Russian and foreign manufacturers produce metal tiles with a service life of 20 to 50 years, which is confirmed by official guarantees. The actual period of operation depends on the technical characteristics and quality of installation work. Climatic conditions in the region also influence - temperature, wind and snow loads, amount of precipitation, as well as other atmospheric phenomena.

Sheet width and length: important terms

When calculating the required amount of metal tiles for a roof, the buyer will definitely encounter a number of new concepts. It is these values that will determine how many sheets are needed, what length and width they should be:

Full length of metal tile sheet. Represents the distance between the horizontal edges of the sheet. The value ranges from half a meter to 6 m. Many developers mistakenly believe that the longer, the more economical and easier installation will be. But in practice, such savings will lead to the need to use special equipment to lift sheets onto the roof, or it will be necessary to hire several teams for work at once. With very small sheets, the installation process will be even more difficult and lengthy. The optimal choice is a sheet length of 4 m.- Full width. Distance between vertical edges. Manufacturers produce standard sheets of metal tiles with a width of 1160 mm and 1190 mm.

- The width is useful. That part of the sheet that covers the roof without the required overlap distance. In the case of metal tiles, the sheets are laid overlapping both in width and length, which reduces the working length and width.

- The amount of overlap in width. This is the distance that will cover the sheet located on the side of the first sheet. The overlap size is 60-80 mm.

- The amount of overlap along the length of the metal tile sheet. The size is slightly larger than in the case of width and ranges from 110 to 140 mm.

Important: overlaps along the length or width protect the roof from leaks, so these two dimensions must be strictly observed during installation work.

- The thickness of the sheet is calculated depending on the type of rafter system and the entire structure. Thick sheets are easier to work with, they last longer, but they place a greater load on load-bearing walls. Thin sheets can become deformed if installed incorrectly, but such a roof is much lighter.

- Wave height and step between waves. The pitch in the case of metal tiles is standard - 185 mm. Wave height from 50 to 70 mm. The higher the height, the better, but the material itself is also more expensive. Material with a large height has high rigidity, and therefore is more durable.

What are the sizes of metal tiles? Sheet material from different companies may differ in many respects. A table with examples is presented below.

| Manufacturer | Total length, mm | Length overlap, mm | Useful length, mm | Full width, mm | Overlap width, mm | Usable width, mm |

| Metalprofile | 3650; 2250; 1200; 500 | 150 | 3500; 2100; 1050; 350 | 1190 | 90 | 1100 |

| Grand Line | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Stynergy | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Finish Profiles | 3600; 2200; 1150; 450 | 100 | 3500; 2100; 1050; 350 | 1185 | 85 | 1100 |

| Poimukate | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Interprofile | 3620; 2220; 1170; 470 | 120 | 3500; 2100; 1050; 350 | 1160 | 60 | 1110 |

| Mera System Anna | 3620; 2220; 1170; 470 | 120 | 3500; 2100; 1050; 350 | 1140 | 90 | 1050 |

| Mera System Eva | 3620; 2220; 1170; 490 | 120 | 3500; 2100; 1050; 300 | 1160 | 80 | 1080 |

| Pelti and Rauta | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Weckman | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1190 | 90 | 1100 |

| Ruukki® Adamante | 3650; 2250; 850 | 150 | 3500; 2100; 700 | 1153 | 28 | 1125 |

| Ruukki® Finnera | 705 | 45 | 660 | 1190 | 5 | 1140 |

What parameters determine the service life of metal tiles?

The material is a multilayer structure based on rolled steel with protective layers that prevent the formation of rust. The polymer coating also performs a decorative function and is painted in different colors. There are several technical parameters on which the actual service life of metal tiles depends.

- The thickness of the rolled steel determines the ability of the profile to withstand mechanical loads. As the parameter increases, the resistance of the sheets to deformation increases. The minimum permissible thickness is 0.5 mm. Smaller values of 0.4 and 0.45 mm lead to changes in geometry during installation and operation, which compromises the integrity of the decorative and protective coating.

- The thickness of the zinc affects the corrosion resistance of the steel base. The protective coating is applied on both sides. The minimum layer thickness according to the Russian standard must be at least 140 g/sq.m. m. The higher the value, the lower the risk of rust.

- The type of polymer coating determines the resistance of metal tiles to atmospheric influences. Polyester has the shortest service life. The layer thickness is about 25 microns. More durable analogues are pural, plastisol, PVDF. They last longer and have good resistance to mechanical damage and chemical influences.

Attention! Requirements for the quality of metal protective coating are set by GOST R 52246-2016, and for polymer coating - GOST 34180-2017. The regulatory documentation reflects permissible errors and control methods.

Requirements for thickness of steel and coatings

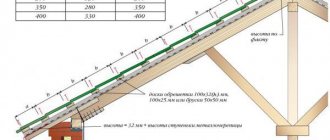

Installation features taking into account the size of metal tiles

The dimensions of the metal tile sheet strictly depend on the roof area. It is from the results obtained that the most optimal length option is based. If the roof has a complex shape, the size of the sheets can be adjusted - the excess is simply cut off. Cutting is carried out exclusively with professional equipment designed for these purposes. Otherwise, corrosion at the cut points cannot be avoided.

Important: metal roof tiles are not symmetrical material, each sheet has its own top and bottom. This feature significantly complicates the installation process, especially for broken roofs, since turning over sheets of metal tiles on the roof will not work.

How long does a metal tile last: manufacturer's warranty

Large manufacturers divide metal tiles into categories based on the warranty period. To manufacture durable products, they use more expensive polymer coatings and introduce their own developments. Warranty obligations determine the minimum period of operation of the material.

| Brand | Peculiarities | Guarantee period |

| Ruukki | Divides metal tiles into three quality categories. An extended warranty is provided when using Pural coating. Polyester and Purex are also used for budget lines. | 30-50 years |

| Grand Line | When providing a guarantee for maintaining technical characteristics, it takes into account the distance to the sea. Standard conditions apply at a distance of more than 3 km. | 20-50 years |

| Weckman | The range of metal tiles is divided into two price segments – Standard and Premium. They produce sheets with a thickness of 0.5 and 0.6 mm, which affects the warranty. | 40-50 years |

| "Metal Profile" | Provides three warranty options. The minimum period is provided for development objects at a distance of less than 1 km from the sea. Normal conditions apply at a distance of more than 3 km from the coastline. | 20-40 years |

| UZKM | The longest warranty period is provided for metal tiles coated with Printech, which gives decorative effects and imitates copper, bronze and other materials. | 10-20 years |

| OZLK | Produces standard and narrow sheets with hidden fastening “Spanish Dune”. The production complex is located in Odintsovo. | Up to 30 years old |

Note! The warranty begins from the moment of purchase of metal tiles from the manufacturer. Within the established period, the consumer can make a claim in case of cracking and peeling of the coating, or the appearance of corrosion.

Additional elements

The parameters of additional elements, as well as the dimensions of metal roofing tiles, can be of different sizes. Their parameters are calculated as follows:

- The elements covering the ridge and located at the joints of the ribs are calculated using the following formula: total length of the ridge with ribs + 8-9% (overlap).

- The lower end, located at the junction of the internal slopes of the edges, is calculated by the formula: length of the edges (converging) + 10% (overlap).

- The cornice strip, which runs along the entire contour of the cornice part, is strictly equal to the length of the cornice contour.

- The end strip is equal to the sum of the lengths of all the ends of the roof.

- The sealing strip installed at the joints of the skates is taken with a 10% margin.

Soft roof

This concept today includes such a popular material as bitumen shingles. Externally, these are flat sheets of small size, approximately 100 by 34 cm. The sheets have figured petal cutouts of various shapes. This coating looks like a more expensive material - tiles.

Unlike other rolled roofing coverings, soft roofing copes “excellently” with high temperatures from 100 to 120 degrees above zero. This negates the fear that after a hot summer the roof will begin to slide. Bituminous shingles are not afraid of cold, and also have low thermal conductivity. It is unpretentious in repair, the damaged area is easily cut out, and a new one is glued in its place.

The service life according to the documents is 15 years. But if the installation of a soft roof was carried out in compliance with all the rules, then it will last much longer, at least 30 years.

Video

| Manufacturer | Total length, mm | Length overlap, mm | Useful length, mm | Full width, mm | Overlap width, mm | Usable width, mm |

| Metalprofile | 3650; 2250; 1200; 500 | 150 | 3500; 2100; 1050; 350 | 1190 | 90 | 1100 |

| Grand Line | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Stynergy | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Finish Profiles | 3600; 2200; 1150; 450 | 100 | 3500; 2100; 1050; 350 | 1185 | 85 | 1100 |

| Poimukate | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Interprofile | 3620; 2220; 1170; 470 | 120 | 3500; 2100; 1050; 350 | 1160 | 60 | 1110 |

| Mera System Anna | 3620; 2220; 1170; 470 | 120 | 3500; 2100; 1050; 350 | 1140 | 90 | 1050 |

| Mera System Eva | 3620; 2220; 1170; 490 | 120 | 3500; 2100; 1050; 300 | 1160 | 80 | 1080 |

| Pelti and Rauta | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1180 | 80 | 1100 |

| Weckman | 3630; 2230; 1180; 480 | 130 | 3500; 2100; 1050; 350 | 1190 | 90 | 1100 |

| Ruukki® Adamante | 3650; 2250; 850 | 150 | 3500; 2100; 700 | 1153 | 28 | 1125 |

| Ruukki® Finnera | 705 | 45 | 660 | 1190 | 5 | 1140 |

overlap

To prevent leaks from rain or snow, sheets of metal tiles are laid on the roof, not edge-to-edge, but overlapping. If you subtract the overlap, you can determine the usable area of the sheet on a metal base. The total overlap in the longitudinal direction is usually from 10 to 15 centimeters; in width it reduces the width of the sheet to 110 centimeters.

The overlap of sheets directly affects the useful (working) area of sheets of roofing material Source spb-artstroy.ru

Comparative characteristics of roofing materials, taking into account their service life

In conclusion, we note that a roof made of any roofing material will require repairs over time, but will require repairs. To increase this period, you need to ensure proper operation of the coating. Each manufacturer makes its own recommendations to owners, the main thing is not to neglect them.

Other useful materials:

— How to calculate the roof area of a house

— Seam roofing

— Major repairs of soft roofing