The heating system of a house or apartment, consisting of pipes and radiators, is subject to a phenomenon called airing. Air enters the heating system, forming a plug, and water cannot move through the pipes. The result is a decrease in room temperature. Knowing how to act in such a situation will help you avoid problems.

Airing of the system - an air lock formed in the pipe

Removing air from systems in an apartment building

In order for all the batteries in a multi-storey building to be hot, the coolant must constantly move within them. In houses with centralized heating, water acts as a carrier of thermal energy.

The heating main consists of two threads - supply and return. In this case, in operating mode, the pressure difference between them is at least 2 kgf/cm2. The heated coolant from the supply enters the heating circuit not from the heating main, but after connecting with water flowing through the return line. The function of obtaining mixed liquid is assigned to a water-jet elevator, which is a tee made of steel or cast iron with a nozzle located inside it.

Thanks to partial recirculation of water, the highest speed of its movement in the circuit and the minimum temperature difference between the first and last radiator in the building heating system along the movement of the coolant are ensured.

The difference in pressure between the supply pipe and the return pipe in the battery is 0.2 kgf/cm2. This indicator corresponds to the pressure of a two-meter water column. The presence of air does not allow water to circulate, so information on how to remove an air lock from a heating system will not be superfluous for many property owners.

The fact is that the presence of a small difference prevents the plug from being pushed down due to a significant difference in the density of the air and the working environment. To remove air from the heating system, the hydraulic pressure expressed in meters must exceed the height of the bottling risers.

Fixing the problem

You can solve the air lock problem yourself. The main thing is to identify the reason for its formation.

- First, it is worth inspecting the pipeline along its entire length for cracks or depressurization (provided that the sewerage system has a water seal). If any are found, it is worth replacing the collector section with a whole one. In this case, the air will freely flow into the drain pipe during a volley discharge of water into the system. That is, the water seal cover will close when the pressure in the pipeline increases and thereby prevent stagnation of water.

- If an air lock is observed in the area of a specific plumbing fixture, then perhaps the slope of the pipes towards the riser was not observed during installation. To do this, you need to reposition the pipeline section to create the required slope or, if possible, raise the plumbing fixture to create the optimal level of slope for the drains.

- If the sewerage system basically does not have a drain pipe, then it will have to be installed with the installation of water seals near each plumbing fixture.

And always remember that if you are not confident in your abilities and think that you are prone to make mistakes when installing sewerage in your home, it is better to use the services of professionals. The craftsmen will create a reliable drainage system with a properly functioning drain pipe,

Most often, clogged sewer systems occur in old houses, and the reasons for this phenomenon can be completely different.

For example, due to the owner’s negligence, a rag or some hard object may get stuck in the system. Over time, the diameter of the pipe narrows as fat deposits form on its walls. Therefore, a minor blockage can cause a big problem.

Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional

Therefore, a minor blockage can cause a big problem. Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional.

How to bleed air in autonomous systems

For autonomous heat supply systems with forced circulation of the working environment, everything is different. Typically, the pressure created by pumping equipment exceeds the height of the heating circuit and it can function even if the pipes are airy.

But as air bubbles move in pipes and batteries, extraneous sounds arise - hydraulic noise. If they are distributed continuously, this will cause a lot of unpleasant moments for residents.

In addition, air contributes to the formation of corrosion processes in steel parts of the heating circuit, such as panel radiators, pipes made of black steel, and cores of bimetallic devices.

When there is no oxygen, it does not come into contact with the coolant and rust does not appear. Now it’s clear why an air lock in the heating system of a private home is such a nuisance.

Why does water from the well come with air when the pump is running?

A water well is a convenient alternative to autonomous water supply in the private sector. Having a number of advantages, the design requires not only proper installation and equipping with a filtration system, but also timely cleaning, as well as preventive maintenance and rinsing. Failure to comply with at least one point may result in disruptions to the operation of the entire station. For example, water from a well often comes with air. The life of the pump, water quality and much more depend on the timely identification of causes and their elimination.

Causes of airiness

Air plugs form in heating systems for a number of reasons:

- As a result of replacing radiators in the apartment. It is most often produced in the summer on the eve of the new heating season. After the pressure testing is completed, the risers are filled with water, and the bleeding of air from the heating system is postponed until the fall.

- After carrying out an inspection of the shut-off valves on the risers, which are needed to drain the circuit.

- As a result of checking the shut-off valves in the elevator unit. The circuit should be reset completely.

- From coolant leaks through battery intersections, threaded connections, fistulas formed in pipes, etc. If the valves in the elevator are in good condition and closed, the pressure in the circuit gradually begins to drop. In this case, you need to slightly open the Mayevsky tap or the flusher located on the top floor. As a result, the vacuum that arises at the top of the circuit sucks in air.

Types of sewer clogs

If the sewer system in a house is operated in violation of all the rules for its use, then over time, blockages and plugs inevitably appear in the collector, which impede or completely stop the flow of wastewater. As a result, either someone from an apartment building or the owners of a private building will suffer from at least an unpleasant odor in the living space. The maximum possible flooding of the kitchen or bathroom with fecal water. This is not very pleasant, so to avoid such situations you need to use the collector correctly, namely:

- It is strictly forbidden to flush used personal hygiene items, such as pads, diapers, tampons, etc., down the toilet. Only flushing toilet paper is allowed.

- It is prohibited to flush bulk construction mixtures such as cement, sand, chalk, clay, etc. down the drain.

- Accidental flushing of rags and other similar items down the drain should be avoided.

- It is advisable to install grease traps in the kitchen, which will prevent the deposition of heavy greasy deposits on the walls of the collector. This, in turn, can create fecal growths-stalactites in the system and impede the flow of gray water.

It is always worth remembering that a traffic jam can form either in a specific place in the sewer system in an apartment or in a private house, or at any point in the central riser. If the last option is checked, then the drains will have nowhere to go but to return back from the blockage under the influence of hydraulic force. As a result, fecal or gray water will try to escape through the unoccupied openings of the bathtub, sink, and other plumbing fixtures.

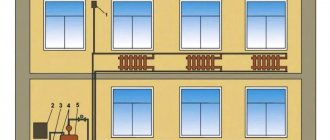

Bottom heating supply in a high-rise building

For modern buildings, the standard solution is a bottom filling scheme. In this case, both pipes - supply and return - are laid in the basement. The risers connected to the bottlings are combined in pairs using a jumper in the attic or upper floor.

Option No. 1 to solve the problem - start the elevator for dumping

Bleeding air from the heating system is carried out by housing and communal services specialists at the stage of starting the circuit, which is partially or completely vented. For this purpose, it is discharged: one valve is opened, and the second is left closed.

From the side of the heating circuit, up to the closed valve, open the vent, which is connected to the sewer. The fact that most of the air has escaped can be seen from the water flow in the discharge - it moves evenly and without bubbles.

Option No. 2 to solve the problem - installing an air vent

Before releasing air from the heating system, an air vent is installed in the upper part of all paired risers in the case of bottom filling. It can be not only a special Mayevsky tap, but also a screw valve, a water folding or ball valve mounted with the spout facing upward.

Venting air from the heating system is performed in a certain sequence:

- Open the tap more than one turn. The result should be a hiss of moving air.

- Place a wide container under the tap.

- They wait for water to flow instead of air.

- Close the tap. After 10 minutes the riser should warm up. If this does not happen, you need to bleed the plugs again.

Before getting rid of air in the heating system, you should remember these important rules:

- In the Mayevsky tap, you cannot unscrew the screw completely, since with a pressure of 5–6 atmospheres and boiling water pouring from the hole, it is impossible to return it to its place. The result of such actions may be flooding of your own apartment and that located below.

- There is no need to unscrew the air vent under pressure, even half a turn, since it is unknown what condition its thread is in. When a drain valve is faulty, before replacing or repairing it, you should shut off the two paired risers and ensure that their valves are holding water.

- If you live on the top floor, before the start of the heating season, you need to make sure that you have a tool that works with the air vent. Models of modern Mayevsky taps can be opened with a screwdriver or by hand, but in older buildings a special key will be required. It is easy to do - you just need to take a rod of the required diameter and make a cut at its end.

Option No. 3 to solve the problem - bypass the heating riser to discharge

With lower bottling, the main problem with air vents is that they are located on the upper floors of apartments. If their owners are constantly away from home, how to remove airiness from the heating system?

You can bypass the paired risers from the basement side, for which:

- They are examined for the presence of valves, after which plugs or vents can be installed. In the second case, there will be no costs, but in the first case, you need to buy a ball valve with a thread of the same size as the plugs.

- Shut off the valves on two risers.

- At one of them, unscrew the plug a few turns and wait for the pressure of the liquid that hits the thread to decrease. This way you can make sure that the valves on the floors are working properly.

- A ball valve is mounted in place of the plug, first winding up the threads.

- The mounted vent is opened completely.

- Now open the valve located on the second riser. When the pressure removes air from the heating system, close the vent and open another riser.

There are also some nuances to this:

- When all the batteries are installed on the supply riser, but there are none on the return riser, the dumper needs to be mounted on the return and then the problem of how to remove the air lock from the heating system will be solved. If radiators are located on paired risers, it is not always possible to remove the air.

- If it is not possible to bypass the risers in the same direction, then the vent is moved to the second riser and the coolant is transferred in the opposite direction.

- If there are screw valves on risers, it is necessary to avoid moving water through them in the direction opposite to the arrow on the body. The desire to slightly open the valve with the valve pressed down may result in its separation from the stem. To fix the problem of how to bleed air from a heating system, it is quite common to reset the building's heating system.

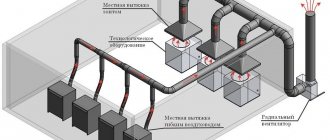

Elimination of cavitation

What can be done to avoid the appearance of air in the well and the entry of water with bubbles:

- Replacing a small-diameter suction pipe with a larger one;

- Moving the pump closer to the storage tank.

Attention! When moving the pump, follow the established standards: the distance from the pump to the tank cannot be less than 5 diameters of the suction pipe!

- Reduce the pressure of the suction element by replacing it with a smooth pipe, and the valve can be replaced with a slide valve, and the check valve can be removed altogether;

- The presence of a large number of turns in the suction pipe is unacceptable; they must be reduced or the bends with a small radius of turns must be replaced with large ones. The easiest way is to orient all the bends in one plane, and sometimes it’s easier to replace rigid pipes with flexible ones.

Top supply in an apartment building - how to release air

Buildings with a top spill have the following characteristics:

- The supply bottling is located on the technical floor, and the return bottling is in the basement;

- each riser is a jumper between them, disconnection is possible both from below and from above;

- the feeding bottling is done with a slight slope;

- at the very top there is an expansion device with a discharge outlet, while the discharge is often discharged through all floors to the elevator unit in the basement or at most close to it.

The function of the air vents is assigned to the vent on the expansion device. Thanks to the discharge to the basement, the start of heat supply in the fall is simplified.

Option No. 4 to solve the problem - sump on the expansion tank

To fix the problem, before pushing through the air lock in the heating system, the top filling must be put into working condition.

To do this you should:

- Slowly fill the system to prevent water hammer. It is necessary to slightly open the house valve on the supply or return, located between the elevator unit and the heating circuit.

- After filling the system, open the second valve completely.

- After 5 - 10 minutes, open the vent on the expansion device and wait until the air is replaced by water.

Video description

For an example of protective equipment for damping water hammer in a water supply system, see the video:

Pressure surges or water hammer are a dangerous phenomenon inherently associated with the operation of plumbing or heating systems. Their number and negative impact can be minimized using preventive measures and technical solutions. In order to comprehensively solve this problem, to prevent as much as possible the risks of danger to people and material damage, it is better to turn to professionals.

Open heating system in a private house

Such a system operates when the pressure and height of the water column formed by the lower and upper points of the heating circuit correspond. In this case, the bottling is arranged at a constant slope, and an open expansion device is located at its highest point.

It combines a number of functions:

- expansion tank, which compensates for the increase in liquid volume when heated;

- a safety valve that serves to relieve excess pressure in the event of water boiling in the heat exchanger of the heating unit;

- an air vent, thanks to which the problem of how to expel air from the heating system is solved - it must be forced into the upper part of the circuit, or rather into the expansion tank, from where it is sent into the atmosphere.

With this scheme, no additional installation of air vents is required. But they can be individually supplied to radiators located above the spill: the Mayevsky valve allows air to be removed from the radiator and forces the working medium to circulate through both collectors.

Technical means of protection

The system must be maximally protected from rash human actions, improper operation and untimely and incomplete maintenance. To achieve this, there are a number of technical solutions to minimize the consequences of fluid pressure surges in water supply and heating networks and prevent their occurrence.

Pipe replacement

To do this, it is necessary to inspect the entire pipeline; old steel pipes should be replaced with modern ones made of polymer materials. They are more reliable, practically resistant to corrosion and last longer. In this case, pipes must be selected taking into account operating conditions (pressure and temperature in the network) with a small margin in parameters. To reduce the flow rate, it is advisable to choose products with the maximum possible diameter for the pressure. Find a middle ground.

Modern reliable pipes and connecting elements made of polymer materialsSource santehnika-nk.ru

Replacing shut-off valves

Replacing ball valves with valve valves can be called a return to the past, but this will avoid sudden pressure changes regardless of how the shut-off valves open and close. It is not necessary to change all locking devices; you can limit yourself to only those that are critical to the system.

Installation of shock-absorbing elements

The use of reinforced plastic or rubber inserts that can stretch or compress during pressure surges will reduce the deforming effects on the remaining parts of the pipeline. The walls of shock absorbers, unlike rigid pipes, do not deform when compressed or expanded and return to their original state, taking the bulk of the impact of the liquid upon themselves. For most systems, a section of 20 to 40 centimeters is sufficient.

Application of compensators

Compensators are cylindrical containers (an inverted glass) inside which there is a spring. One end of it rests against the upper fixed part of the inverted “glass”, and the lower end rests against a movable plastic disk. When the pressure in the system increases, the water presses on the disk, compressing the spring; when it decreases, the elastic force of the spring compensates for the loss of pressure.

Local water hammer compensator (mechanical) for water supply systemsSource gothac.rickyhil.com

Compensating protection against water hammer in the water supply system is also carried out using hydraulic accumulators. This device is a tank of a certain volume divided into two parts (with water and air) by a rubber membrane. In case of excess pressure, it will be released into the tank due to stretching of the rubber membrane and reducing the volume of air inside the tank.

Using pumps with frequency converters

Such pumping equipment, due to automation, allows for smooth starting and stopping of working parts. This makes it possible to avoid a rapid increase in pressure, which causes water hammer. The frequency converter regulates and sets the number of rotations of the pump wheel per unit time by changing the frequency of the alternating current received from the electrical network. The adjustment is carried out automatically depending on the values of the parameters transmitted by the sensors.

Safety valves

The operating principle of these devices is quite simple. When pressure values at the valve installation points reach values above critical parameters, the valves open and liquid is discharged.

Main safety valve for relieving pressure at critical values Source ultra-term.ru

They can be standalone devices whose opening occurs due to the operation of mechanisms or electronic sensors, or be part of a system consisting of many sensors and valves controlled by a computer.

Closed system of a private house - how to remove an airlock

An automatic air vent is placed in the circuit through which the coolant is forced to move, operating at excess pressure. It is an element of the safety group of the heating unit and is mounted at the outlet of the heat exchanger.

Some boiler models have their own safety group installed inside the housing. All batteries located above the bottling points are equipped with Mayevsky taps or air vents. The latter are certainly needed when connecting devices diagonally or sideways. In the case of a lower two-way connection, the operation of an air-filled radiator is possible. The following method is used to bleed air from the heating system: it is forced into the upper collector, and the coolant is released through the lower one. The battery sections are heated in height due to the thermal conductivity of the metal.

Determining the location of the plug and removing it

How can you tell if there is air in the radiator? Usually, the presence of air is indicated by extraneous sounds, such as gurgling or water flowing. To ensure complete circulation of the coolant, it is necessary to remove this air. When the system is completely aired, you must first determine where the plugs are forming by tapping the heating devices with a hammer. Where there is an air lock, the sound will be louder and stronger. Air is collected, as a rule, in radiators installed on the upper floors.

Having realized that there is air in the heating device, you should take a screwdriver or wrench and prepare a container for water. Having opened the thermostat to the maximum level, you need to open the valve of the Mayevsky tap and substitute the container. A slight hiss will indicate that air is escaping. The valve is kept open until water flows and only then closed.

Eliminating an air lock in a heating battery using a Mayevsky tap installed on it: the valve is opened with a special key or manually and kept open until water appears

It happens that after this procedure the battery does not heat up for long or not well enough. Then it needs to be blown out and washed, since the accumulation of debris and rust in it can also cause air to appear.

If, after bleeding the air, the battery still does not heat up well, try draining about 200 g of coolant to make sure that the air lock is completely removed. If this doesn’t help, you need to blow out and flush the radiator to remove any accumulated dirt.

If there is no improvement after this, you need to check the filling level of the heating system. Air locks can also form at pipeline bends.

Therefore, it is important during the installation process to observe the direction and magnitude of the slopes of the distribution pipelines. In places where the slope for any reason differs from the design, additional air vents are installed

In aluminum radiators, air pockets form more intensively due to the poor quality of the material. As a result of the reaction of aluminum with the coolant, gases are formed, so they must be regularly removed from the system. In such situations, it is recommended to replace aluminum radiators with devices made of higher quality materials with anti-corrosion coating and install air vents. In order for the heating of the rooms to be normal, before filling the heating system with water, it is necessary to promptly remove air from it, which impedes the normal movement of the coolant, and then in winter your home will be warm and cozy.