As you know, when building a private house in northern latitudes, the first thing that needs to be done is to take care of the heating system and insulation of the house. But even if you did not skimp on these components and the most reliable materials were used during installation, even in this situation situations may arise when the most reliable heating systems sometimes fail. And if a breakdown of a component occurs during the winter, this is doubly unpleasant.

Heating radiator in a country house.

Every owner of a private home has at least once encountered some kind of malfunction in the heating system. In this article we will look at possible malfunctions and appropriate heating repairs in a private home. There can be a variety of breakdowns, but we will look at the most common ones.

Rules for choosing a material to solve a problem

When the cause of the pipe damage has been established, it is necessary to look for acceptable repair methods. There are several of them. Only most are suitable for low water pressure in the water supply circuit or heating system.

If you don’t have such a device at hand, then any piece of rubber (for example, from a bicycle inner tube) and wire or something similar will do .

But other methods of eliminating leaks when it comes to heating or hot water supply systems are unlikely to work. Thus, often used cold welding and special sealants are not relevant for wet surfaces.

Other instantly hardening composites (epoxy resin, dichloroethane) are also excluded, since they can be used on dry and disconnected water supply routes.

A minor leak in the pipeline can be repaired on your own . But this will only be a temporary measure. At the end of the heating season, it is recommended to carry out major repairs so that the system no longer fails.

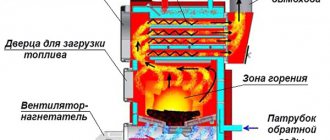

Installation based on a wood stove

If the project has been drawn up, it’s time to stock up on the necessary materials and tools. A previously drawn up project will allow you to calculate the required number of system elements.

All turns, connections, tees, radiator installation locations, etc. should be marked on it. In addition, it is necessary to purchase pipe clamps, as well as brackets on which the radiators will be installed.

The boiler of the steam heating system, based on a wood-burning stove, is installed directly in it. A steam line and a condensate line are connected to the boiler

The length of the pipes is also calculated according to the diagram. To reduce the steam pressure in the system if necessary, you will need a pressure reducing valve. The hydraulic seal is required to allow the system to be completely drained for cleaning, maintenance or repair.

It is recommended to install a shut-off valve in front of each radiator, which will allow it to be turned off for repair, flushing or replacement. Mayevsky taps are also installed on radiators to release air trapped in the system. Although steam is a gaseous substance and not a liquid, the presence of air in the system can negatively affect its efficiency.

To ensure that the condensation process occurs in the radiators, and not in the storage tank or riser, it is recommended to install a tee with a plug at the outlet through which only water will pass. If you plan to install a system with forced circulation, you will need a circulation pump. In addition, you need a container to collect condensed moisture.

Gravity flow systems do not need such devices. But the pipe that carries the water to the heat exchanger must be wide enough to allow the liquid to move quickly for further heating.

The absence of a pressure reducing valve in the steam heating system, the device of which is shown in the diagram, can lead to serious damage due to excess pressure

In addition to the usual installation tools, you will definitely need a welding machine to connect copper pipes. Galvanized steel structures usually have threaded connections that must be carefully sealed. If you plan to install steam heating from a furnace, you will have to start with the manufacture of a heat exchanger.

A steam heating heat exchanger built into a wood stove consists of a system of hollow metal pipes through which water circulates. The element can have any shape corresponding to the size and shape of the oven

It is made from metal pipes 2.5-3 mm thick or even a little thicker. The heat exchanger can be made either in the form of a coil or in any other form. The main thing is that the device fits inside the wood-burning stove, and also that its surface is large enough to heat the water and generate steam.

The welding quality of the heat exchanger must be, without exaggeration, ideal. Even microscopic cavities in the seams are unacceptable, since the device will be exposed to increased pressure from hot steam. Once the heat exchanger is ready for installation, each weld should be checked.

To do this, first coat all seams with white chalk. After this, one of the heat exchanger holes is closed, and kerosene is poured into the second until the device is filled to the top. Now you need to wait a little and then evaluate the condition of the seams. If there are cracks, kerosene will seep through them, and in such places the chalk will darken.

Identified flaws are corrected, and then the test is repeated to ensure the integrity of the device. Now you should wash it, and then start laying the wood stove. The heat exchanger is securely built into the firebox, and pipes are connected to its inlet and outlet, which are then used to connect the heat exchanger to the heating system of the house.

The laying of the furnace is completed in the usual manner for such structures. Then the installation of pipes and radiators of the heating system is carried out in accordance with the project drawn up earlier. First, radiators are installed, using brackets that will dampen the noise from the operation of steam heating.

Mayevsky taps are installed on each radiator so that air can be released. You will need one more shut-off valves than radiators, since you need to install one common shut-off valve at the very beginning of the system. A pressure reducing valve and a reducing-cooling unit are also installed in front of this tap.

At the end, if provided for by the project, a coolant storage tank and a circulation pump are installed. For systems designed with natural rather than forced circulation, a tank and pump are not needed. But the pipe that leads to the heat exchanger needs to be given a slight slope, about 3 mm per meter.

Modern boilers for steam heating in the house are reliable devices that run on various fuels and are equipped with automated control systems

Systems with a steam boiler are installed in approximately the same way: in accordance with the design and adjusted for the features of the equipment. For example, a pressure reducing valve and a cooler will most likely not be needed since the steam pressure and temperature control system is already built into the boiler.

Hot and cold H2O - is there a difference in the way the gap is sealed?

It's all about the difference in coolant temperature. It is this factor that is decisive when choosing a material.

With hot pressure, minor damage can heal without outside intervention . Larger gaps can be easily repaired with regular salt and a bandage.

But when the water cools, the flow will resume. It will not be possible to fix a leak in a cold water pipe with salt and a bandage. It is easier to repair a failed hot water pipe in the summer when it is turned off. Then you don’t have to control the temperature in the room while fixing the leak.

Before the start of the season

Before the start of the season, it is necessary to regulate the system according to a certain algorithm. First, the valves at the heating system inlet are opened. Then water from the heating network is supplied to the pipelines - this happens with all equipment intended for heating.

When there is water inside the pipes, experts examine the lines for heating the lower sections of the risers. If any of the system elements gets very hot, the taps are closed. The main objective of the measures is to create the same temperature conditions for all risers operating within a particular system.

Following the risers, uniform heating must be ensured for heating equipment on each floor of the house. As in the previous case, taps in very hot areas are covered. The required temperature is controlled in the central section of the device section, which is furthest from the riser.

The study of the system is considered successful if the temperature conditions in the premises deviate from the specified value by 1-2 degrees. Otherwise, you need to carry out troubleshooting work.

When starting a system after a long period of inactivity, it may take a couple of days to a week to balance.

How does the pipeline material affect the solution to the problem?

Metal pipes are distinguished by their enviable resistance and durability. Almost their only drawback is their susceptibility to corrosion. This is often what causes a leak in the circuit.

Less commonly, other pipelines also fail: plastic, polypropylene (mainly in places of threaded or fitting connections).

It is enough to compress the plastic pipe in the problem area, and all manipulations can be carried out under water pressure. The main thing is not to overdo it with the screed, otherwise the plastic will crack, and then you will have to replace the entire pipe.

A polypropylene pipeline can be easily repaired by soldering a separate fragment; a metal-plastic pipeline requires inserts . In the latter case, if the damage is not extensive, wrapping with electrical tape or treating with an adhesive (polyurethane, epoxy) will be sufficient.

How to solve a problem?

When water circulates under pressure in the pipes, most major repairs cannot be done. Therefore, you have to act in other available ways in order to at least temporarily stop the leak and wait for emergency services.

Using a self-tapping screw

This option is applicable only for minor holes with a diameter of no more than 3-4 mm .

To plug the hole, you need a galvanized self-tapping screw, which is additionally equipped with a press washer.

It is simply screwed into the hole and secured . As a result, the water is blocked. After such repairs, the pipe can last up to 3 years, but it is better to replace the burst fragment as soon as possible. In addition, a self-tapping screw inside the pipeline leads to clogging of the system.

Cementing

Cast iron or steel pipes can be easily patched using cementation.

The sequence of actions is as follows:

- Using a special hard metal brush, carefully remove the layer of rust in the area of the fistula. The metal that is being painted is also removed, even if this leads to an enlargement of the hole.

- Cut the bandage to a certain length and dip it in the cement solution.

- They wrap it around the crack in several passes to form a kind of cocoon.

- The top is coated with cement to secure the result.

Clamp

A clamp is a fairly simple design consisting of a metal ring, a rubber gasket and a tightening bolt.

This device is sold in stores, but in emergency situations you can quickly make it yourself. You will need a piece of plastic rubber, scissors and a metal clamp corresponding to the diameter of the pipe.

Further actions:

- clean the damaged area from rust;

- put on a clamp, and slip a rubber gasket under it;

- The coupling is pressed tightly.

If the pipe is very rusty, a clamp will be almost the only way to disguise the leak. This is because welding cannot be used here.

Bandage and table salt

Salt is ideal for sealing leaks in hot water pipes under pressure. Step-by-step instruction:

- Distribute digestive salt over the bandage in as large a layer as possible.

- Wrap it around the hole, preferably more tightly.

Sealant

Using sealant (also called “cold welding”) to eliminate leaks in existing pipelines is not productive, since there is no guarantee that the problem will be solved 100%.

This is due to the fact that such compositions are designed to work with dry surfaces , and condensate is present on pressure pipes.

But if there is a small crack, you can try to seal it with a heat-resistant sealant. Outwardly, it is similar to plasticine.

Break off a small piece, carefully crumple it with your fingers and insert it into the hole, followed by smearing it to the sides . Large holes cannot be masked this way; first you will need to insert a wooden chip.

Here you will need fiberglass fabric and BF-2 glue.

Step by step steps:

- the problem area is thoroughly cleaned of rusty particles and degreased with aviation gasoline (acetone is an alternative);

- wait 15 minutes until the surface dries;

- cut a tape from the fiberglass of such a width that it completely covers the area of the leak;

- an adhesive composition is applied along the edges, and epoxy resin is applied to the center;

- apply to the crack, press with your hand and wrap;

- fixed with copper wire.

Wire or harness

A method somewhat reminiscent of the one with a clamp . Only instead of it they take a medical tourniquet and any metal wire. Rubber is tightly wrapped around the damaged pipe fragment and tightened with wire.

Wooden chop

It is necessary to quickly plan a wedge-shaped peg of a suitable diameter from any piece of wood. Then they hammer it into the hole with a hammer.

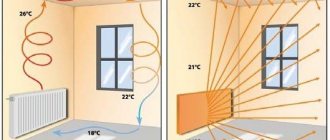

Assessing advantages and disadvantages

What are the benefits of a steam heating system? It is relatively easy to make even on the basis of a conventional wood stove. This is especially true in areas where there is no centralized gas supply, but firewood or other solid fuel is quite accessible.

Steam is significantly ahead of water as a coolant. Its heating rate is three times higher. In addition, a steam heating system is unlikely to fail during winter cold due to lack of heating.

If the firebox burns out, water from the system will collect in the storage tank or heat exchanger, and the pipes and radiators will remain empty. With water heating, freezing of the coolant, which fills the entire circuit, is known to lead to pipe rupture.

Finally, the dimensions of steam heating radiators should be significantly smaller than for water systems, since the amount of thermal energy obtained as a result increases several times. This will slightly reduce the cost of installing a heating system at home.

Decorative grilles for steam heating radiators are not only an element of interior design, but also a means of protection against burns

This concludes the list of advantages of the steam system, and we can move on to its disadvantages, which are quite significant:

- high risk of burns;

- increased noise level during operation;

- difficulties in adjusting the operation of the system;

- the need to purchase expensive pipes, etc.

Safety standards do not recommend steam heating for residential premises, as it poses a high risk to the health and life of people living in the house.

Thus, the operating temperature of the radiators will be very high, and if you touch them you can get a serious burn. Therefore, all radiators will have to be covered with reliable decorative grilles.

Ordinary PVC pipes are not suitable for such a system, since they must withstand high pressure and temperatures of more than 100 degrees. The same requirements apply to other elements of the system. Steam heating pipes must be copper or galvanized steel.

Copper pipes are an ideal, but not at all cheap, communication option for steam heating systems. To connect these pipes you will need a welding machine

In any case, this moment cannot be called budgetary. Security issues must be given the utmost attention. All installation work, for example, welding copper pipes, will require the highest quality performance. If the connection ruptures and a stream of steam escapes through the hole, one of the occupants of the house risks serious burns.

Stainless steel pipes are able to withstand the loads typical of steam heating systems, such as high temperature and increased pressure in the system

Another disadvantage of steam heating is the increased noise level. To fix this problem, you must install the radiators correctly. They are suspended on special anti-noise brackets. It is best to place the boiler or stove in a separate room. In addition, copper pipes can be placed in the thickness of the walls, which will also reduce the noise level.

Finally, it is a little difficult to regulate the heating temperature in rooms with steam heating. You cannot install a thermostat and simply reduce the amount of steam. You will have to reduce the amount of fuel, which is not always easy, or ventilate the premises. Before starting work on installing a steam heating system, all these points should be taken into account.

How to stop a leak in a hidden pipe?

You won’t be particularly happy when a pipe hidden under a building structure starts leaking. Especially if the renovation has only recently been done. Since it is not always possible to quickly reach the source, you need to know how to temporarily stop the flow.

Here are a few techniques that are suitable for a water supply system in a private home:

In just a couple of hours, mustard will seal microcracks from inside the pipeline. When the leak is fixed, the circuit should be flushed.

- The heating system is temporarily filled with industrial sealant. It will settle on the internal surfaces of the pipeline and thereby stop water from seeping through microscopic gaps. After a major overhaul, the coolant is replaced with a new one.

Large holes cannot be sealed this way. Then they turn off the system, drain the water from the riser and begin straightening. Namely, it will be necessary to dismantle the structure and replace problematic spans. If you live in an apartment building, neighbors are warned about the upcoming event.

Design of a steam heating system

Even for a small room, it is best to draw up a project. A system made at random will most likely soon require rework, and a diagram drawn up on paper will allow you to immediately identify weak points and correct them.

For example, in order to create a system with natural coolant circulation, the heat exchanger, and accordingly the heating device, should be located at the lowest point of the house.

The steam and condensate pipelines of heating systems with a natural type of coolant movement are arranged with a slope in the direction of its movement (+)

This means that the stove or boiler must be located below all radiators, as well as pipes that are not vertical, but horizontal or at an angle to the vertical.

If it is not possible to place the heating device in this way (the house does not have a basement, the basement is used for other purposes, etc.), preference should be given to heating with forced circulation.

The diagram shows a heating system with forced circulation. To install it you will need a circulation pump and a storage tank.

Therefore, it is necessary to include a pump in the steam heating circuit that will pump water into the heat exchanger. An important point in designing a heating system is the order in which the radiators are connected. A sequential connection or the so-called one-pipe system involves connecting all radiators in order.

As a result, the coolant will sequentially move through the system, gradually cooling down. This is an economical connection option, which is easier to install and will be cheaper.

But the uniformity of heating with this method will suffer, since the first radiator will be the hottest, and the last coolant will enter in a half-cooled state.

Single-pipe connection of radiators, as can be seen from this diagram, involves sequential installation. The coolant reaches the last radiator already cooled down

A single-pipe solution may only be acceptable when connecting steam heating in a country house or in a small house with an area of less than 80 square meters. m. And for a spacious cottage or two-story building, a two-pipe system in which radiators are connected in parallel is more suitable.

The single-pipe design ensures simultaneous rather than sequential flow of coolant into each radiator, and the rooms are heated more evenly. But with a two-pipe circuit, two pipes will have to be connected to each radiator: direct and return.

Such a system is more difficult to implement, and it will cost a little more than when installing a single-pipe system. However, the vast majority of water heating systems are made according to a two-pipe scheme, despite the difficulties, and function quite successfully.

This diagram shows a two-pipe installation system for steam heating radiators. Each radiator is connected to a common riser and has a return pipe, which ensures uniform distribution of coolant

If you plan to use a wood stove as a heat source, you should immediately calculate and design a special heat exchanger. It looks like a coil welded from metal pipes. This element is built directly into the furnace structure, and is not installed separately.

Therefore, the design of a new furnace should also be considered at the design stage. You can also use an existing stove, but it will have to be partially disassembled in order to install the heat exchanger inside.

To obtain 9 kW of heat, a heat exchanger with a surface area of about one square meter is required. The larger the heated area, the larger the size of the heat exchanger should be.

If you plan to heat the room using a boiler, then everything is a little simpler: you need to buy and install it. Usually, for steam heating in a house, it is recommended to take a water-tube boiler model, as it is the most efficient.

Although fire-tube, smoke-combustion or combined smoke-fire-tube models can also be a completely acceptable option.

Sometimes, to organize steam heating, they use a homemade boiler in which waste engine oil is burned. But this option is considered suitable for use in utility rooms, for example, in a garage. For a residential building, this option is not very good.

Preventing the problem from recurring

It is easier to prevent problems in the heating circuit than to suddenly look for ways to eliminate them. So before the start of the heating season, communications are checked by testing, especially focusing on dangerous areas.

These include:

- level spans;

- threaded connections and welds;

- zone of joining sections at radiators;

- places of implantation of heating equipment;

- near fittings;

- hard-to-reach areas.

First, everything is checked by eye, then with the circuit running.

What games can you play together in the hospital?

- Rock, Paper, Scissors - Players must say the name of the game and count to three. The players' hands are clenched into fists. On the count of three, you need to draw one of the figures in the name. The stone beats the scissors, the scissors cut the paper, the paper wraps around the stone. Whoever has the stronger symbol wins.

- Lotto – you need cards and barrels with numbers. It is necessary to take the barrels out of the bag one by one and check whether the dropped number is on the card by marking it (covering it with a chip). Whoever closes the horizontal line (or all the numbers on the card) faster wins.

- Yes and no - the player makes a wish for an object, character or movie. The opponent’s task is to guess what the opponent has in mind by asking a minimum of questions that can be answered affirmatively or negatively.