Proper installation of the chimney pipe through the attic floor, rafter system and roof is no less important than compliance with all other requirements when building the stove itself. The fire safety of the house, and therefore of everyone living in it, as well as the efficiency of the heating device, will depend on how reliably these components are equipped.

Chimney passage through a wooden ceiling

The passage of the chimney through a wooden ceiling must be especially reliable, since in this area the heated walls of the pipe are in close proximity to flammable materials. In order to protect the floor elements, various thermal insulation materials and special devices can be used - there is no shortage of them on the market today.

Such work must be carried out with the utmost responsibility. Therefore, in order to understand these issues, you should familiarize yourself with the current requirements of regulatory documents, consider the process of installing a chimney through the ceiling in order to carry out everything strictly according to the rules established by regulatory organizations.

Manufacturers

A universal option for most popular gas boilers is the coaxial design of the STOUT brand.

All components of the system fit together perfectly, are easy to install and maintain, and are adapted for use in our country. The variety of elements allows you to create absolutely any smoke removal system. The manufacturer provides a two-year warranty on all products. The technological manufacturing process is carried out at the same factories in Italy where similar, but more expensive goods are produced. STOUT is the choice of those who do not overpay for a well-promoted brand name, but are accustomed to choosing only high quality.

Coaxial chimneys from Baxi are manufactured for boilers that operate on gaseous fuel. Their construction is made of the highest quality stainless steel.

The Immergas company produces horizontal coaxial chimneys. It is possible to use such a device for gas boilers, as well as for units operating on liquid fuel.

The Buderus company produces horizontal chimney systems. For their production, two types of steel are used: galvanized and stainless.

The coaxial chimney for Hermann gas boilers is manufactured in certain sizes: the diameter of the inner pipe is 6 cm, the outer pipe is 10 cm. Such systems are made both horizontal and vertical.

Vaillant coaxial chimneys are manufactured with some design features that allow the devices to be used in conjunction with boilers from other companies.

The Korean manufacturer Navien produces chimneys that can be used in conjunction with floor-standing or wall-mounted boilers with a power not exceeding 75 kW.

Coaxial chimneys from the popular Viessmann company are produced in several versions with diameters of 6/10 cm, 8/12.5 cm, 10/15 cm. The design can be either vertical or horizontal.

Protherm produces both types of coaxial chimneys in sizes 6/10 cm and 8/12.5 cm.

The design of such Daewoo devices is made in such a way that installation can be done from any side of the boiler unit.

Ariston horizontal and vertical chimneys are made of enameled steel.

Chimney pipe lining and special caps

One of the finishing methods is cladding. For this, natural or artificial stone is used, but this option is not practical. This is explained by the fact that often the cladding is torn off from low-quality bricks, along with the top layer of ceramics, which spoils the roof. If the brick is of high quality and beautiful, there is no point in covering it.

When the sheathing is heavy, it should be fixed not only with adhesive, but also with hardware. For this purpose, metal brackets or dowels are used - nails directly through the stone tiles.

To protect ventilation ducts from atmospheric hazards, protective caps are installed on the pipe heads. They reduce traction force, so their size should not be too large. In this case, the distance from the top of the pipe to the bottom point of the cap must be at least 15 centimeters. The shape of this product and the material it is made from can be very different.

Main types of chimneys and rules for their installation

Today, various types of chimneys for a gas boiler are known, one of which is a coaxial chimney that is led outside through a wall. With its help, air is taken from the outside to prevent extinction in the combustion chamber of the boiler. The coaxial chimney also removes exhaust gases from the premises to the street.

Coaxial chimney and its installation rules

Coaxial chimney

Installing a coaxial chimney for a gas boiler requires various materials and elements:

- smoke exhaust pipe;

- flange;

- an adapter through which the chimney is connected to the boiler;

- decorative wall coverings;

- chimney elbow and connecting clamp.

The chimney is most often installed, taking into account the shortest distance from the gas boiler to the nearest wall of the house outside. All substances and objects that can cause ignition or are damaged by high temperature are removed from the chimney area.

Let's figure out how to install a chimney correctly?

First of all, it is necessary to observe safety precautions and carry out work within the limits of personal protective equipment. Therefore, people working with chimneys must wear protective gloves made of very thick material or have synthetic covers on their palms.

Installation of a boiler for a coaxial chimney

Following the rules for installing a coaxial chimney for a gas boiler, you should install it in an opening in the walls and cover it with a canopy to prevent moisture from penetrating. It is necessary to choose a place to puncture the wall. This will be the area where the pipe is removed from the premises to the street. It is advisable that this place exceeds the level of the chimney outlet by 1.5 meters.

If the gas boiler is positioned incorrectly, at a large distance from the external wall, this type of chimney can be significantly extended, but not more than three meters. For this purpose, two connecting elbows are used. The areas where the chimney is built up are stretched with a crimp clamp.

How to install a coaxial chimney in areas of high humidity?

If a coaxial chimney for a gas boiler is installed in regions with high precipitation, in this case the chimney is located at some level from the ground to prevent clogging or clogging of the pipes.

A slight slope must be taken into account. This is necessary to allow condensate to drain by gravity to reduce the risk of the chimney becoming waterlogged.

After the chimney has been installed, the wall openings are covered with decorative trims, in accordance with the diameter of the pipe itself. Most often, to avoid the formation of cracks, the holes around the chimney are foamed. The rules for installing a chimney for a gas boiler are observed in accordance with safety regulations.

The most common and popular chimney is the stainless steel chimney. The characteristic features of this type include a beautiful aesthetic appearance that can harmoniously fit into any interior of the room.

The main task of such a chimney is to remove combustion waste from various rooms and ensure the functioning of heating equipment.

Stainless steel chimney, its composition, properties and installation

Stainless steel chimneys

Installation of stainless steel chimneys does not require a reinforced foundation, unlike brick chimneys.

Such chimneys are resistant to corrosion and are very durable. Stainless steel chimneys are suitable for almost all combustion devices and require a small installation area.

They are used not only at temperatures of 600 degrees, but also in heating systems together with condensing boilers. These products are manufactured using high quality stainless steel.

Coaxial chimney ESR 100/75 for boilers

Chimneys for gas boilers

Installing a chimney for a boiler requires knowledge of building codes and requirements for exhaust ducts.

The chimney for boilers must not only be sealed, but also be resistant to condensation. The composition must include a channel: a valid connection of two devices to one channel. The distance must be at least 750 mm.

The chimney should go into the sky and not have covers or canopies. These standards must be observed during the construction or repair stages, since defects during operation are difficult to correct.

I encountered a problem with extending the chimney

The situation is this: two asbestos pipes are coming out (outer diameter 180, inner 143), they need to be extended using galvanized ones. There are galvanized pipes of 135 diameter. How can they be combined with asbestos? Some kind of adapters? so that it all holds tightly, because... increase 220 cm

It is not clear what kind of pipes are, but in any case you should not narrow the pipes. I advise you to find a pipe of larger diameter and put it on top, securing it with a clamp

chimney pipes, on the roof they come out touching each other. Everything around is cemented, you can’t move them apart, i.e. putting it on top is a problem

What are the initial conditions? Maybe you can do without building up the chimney.

Initially, everything was fine, then a neighbor’s wall of the second floor appeared nearby (the house is divided in half - one half is one-story, the other was built into two floors). There are chimney pipes on the roof of the one-story half; they are about a meter away from the wall. There are turbulences from the wall and the boiler goes out. That's what the experts said. It needs to be built higher than the ridge of the neighbor's extension. this is 220 cm.

Well, no one will tell you

You have a flue made of two pipes! Put one large pipe on them. Bend it into an oval and put it on. Or order... Just remember, the pipe will start crying. I have an iron pipe, I heat it with gas, I wrapped it on top with polystyrene foam film and foil and secured it with tape with the foil facing outward - protection from the sun and it turned out beautifully. And seal the joint with the asbestos pipe with mortar, even clay will do. You can’t do anything else - it’s winter

It's winter though. Equip existing pipes with clamps to prevent them from flying into the chimney, prepare a clamp for attaching guy wires, make or buy caps, stock up on asbestos sheets and asbestos cord. Secure the clamps with prepared braces, wrap the steel pipes with asbestos and push them into the existing chimney. Secure with stretch marks. Wrap the pipes with Izover, Ursa, etc. Wrap with foil, foil-foil polyethylene foam, etc. Wash three times to complete the job successfully. It is not advisable to combine chimneys. I won’t get into theory, this is on the topic of heating and ventilation.

Related article: How to secure a roof to a foam block

In your case, I would do this: I called companies involved in tin production and ordered from them an F180 pipe with flaring on one side up to F184, the length of the flaring is 15-20 centimeters. After which this pipe is put on the asbestos pipe and fixed with self-tapping screws. To reassure yourself that the fastening is secure, you can install guy wires. Use F135 pipes somewhere else, for example, in a bathhouse. Because It’s pointless to even make a sandwich with it (it’s not stainless steel, there’s a big difference with the internal diameter). I don’t recommend sticking them into asbestos pipes, wrapping them with asbestos fiber, because... similar operations are carried out on the ground. Otherwise you will end up with “snot”, and snot and carbon monoxide in the room are a RISK.

Installation of a chimney

There are two ways to exit the chimney through the wall:

- The pipes inside the room must be raised a short distance from the ceiling, where they are brought outside.

- From the boiler nozzle, pipes lead immediately through the wall in a horizontal position. The advantage of this method is that fewer bends are formed, and this has a positive effect on the performance of the chimney.

Assembling a sandwich pipe when installing the vertical part of a chimney can be done in two variations - “smoke” or “condensate”.

Assembling a chimney “for smoke” and “for condensate”

When installing a pipe along the smoke, gas and combustion products move upward, but here you will have to deal with such a negative aspect as the formation of condensate that accumulates in the pipe. This method has gained popularity in cases where the chimney is assembled through the roof. Here, almost the entire pipe is located in the house, and not much condensate is formed.

Condensate installation is an installation method in which the pipe with its expanded end is directed upward.

With this assembly, the condensate simply flows through the pipe into the glass. The disadvantage of this method is that smoke can leak out if the areas at the joints are not properly sealed.

Troubleshooting Methods

If you have identified problems with traction, then, of course, they need to be eliminated as quickly as possible.

The choice of means to combat poor or reverse draft depends on the reasons that led to the abnormal operation of the chimney.

Pipe cleaning

One of the common methods of improving traction is cleaning the pipe. Fuel, burning in a stove, releases various substances that settle on the inner surface of the chimney. Soot sticks well to pipes if they are uneven or bent.

When carrying out work, do not forget about safety measures

How to clean a chimney so that there is good draft?

First of all, acting purely mechanically. The chimney channels can be made wider, getting rid of plaque, in the following ways:

- After preparing about one bucket of potatoes, peel and cut them. Potato peelings will also work. Throw a little into the firebox and wait. When burned, potatoes will release starch, which will become a means that can soften carbon deposits. Soft pieces of soot will fall off on their own, but firmly stuck ones will have to be removed mechanically.

- Firewood from aspen. Heat the stove with two or three logs. They will heat up the chimney pipes very much and help get rid of carbon deposits. But this method requires special care, since the likelihood of a fire will be very high (soot may ignite).

- Rock salt. This method is more suitable for prevention. Salt added at the time of combustion improves the condition of the chimney pipes.

- Pipe brush. A heavy weight is attached to a brush suspended on a steel rope and lowered into the chimney openings. By lowering and raising this structure, you can force soot formations to fly off the walls of the pipes and fall into the furnace. These fragments are then removed from the firebox.

The second group of anti-particulate measures is based on the use of chemicals. The most popular chemicals for cleaning chimneys are “Log-chimney sweep”, “Komichek”. Chemicals are added to the coals formed during the heating of a stove or fireplace according to the instructions and the heating continues. After all the fuel has burned out, it is advisable to leave the coals, since they continue to “work” in terms of cleaning the chimney (at least, that’s what the manufacturers advise).

When used correctly, chemicals will not cause harm to your home.

Do not believe the spiteful critics who talk about the obligatory combustion of soot when using the chemical method. This method does not pose any danger, since the beneficial effect occurs due to chemical reactions, and not due to the ultra-high combustion temperatures of the reagent.

Special mention should be made of the observance of safety measures when carrying out all work related to the chimney. Do not fix chimney problems in windy weather! Try to use safety devices when working at height!

Troubleshooting structural problems

If certain features of the chimney design are identified that negatively affect the draft force, adjustments should be made to eliminate them. These actions include:

- dismantling several separate pipes and installing a single chimney channel;

- adding roof pipes to the required height;

- insulation of chimney elements, etc.

Ventilation arrangement

In some cases, traction may improve if drafts are avoided in the house or bathhouse. You can help with draft problems by installing ventilation devices on windows.

If there is no desired effect after all the methods described above, you should adopt modern devices to improve draft in the chimney.

Installation of devices

To improve the operation of the chimney, it is best to use special devices that allow you to regulate and control the draft. Such devices can be bought in a store or made with your own hands.

Which chimney is considered incorrect

In order to take into account the mistakes of other owners when constructing a chimney, you need to know the criteria that cannot be violated during installation. The most significant and serious mistake is the absence of a deflector above the chimney; precipitation should not be allowed to get inside the channels, since it will increase the formation of condensation, and ice, at subzero outside temperatures, can block the passage for flue gases.

In the case where the chimney outlet goes to the roof, in a single block with ventilation pipes, the chimney must be 50.0 cm larger than the ventilation pipe. At the passage points of building structures, it is strictly forbidden to place joints of structural elements, since they can become a place for carbon monoxide leaks, and in the case of a large volume - a source of ignition.

In order to properly equip a chimney for long-burning boilers, its structural parameters must be determined at the stage of a building construction project or reconstruction of a heating system.

The important outputs of such a project will be the choice of: pipe material, geometric dimensions and installation point, as well as the technological sequence of installation. If all this is done exactly, then such a chimney will be safe and effective, capable of serving its owner for decades.

Installing a chimney on the roof with your own hands or with the help of specialists?

Installation of a smoke exhaust route is a complex and responsible process that requires mandatory knowledge of many technical norms and regulations, standards and nuances. Failure to comply with even one rule or regulation can lead to unpleasant consequences - fire, failure of heating and smoke exhaust equipment. Due to these factors, it is highly recommended to carry out the installation and installation of the chimney, including fixing it to the roof, with the involvement of specialists.

Professional installation will guarantee both the safety of the entire heating system and its long service life. Self-installation cannot guarantee safety, health and property.

Do it yourself or order it?

You can only make a brick chimney yourself or a structure from an insulated single-layer steel pipe. But laying smooth and beautiful walls of a brick pipe is more difficult than laying just a brick wall, and you must have the skills of an experienced mason. Single-layer pipes will have to be insulated; the quality of self-insulation is much worse than that of ready-made factory-made pipes.

You can independently install a chimney made of ceramics and sandwich pipes. It is impossible to manufacture elements of such chimneys on your own, but the industry produces many modules that allow you to assemble a pipeline of any design.

The question of whether to install a pipe yourself or hire a team of professionals is quite complicated. Installing a chimney is quite a complex job, and it is worth thinking about and carefully assessing your capabilities: is it possible to take prefabricated scaffolding or scaffolding of the appropriate height, will you have assistants, do you have the skills to install building structures, how do you react to height.

Pros and cons of heating under floor screed

Heating rooms using floor heating circuits has a number of strengths and weaknesses. Pros:

- Heating pipes in the floor screed are economical.

- There is no need to install bulky radiators in the premises, which take up additional space.

- If the right material is selected, the active service life exceeds 50 years.

- Optimal humidity level in heated rooms.

- Uniform heating of the room.

Minuses:

- There is a possibility of damaging the pipeline when installing it, pouring concrete, or drilling holes in the flooring.

- If there is a breakdown in the heating circuit, there will be big problems with its repair.

Operating principle and device

In the family of devices for removing combustion products, the coaxial chimney stands apart. This modern design is much more efficient and safer than a conventional chimney pipe. This system is ideal for boilers with a closed combustion chamber.

To make a coaxial chimney, you need to take two pipes of different diameters and place the narrow pipe inside the wide one. You also need to connect the inside of the wide pipe and the outside of the narrow pipe with special jumpers so that the central axes of both pipes coincide. Well, the coaxial chimney is ready.

In practice, such a design is, of course, easier and more reliable to buy than to make. The cost of a coaxial chimney will be higher than the price of an ordinary stainless steel pipe, but the costs will be fully recouped.

Using a coaxial chimney allows combustion products to be removed through the facade of the house; there is no need to install a 5m vertical chimney

A double pipe is necessary to perform two functions simultaneously. Combustion products are removed from the boiler furnace through an internal narrow pipe. And through the gap between the inner and outer pipes, air enters the combustion chamber, i.e. oxygen necessary for fuel combustion.

This solution has a number of advantages. An alternative to a coaxial chimney is a traditional chimney combined with forced air injection into the combustion chamber.

In this case, the air is usually taken from the room in which the boiler is installed. A coaxial chimney allows you to take air from the street and supply it directly to the firebox.

The diagram shows the general principle of operation of a coaxial chimney, as well as its structure in comparison with a traditional chimney pipe (+)

What happens in such a chimney during boiler operation? Hot combustion products move outward through the inner pipe, and in the opposite direction there is a parallel flow of fresh cold air. As a result, a completely natural heat exchange occurs: hot gases give off heat to the adjacent cold flow.

The air enters the combustion chamber already in a heated state, which increases the overall efficiency of the boiler, because there is no need to waste precious kilojoules on heating the air masses. At the same time, the temperature of the outer surface of the coaxial chimney is noticeably lower than when using a standard chimney pipe. This circumstance makes the design safer.

Another advantage of a coaxial chimney is easier installation of the boiler, because you do not have to install a forced ventilation system. In addition, these structures have different requirements than traditional chimneys. As a result, the combustion product removal system takes up less space.

On the outside of the building, the coaxial chimney pipe looks much more laconic and takes up less space than with the external installation of a traditional chimney

Coaxial chimneys are universal; they can be installed with gas boilers and with devices operating on liquid or solid fuel. Chimneys with different diameters are available for sale, which allows you to select suitable pipes for a particular boiler.

Installing a traditional chimney in an already constructed building is a rather difficult task. If the installation of a chimney was not provided for during the design, you have to go through the floors and roof or take the chimney outside.

A bulky structure can create problems both inside and outside the building. But coaxial designs are simpler and more compact. The installation of such a chimney on the outer wall looks laconic and will not spoil the appearance of the house.

Chimney extension technology

If the chimneys are made of modern materials, stainless steel (double-wall sandwich pipes) or ceramics, for example Schiedel Uni, the chimney extension should be carried out with pipes from these manufacturers, strictly following the work technology recommended by the manufacturers.

Brick chimneys are built up either with brick or stainless steel pipes. Stainless steel is used to extend chimney pipes or one of the channels of a brick shaft to remove combustion products from a heating device (stove, fireplace, gas boiler).

Adapter from brickwork to stainless pipe

When switching from masonry to stainless steel, there are two main issues to consider:

- The cross-section of the chimney must not be narrowed. To do this, it is necessary to calculate the internal cross-sectional area of the existing pipe, multiplying the lengths of the internal surface of the pipe by each other and select the diameter of the round pipe corresponding to the area, calculating it using the formula πR².

- Increasing the height of the chimney should be done with insulated, double-walled pipe sections. Single-wall pipes freeze in cold weather and air pockets form in them, preventing the startup of boilers and the ignition of stoves and fireplaces.

What do the professionals advise?

As you can see, making an attached chimney yourself is not so difficult. The main thing is to choose all the materials correctly and take into account fire safety standards, which will allow you to avoid many unpleasant situations. It’s up to you to decide whether to vent the chimney through the roof or make it external. After all, what is better or worse is always easier to determine in each specific situation.

And finally, I would like to share some advice that professional stove makers give:

- Before you start purchasing chimney elements and installing it, be sure to determine the power of your firebox. The more powerful it is, the larger pipe diameter you will need.

- Be careful when choosing the height of the structure, which has a significant impact on obtaining good traction. A chimney that is too short will poorly remove combustion products, while a chimney that is too long will lead to excessive heat loss. Practice shows: the optimal pipe height is 5 meters. But here, too, everything is individual.

- If your boiler is equipped with forced draft, then the output of the external chimney can be completed at the stage of arrangement of only the horizontal section (without further extension of the vertical pipe).

- It is better to remove the chimney from the side of the gables (if possible). This greatly simplifies the task, since its arrangement will not be hampered by awnings and roof eaves.

- The maximum length of the horizontal section should not exceed 1.5 meters. It is here that the smoke flow is inhibited, which significantly reduces draft.

- Here, provide a special hole for technical needs: inspection and cleaning of the chimney. After all, the horizontal section is the most problematic in this regard. Sales consultants will help you choose the right item.

- If there is a wooden wall on the side of the boiler, fireplace, or stove, be sure to install a protective screen. These can be sheets of mineralite, asbestos, galvanized, fire-resistant plasterboard, glass magnesium or other fire-resistant material.

There is no need to do this

. With this I will finish my short review. I hope that this information will help you avoid mistakes when making an external chimney yourself. I will be happy to answer all your questions, listen to your wishes and criticism (this is always useful).

Warmth and peace to your home, and impeccable operation to your boiler and fireplace. And don’t forget to recommend the article to your friends, in case someone finds it useful... See you, bye!

Wisdom Quote: Nothing teaches you more than realizing you made a mistake. This is one of the main means of self-education.

How to make a pipe passage through the ceiling and roof: a step-by-step guide from the master

The most common type of chimney for a bathhouse is made from sandwich pipes. It is his installation that I will consider. The sandwich is very easy to install; elements for pipes of any configuration are available for sale. Stainless steel chimneys last for several decades; the calculated thickness of the insulation ensures good draft.

Step 1

Initial installation stage:

- connection to the outlet pipe of the tee;

- connection of a horizontal or vertical section without insulation, transition from an uninsulated pipe section to an insulated one;

- installation from below of an element with revision and a container for condensate drainage.

Chimney installation: calculation and main mistakes

When installing a smoke exhaust system, it is very important to correctly calculate the chimney for a wood-burning stove. Any errors that are made during the calculation process will affect its operation in the future.

When calculating the chimneys of wood-burning stoves, we pay attention to two indicators - the height and diameter of the pipe section. We will talk about the section and its types later, first we will deal with the height.

When calculating the optimal height of the structure, it should be understood that the chimney must maintain natural draft. The chimney should not be too high (despite the fact that in a high chimney the draft will increase, too much cold air will flow inside). However, you can’t make it too low, in which case you risk losing traction altogether.

Calculating the height of a chimney is a complex operation that is best left to a professional. However, if you decide to do it yourself, then remember two things:

- Pipe diameter and height are directly related and vary depending on each other;

- In general, the height of the chimney above the roof level cannot be less than 500 mm.

Lining the middle part of the chimney

The middle part of the smoke exhaust pipe passing through the attic is lined only for thermal insulation. If an attic is being built, the pipe passes through it and heats the room. In this case, the chimney lining should be harmoniously combined with the interior of the attic. For work, you can use heat-resistant plaster, but first the pipe must be insulated. To do this, use basalt wool, which is attached to a pre-installed metal frame.

The wool slabs are laid so that they are held by the frame itself. Additionally, self-tapping umbrella screws are used. For plastering work, a reinforcing mesh is stretched over the insulation boards. Such thermal insulation prevents the formation of condensation inside the chimney and its subsequent destruction.

How to install a chimney through a wall

The algorithm for installing a chimney through a wall is simpler than an outlet through the roof. However, there are certain installation requirements that you should know at the bathhouse planning stage:

- The technological hole for the pipe outlet in the wall of the bathhouse is made at a height of at least 1.2-1.5 m.

- The horizontal section of the pipe (from the stove to the external turn to the vertical) should not exceed 1 m. The large length of this section leads to a significant decrease in draft and rapid clogging of the chimney with combustion products.

- The vertical section of the pipe running along the outer wall of the bathhouse should not be adjacent to it by more than 1.5 m. The same distance is left when going around the roof overhang.

- The distance to neighboring buildings when leading a pipe along the street through a wall is prohibited to leave less than 1.5 m to your own building, and less than 3 m to a neighbor’s building.

- For effective smoke removal, it is prohibited to make more than 3 turns of the pipe from horizontal to vertical position.

- The total length of the vertical section must be at least 5 meters to ensure effective traction.

- The pipe has no thermal insulation in the room. After passing through the wall, the insulated sandwich comes out.

Installation of a chimney in a bathhouse through a wall is carried out as follows:

- A segment with a damper (shaver) is connected to the oven through a special adapter. The damper, like in a classic stove, regulates the draft level. Its complete overlap prevents heat from escaping into the atmosphere after the stove goes out. Each joint is treated with fire-resistant sealant and tightened with special clamps.

- A heat-protective reflector screen is installed on the wall in the area of the technological opening. The diameter of the hole is calculated so that the pipe wall does not reach the wall of the bathhouse 45 cm.

- The pipe is taken outside, covering the free space of the box in the wall with thermal insulation. The mineral wool is placed in a special metal mesh, which serves as a mechanical limiter.

- When withdrawing, the structure is continued with a tee. The lower hole of which has a plug, forming a container for collecting resin and condensate. The chimney is periodically cleaned through this hole.

- The vertical section leads straight to the roof canopy. It is bent around corners at 45 or 90 degrees. It is preferable to mount sharp corners for a smooth bend.

- The top of the chimney is decorated with a protective umbrella.

To support the weight of the pipe, special supports are installed on the outside. In addition, after 50 cm, special brackets are installed on the wall of the house to hold the vertical structure in an immovable, fixed position.

We recommend that you read: Is it possible to pour polypropylene pipes into a screed?

The lower supports on the outside of the bathhouse support the weight of not only the vertical section of the structure, but also fix the horizontal elbow, keeping the guide axis away from the stove.

How to provide traction

Primary requirements

The draft in the pipe occurs due to the pressure difference at the base of the pipe and outside it. Accordingly, the traction efficiency is largely influenced by the height of the pipe. Therefore, when installing a chimney, the following rules must be observed:

- If the chimney is located at a distance of no more than one and a half meters from the ridge, then it should be half a meter higher than the level of the latter;

- If the chimney is one and a half to three meters away from the ridge, then its top point should not be lower than the ridge;

- If the distance from the ridge to the chimney is more than three meters, then it can be lower than the top point of the roof, but the line from the top of the chimney to the ridge should have an inclination angle of no more than 10 degrees, as shown in the diagram below.

Related article: Do-it-yourself roof drainage installation

Diagram of the dependence of the height of the chimney on the location on the roof

It must be said that the principle “the higher the better” does not work either. If the structure is too high, the gases cool down before escaping, which leads to poor draft and the formation of condensation. True, insulating the pipe can solve the problem to some extent.

An important point affecting draft is the cross-section of the chimney. It must correspond to the power of the heating device. Therefore, before installing the chimney, study the technical documentation that comes with the heating device.

Extending the chimney

If a chimney is installed on the roof, the height of which does not meet the given requirements, it must be increased. If the chimney is made of brick, then this operation usually does not cause problems, since you only need to add several rows of bricks to the existing structure.

If the chimney is metal, you can build it up as follows:

| Illustrations | Actions |

Preparing a new pipe:

| |

Extension:

| |

Fastening with guy wires:

|

This completes the installation.

Functionality and design features

So, how to bring a chimney through a wall, what features do you need to know and what to pay attention to first? Consider not only the passage through the wall, but also the exit of the chimney to the top. That is, the optimal height for any type of chimney structure should correspond to 5 - 10 meters

Using a smaller channel is 100% guaranteed to result in poor draft and, accordingly, problems with smoke emission. By the way, it is not recommended to increase the height of the channel too much; above 10 meters will already be accompanied by excessive combustion and high fuel consumption.

Considering that over time you will definitely need to clean the channel from soot, round pipes made of expanded clay or metal are often chosen

And the installation of this kind of structure is much easier, especially if we take into account modern proposals, such as a two-channel or two-layer pipe. Representing a ready-made structure that does not require insulation and additional sealing

This type of design has proven its practicality and optimality; condensation and negative deposits do not form in it. In addition, the outer walls do not heat up to prohibitive temperatures, so a fairly serious fire safety situation is maintained.

Sealing with a metal pipe - how to secure it correctly

In addition to elastic penetrations, you can use metal passage pipes, which also help solve the problem of how to attach a chimney to the roof. They can be purchased at construction stores. This element is used to arrange the passage of a chimney through a flat roof. Most often, the pipes are made of alloy steel; they are selected in accordance with the angle of the roof.

Installation of a metal passage pipe is carried out as follows:

- Mark a mark on the roof surface with a marker and cut out a hole of the required size for the chimney to exit onto the roof. For cutting, you can use a grinder or special scissors, retreating 1-2 cm inside the circle.

- Clear the passage for the chimney by removing waterproofing material and insulation. If necessary, cut down elements of the rafter system.

- A fire-resistant material with a hole for the pipe and a size that exceeds the diameter of the chimney by 15-20 cm is fixed on the roof from the attic side.

- Insert the pipe into the hole and connect it to the laid chimney; the joint is tightened with a clamp.

- The pipe is placed on the chimney and fixed to the roof surface using sealant or self-tapping screws.

- The pipe is extended with new segments until the required height is reached.

Covering bathhouse walls with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with increased thermal insulation properties and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall cladding, consisting of thermal insulation with fire-resistant properties and a metal covering in the form of a sheet.

Insulating walls with reflective sheathing

A protective cake with reflective materials is done this way. First, the thermal insulation is attached using ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since heating may release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow inside the steam room, reducing heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-flammable, environmentally friendly;

- asbestos cardboard, which reliably protects against flames and has a long service life;

- mineralite, an artificial material made specifically for these purposes.

Protective sheathing requires ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close to the wall as possible, make a double skin of non-combustible insulation, use ceramic bushings to maintain gaps of 2-3 cm and sew them up with a steel sheet.

Insulation with cladding

Measures to protect walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bathhouse. It is based on tile cladding, which is laid on fire-resistant cladding made of gypsum plasterboard, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-flammable cement-fiber material, moisture-resistant and resistant to biochemical influences, LSU, fiberglass material bound with magnesium additives, resistant to high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from fireclay dust bound with kaolin additives, intended for tiling stoves, fireplaces, and all heated surfaces.

The recommended facing materials are quite varied, the best of them are:

- terracotta tiles, they are made from specially fired clay, which gives increased heat resistance and durability;

- clinker, denser clay tiles with a surface of various colors, similar to facing bricks;

- tiles, also made from clay, having an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under a pressure of 400-500 kg/cm², with imitation of stone, wood, durable artificial material;

- soap chloride, a rock mineral consisting of talc, magnesite and chlorite, an environmentally friendly natural material that does not absorb moisture at all, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use soap chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes due to the release of vitamin D when heated.

All of the listed tiles are an element of protection that forms a cake, the basis of which is a fire-resistant material. Just like a screen, sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tile should be 20cm.

Protection with cladding decorates the room, creates a positive mood, and helps to increase the efficiency of procedures. And most importantly, properly installed insulation prevents wooden walls from overheating and catching fire. Have a nice steam!

Selection of devices for regulation

Let's consider some characteristic features and methods of using devices for monitoring and adjusting traction.

Deflectors

Such structures are installed on the chimney (at its very top) to create obstacles to air flow. The intensity of the wind force drops noticeably when encountering such devices placed on a pipe. The smoke escapes through the channel “to freedom” due to weak air currents entering the pipe. These flows “catch” the exhaust gases and “push” them out.

Deflectors eliminate the possibility of pipe clogging, and, if made with taste, they significantly improve the appearance of the entire building.

There are several types of deflectors:

- TsAGI;

- round Wolpert;

- Grigorovich;

- plate-shaped;

- in the form of the letter H;

- rotating;

- vane.

Almost all of these devices are made from stainless steel, in rare situations - from copper. Using brackets, clamps, bolts, sealing tape, the deflector is attached to the chimney pipe. Some devices are also equipped with additional functions: to extinguish sparks (to eliminate a possible fire in the roof), to control the temperature of the exhaust air (in this case, the sensor is triggered if hot air does not come out and there is a possibility of reverse draft).

The disadvantages of using deflectors are their minimal effectiveness in calm weather.

Photo gallery: types of deflectors

The most common device for improving traction

Such a device can be purchased in specialized stores

The choice of device depends on the design features of the pipes and your preferences

Rotary devices

Turbines installed at the head of the chimney use the energy capabilities of the wind. Air flows set the rotary nozzle in motion (it always moves in one direction), and thereby the air becomes rarefied near the chimney. The entry of any foreign objects and sediment into the chimney with a rotary pipe is completely excluded.

Rotary pipes have a big disadvantage, similar to the operation of a deflector. Their use on a windless day is ineffective.

If you do not have great abilities, buying such devices is not a problem.

Traction regulators

Such devices are a real find for residents of country houses, lovers of baths and fireplace gatherings. These devices are attached to the boiler chimney. They are equipped with a metal plate with a weight that balances it on one side. When the draft is good, the metal plate does not interfere with the free access of air into the chimney. With weak or reverse thrust, the metal plate serves as a kind of stupor.

The range limits for thrust are set by the consumer himself, the usual parameters are 10–35 Pa.

The device operates completely autonomously and does not require any electrical current.

It is important to know

Before starting installation, you should familiarize yourself with some subtleties

For example, it is important to know that the larger the structure area inside the room, the less heat loss there will be. When creating a detailed diagram, take into account the fact that smooth horizontal sections should be up to one meter

Please note that contact of the system with any communications, such as gas and electricity, is unacceptable. And if there are wooden parts in the way of placing the chimney, then the pipe must be moved away from them using special steel brackets. The distance between fastenings should not exceed one meter.

Also include in the plan a part of a collapsible pipe or insert with a door through which inspection and cleaning of soot will be possible. Of course, installing a sandwich chimney is a serious and responsible matter, so if you decide to do it without specialists, then understand the degree of responsibility and strictly follow the step-by-step instructions.

Useful information about chimney draft

All residents of country or private city houses are familiar with the concept of chimney draft. Do they know the essence of this term?

If we move a little away from the dry scientific terminology, then draft can be defined as a natural phenomenon in which air moves from one area to another, namely, from an air zone with high pressure to a zone with low pressure. All this happens with the help of a ventilation device - a special channel in the chimney.

Using this process of aerodynamics, humanity began to use fireplaces, stoves, boilers, heating their homes using different types of fuel - coal, firewood, peat, etc.

With good draft, the stove lights up quickly and the room is filled with pleasant warmth.

The following depends on a properly designed and constructed chimney and, accordingly, on good draft:

- quality of room heating;

- reduction in fuel costs;

- safety in buildings with their own heating.

What influences the value

There are three groups of factors that must be taken into account when constructing and inspecting a chimney.

In-house moments

A number of factors indoors can significantly influence the presence/absence of draft and its strength:

- The material from which the building is constructed.

- Average room temperature.

- The maximum volume of air space in the home.

- The number of people permanently staying inside the dwelling.

- The presence of internal sources that additionally consume oxygen (heaters, heaters, stoves, etc.).

- Regular supply of fresh air (airing, ventilation).

External factors

There are other factors that determine the chimney draft, and they are located outside the heated room. We are talking about external temperature, atmospheric pressure, humidity, wind direction. A phenomenon such as changing temperatures during the day can also affect draft - due to the movement of cold and warm layers of air.

Difficulties with traction appear for various reasons, some may simply not be noticed. For example, problems with air outlet through the chimney may arise if the pipe is located much lower than the ridge of the building or tall nearby trees.

Chimney design features

The draft may vary depending on the design characteristics of the chimney:

- height;

- presence of insulation;

- tightness;

- location (internal/external);

- length;

- presence/absence of irregularities or roughness, etc.

It is necessary and possible to control the draft in a room using the “levers” of the first and third factors (intra-house and design). Natural changes, of course, do not depend on humans.

Keeping the draft in the chimney under control is a prerequisite for safe and comfortable living in your own premises. If the draft is very weak, then it is almost impossible to light the stove and heat the home.

With reverse draft, the gases generated as a result of combustion are “thrown” into the living space, and not into the air through the pipe. This is very dangerous for human health and life!

It is impossible not to notice this atypical behavior of smoke

With very strong draft, all the heat is rapidly drawn out through the chimney channels, without having time to warm the heated room to the desired temperature.

The main stages of installing a sandwich chimney

How to install a chimney quickly? The answer is simple: buy a sandwich pipe. This material is an ideal solution for a private home, especially if you do not have much experience in construction. You don’t even need an assistant to install this material; you can complete all the steps yourself.

We connect all structural elements

The sandwich pipe has one design feature - a ribbed coating on both sides. This device allows you to connect elements to each other by simply inserting different parts into one another. To drain condensate that will arise during operation, additional tees should be installed.

Series connection of the chimney pipe

All joints must be fastened efficiently and reliably with steel clamps. To connect the starting part to a boiler, fireplace or other heating device, you should purchase an appropriate adapter with two different diameters.

A simple method is used to connect internal products. Take one inner pipe out to a distance of 10 cm, connect it to the second (using a steel clamp of a smaller diameter) and push it inside the outer pipe. For greater tightness, it is not enough to use only clamps; you will also need a special sealant designed to work at high temperatures.

We will secure the floors

When installing a chimney made of sandwich pipes or other material through a wall, fire safety rules should be taken into account. If it is concrete or brick, then it will be enough to simply treat the joint with sealant. It is much more difficult in wooden houses, where contact of the chimney with a wooden wall will lead to a fire.

Sealing the pipe passage

How to secure the junction of the drainage system with the ceiling:

- Use galvanized sheet, which should be fixed to the ceiling. A hole is cut in the middle of the sheet and a chimney is inserted into it. Galvanized sheet does not heat up completely and does not transfer excessive heat to the wooden surface.

- Treat the distance from the pipe to the nearest wooden surface with insulation. Almost all modern insulation materials are heat-resistant and do not ignite at high temperatures.

Instead of galvanized sheet, many builders use asbestos material. It also has increased resistance to high temperatures.

We bring the pipe to the roof

Installing a chimney from sandwich pipes and laying it through the roof is the most painstaking part of the work. Here you will need not only to apply physical strength, but also to calculate everything accurately and correctly.

Protective structure for chimney pipe

The procedure for bringing the chimney to the roof:

- Make a hole in the roof. To make it neat, the place should be marked in advance using a construction marker. There is no need to rush, because a crooked hole will not add to the aesthetics of the entire structure. It is most convenient to cut out the roof from its inner part.

- An under-roof sheet is installed from the inside, securely fastened, and a roof trim is installed on the outside.

- All that remains is to bring the outer part through the hole and securely seal the edges with sealant.

Now you can once again check the quality of the design, and as a final step, remove all the protective film. You can safely light up the boiler or fireplace and look at all the joints and holes treated with sealant.

Arrangement of the passage

The most difficult task that needs to be solved when installing a chimney is creating a sealed and fireproof passage through the roof. The fact is that the temperature of the surface of the structure in the passage area can be several hundred degrees.

We will roughly divide the work into three stages:

The main stages of arranging a chimney passage through the roof

Next, we will look step by step at how to arrange a chimney passage through the roof.

Preparation of materials

So, to arrange the passage we will need the following materials:

- Roof passage - selected individually, taking into account the shape of the chimney, its size, as well as the type of roofing;

- Fire-resistant sheet material - you can use stainless steel, galvanized or any other sheets from which you can make a box to protect the roofing cake from fire;

- Stone wool (can be replaced with expanded clay);

- Fire resistant sealant.

In addition, you will need self-tapping screws to secure the structure.

To arrange a passage through the floors or roof, it is necessary to use a box filled with thermal insulation

Arranging a passage from below

First of all, I note that in the passage section, the distance from the chimney to any flammable material, including wooden roofing elements, must be at least 25 cm. Moreover, the space between flammable materials and the chimney must be filled with non-flammable heat-insulating material.

Therefore, the connection unit from the room side is performed as follows:

| Illustrations | Actions |

Making a box. Even before installing the chimney, it is necessary to make an internal apron, also known as a box. It is performed as follows:

| |

Passage arrangement:

|

Beginners are often interested in whether a chimney and ventilation can be combined in one box? This should not be done, as smoke from the chimney may enter the ventilation duct.

Arrangement of passage outside

To seal the chimney outlet, it is necessary to use a special passage element. The installation process depends on the type of pipe. If the structure is rectangular, then installation of the passage begins even before laying the roofing material:

| Illustrations | Actions |

Installation of wall profile (bottom apron):

| |

Installing the top bar.

|

It is even easier to install a passage on a round chimney - the casing is simply put on top and attached to the roofing material with self-tapping screws. The joint between the roofing material and the casing is coated with sealant. If the roof is made of ondulin, then an elastic apron is used, which is simply glued to the surface of the roofing.

Pipe passage through an ondulin roof

Sealing with elastic penetration

In private housing construction, the question of how to install a chimney through the roof is most often solved using round metal pipes. The tightness of the outlet in this case is achieved through the use of elastic penetration. This special device is made of rubber or silicone in the shape of a funnel with a wide round or square flange called an apron. A feature of elastic penetration is the ability to take any shape and adapt to the slope of the slope. In addition, the element is characterized by resistance to extremely low or high temperature values, and to the effects of aggressive chemicals. May have different colors.

Before purchasing an elastic penetration, it is important to accurately determine the diameter of the pipe and the color of the roofing material. The universal type model is made in the shape of a stepped pyramid, so it can be used on chimney pipes of any size. To fit the sealing element, you need to trim the penetration to the required height. To install an elastic apron, it is adjusted to the outlet of the chimney, pressed with a metal circle in which there are holes for fasteners. The joint is treated with heat-resistant sealant and fixed with self-tapping screws. If the chimney pipe is installed on a roof with steep slopes, then plastic penetrations are used, the flange of which has a given angle.

Do I need to make a foundation for the stove?

Installing a stove in a wooden house may require the presence of a foundation. However, a permanent foundation is required for a metal stove only if its weight exceeds 750 kg. Typically, steel stoves weigh much less (up to 300-400 kg). But if the equipment is covered with brick, then the weight of the entire structure will be very impressive.

When the stove weighs up to 80 kg, a foundation is not needed; the device must be installed on a solid, non-combustible base.

Another way to determine whether a foundation is needed is to consult a professional stove builder. This must be done at the stage of designing a wooden house, since the foundation for the stove is built during the creation of the foundation for the house. If the building has already been built, then the flooring at the installation site will have to be dismantled. After this, you will need to remove the soil and make a foundation for the stove.

Is it possible to hide polypropylene pipes in the wall Construction and repair

Self-installation of plumbing and heating systems is no longer uncommon: with the advent of accessible and inexpensive materials on sale that do not require cutting and joining equipment, many craftsmen take on such work without fear.

Numerous master classes and video lessons are ready to clearly demonstrate all the stages from scratch to putting the system into operation.

And yet, some moments sometimes remain outside the frame: the question of whether polypropylene pipes can be hidden in the wall in order to effectively complete the decorative finish often remains open.

Hidden heating system

Modern technologies make it possible to improve the aesthetic appearance of a room in various ways. The method of placing heating pipes in the room was no exception.

It becomes possible to place them in the wall, thanks to the durability of the material used in their production.

Advantages and disadvantages

It is most convenient to place communications in the wall at the construction stage in a private house according to a previously created drawing. You can hide pipes in the wall in an apartment building if you are planning a major renovation of the premises or the entire building.

By placing the heating in the wall, the room certainly looks more prestigious, and the freed-up space can be decorated.

Pros:

- heat transfer increases, since building materials have an increased level of heat transfer, unlike air;

- the service life of the polypropylene from which the pipes are made reaches up to 50 years, ensuring the reliability of the design while observing technical standards during their installation;

- the space increases by several centimeters.

However, difficulties must be overcome in obtaining the right to permit changes in the position of communications in the premises or their so-called redevelopment.

Minuses:

- low-quality propylene increases in volume when heated;

- ordering a project to change the location of communications;

- coordination of the project with supervisory authorities. Alteration of engineering systems in an apartment building will require a special permit;

- joints may lose their sealing, which can only be determined using a device that measures water pressure;

- risks associated with preparedness for wall destruction in the event of a possible leak.

A break in the heating system pipes in the wall in the event of a leak will cause water to enter the adjacent lower apartment, since it will not be possible to quickly eliminate the leak.

How to brick up heating pipes in a wall

To disguise the pipes of the heating system in the wall, you need to find out what material the wall is made of, and select the method and sequence of work, as well as the necessary materials.

Before laying heating pipes, it is necessary to test them for strength and visually carefully check for possible damage.

Concrete

In an apartment in a panel apartment building, there are two ways to lay heating system pipes: using grooves - specially created channels for laying heating pipes in them, or creating a false wall.

How to remove heating in a wall in a panel house step by step using grooves:

- You need to start by de-energizing the common building heating riser. You should make sure that the desired riser is turned off;

- The grooves should not be located end to end. The contour should not be infringed. The recess is calculated based on the parameters of the fasteners, their quantity and the layer of prepared insulation;

- directly covering heating pipes with an insulating layer. Insulation is used to prevent condensation;

- Next, they calculate the places for fastening and mark the locations of the fasteners.

The work is carried out with a grinder. It allows you to perform high-quality actions in automatic mode and facilitates wall slitting.

When erecting a false wall, it should be taken into account that the space of the room will decrease.

Brick

Strobes are made in a brick wall in the same way as in a panel wall.

The procedure for laying part of the heating system into a brick wall:

- the depth or width of the channel is determined taking into account the amount of insulation wound on the surface of the pipe;

- after which they are placed in the marked places and secured with clamps pre-fixed with self-tapping screws.

It is necessary to test the system by running water at excess pressure for several days. After making sure that there are no leaks, the wall with communications is covered with mortar and putty.

Where to put a metal stove?

Ideally, you should choose a location for a steel stove after windows have been installed and doorways have been erected. Then it becomes clear how the air flows inside the room will be directed. To achieve the most efficient operation of the furnace, it should be placed where there is not too much air movement.

- Narrow rooms are not a suitable place to install a stove. According to fire safety rules, there must be at least 130 cm to the wall opposite the firebox.

- In addition, the stove itself should be 110-125 cm from the walls, and when using insulation made from non-combustible materials - 40 cm.

- It is also not possible to install a stove in a room that is too small: heating equipment that runs on wood is allowed to be installed in rooms with an area of at least 16 m2.

If the device is equipped with a hob, then you can safely install it in the kitchen. For example, among the Teplodar stoves, the Matrix, Vertical, Meteor and other models have this design. These stoves can operate for up to 8 hours on one load of wood thanks to an effective two-channel afterburner system.

Owners of two-story buildings should take into account that to heat the second floor they will need another metal stove.

Background.

Since the construction of the stove in my house, an asbestos-cement pipe with an outer diameter of 250 mm has been used as a stove pipe. It consisted of two sections screwed into one another.

The stove is located in the annex. But despite the height of the pipe being 2.5 m, it turned out to be lower than the height of the ridge of the main house. Any stove maker will say that such a scheme will not provide good draft and, moreover, a reverse of the air stream is possible.

And so it was. In windy weather, the stream often overturned and the smoke, instead of going into the chimney, went into the house. Partially, this problem was solved by installing a “Mushroom” visor on the pipe.

Of course, I understood that the best solution to this problem would be to increase the height of the pipe. But... somehow I never got around to it. But the situation turned out so bad that I had to do it unplanned.

As I already said, the asbestos-cement pipe consisted of two sections screwed into one another. So... The upper pipe burst at the junction with the lower one. I had to dismantle it.

There were no such pipes in any hardware store in the city.

A neighbor suggested a solution to the problem. He suggested building it up with a regular asbestos-cement pipe with a diameter of 200 mm. To be honest, I didn't really like this idea:

— firstly, I was afraid that the narrowing of the pipe’s flow area would have a negative impact on traction;

— secondly, there was no idea how to connect two asbestos-cement pipes of different diameters;

Looking ahead a little, I will say right away: the pipe was successfully extended, the thrust... increased significantly. I forgot about the overturning of the jet like a bad dream.

And now the actual pipe connection technology itself.

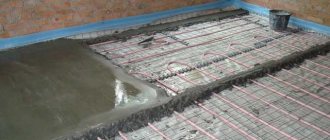

Methods for installing heating pipes in the floor

In this block we will look at two options:

- installation for pouring;

- installation under wooden covering.

Pouring installation

The method is suitable for both apartments and houses, even with wooden floors. The screed can also be poured onto a wooden subfloor. In both cases, the algorithm of actions is the same:

- waterproofing is spread;

- insulation is installed;

- reinforcement mesh is laid;

- pipes are separated and secured;

- damper tape is glued;

- everything is filled with a layer of solution.

Now let's talk about everything in order. Waterproofing is spread on the floor to prevent moisture from entering from below, and also to avoid contact of wet mortar with the wooden subfloor. Then the working surface is insulated. The best insulation option is polystyrene foam and its derivatives, such as penoflex. A steel mesh is laid on the insulation, which will distribute the load in the layer of hardened mortar. Without reinforcement, the screed will crack.

There are special foam mats that have bumps on the surface. They are arranged in rows at regular intervals, like grid cells. Such mats are simply placed on the floor, routing is carried out along them and the whole thing is filled with mortar. Easy, fast and high quality. New technologies, however.

Layout diagram of heating pipes in the “snail” floor

The distribution of heating pipes in the floor is carried out according to one of two schemes:

- snail;

- snake

The snail pattern involves a circular laying of the contour from the walls to the center of the room. There are no sharp turns in the direction of circulation. The snake passes from one wall to the opposite and at each segment the direction of water movement changes by 180 degrees. Not to say that this is very bad, but the first scheme is more preferable.

The contour must be fixed to the surface, and it must be remembered that it increases in length. Therefore, the fastening should not be rigid; the line should be able to slide in it. Alternatively, you can use plastic clips that are drilled to the floor. It is easier to use ordinary clamps that secure the pipes to the mesh.

In fact, a warm floor is a layer of hardened mortar in which heating pipes are hidden. At the same time, the cement slab does not have a rigid connection either with the subfloor or with the walls. This large rectangular parallelepiped simply lies on the floor, periodically increasing and decreasing in volume.

Under no circumstances should you forget about the damper tape. This is a strip of foamed polymer that is glued along the entire perimeter of the room to the wall. The bottom edge should run along the floor. The damper tape compensates for the expansion of the screed and prevents the mortar from sticking to the walls when pouring. The thickness of the screed above the heating pipes should be at least three centimeters, and in total - about seven centimeters. If the layer thickness is insufficient, it will crack; if it is too thick, the temperature on the surface will be lower than expected.

Installation under wood flooring

Heating pipes in a wooden floor

This method is not as effective as installing pipes in a screed, but is sometimes used. First you need to create a buffer zone for laying heating pipes in a wooden floor. To do this, logs (bars) are laid. Then pipes are laid between the lags. At the intersection of the contour and the bars, grooves are cut out in the wooden logs so that the entire highway is in the same plane. Naturally, it is necessary to provide insulation and waterproofing so that all the heat goes up. The finished floor is carefully pricked onto the joists so as not to pierce the main line.

Now let's summarize. For installation of heating pipes under screed, products made of cross-linked polyethylene reinforced with ethylene vinyl alcohol, marked PEX/EVON/PEX, are best suited. There should be no breaks in the line; everything is done from one piece. The floor must be insulated and waterproofed before pouring. The thickness of the heating pipe screed must be at least three centimeters and no more than seven. Damper tape is glued around the perimeter of the room. The temperature in the heated floor system is about 40 degrees, and on the surface of the finished floor - about 30 degrees.

Pipes for heating in the floor (in the interfloor or basement ceiling) are installed either during the hidden installation of the heating system, or during the installation of the “warm floor” structure. It is worth noting that in these cases, pipes are used in principle and various pipeline assembly technologies are used.

Therefore, in this article we will describe the installation of heating pipes in the floor, placing emphasis on all the details of the technological process. In addition, we will say a few words about the “warm floor” technology itself.

Warm tiled floors

Tile floors are durable and resistant to moisture and aggressive liquids. Therefore, many homeowners opt for an electric heated floor followed by laying tiles.

Tiled floor heating

In addition, they are economical because they allow you to adjust the temperature according to the season. The installation of heated floors under tiles is made of cable, film and in the form of heating mats. Let's look at their pros and cons.

Cable underfloor heating system

Today, cable underfloor heating under tiles is rarely used. Due to the high pie of this system, which includes a concrete screed up to 4 cm thick, the height of the room increases and the load on the base increases. Therefore, it is better to use it in rooms without finishing.

Cable underfloor heating systemCheaper products include single-core cables. Their use is problematic in rooms with complex layouts, since there is a need for a thermostat. Easier to install are taller two-core options, the ends of which do not meet at one point. This floor is started after the screed or tile adhesive has completely hardened.

Warm floor made of electric mats

This option is suitable for rooms with a concrete base. The mats have a base of thin cables embedded in a reinforced mesh. They are produced with a thickness of no more than 3 mm and do not reduce the height of the room. The absence of screed and the minimum thickness of heating mats allow the use of such floors in rooms with low ceilings.

Appearance of mats with electric cable for heated floors

They are laid directly on concrete, covered with tile adhesive, onto which the tiles are fixed. Despite the ease of installation of this heating system, it is much more expensive than its cable counterpart.

Film floor option

Film heated floors under tiles are among the most modern and efficient electrical systems.

Film heated floor

It is easy to install and can be used on all topcoats. The coolant in the form of infrared radiation not only has high efficiency, but is also harmless to health.

Now you know how to make a heated floor with your own hands, and choosing the appropriate option will allow you to create not only a reliable heating system yourself, but also save on installation and commissioning work.

Where is the best place to put a stove in a wooden house?

The installation location of the stove in a wooden house is determined as follows:

Principle of operation :- Air-heating furnaces, operating like the Russian “Burzhuika” or the Canadian “Buleryan”, are installed in a place where convection currents move unhindered. If it is planned to heat adjacent rooms, the structure is built into the interior partition, or air ducts are connected.

- A stove with a built-in water heat exchanger is installed so that the circuit in the stove is the lowest point of the heating system. The location is not critical and is determined only by fire safety requirements.

- Connecting a chimney - installation of a heating stove and chimney in a wooden house are closely interconnected. The stove is located where it will be easier to connect the chimney in compliance with fire safety requirements.

- Ease of maintenance - to fire and clean the stove, you will need a sufficient distance towards the opening of the combustion chamber door. Furnace equipment with panoramic glass provides the opportunity to admire a live flame; this feature is also taken into account when choosing a location

- Fire breaks - from the heating surfaces of the stove body to the walls made of combustible materials, leave a distance of 110-125 cm. In the direction of the opening fire door, at least 125 cm.

A rational installation is important, taking into account the optimal location of the furnace, ensuring better heat transfer, safety and ease of use.

How to extend a chimney.

To connect two pipes of different diameters, I had to make a coupling. The starting material is steel sheet, 1.5 mm thick.

Using a grinder, two rectangles were cut out, measuring 200x630 and 250x790, as well as a circle with a diameter of 300mm with a cut out window with a diameter of 190mm.

Rectangular blanks were bent into a cylinder shape. I used the appropriate asbestos-cement pipes as a template. The resulting joints are welded using electric arc welding.

I assembled the structure in this way: I placed a cylinder with a diameter of 250 mm on a flat surface, placed a circle with a cut-out window on top, and placed a cylinder with a diameter of 200 mm on top of the circle.

This entire structure was welded with electric welding.