For greater savings, it is recommended to choose a location near your home. Thanks to this, one of the walls is already completely ready, so you don’t have to waste time, effort and money. In order for the main part of the greenhouse to be constantly warm, it is necessary to attach a vestibule at the front door. For high-quality sealing, you can use polyurethane foam and special sealants.

Construction sequence

There is no universal sequence for constructing a greenhouse, since in each case it is determined by many factors. Usually, a foundation for a winter greenhouse (if necessary), a frame, and then sheathing are built.

The most important stage is the cladding. Before it you need to take accurate measurements. Also, do not forget about the heating system and ventilation.

Internal arrangement of the building

After all construction and sealing work has been completed in full, you can begin arrangement. So, it is necessary to supply water and electricity for lighting to the greenhouse. It is also important to take care of the shut-off valves, which will ensure a high-quality water supply.

When choosing light scattering sources, it is necessary to take into account the characteristics of growing the selected crops. An equally important issue is the soil. The substrate is prepared, fertilizers and special additives (feeding) are added. They will ensure fast and proper growth of all vegetables and fruits that have been selected.

Winter greenhouse

Guided by the tips provided, you can build and prepare a winter greenhouse for growing various crops in the winter in just a few days. It is enough to use all available materials and purchase missing ones. You can handle all the work alone, but it is better to have an assistant, especially when it comes to installing the skeleton of a winter greenhouse.

We recommend that you read the article “Do-it-yourself greenhouse made of profiles and polycarbonate.”

Greenhouse made of PVC frames or wooden structures

Such a greenhouse requires a solid foundation and frame. The frame can be metal or wood. Such a greenhouse is assembled very quickly, since the frames are ready and have windows and transoms for ventilation.

The roof in such a greenhouse can probably be made gable from a modern material - polycarbonate with a diameter of at least 8-12 mm, or even thicker.The thicker the carbonate, the more efficiently it will retain heat. Polycarbonate with a thickness of 4 mm is not suitable for heated greenhouses at all, or it is necessary to make a double coating.

If you break this rule, your greenhouse will lose heat and may be subject to destruction, especially if there is a snow load. You can make greenhouses with your own hands from any suitable materials.