Navien boilers are modern heating equipment equipped with automation and a protection system. Sensors for detecting problems of varying levels of complexity allow the user to eliminate many minor problems on their own, without resorting to the services of a service center. The accompanying instructions contain codes that characterize a particular problem in the operation of the boiler. Based on this list, the user can easily find information on solving many problems. In this material we will analyze error 03 and tell you how to fix it.

It is important to mention that for high-quality and long-term operation of the equipment, it is necessary to adhere to the universal rules for operating high-tech devices:

- Responsible approach to equipment installation, carried out in strict accordance with the instructions.

- Using high-quality components and materials that will ensure uninterrupted operation of the equipment for a long time.

- It is important to carry out preventive maintenance of equipment (inspection and cleaning of components).

- Do not forget to check the readiness of the equipment for operation (gas supply, sensor condition, water supply).

By observing these conditions, you can avoid rapid wear of equipment and frequent breakdowns.

The Korean company strives to minimize information on user intervention in fixing problems. This is caused by the manufacturer’s concern for the safety of customers who may make mistakes in fixing a technical problem and thereby harm themselves and their loved ones.

It is important to remember that Navien boilers are complex and explosive equipment. Therefore, troubleshooting on your own must be done with the utmost care, following the clear instructions of specialists.

Fault 03

Each malfunction characterizes a specific problem in the operation of the equipment. So error 03 on the Navien boiler model Deluxe Coaxial 16K indicates that the device has problems igniting the gas burner or gas is not supplied to the burner. This article will discuss fault diagnosis and repair.

If the Navien boiler gives error 03, you need to check the presence of gas in the house, and also whether the gas supply tap located near the boiler is open. Only after you are convinced that the cause of the error is a malfunction, should you start diagnosing the equipment.

Self-diagnosis of Navien boilers

The self-diagnosis system guides the user to timely identification of faults in Navien. The electronic unit interrogates all sensors, analyzes the received data, and displays critical failures on the LCD display in the form of digital symbols. Practical guidance on troubleshooting is given in the technical documentation.

With the latest digital modifications, the monitor is located on the control panel. The codes are clearly visible even in the dark, due to the presence of bright multi-colored LED backlighting.

For different Navien boilers, information is presented in both digital and alphanumeric characters. There is absolutely no difference between failure “10” and “E10”.

Diagnosis of the error

Let's diagnose and fix this problem. If this blockage occurs, you must try to restart the boiler. To do this, press the “power on” button on the remote control. Re-ignition is in progress. If error 03 occurs again, so now you need to:

- turn off the boiler;

- turn off its power supply;

- close the gas supply valve.

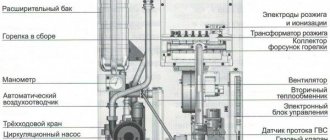

Let's remove the front panel. For these purposes you will need a Phillips screwdriver. It is necessary to unscrew two self-tapping screws located at the bottom of the boiler. And then unclip the two latches on top and remove the lid from the boiler. When a problem arises with igniting a gas burner, first of all, it is necessary to check what gas pressure is present in front of the boiler, and then the operation of the ignition electrodes. Check for spark.

Useful tips

- The instructions for Navien gas boilers note the stability of their operation when the supply voltage is unstable, hence the minimal list of errors.

This is ensured by the presence of a security chip in the microprocessor - one of the features of Navien models. But what to do if there is an emergency on the line? For objects located in rural areas, the question is far from idle. Experts recommend turning on the heating unit via a UPS. The unit contains a stabilization circuit, a group of batteries, and a charger. In the event of a power line break, problems at a substation, or with starting a backup generator, an autonomous source will ensure stable, continuous operation of the Navien boiler for several hours (the period is determined by the total capacity of the battery).

- When contacting a specialized organization, you need to clarify whether it is certified by the Navien boiler manufacturer. Otherwise, you will have to face a number of problems, and eliminating error 03 will be expensive. “Simply Workshop” pays for spare parts like everyone else: in retail outlets, via the Internet. And this is time and extra money. As for detailed instructions for testing and troubleshooting Navien boilers, the manufacturer supplies them only to its service centers. This means that specialists from a third-party organization will not be able to do the work really well.

[/vc_column][/vc_row][/vc_column][/vc_row]

Did you like the article? A repost will be the best thanks.

Checking the operation of the ignition electrodes

At the next stage, we will check for the presence of a spark at the ignition electrodes. Using a Phillips screwdriver, you need to unscrew the two screws that secure the electrode block in the combustion chamber. And then carefully remove the electrodes and pull them out of the boiler firebox. Let's connect the power supply and put the boiler into operation. The pump starts up, the fan turns on, we hear the gas valve closing the coils open, but ignition does not occur. No spark. I'm guessing the problem is with the ignition transformer. It requires replacement. Let's turn off the boiler and turn off its power supply.

Check if the spark plug produces a spark

Differences between Navien Ace and Navien Delux

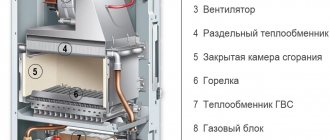

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

- Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

- The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

- It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

Repair

To remove the transformer, you must:

- disconnect the connector by pressing the lock;

- Carefully remove the ignition electrodes.

Connection occurs in reverse order:

- first the electrodes are connected;

- then the connector is fixed.

Now you can reconnect the power supply and turn on the boiler in operating mode. The pump turned on, the fan started and a spark occurred.

Turn off the boiler again and turn off the power supply. We connect the electrodes to the boiler firebox. It is important to do this very carefully so as not to damage the gasket.

Specifications

Most of the components for Arderia gas boilers are imported.

Most often these are Japanese, Danish and German spare parts. It is this detail that is a certain disadvantage of this equipment, as it complicates the maintenance of the units. For a more detailed look at Arderia boilers, it is necessary to understand their technical characteristics.

- Heat exchanger. The heating performance of the boilers under consideration increases due to the fact that copper heat exchangers are used in the primary circuit. As for these components of the secondary circuit, they are made of stainless steel.

- Monitoring operating voltage in the control circuit. These boilers have a voltage stabilizer. It supports the correct operation of electronics and allows them to operate over large ranges: from 150 V to 290 V and even more. This function allows you to extend the service life of boiler automation. It is worth noting that all Arderia gas boilers are equipped with a good security system. Special systems monitor excessive heating, current status, disposal of combustion products, and also control unexpected gas leaks.

- To improve combustion capabilities and increase the efficiency of boilers, additional pressurization is used, achieved through the use of a fan. It runs on electric current. Using a fan helps increase the service life of the device.

- Using a Grundfos circulation pump operating on a dry rotor reduces susceptibility to current and also improves the operating conditions of the pump.

It should be noted that many heating boilers are equipped with a remote control. This helps you turn the device on and off without going near it.

Arderia heating boilers use a three-way valve. It is installed so that the optimal heating level is achieved and the pipes are heated evenly. This spare part is most often made of stainless steel or bronze. These materials are durable and have positive reviews among owners.

Power-on problems

There may be several reasons for such a malfunction.:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by a protection system that was activated due to a critical error (overheating above 98°).

Other reasons for failure may also occur . First of all, you should check the voltage in the network.

The boiler is capable of compensating for fluctuations of up to 30%, but with more significant changes, it simply will not start. You can solve the issue by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, but the boiler continues to be silent, you should invite a specialist . Perhaps the cause was a failure of the control unit, a breakdown, or another serious problem.

You should not attempt to resolve the issue yourself; this may cause the final destruction of the unit.

Doesn't start for a long time

The boiler is started when certain conditions are reached. If the temperature or pressure of water (OB, DHW) is within the specified range, heating will not start until it cools down .

A possible cause may also be partial clogging of the water filter, which slows down the flow and changes the circulation mode. It may be difficult for the circulation pump to operate if it is clogged with lime deposits or small debris.

Who is the manufacturer

The ARDERIA boiler brand appeared on the Russian market relatively recently, 12 years ago, then a joint Russian production was created with the South Korean company DAYSUNG SELTIC, first in the form of an OEM project with adaptation to Russian heating equipment, then the SAUDI CERAMIC line and Bulgarian ELDOM were added. and Italian "ELBI".

In 2015, the ARDERIA company in Russia expanded with new production facilities, a logistics and support technical complex with a modern laboratory, all of this is located at 6.5 thousand. m2 in the Krasnodar village of Enem.

Operating principle

The Arderia gas heating boiler has two varieties: it can have one bithermic heat exchanger or two radiators. The first type is distinguished by the fact that water is simultaneously heated for both water supply and heating.

The second type consists of two nodes. They are each heated separately. One radiator is made of copper, the second is made of stainless steel. Water circulation occurs using a pump. The removal of combustion products is also forced. This happens with the help of a special fan.

The control of such gas boilers can be either electronic or remote. The remote control is always sold included.

All Arderia gas heating boilers have a number of features, which include:

- this equipment is fully suitable for Russian heating systems;

- boilers have a special voltage stabilizer, which helps the device operate smoothly even during power surges;

- boilers have a gearbox that stabilizes operation when gas pressure drops;

- Arderia gas heating boilers are practical, stylish and of high quality.

The operating principle of these boilers is as follows:

- first of all, you need to set the required temperature using the remote control;

- the boiler turns on automatically using a temperature sensor and operates until it reaches the set parameters;

- after this, the sensor turns off the boiler;

- as soon as the temperature drops by 15 degrees Celsius, the sensor turns the boiler on again.

The pressure in the boiler is constantly regulated by an air valve, as well as a gas flow sensor.

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (symbol of a snowflake or sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature . By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.