Noisy neighbors are a problem for many Russian families. Therefore, the demand for materials for sound insulation (SI) of apartments remains consistently high. Where there is demand, there are many different offers. True, not all of them really solve noise problems. We have selected 6 reliable soundproofing manufacturers and offer you an overview of their products.

The purpose of the article: to provide basic information about the characteristics of sound insulation and introduce the reader to leading companies in the field of development and production of soundproofing materials. Such enterprises have their own research centers, laboratories, scientists, engineers - everything is serious.

Brief information about materials for sound insulation

Hereinafter, by the term “sound insulation” we mean the use of insulating and absorbing materials in combination. The first of them reflect sound, preventing it from penetrating into the structure, the second - prevent reflection, due to which sound waves attenuate faster.

Noise from neighbors in the apartment can be of different nature:

- Air. If you hear the cough of a heavy smoker behind the wall, you almost don’t need to listen to the neighbors’ conversations, and the screams of children are driving you crazy, know that airborne noise is to blame. To minimize it, use structures with an absorbent layer thicker than 50 mm or more.

- Structural. The work of a neighbor hammer drill, the sounds of footsteps and each call of the elevator - all this is caused by the mechanical or vibrational effect of objects on walls or ceilings. Impact noise is often included in a separate group from this category. Thinner materials can be used to control it effectively if the manufacturer provides evidence of effective noise reduction.

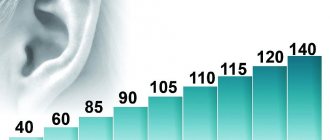

The effectiveness of soundproofing materials in terms of airborne noise is determined by the sound insulation index (Rw) in dB. This is a certain average value in the frequency range characteristic of sounds in residential premises. To create acoustic comfort, it should be 50-60 dB in the case of walls, i.e. the entire wall should reduce the acoustic load by this amount. If you are interested in more accurate values, be sure to take a look at SP 51.13330.2011 “Noise Protection”.

Some manufacturers in their specifications provide the value of the additional noise index (Δ Rw), which shows by what amount the sound will decrease when passing through the material. However, most indicate the characteristics of the material in the composition of the gypsum board or gypsum board pie.

The quality of sound absorption (αw) is assessed on a scale from 0 to 1, where 0 is the complete reflection of sound from the material, 1 is its complete absorption. This concerns airborne noise.

To assess the effectiveness of reducing impact impacts on walls and floors, use the value of the index for reducing the reduced impact noise level (Lnw). It shows the noise level under the ceiling, what we hear when neighbors above drop dumbbells. Here, most manufacturers already indicate exactly the difference (ΔLnw) that can be achieved when using GI coating.

To summarize the above: the higher Rw and lower Lnw, the better for creating acoustic comfort in a particular room.

Noise Elimination Solutions

| Type of noise/Approach to solving the problem. | Material | Peculiarities |

| Air. You can increase the massiveness of the walls and ceilings, but even with a 2-fold increase in mass, Rw increases by only a few dB, and the usable area of the apartment melts before our eyes. It is better to create a multi-layer structure in which dense (concrete or brick wall, plasterboard finishing) and fibrous materials will alternate. They dampen sound waves from the middle and high frequency range well, the absorption of low frequency waves is no more than 0.4. | Stone wool in the form of slabs |

|

| Glass wool in the form of slabs and rolls |

| |

| Multi-layer panel of alternating layers of gypsum fiber with glass wool or mineral wool with a finishing layer of plasterboard |

| |

| Shock. For insulation, use elastic materials with a thickness of 3 mm or more. The energy of the sound wave will be spent on elastic deformations of the insulating layer. The best effect is achieved when laying the GR under the screed, resulting in a “floating floor”. | Polyethylene foam |

|

| Sheet of pressed cork chips |

| |

| Extruded polystyrene foam |

| |

| Dense mineral wool slabs |

| |

| Composite materials |

|

Advantages and disadvantages

For ease of use, mineral wool manufacturer Knauf Acoustic produces products in rolls and sheets. The material can withstand heavy loads when laid on floor coverings and does not require special fixation when installed in frames. Due to their flexibility, the panels are used for insulation of communications and pipes.

Main advantages of the product:

- excellent sound insulation;

- low thermal conductivity;

- no pungent odor;

- easy cutting;

- environmental Safety;

- durability;

- ease of installation;

- high resistance to ignition;

- no shrinkage over a long period of time.

There is only one disadvantage of Knauf Acoustic insulation - high cost. One package of material, which contains only 16 slabs, costs about 1,500 rubles.

About frame and frameless systems

For walls, suspended, suspended or ceilings that will subsequently be covered with plasterboard, profile frames are used when attaching sound and thermal insulation. Most manufacturers of mineral wool protective equipment are guided by this installation technology. In addition to sound insulation, you will need to purchase gypsum plasterboard, a metal profile, vibration and sound insulation tape for laying between the frame and the base to which it will be attached, and a special sealant for sealing joints to avoid the creation of acoustic bridges. For ceilings, vibration suspensions are also needed.

You can go another way.

After all, what is the frame needed for? To create that notorious pie from sound insulation and drywall. Some companies have developed ready-made multilayer panels that only need to be attached to the base. This turns out to be more expensive than a frame version, but faster and more economical in terms of using the usable space of the room. Summary table with manufacturers

| Manufacturer | Materials | ΔRw, dB | ΔLnw, dB | αw | Price*, rub./m² |

| 1. "Acoustic Group" | ZIPS, Shumanet | 6-18 | 24-38 | 0,85-0,95 | 870/215 |

| 2.Knauf | AcoustiKnauf, Knauf Insulation Acoustic Partition | 51-52 dB – as part of a design with gypsum plasterboard or gypsum fiber board | — | 0,8 | 59-69 |

| 3. "TechnoNIKOL" | Technoflor, Technoacoustic, Technoelast | — | 23-39 | 0,4-0,8 | 116/190 |

| 4.Rockwool | Acoustic Ultrathin, Acoustic Butts, Floor Butts | — | 38 | 0,6-0,96 | 124/156 |

| 5.Isover | Quiet House, Sound Protection, Acoustic, Master of Acoustics | 53-54 dB – as part of a design with gypsum plasterboard or gypsum fiber board | — | 0,9-0,95 | 67-116 |

| 6.URSA | GEO Noise protection, TERRA 34 PN Noise protection, PUREONE 37RN | 44-53 dB – as part of a design with gypsum plasterboard or gypsum fiber board | — | 0,8-0,9 | 72-83 |

* Value in X/Y or X format, where X is the cost of airborne noise insulation, Y is the cost of material for impact noise insulation.

Installation

Frame:

■ On profiles that are attached to load-bearing structures, two strips of non-hardening sealant or sealing tape are applied on the reverse side.

■ If a ceiling deflection of ≥ 10 mm is possible, sliding joints should be used.

■ The frame is secured to the adjacent enclosing structures using soundproofing guide profiles and corresponding fastening elements. Distance between fastening elements max. 1m, minimum 3 attachment points to walls.

■ Fastening elements for massive enclosing structures: dowel with screw / for non-massive elements - special anchor fastenings.

Sheathing:

■ Place the joints of gypsum boards offset.

■ Place the sheathing slabs vertically. The preferred size of the slabs corresponds to the height of the room.

■ If there are requirements for fire protection, the lower junction seam is covered with putty material; if only requirements for sound insulation are put forward, acrylic or silicone sealant for partitions can be used.

■ There are no slab joints on the profiles for door posts.

Acoustic Group

Acoustic Group LLC specializes in the development and production of solutions for sound and vibration insulation. Products under the TM ZIPS, Shumanet, Shumostop, Soundlux, etc. - all of them were developed by this company. Operating since 1999.

The range includes the following materials:

- for frameless finishing of walls and ceilings (ZIPS, AKU-line GKLA, Vibrostek, Vibrosil);

- for frame insulation of walls and ceilings (Shumanet, Vibroflex, Soundline, Vibrostek);

- for frameless sound insulation of thin partitions (Soundline-PGP Super);

- for floors (ZIPS, Akuflex, Shumanet, Acuflor);

- for vibration isolation and vibration absorption (Sylomer, Isotop, Vibroflex);

- finishing acoustic materials for walls and ceilings (Soundboard, Sonaspray);

- noise barriers (perforated, anti-vandal and translucent panels);

- soundproof doors

Main technical characteristics of Acoustic Group*

| Characteristics/Product Line | ZIPS | Schumanet |

| Peculiarities | Sandwich panels measuring 1200×600 mm with a set of fasteners for frameless work and flooring. | Basalt-based slabs or fiber-based fabric coated with bitumen-polymer binder. For frame work and flooring. |

| Modifications and their purpose | III-Ultra, Vector, Module, Cinema - for walls and ceilings. Floor Vector, Floor Module - for floors. | BM, SK, ECO - for walls and ceilings. 100 Hydro, 100 Combi - for floors. |

| Thickness, mm | 52,5-133 | 5 and 50 |

| Surface density, kg/m² | 36-62 | 1,5-3,4 |

| Additional airborne noise insulation index, ΔRw, dB | 6-18 | — |

| Impact noise level reduction index for floor modifications, ΔLnw, dB | 32-38 | 24-26 |

| Average sound absorption coefficient, αw | not specified | 0,85-0,95 |

| Price, rub./m² | 872,6-2080 | 215-275 |

* The table shows the most popular solutions.

Additionally, for installation work, the company offers soundproofing gaskets at a price of 308 rubles/m², vibroacoustic sealant for 290 rubles, all types of profiles for creating frame systems, as well as wall fastenings and a Vibroflex ceiling suspension at a price of 300 rubles. a piece.

Be sure to watch the video presentation of ZIPS-III-Ultra to ensure maximum additional insulation with minimal thickness:

Knauf

Knauf products are widely used for insulation, sound insulation of all types of foundations, as well as leveling walls and ceilings. For insulation of premises, the manufacturer offers 2 lines of materials:

- AcoustiKnauf. Mineral wool slabs with increased length and reduced fiber thickness.

- Knauf Insulation Acoustic Partition. Mineral wool insulation in the form of mats or slabs of increased elasticity. Also has ZI properties.

Both solutions can be used for floors, ceilings, walls and partitions. For all bases except the floor, the work requires preliminary installation of a frame.

The company also has perforated sound-absorbing panels made of plasterboard with a thickness of 6, 5, 9.5 or 12.5 mm. They are used for finishing suspended ceilings and walls as a finishing layer.

Mostly suitable for administrative buildings.

The average sound absorption coefficient is within 0.55. Main technical characteristics of Knauf

| Characteristics/Product Line | AcoustiKnauf | Knauf Insulation Acoustic Partition |

| Peculiarities | Mineral wool slabs 1230×610 mm without phenol-formaldehyde resins, odorless, non-flammable. Hard, elastic and shape-recoverable material. It does not slip in the frame and is easy to install. | 1250x610 fiberglass mats or slabs. The material does not contain harmful impurities, is non-flammable and retains its properties for a long time. |

| Thickness, mm | 50 | 50 |

| Surface density, kg/m² | 0,75 | 0,8 |

| Airborne noise insulation index, Rw, dB | cake: 2 sheets of gypsum board 12.5 mm + 50 mm AcoustiKnauf + 2 sheets of gypsum board 12.5 mm = 51 dB 1 sheet of gypsum board 12.5 mm + 50 mm AcoustiKnauf + 1 sheet of gypsum board 12.5 mm = 52 dB | |

| Average sound absorption coefficient, αw | — | 0,8 |

| Price, rub./m² | 69 | 59 |

When installing sound insulation, in addition to profiles to create a frame, you will need vibration suspensions at a price of 120 rubles per piece, and a Dichtungsband sealing tape 50 mm wide for 190 rubles. (30 m). More accessible analogues with suitable properties can be used.

We recommend watching a video about using AcoustiKnauf to reduce noise from a neighbor on the floor:

Advantages of Knauf Acoustic plates

The main advantage of the material is its ability to absorb various types of sounds and noise. The soft base captures and absorbs sounds as effectively as possible. Thin fibers provide good air and steam permeability, which makes it possible to use insulation in rooms with high humidity. The flexible structure helps insulate and isolate sewer sounds. The material can be tightly wrapped around the pipe, thereby reducing the noise of the sewer drain. You can use cotton wool both for apartments and private houses. Quite often, Knauf ceiling soundproofing is used as insulation for roofs, attics and attics.

@Knauf

Speaking about the advantages, one cannot fail to note the environmental friendliness of the material. The product is made from natural raw materials, so it does not contain any harmful elements or resins. Knauf soundproofing walls are odorless, so they are often used in soundproofing residential buildings and public spaces.

The material is easy and convenient to work with. Considering the light weight of the material, it does not require special equipment for loading and transportation. One package contains 16 slabs measuring 1250*610*50 mm. This number of slabs is enough to cover an area of twelve square meters. To work with the slabs, you do not need special equipment or tools; the installation technology is similar to those used when installing basalt or mineral wool.

@Knauf

Knauf ceiling soundproofing is carried out using a structure made of aluminum profiles or wooden beams. Due to the parameters of the slabs, the frame base is built according to generally accepted dimensions with a step width of 60 centimeters. The slabs have the same width, which makes it possible to use sound insulation with virtually no waste.

TechnoNIKOL

The Technonikol Corporation was founded in 1992 and specializes in the production of roofing materials, hydro- and thermal insulation. Sound insulation is represented by slabs of mineral wool based on basalt rocks, as well as rolled material based on bitumen-polymer.

- to soundproof the floor under the screed, use the Technoflor and Technoelast ;

- for work with walls, partitions and suspended ceilings, choose Technoacoustic

A special feature of floor coverings is the combination of sound and waterproofing properties.

This is very convenient if work is carried out in wet areas or you need to fill the screed. Main technical characteristics of TechnoNIKOL

| Characteristics/Product Line | Technoflor | Technoacoustic | Technoelast |

| Peculiarities | Dense slabs 1200×600 mm made of stone wool, covered on one side with fiberglass. For sound and heat insulation of floors. Non-flammable. | Slabs 1200×600 mm made of basalt fiber for installation in a frame system. They provide absorption of extraneous noise and also act as thermal insulation. Non-flammable. | Bitumen-polymer material in a 10×1 m roll with an aluminized film on the top side. For floor work. Suitable for waterproofing premises. |

| Modifications and their purpose | Standard – for floating floors, laying the screed directly on the material. Prof – for any floors with increased loads. | Packages with different numbers of slabs. | Acoustic C - without a base with a self-adhesive overlap on the sides. The soundproofing fabric is glued with a bitumen binder with a metallized film. Acoustic Super A350 - with a fiberglass base and double-sided coating with a bitumen-polymer binder. On one side there is a thermally bonded sheet, on the other there is an aluminized film. Provides absolute waterproofing. |

| Thickness, mm | 40 and 50* | 50 | 2.5 and 4.8** |

| Surface density, kg/m² | 4.4 and 8.6 | 2,1 | 0.7 and 2.2 |

| Impact noise level reduction index for floor modifications, ΔLnw, dB | 37-39 | — | 23 and 26 |

| Average sound absorption coefficient, αw | — | for low and high frequencies: 0.4-0.8 for mid frequencies: 0.8 | — |

| Price, rub./m² | 190 and 405 | 116 | 241 and 231 |

* The first value is for Standard, the second is for Prof. ** The first value is for Acoustic S, the second is for Acoustic Super A350.

As additional materials, you may need Nicoband Inside sealant tape 10 m long and 0.1 m wide at a price of RUB 1,923. per piece, you will have to look for special sealant produced by other companies.

Be sure to watch a short video about using Technoacoustics to reduce noise transmission through walls:

Areas of application of Knauf insulation

When is it logical to use knauf insulation in the construction of frame houses? Primarily for high-quality thermal insulation and reliable sound insulation. Let's consider the areas of application of KNAUF insulation.

- Thermal insulation of walls, both external and internal.

- Thermal insulation of foundations.

- Heat and sound insulation of floors.

- Enhanced sound insulation of buildings located near highways and railway lines.

- Thermal insulation of the roof.

- Thermal insulation of individual spaces, such as balconies, loggias, basements, attics.

- Insulation of non-residential buildings, including unheated premises for keeping animals.

Teploknauf for the roof of a frame house.

That is, we have reliable insulation with increased sound insulation properties. This feature allows the use of KNAUF insulation in suburban construction of frame houses, insulation of constructed houses, organization of sound insulation between floors and parts of the house.

Rockwool

Rockwool is a large manufacturer of heat and sound insulating materials based on stone wool. The company offers 3 materials for sound insulation:

- for walls and suspended ceilings use Acoustic Ultrathin or Acoustic Butts ;

- for floating floors use Floor Butts

The original development is the modification of Rockwool Acoustic Ultrathin.

The thickness of the material is only 27 mm and, according to the manufacturer, its noise insulation properties correspond to 50 mm slabs from other companies. This allows you to significantly save the usable space of the room without discounts on the quality of the information. Main technical characteristics of Rockwool

| Characteristics/Product Line | Acoustic Ultrathin | Acoustic Butts | Floor Butts |

| Peculiarities | Non-combustible material for walls and ceilings in the form of mineral slabs 1000×600 mm. Used in confined areas, it provides noise absorption of medium and high frequencies. | Non-combustible slabs 1000×600 mm in size made of basalt fiber for walls, suspended ceilings, floor joists. Particularly effective for absorbing sounds in the mid and high frequency range. | Dense stone wool slabs 1000x600 mm to improve the acoustic properties of floating floors. Suitable for dry and wet screeds. Significantly reduces the amount of impact noise. |

| Thickness, mm | 27 | 50 | 25 |

| Surface density, kg/m² | 1,62 | 2,1 | 3,1 |

| Impact noise level reduction index for floor modifications, ΔLnw, dB | — | — | 38 |

| Average sound absorption coefficient, αw | 0,6-0,75 | 0,87-0,96 | — |

| Price, rub./m² | 132 | 124 | 156 |

When constructing the frame and sealing the seams, you will need a sealing tape based on foamed polyethylene, one side of which is self-adhesive. This is another 260 rubles. per roll 20 m long and 50 mm wide.

Watch a short video about how easy it is to achieve acoustic comfort in a single room using Rockwool Acoustic Butts.

Soundproof ceilings. Design

KNAUF soundproof suspended / suspended ceilings are fixed to the ceiling using direct hangers with an elastic soundproofing element Vibrofix. KNAUF soundproof suspended ceilings are fixed to the ceiling using adjustable hangers (a spoke with an eye and an anchor) with an elastic soundproofing element.

Knauf slabs are fixed to a suspended metal structure made of the main and load-bearing profiles (D112) or a suspended metal structure made of the main and load-bearing profiles at one level (D113). Expansion joints of the building should be taken into account in the design of the ceiling frame.

In large area ceilings, expansion joints should be installed at a maximum interval of 15 m.

Isover

TM Isover belongs to the Saint-Gobain Group of Companies, specializing in the production of building materials. The brand's profile is insulating materials. The material we are interested in is represented by slabs and mats made of stone wool and fiberglass.

It should be taken into account that the company’s assortment does not include materials against impact noise, as well as related materials and structures for carrying out work.

Main technical characteristics of Isover

| Characteristics/Product Line | Quiet house | SoundProtection | Acousticist and Master of Acoustics |

| Peculiarities | Plates 610×1170 mm made of fiberglass without volatile inclusions. Non-flammable and environmentally friendly. For joist floors, walls and suspended ceilings. | An analogue of the material Quiet House, but in the form of mats of varying thicknesses. | Non-combustible slabs 600×1000 mm made of basalt fiber for installation in frame structures of walls and ceilings, floors on joists. |

| Thickness, mm | 50 | 50, 75 or 100 | 50 |

| Surface density, kg/m² | 0,7 | 0,8 | 2,1 |

| Airborne noise insulation index, Rw, dB | 54 dB for a pie made of two sheets of plasterboard on both sides and in the middle - 50 mm SI. | 51 dB for a pie made of 50 mm ZI and two sheets of plasterboard on each side. | 54 dB for a pie made of two sheets of plasterboard on both sides and in the middle - 50 mm SI. |

| Average sound absorption coefficient, αw | 0,9 | 0,9 | 0,95 |

| Price, rub./m² | 67 | 69 | 116 |

Watch the promotional video that clearly demonstrates the benefits of using Isover materials:

ALBUM CONTENTS

W112 – KNAUF partition on a metal frame

W115 – KNAUF partition on a metal frame

W623 – KNAUF cladding on a metal frame

W626 – KNAUF cladding on a metal frame

D112 – KNAUF suspended ceiling on a metal frame

D113 – KNAUF suspended ceiling on a metal frame

URSA

URSA is another company that those involved in construction or renovation have heard of at least once. This brand produces thermal insulation made from mineral wool and extruded polystyrene foam, as well as soundproofing materials. The company offers 5 product lines, 3 of which include sound insulation:

- Geo – soft and lightweight fiberglass material for framing work;

- Terra – semi-rigid fiberglass mats with enhanced moisture resistance;

- Pureone - fiberglass mats with the addition of acrylic as a binder to achieve exceptional environmental friendliness of the product

According to the tests carried out by the Research Institute of Construction Physics of the Russian Academy of Architecture and Construction Sciences, all 3-material materials have a sound absorption index: not lower than 0.8 for mats, not lower than 0.9 for slabs.

Main technical characteristics of URSA

| Characteristics/Product Line | GEO Noise protection | TERRA 34 PN Noise protection | PUREONE 37RN |

| Peculiarities | Non-flammable fiberglass mat 610 mm wide and 5 or 7 m long. Designed for plasterboard partitions. | Dense elastic fiberglass boards 610x1000 mm for laying in the frame and between joists. Non-flammable, retain elasticity, suitable for uneven substrates. | Roll material 1200 mm wide and 6250 or 10000 mm long. For insulating the walls of children's rooms, gardens, medical institutions. |

| Thickness, mm | 50 or 75 | 50 | 50 and 100 |

| Surface density, kg/m² | 0,82 | 1,15 | 0,55 |

| Airborne noise insulation index, Rw, dB | 44 dB for 50 mm sheathed on both sides, one sheet of plasterboard | 45 dB for a cake made of 50 mm ZI, sheathed on both sides with a gypsum board sheet. | 53 dB for a cake made of 75 mm ZI, covered on both sides with 2 sheets of gypsum board |

| Average sound absorption coefficient, αw | 0,8 | 0,9 | 0,9 |

| Price, rub./m² | 72 | 78 | 83 |

Watch a short video about the use of URSA materials to create acoustic comfort in a single room:

Installation

Frame:

Attaching to load-bearing floor

■ made of wood: self-tapping screws

■ from reinforced concrete: KNAUF dowels BZN 6-5

■ from other building materials: anchor fastening elements standardized or approved on the basis of a special permit for a given building material.

Sheathing:

■ GKP slabs are mounted perpendicular to the load-bearing profiles (D112).

■ Shift the joints of the longitudinal edge of the GCP by at least 400 mm and place them on the profiles.

■ Start fastening the slabs in the center of the slab or to the corner of the slab to avoid deformation during compression. When attaching the sheathing, press the boards firmly against the frame and secure with TN self-tapping screws at a distance of about 170 mm.

■ Connections to other building parts are made using separating tapes and silicone (acrylic) sealant.

Other manufacturers

You can also find Tecsound and Soundguard products. These manufacturers offer original developments, for example, membranes, the effectiveness of which is comparable to using a regular gypsum board sheet. Only in the latter case will the thickness of the partition increase by 5-7 mm, but this will reduce costs several times.

In order not to be unfounded, as an example we give a test of the Texound material:

And here is a small test comparison of gypsum board and Soundguard. Pay attention to the different box designs. Everything is done in order to demonstrate the advantage of ZI, which really does not exist:

These manufacturers also have mineral wool-based materials that are really effective. However, unlike Russian analogues, their cost is 3-5 times higher.