Over time, mud deposits consisting of scale, rust, and other solid impurities accumulate in pipelines, pumps, heat exchangers, and batteries. They interfere with the normal circulation of the coolant and cause premature wear of the equipment. For long-term and efficient functioning of the heating system of a private home, it is necessary to periodically flush it. If you decide to do it yourself, you need to know how to do it correctly.

Why does the heating system become clogged?

The following factors contribute to the appearance of blockages in the heating system of a private home:

- replenishment of the coolant with ordinary, and not distilled, water from the water supply system, which may contain metal salts that provoke the formation of scale;

- Exceeding the service life of antifreeze (for example, ethylene glycol or propylene glycol);

- exceeding the operating temperature of antifreeze (for example, in the event of a heating equipment failure), leading to the appearance of solid sediment;

- the use of low-quality antifreezes that decompose with the formation of insoluble particles;

- corrosion of heating elements and pipes made of steel and cast iron, due to which rust forms in them, narrowing the working clearance of pipelines;

- the appearance in the heating system during low-temperature operating conditions of bacterial colonies, whose waste products form blockages.

Powders

G63

The powder removes scale from the heating system. The finished solution is compatible with cast iron, metal, and aluminum surfaces. When saturated with scale, the solution turns brown. The product is used in a concentration of 25–100 g/l of water. Washing is carried out at a temperature of 30...40 °C.

Price: from 61$/2 kg.

Descaling powder - G63

pros

- with corrosion inhibitor;

- contains a scale saturation indicator;

- suitable for steel;

- The line includes an acidity neutralizer;

- contour processing in 45 minutes.

Minuses

high price.

SteelTEX ZINC

The drug is compatible with most metals used in heating systems, enameled surfaces and zinc. Before pouring the finished solution into the system, mix it with water until a concentration of 7–15% is achieved; more powder is added during the washing process. The composition includes an indicator of residual acidity. It is recommended to use it with a neutralizer of the same line, which will enhance protection against metal oxidation.

Price: from 4557 rub./5 kg.

SteelTEX ZINC

pros

- the solution can be poured into the sewer;

- compatible with most metal surfaces;

- anti-corrosion protection.

Minuses

No.

SteelTEX ZINC

When to flush

Cleaning the heating system of a private home from blockages is carried out not at a certain frequency, but as problems arise in the operation of the heating equipment. The need for a procedure can be determined by the following criteria:

- insufficient or too long heating of radiators, heated floors due to poor coolant circulation;

- contamination of filter cartridges installed in the heating system in transparent flasks;

- increased consumption of electricity or fuel by the heating boiler due to scale formation in the heat exchanger.

How do you know when rinsing is necessary?

You will understand that flushing the heating systems in a private home will be necessary when you see the following signs in operation:

- the temperature regime in the house has decreased, although the boiler does not stop working stably;

- pipes become warmer slower;

- heating elements heat up unevenly;

- the pipes are hot and the radiators are cold;

- Fistulas in the pipes often began to appear, and ruptures occurred.

The appearance of at least one of these signs indicates that the heating system is clogged.

Why is it necessary to wash?

This procedure is necessary for the following reasons:

- blockages narrow the clearance of the heating circuit, thereby preventing the coolant from circulating and ensuring uniform heating of the entire house;

- for normal circulation of the working medium in a clogged heating system, the boiler must operate at increased power, which leads to excessive consumption of electricity and/or fuel;

- blockages cause water hammer and uneven temperature distribution along the heating circuit, which often leads to leaks;

- solid insoluble particles have an abrasive effect on the material of pipes, radiators, heat exchangers, causing their damage and, ultimately, failure of heating equipment;

- When the coolant circulates through a clogged circuit, turbulent turbulence occurs in it, which causes strong noise (hum, knocking, etc.) that interferes with the normal functioning of the residents of the house.

Conclusions and useful video on the topic

Video #1. The effectiveness of using hydropneumatic radiator flushing can be assessed by the amount of dirt thrown out:

Video #2. The subtleties of performing a chemical type of flushing of the heating system are outlined in the following story provided by the owner of a private household:

Any of the considered options for flushing heating systems does not represent an overly complicated procedure. If you have some experience in plumbing work and, in some cases, special equipment that can be rented, you can perform this operation yourself.

Would you like to talk about the effectiveness of flushing or tell us how you flushed the heating circuit in your home? Do you have valuable recommendations or important nuances that you would like to share with site visitors? Please write comments in the block form below.

Washing equipment

A correctly designed heating system has a pipe with a ball valve in the lower part, through which coolant is filled and drained. The following equipment is used for washing:

- compressors or pneumatic guns for cleaning pipes from insoluble blockages;

- electric water pumps (circulation, borehole, etc.) or vibration pumps for pumping coolant;

- flexible connecting hoses for connecting pumping equipment to the heating system.

Signs of scale on the inner surface of pipes

It is possible to determine excess scale accumulation by monitoring the system or in the presence of several indirect factors:

- Significant increase in energy consumption and resources for heating the room.

- Temperature difference between batteries and riser.

- Radiators heat up unevenly, this is especially noticeable on the upper and lower parts of the devices.

- When the heating element is operating, noise (especially crackling) is heard.

- The time required to heat up the heating system increases significantly.

Often the appearance of contamination is accompanied by the replacement or addition of radiators.

Methods for cleaning your heating system yourself

The choice of one or another method of cleaning the heating system from blockages depends on the type of contamination, the coolant used and the material from which the pipes and radiators are made. There are two ways to perform washing.

- Hot water. This method is most often used when replacing old antifreeze. To do this, the liquid is drained through a fitting at the bottom of the heating system, after which a pump is connected to it and with its help water is pumped in under a pressure of 1–1.5 bar. Then the boiler is turned on to the maximum heating temperature, and with the help of a pump the working medium is forced to circulate through the circuit. After some time, the water is drained and replaced with new antifreeze. The advantage of this method is the careful handling of the material of the pipeline and radiators. However, water does not dissolve stagnant mineral clogs.

- Chemical reagents. Typically, their role is played by aqueous 3–10% solutions of acids (hydrochloric or sulfuric) or alkalis, as well as special mixtures sold in plumbing stores. Using a pump, they are pumped into the heating system and circulate in it for several hours, dissolving solid deposits. Acidic reagents are used more often, as they have less impact on the materials of the heating circuit, and also better dissolve scale and rust, which are the main cause of blockages. However, even in this case, it is necessary to take into account what the elements of the heating system are made of and be able to select the appropriate concentration of the active substance.

How to temporarily remove a heating radiator

This article is about how to temporarily remove a heating radiator. to replace it or paint the wall behind it. Removing the radiator is not at all difficult, as it might seem at first glance; we will talk about this in the article. First of all, you must understand the consequences of a failed attempt to remove the radiator: if you do not know how to remove the radiator correctly, a leak may subsequently appear and you will ruin the flooring

However, if you pay attention to our tips, you will eliminate all problems at once during the radiator removal process

First of all, we must show you the main elements of the radiator: at the top right - the control valve, at the bottom left - the shut-off valve (for regulating the water supply), at the top left - the Mayevsky valve for bleeding air from the heating radiator.

Using a control valve, you can adjust the flow of incoming water into the radiator by opening or closing the valve, you will regulate its heating temperature by increasing and decreasing it accordingly. Using the shut-off valve, you can adjust the intensity at which the water will flow out. Most often, such a valve is used to balance all radiators and is installed on each one.

First of all, close the valves. The adjusting one is closed by hand, and the locking one is closed using a hex key.

TIP: When you close the shut-off valve, remember how many turns you made so that you can then open it the same amount.

Now you need to disconnect the radiator from the valves. To do this you will need a wrench or a gas wrench. The faucet structure consists of an American type (removable coupling). Unscrew the American nut to separate the radiator from the valve.

TIP: To avoid damaging the flooring, place unnecessary rags under the radiator.

Unscrew the shut-off valve...

We unscrew the control valve in the same way... For reliability, use a second wrench to hold the American fitting while unscrewing the nut.

The last step is to remove the radiator from the brackets. The best advice we can give you is that you remove the radiator with someone, as a radiator with water is very heavy. This operation requires at least two people.

ADVICE. If you will be painting the wall behind the radiator, seal the valves in bags or paper.

During the process of painting or gluing the wall, place the radiator so that it does not get scratched. When you are finished painting, hang the new radiator you bought or the old one on the brackets.

With the radiator hanging in place, connect the valve and radiator using an American tie rod. When tightening the shut-off valve, remember the number of turns you had to turn to close it and open it exactly the same amount.

Open the control valve to supply coolant, while you need to open the Mayevsky tap so that air comes out through it and the radiator is filled with water. After water drips from the Mayevsky tap, turn it off, this will mean that the radiator is filled with coolant.

Thanks for reading our article on how to temporarily remove a radiator. and our other articles. Don't forget to Love our projects and share them with your friends using social widgets.Methods for professional heating system cleaning

The following 2 methods of cleaning a heating system require special skills and equipment and are therefore recommended for use only by trained professionals.

- Hydraulic. This method is based on the mechanical impact of water supplied under high pressure or continuous shocks on blockages. Due to the resulting water hammer, the deposits flake off and, together with the liquid, are drained from the heating circuit. For hydraulic cleaning, an electromechanical compressor unit is used, which is connected to the water supply system. The advantage of this washing method is its high efficiency. However, high pressure of the working environment can cause destruction of pressed and soldered joints, and breakdown of boilers (they are designed for a pressure of no more than 3 bar). Therefore, hydraulic cleaning is used only in metal pipelines, and before the procedure, all sensitive equipment is disconnected from the heating system.

- Pneumohydraulic. This cleaning method is a variation of the previous one and differs from it in that a water-gas mixture is used as the working medium. Water comes from a water supply system or container using a pump, and air is pumped by a compressor. For a more effective impact on blockages, the working medium is supplied using a special pneumatic gun in impulses, due to which water hammers occur in the system, affecting the deposits. As in the previous case, the pneumohydraulic method is used to wash mainly the metal elements of the circuit (pipes and radiators). More pressure-sensitive equipment (for example, boilers) is first disconnected from the system.

How to clean the heating system in a private house on your own step by step?

We are going on vacation for a long time, so we decided to wash the heating system and turn it off. How to properly clean the heating system in a private house?

Flushing heating systems in a private home is a delicate matter and not always appreciated. Unfortunately, you did not indicate in the explanation of the questions what components your heating system consists of (material of pipes and heating devices, what circulation of the coolant is used in the system, where and what type of boiler is installed, whether filters are installed or not) - without such data it is difficult to give The answer to your question is exactly. It will be necessary to tell here only basic tips for flushing heating systems.

In itself, flushing heating systems is an essential necessity, but only in centralized heating systems of apartment buildings and high-rise residential buildings and it increases the operating efficiency of heat supply. Why is flushing most effective only in central heating systems? This is a separate conversation - I will only say that the centralized heating system includes tens of kilometers of profile pipes, thousands of heating radiators, dozens of heating units, heating points and control frames, and it also includes dozens of circular pumps and heat exchangers of boilers and much more. In addition, in such very large, branched systems there are often leaks of the coolant, and boiler systems are forced to work on “feeding” the system with fresh tap water rich in oxygen. In such systems, many elements are made of metal (usually steel and cast iron). so - these metals, when exposed to oxygen (and it is always contained in the water mass) and high temperature, oxidize, corrosion occurs on the internal iron surfaces of heating systems (on steel), a black, oily coating (on cast iron) - it is natural that The coolant carries these deposits throughout the system, and they settle in the narrowest places, thus creating traffic jams.

It is to remove such plugs that the central heating system is washed.

In individual residential buildings, the picture is completely different, because there the length of pipelines is small, and the system itself is much lighter and more compact than a central heating system. Therefore, the likelihood of traffic jams forming in such a system is quite low, especially if new materials and equipment are used in the heating system (pipes, heating devices, filters, etc.) And the question - is it really necessary to flush heating systems in such houses - is quite ambiguous . On the Internet there is a lot of advice and advice on flushing from people who are absolutely incompetent in this matter. Whether it is necessary to flush the heating system in a private house is up to the owner of the house to decide. After all, he alone knows what elements his heating system consists of, what is used as a coolant, how and how long the system does not stop working (whether there are any failures to warm up), etc. The decision to wash or not to wash is made on a case-by-case basis.

When there is no need to wash the heating system:

- If the heating system is new, it does not stop working for less than 5 years.

- If there are no complaints about the operation of the system

- If the filter (mesh) on the return line at the end of the heating period is clean

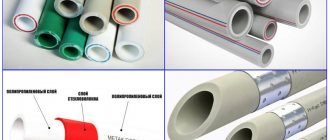

- If the system uses pipes (PP) - polypropylene, or metal - plastic (plaque does not appear in such pipes)

- If the system does not have cast iron or steel radiators.

In any other situation, the system can be washed as a warning, but without fanaticism. Don’t listen to the “smart guys” who recommend cleaning the system with chemicals (especially acid-based ones). Chemical flushing can significantly reduce the service life of heating systems. Wash with ordinary tap water under pressure of 2 - 4 atm (pressure of the water supply network). The duration of the procedure is until the purest water flows from the return.

Flushing heating systems in an individual house in stages (one type):

- We drain the coolant from the system through the return valve.

- We close the supply and return valves at the boiler (if you have them installed) - it is not best to drive all the sludge through the boiler.

3. Turn off the expansion tank.

- We cut a pipe into the supply pipe to connect it to a 15 valve at the end (similar to a relief valve on the return)

- We use a bendable hose to connect the valve on the supply with the valve on the water pipe.

- We put a rubber hose on the discharge pipe for connection on the return line and attach it with a clamp. We take three ends of the hose out into the street or into the sewer.

- Open the valve to 15 on the supply and the drain valve on the return

- We open the valve on the water pipe and wash the system until the purest water flows from the return line.

- We close the relief valve, remove the plug from the expansion tank, and recharge the system to the required level. We turn off the water supply mixer to the system.

In very severe cases, you can add biological reagents (extract) to the heating system and drive the coolant through the system (including through the boiler, of course) within 24 hours using a pump (if you have one), you can also warm up the system - if there is no pump. Then you need to drain the coolant with the reagent and wash the system with drinking water.

If this method does not help, then it is easier to replace “clogged” heating devices and pipes.

Preventing heating system blockages

Instead of frequently cleaning the heating circuit from blockages, it is better to prevent their rapid occurrence. For this it is recommended:

- do not use elements made of polypropylene and metal in the same system. Plastic allows oxygen to pass through, which dissolves in the coolant and causes rust. It is necessary to use pipes made of metal-plastic or polypropylene, reinforced with aluminum or having an oxygen-impermeable EVOH sheath;

- install a filter with ion exchange resins in the heating system. It will prevent the formation of insoluble sediment from tap water in which metal salts are dissolved;

- Do not clean too often. The oxygen content in any coolant decreases over time, which is why its chemical activity, which has a destructive effect on metal elements, is also reduced. It is better to clean the working environment from solid impurities using self-cleaning filters installed in the system.

Regardless of the washing method chosen, this procedure requires certain skills and the availability of suitable equipment. If you do not want to waste time and effort on its implementation, contact our company. We will select the appropriate cleaning method and ensure efficient and long-lasting operation of your home’s heating system.

Useful tips

What kind of water is used to flush heating systems? To clean the heating system, it is necessary to use soft water with a low concentration of salts. It is possible to mix concentrated baking soda with tap water.

After finishing work, it is better to use either distilled or pre-purified water.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Features of the use of mud collectors

All mud filters for heating systems can also be divided into those intended for vertical or horizontal installation. Vertical structures are more often used in large heating systems. It should also be remembered that vertically installed mud traps need to be serviced more often. The choice of size and cleaning parameters is made based on the diameters of the pipelines, pump power and installation locations.

Dirt trap with drain cock.

During installation, there are several rules that must be followed.

- Arrow on the body. As a rule, the filter has an arrow indicating the direction of movement of the coolant.

- The best location is a horizontal section of the pipeline.

- Spatial orientation. The branch with the mesh and nut or drain valve should face down.

- The presence of shut-off valves before and after the mud filter for water, as well as a pressure reducer after it.

- Ease of maintenance.

Strainers DN25, 1”.

Advantages and disadvantages

Debris from the mud trap gets into the boiler elements and interferes with normal operation.

The advantage of filters is to prevent contamination of the main components in the heating equipment. The presence of a mud trap in the system increases the service life of the coolant. In addition, among the advantages of the device are:

- fuel economy;

- reducing the cost of reagents for water purification;

- protection of convective elements of boilers.

The disadvantage of the mechanical principle of water purification is manifested in the rapid clogging of mesh filters with a high level of contamination of the working fluid. To solve the problem, a complex filtration technique is used. It consists of using magnetic mud scrapers to remove scale and rust, as well as a device with a mesh to remove suspended particles.

Principle of operation

The principle of operation of a self-flushing dirt trap is based on slowing down the flow rate of the coolant:

- The coolant, when it is inside the housing of the filter element, begins to move at a lower speed. This happens due to the fact that the diameter of the pipeline expands in this section. Therefore, under the force of gravity, the particles precipitate.

- After this, the liquid flows through the filter located at the outlet pipe, and then goes into the main pipeline.

- Removal of accumulated dirt and particles is carried out through a drain pipe or cap, which is separated by ball valves. After each cleaning, it is important to check for leaks, rust on connections, and so on.

Attention! We recommend installing a hydraulic resistance sensor into your system, in this case you will always know when it is necessary to clean the dirt trap. You just need to install it strictly following the instructions from the manufacturer, in which case it will display reliable data.

How to maintain a dirt filter

Service algorithm:

- If the heating system begins to work incorrectly, the first thing you need to do is stop the circulation pump.

- Next, turn off the taps on both sides of the filter.

- Next, the connection securing the mud catcher is unscrewed.

- The filter glass is washed and cleaned well by any means.

- Next, assembly is performed in reverse order.

Additionally, you can clean the section of the pipe adjacent to the mud trap; this can be done with a long, strong stick or wire with a foam sponge attached.

We hope that you have carefully studied our article and now understand how to install a mud trap on a heating system. We wish you all the best, do not forget to periodically clean the mud pan, and then the heating system will serve you faithfully for several decades!

Classification of mud worms

The principle of operation is to pass the coolant through a special mesh or magnetic filter, sifting out dirt fractions and depositing them at the bottom of the glass. The main condition for proper operation is the installation of the sump in the direction of the coolant flow.

Dirt filter, partially coated with primer.

Classification of mud collectors for heating systems is made according to several criteria. Depending on the degree of cleaning, fine and coarse cleaning devices are distinguished. Mounting options: threaded, flanged and welded. By service method:

- self-flushing - sediment from the sump and from the surface of the mesh is washed away by a stream of water when the tap on the mud pan is opened;

- rinsing - the glass is washed without dismantling the filter, but manually;

- non-flushing - for cleaning it is necessary to dismantle and disassemble the unit.

Wash filter for mechanical water purification.