In this article:

- Nuances of designing water supply networks

- JV requirements for the design of water supply and sewerage networks

- Types of water supply networks

- Stages of designing water supply networks

- The importance of developing a water supply network project by professionals

Designing water supply networks is a complex process that must be entrusted to professionals. Depending on the purpose of the building, at the design stage, water consumption standards, the type of pipes and equipment used, the design capacity and much more are calculated.

What will be included in the final documentation is influenced by various factors: the type of water intake, the height and purpose of the structure, distance from the source, etc. In our article we will tell you what the design of water supply networks consists of, what stages this process is divided into and why it is necessary to select quality performers.

Nuances of designing water supply networks

A plumbing system is a set of interconnected elements that provide water supply to a building and its discharge to the sewer system. The design of such a network must clearly regulate the requirements for drinking, domestic and technical water supply, and also include information about the fire water supply.

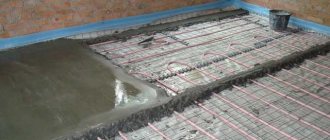

Designing a reliable plumbing system is necessary to avoid possible errors during the installation process, as well as for the rational use of materials. The project calculates the main characteristics of the water supply and sewerage network, such as the diameter of pipelines and the type of metering devices.

First of all, the necessary data is collected:

- layout diagram of risers and distribution units;

- information about the source of water supply;

- drafted technical specifications for connecting the water supply system.

The design process must be based on certain rules to achieve the desired quality of water supply work. Thus, water pipes should be laid in a straight line along access roads, but not under asphalt or concrete pavement. The intersection with the roadway must be done at right angles to its axis.

The choice of water source is important. From this point of view, there are:

- centralized water supply;

In this case, water enters the common network from several sources. Consumers are connected to this unified system. A centralized water supply network operates independently of the general system, which is its advantage.

- autonomous water supply.

Water is supplied to a small number of consumers who use the resource exclusively for personal purposes. The system consists of a water supply and a membrane or storage tank connected to it.

This is interesting!

“Design of water supply systems: features and stages”

More details

It is recommended to design the water supply network together with the sewer network and heating system. The final document in this case is called a heating, water supply and sewerage (HVAC) project. It contains information about the location of boilers, membrane tanks (hydraulic accumulators), filters and other elements of the water supply system. Also, the project must reflect the methods and locations of the pipeline, mark the locations and methods of installation of various branches and taps.

Legislative framework on which design is based

If when creating systems in private ownership there are not many restrictions, then when constructing apartment complexes there are strict regulations, adherence to which reduces the likelihood of future emergency situations. For individual households, a whole package of standards and rules has also been developed according to which a water supply plan is created.

These acts take into account seasonal climate changes, the interconnection of water intake and sewerage systems, and accident-free operation when working together with other communications (electricity and gas supply).

The installation of a central water supply requires coordination with all services (electricians, gas workers, signalmen, architects).

JV requirements for the design of water supply and sewerage networks

The basis for the design is SP 2.04.01-85, which regulates the rules for developing a plan for water supply and sewerage communications for residential, industrial and public buildings. When arranging local treatment facilities, they are guided by SP 2.04.03-85, taking into account the construction standards of regional regulatory agencies.

Pipelines for drainage are also designed in straight sections with a mandatory constant slope. In places where metering devices are connected, as well as where the direction of pipes changes, connecting elements with smooth and streamlined rotation angles are installed.

The internal sewer system is equipped in one of two ways:

- The pipeline is attached openly to the wall, ceiling or supports.

- Pipes are laid in boxes and shafts, mounted inside walls and ceilings, followed by sealing.

The internal system requires protection from mechanical damage; external pipes must be deepened into the ground below the freezing level and additionally insulated. Sewer risers are mounted on the roof or inside a prefabricated exhaust ventilation shaft.

It is necessary to design clearings at turning and dead-end sections. They are also provided in risers. Multi-storey buildings are equipped with revisions of risers, located, as a rule, on the lower and upper floors, and if there are indentations, also on the floors above. If the house has 5 floors or more, revisions should be constructed every 3 floors.

SP 2.04.01-85 also contains additional requirements for the design of water supply networks and drainage systems in special climatic conditions. This applies, for example, to seismically hazardous areas, areas with permafrost, subsidence and undermined soils.

Compliance with regulated standards when designing water pipelines will minimize possible breakdowns and malfunctions in the system in the future.

Hot water project for a private house

Supplying heated liquid to the consumer imposes some specifics on the placement and laying of communications:

- If possible, you need to reduce the distance from the heating point to the tap as much as possible.

- It is advisable to thermally insulate all pipes. This will help avoid unnecessary losses during transportation.

- Particular attention is paid to the properties of the reinforcement. For hot supply, propylene with a specially designed structure is used.

- You must understand that connection points may leak over time due to temperature changes. Their installation is carried out with special care.

Types of water supply networks

Water supply systems are divided into centralized and autonomous.

- In the first case, such networks are designed to provide a large number of consumers with water, which comes from a unified communication system. As a rule, a centralized system includes both cold and hot water supply. When designing, complex schemes are created, consisting of many separate communications and installations.

- The autonomous system provides water to a relatively small number of consumers. In practice, such networks are designed for water supply to private households. In this case, the water source is located near the connected residential building, from where it is distilled by a pump. Water is heated using domestic water heaters.

Next, we classify different types of water supply according to certain criteria.

1. Purpose of the plumbing system

Depending on the purpose, there are 5 types of systems:

- household;

They are used to provide water to most facilities in large settlements - residential, administrative, commercial and other buildings.

- agricultural;

Accordingly, they are designed for water supply to livestock and crop production facilities.

- production;

These water supply systems provide water to industrial enterprises operating in various industries.

- fire-fighting;

This includes specialized water supply networks for firefighting and emergency response.

- combined.

Systems used for multiple purposes.

2. Type of water source

- using surface sources;

Water from rivers, lakes and reservoirs is used for water supply.

- using underground sources.

Consumers are provided with groundwater.

- combined.

Water sources include both surface reservoirs and underground aquifers.

This is interesting!

“Stages of building reconstruction: understanding the requirements and documentation”

More details

3. Water supply technology

- gravity;

Water flows to consumers by gravity, under the influence of gravity.

- with forced circulation;

Water is delivered using pumps.

- combined.

Both methods are combined to deliver water.

4. Nature of water use

Industrial plants may use water in different ways. In this regard, there are 3 types of water supply systems.

- straight-through;

This implies a one-time use of water, which is then discharged through the sewer system or supplied to a treatment plant. This technology can be used for two reasons. First, water must be part of some product (for example, liquid fertilizers, mineral acids, etc.). Secondly, the quality of the incoming water after use deteriorates significantly, its subsequent use is not possible (for example, the electrolysis process).

- negotiable;

Water here is usually used as a cooling medium. In this case, there is a certain heated medium that needs to be cooled for reuse. Sometimes circulating water supply networks include treatment facilities.

- direct flow with repeated cycles of use. In this technology, used water, unsuitable for one object, is further used at another object.

5. Customer service form

From the standpoint of comprehensiveness of consumer services, there are integrated, incompletely separate and separate water supply networks.

The first type provides water (usually drinking) to all consumers. For industrial enterprises, it is advisable to connect such a system only when there is a need for high-quality water, or when a small amount of liquid is required.

Networks of the second type are connected to consumers requiring large volumes of low-quality water.

Separate systems actually represent several independent water supply networks intended for domestic, industrial and fire protection needs. This species is much less common.

Recycling water supply system

This scheme is not in demand in household construction, but is very useful, for example, at a car wash. Due to repeated use, significant savings in valuable resources are achieved.

A mandatory element of such complexes is the equipment of settling tanks and filters. The benefits include reduced consumption and wastewater, which has a negative impact on the environment. In large industries, steam can be used as a source. This results in large volumes of distilled water needed in many production processes.

Stages of designing water supply networks

The project of an external water supply system is carried out in 3 stages:

- Drawing up technical specifications for design

- Development of project documentation

- Development of working documentation

The technical specifications must indicate all the conditions for organizing the design, approve the stages of work on the project, define the design boundaries, and provide the specification of the required materials and equipment. The design documentation includes a text section (explanatory note) and a graphic part.

In turn, the explanatory note contains:

- information about existing or projected water supply sources;

- data on existing water protection zones, if any;

- characteristics of the designed water supply system indicating its main parameters;

- calculation of the design water consumption for economic and domestic needs, for automatic fire extinguishing systems, as well as for production needs (in the case of designing a network for an industrial facility);

- data on water pressure in the existing network and the required value of this pressure;

- characteristics of the pipeline material and measures protecting the pipes from the effects of surrounding soils and aquifers;

- information on the composition of water and measures to achieve the required quality;

- development of measures for water accumulation and accounting of water consumption;

- development of an automated water supply system;

- description of actions aimed at saving and rational use of water resources;

- characteristics of the hot water supply system with calculation of design flow;

- development of a circulating water supply system with a description of measures aimed at reusing thermal energy from hot water;

- calculation of the balance between water consumption and discharge for a given facility or for each connected process (in the case of an industrial enterprise).

Composition of graphic documentation:

- water supply plan;

- schematic diagram of the water supply network.

Development of documentation for the execution of work is carried out to the extent necessary for this. Namely, the information must fully support the complex of installation works for the construction of an external water supply system. A basic set of graphic documentation should contain:

- working drawings (plans, profiles) of network elements and equipment;

- diagram of pressure networks.

In addition, the external water supply project must include:

- hydraulic calculation with determination of the design pressure value;

- strength calculation to determine the maximum permissible deformations of the pipeline walls from soil and water pressure;

- determination of the minimum pipeline diameter;

- calculation of the elongation of pipes under the influence of temperature with a description of measures to compensate for such deformations (usually bends are used for compensation - in this case, the calculation of their characteristics must also be present in the project).

Selection of materials

Pipes made of copper, metal-plastic, and polypropylene are popular for internal water supply.

A water supply and sewerage project includes the selection of pipelines with the required parameters. The industry produces a wide range of pipes for drinking water and waste liquids.

Pipeline materials:

- metal-plastic,

- cast iron,

- steel,

- copper,

- polyethylene,

- polypropylene,

- polyvinyl chloride,

- fiberglass,

- asbestos,

- reinforced concrete.

The most common products are made of polymers, metal-plastic, and stainless steel. Internal water pipes are made of PPRC polypropylene, metal-plastic, PEX cross-linked polyethylene, corrugated stainless steel. Internal drain pipes are made from PP polypropylene, gray PVC and HDPE high density polyethylene.

For external water supply systems, products made of PE polyethylene and polyethylene with a PE-RC protective layer are used. External drainage systems are made of orange polyvinyl chloride, corrugated polyethylene and corrugated two-layer PP polypropylene.

The designer decides on the type of pipe, based on the technical specifications of the project, the advantages and disadvantages of the material, and also takes into account the wishes of the customer.

The importance of developing a water supply network project by professionals

To save on design work, some try to develop a water supply project on their own. In particular, they use standard templates found on the Internet, or order a project from students without experience for pennies.

However, the lack of necessary knowledge and skills on the part of the contractor will inevitably lead to errors during the installation process, and therefore to significant problems during the operation of the water supply system. The consequences can be very serious, often unpredictable:

- It is actually impossible to implement the project on a dedicated site.

- The calculated pressure turned out to be too low.

- Accidents occur in the system periodically.

- The actual costs of operating and maintaining the system are too high.

Only highly qualified specialists can create a water supply network project that fully satisfies all norms, rules and standards. The water supply system installed in accordance with this project will be guaranteed to operate without serious failures.

How work goes on creating a water supply and sewerage project in a private house

Before submitting an application, you must make a geological survey of the area and, based on this data, obtain Technical Conditions (TS). Since you will not be able to complete the design work yourself, it is advisable to seek help. Based on the collected documents, the house design and your wishes, a comprehensive plan for all communications of your country home will be created. In most cases, it is better to create an overall layout that includes drainage systems, ventilation, electrical supply, combined with a heating unit and backup power devices.

Stages of work

Engineers study all the data about the area, connection points, the general plan of the structure, and find out your individual preferences and wishes. Based on all the information received, a comprehensive plan is created. From it it will be clear in what quantity and what material is needed for construction. The location of all highways and the shape of their connections are clearly indicated. For the contractor, a package of such data is a fundamental link in the process of creating the entire complex.

SNIPs

To eliminate errors, a set of rules has been developed, the implementation of which allows us to hope for trouble-free operation. Engineers make accurate calculations based on these technical standards. This is another reason to contact qualified specialists.

How are calculations carried out?

To perform the task correctly, designers combine two factors: possible consumption and source power. Correctly calculating the design of internal wiring (after receiving the data) is a typical engineering job. If we do not consider multi-story buildings, then the entire calculation process comes down to the throughput on each branch to a specific object.

Selecting materials

Polypropylene, polyethylene, metal-plastic, iron, and stainless steel are used for installation of systems. Many countries still have water pipes made from copper. Sewerage can be plastic, cast iron, ceramic. Experts will tell you which option is most preferable in your case.

The most popular is a polypropylene pipeline. It is distinguished by easy installation, a pleasant aesthetic appearance, and no need for painting. Another plus is that it does not lose its seal when frozen.

To create external communications, it is advisable to use polyethylene. Since it does not oxidize or collapse in the trench, and at the same time it has the lowest price.

The metal is gradually leaving the market because welding work with it is expensive, and corrosion quickly destroys it.

Stainless steel is a reliable option, but the cost is highest. But she has all the above positive qualities.

Stages and features

Each specific case requires individual solutions. If on a flat surface with standard construction everything is clear and understandable, then when creating communications on complex terrain with deep or, conversely, low groundwater levels, it is necessary to use non-standard techniques.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

For example, typical pumps are designed to deliver 15-20 meters. If the well is deeper, support stations must be used.

The problem may be rocky soil or salt marsh. When laying highways in such conditions, additional problems arise, and the cost of the work carried out sharply increases.

The first step in any planning is to become familiar with the environment in which construction will occur. At the request of the client, additional parameters can be entered.

The second stage is to match opportunities with needs and find the optimal option.

The further process occurs according to the standard scheme, with the cheapest and most effective path being selected.

We give gifts to our clients!

When ordering a project for an amount over 1 ml. rubles we give away an Apple MacBook Air or a discount of up to 5% !

When ordering a project worth more than 500t. rubles we give Conquest Knight S8 Pro or estimate as a gift !

| We work all over Russia | Contacts. Tel/f +; [email protected] | Author G+ |

| You can contact us from 9.00 – 18.00 (Monday – Friday). Our specialist will always answer your questions and advise on possible solutions to certain problems by phone or upon request by email [email protected] . | by number Our Skype: dc-region Our Telegram by number |

we are in social networks

- Terms of use

- Personal data processing policy