Lemax gas boilers seriously compete with their European counterparts.

They are assembled from spare parts manufactured by recognized leaders in the production of heating equipment - Vaillant, Sit and other well-known manufacturers.

With excellent quality, the cost of Lemax boilers is two or more times lower than that of the “Europeans”.

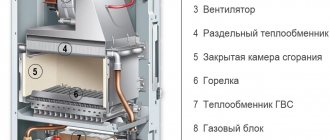

Basically, this is achieved by eliminating all additional devices and components from the design, leaving only the most necessary elements.

This has a positive effect on the performance of the units, reduces the frequency of breakdowns or failures, but some malfunctions still occur.

Main malfunctions of Lemax gas boilers

The most common malfunctions include:

- Gas leak. Immediately open the windows, turn off the gas supply, turn off the boiler and call the gas service workers.

- The color of the flame is reddish, the tongues are elongated and smoke. Weak draft or burner clogging. Clean the chimney and burner, correct the position of the pipe.

- Spontaneous shutdown of the main burner. Problems with the chimney or thermostat.

- There is no water circulation. If there is a pump, the reason lies there. If natural circulation is used, it is necessary to correct the configuration of the pipelines, giving them the correct slope.

- Boiler shutdown. Usually occurs due to a gas supply interruption.

The list of possible malfunctions can be continued for a long time, but there is no point in this, since each situation requires separate consideration.

Possible malfunctions and repair methods

To eliminate complex breakdowns or malfunctions of gas equipment, it is necessary to involve certified specialists or organizations. In some cases, it is quite possible to carry out minor repairs to a gas boiler yourself.

smell of gas

Most often, gas begins to smell when it leaks from leaks in the threads of the supply pipe. If a characteristic odor is detected, immediately turn off the heater and ventilate the room. For repairs you will need the following materials and tools:

- a thick solution of soap in water;

- gas or adjustable wrench;

- thread sealant - plumbing thread or FUM tape.

You can fix the problem this way:

- lubricate all connections with the solution; soap bubbles will appear and burst at the place where gas leaks;

- turn off the gas supply;

- unscrew the liner;

- wrap the sealant around the thread, carefully tighten the connection until it stops, but do not overtighten;

- open the gas supply;

- re-lubricate the connection with soapy water; make sure there are no bubbles.

If they continue to appear, immediately turn off the supply and contact the gas specialists.

fan doesn't work

If the usual tone of the fan operation changes, extraneous sounds appear, or if there are no sounds at all, we can confidently assume that the fan has failed.

To fix the problem you will need:

- crosshead screwdriver;

- replacement bearing;

- rags;

- CIATIM type grease.

Repairs are carried out in the following sequence:

- disconnect the device from the network, turn off the gas supply;

- remove the fan;

- Use a rag to remove dirt from the blades;

- if the fan parts, such as the coil or contact groups, are darkened or melted, the fan will have to be replaced;

- remove the fan casing; inspect the bearing.

If it fails, replace it with a new one, not forgetting to lubricate it.

Another reason for fan malfunctions may be instability of power supply parameters. In this case, you should purchase a voltage stabilizer of appropriate power and connect the boiler through it.

If interruptions in the operation of the fan are caused by a malfunction of the control system, it is necessary to involve professionals to repair the gas boiler board.

high temperatures

Exceeding the temperature is most often caused by contamination of the heat exchangers and a decrease in their ability to remove thermal energy from the firebox.

To correct the situation you will need:

- hydrochloric acid solution;

- stiff wire brush;

- gas or open-end wrench;

- thread sealant.

Cleaning the heat exchanger is carried out in the following sequence:

- turn off the gas and electricity supply to the unit;

- close the valves connecting to the heating system pipelines

- Use a wrench to carefully unscrew the heat exchanger;

- remove carbon deposits and other contaminants with a wire brush;

- gradually pour hydrochloric acid into the radiator through the pipe; the appearance of foam indicates severe contamination of the pipes with scale;

- let the acid drain, repeat the operation;

- Rinse the heat exchanger with plenty of water.

Now you can mount it back, not forgetting to wrap the threaded connections with a sealant.

When working with acid solutions, be careful and be sure to use personal protective equipment: acid-resistant gloves and safety glasses, or a clear face shield.

If leakage of coolant from the pipes is detected, you must contact a workshop to repair the gas boiler heat exchanger.

sensor malfunction

A common malfunction is the erroneous operation of the burner flame sensor. A characteristic sign of such a malfunction is the fading of the torch a few seconds after ignition. On devices with a self-diagnosis option, the corresponding error code is displayed on the display.

To fix the problem, turn off the gas and electricity supplies. Next, apply thin sandpaper to the electrode contacts without removing the sensor from the boiler. If cleaning does not produce results, the part will have to be replaced.

The draft sensor should be removed from the device, washed with an alcohol solution and blown with compressed air to dry it completely. If this does not help, you should contact a professional.

settings failure

Sometimes you can try to fix a control system malfunction by resetting the settings to factory values. The combination and duration of pressing the control buttons for this operation is given in the user manual. If after resetting the unit does not work, you should call specialists.

the chimney is clogged

Chimney blockage occurs in floor-standing gas boilers with an open combustion chamber. The quality of traction is checked as follows:

- turn off the gas supply;

- open a revision;

- in a metal container, bring a piece of paper to the audit and set it on fire;

- if the leaf is not pulled into the chimney, but smoke goes into the room, the draft is insufficient and the chimney is clogged.

It is better to call professional chimney sweeps to clean your chimney.

Why does the device go out?

There may be several reasons why the burner goes out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

Features of breakdowns

No matter what the problems are: minor or costly, they must be eliminated efficiently and quickly, because disruptions in the operation of gas equipment can cause not only emergencies, but also explosions.

Experts classify breakdowns of gas units as follows:

- Explicit or hidden - depends on the ease of detecting the defect.

- Independent and dependent, that is, entailing a whole series of further problems.

- Sudden or gradual, that is, appearing after long-term use or manifesting itself for no apparent reason, unexpectedly.

- Final or intermittent.

If the user notices obvious signs of a breakdown: for example, the water takes too long to heat up, some small part does not work, or atypical sounds appear, then you should not wait for the unit to completely stop; it is better to start repairing it as soon as possible, without taking it to extremes.

According to statistics, about 90% of boiler problems can be determined by visual inspection of the heating system. Most defects can be eliminated without much difficulty, only a few of them require intervention in a service center.

Testing equipment and its in-depth diagnostics is considered a task that can only be carried out by certified specialists. They will also help analyze the economic feasibility of repair and restoration work and provide repairs and regular maintenance of gas boilers. Situations are quite common when replacing parts and repairing a unit are almost comparable in cost to purchasing a new boiler. Most often this concerns cheap, low-power or not very high-quality wall-mounted devices.

The purchase of new, more economical equipment will also be justified in case of obsolescence of the boiler.

Classification of repair work

It is very important to carry out scheduled inspections and timely maintenance of the gas heating system, which will minimize possible costs and ensure long-term operation of the equipment. Maintenance provided by the manufacturer within a certain time period, in contrast to repair work, is carried out for normally functioning heating equipment. Sometimes replacement of small parts is possible.

If it comes to repairs, then the following types are distinguished:

- Capital, entailing significant monetary costs and a large amount of work. Provides for the replacement of obsolete and faulty equipment.

- Current, the purpose of which is to maintain the performance of equipment and eliminate possible technical defects.

- Preventive and planned maintenance of boilers, which is carried out within a clearly defined time frame (this applies to system parts that, according to documents, should fail before other elements due to a limited service life).

- Refurbishment of gas boilers, during which the system is flushed and the electrodes, heat exchanger, etc. are cleaned.

How to turn on (light)

The Lemax boiler is started after filling the system with the required volume of water (12-14 liters for each kW of power) and connecting the gas pipeline.

Procedure:

- Open the lid, providing yourself with access to the regulator and the piezo ignition button.

- Turn the regulator counterclockwise, which will move the boiler to the “on” position.

- Push the regulator all the way in and hold it in this position while simultaneously pressing the piezo ignition button.

- After a flame appears on the pilot burner, the button can be released, but the regulator must be held for about another minute.

IMPORTANT!

If an attempt to ignite the boiler was unsuccessful, it can be repeated only after 1 minute, not earlier.

Doesn't start (ignite)

The unit is ignited according to a certain pattern. It does not always start the first time, and this is quite normal. But, if after repeated attempts the boiler does not ignite, it is necessary to check the condition of the components responsible for ignition.

Possible reasons could be:

- Failure of the electronic or mechanical ignition system. It is necessary to replace the system, or clean the thermocouple contacts.

- There is no voltage in the power supply network (for volatile units).

- The valve on the gas supply pipe is closed.

- The gas pressure in the system does not correspond to the nominal values.

- The main burner nozzles are clogged. It is necessary to clean them and start the boiler.

All these reasons are the most common, but far from the only possible ones. Any malfunction in the system can negatively affect the ignition of the boiler .

NOTE!

If you have tried all the options, but the problem is not solved, you need to call a technician from a service organization.

1.When turned on, the boiler does not work at all

There can be several ways to eliminate this gas boiler malfunction. The simplest one is to check whether the boiler is plugged in or whether the machine has been knocked out . If this does not help, you need to remove the boiler casing and inspect its insides for a short circuit. Perhaps there is some smell or something has leaked. You need to check whether all wires and sensors are in their places. If everything is in order, then you need to move on to inspecting the fuses on the electronic board. Once you are sure that the fuse has blown, you just need to replace it with a new one. If the new fuse immediately burns out, then you need to call a technician, as this means some kind of serious breakdown that is unlikely to be corrected on your own. A specialist should also be called if all the fuses are normal. This indicates that the problem is not with them.

Pay attention to the varistor. It is designed to protect the boiler from voltage surges. If there was some kind of difference, then the varistor will be blown up and only a small part of it will remain. Because of this, the boiler may also not turn on. The solution to this boiler malfunction is to simply re-solder the varistor.

gas boiler varistor

Why is blood pressure rising?

Increased pressure is a serious and dangerous situation. An increase in pressure in the system can only mean an increase in the amount of water.

This occurs due to the expansion of the coolant when heated. Any liquid is incompressible, so an increase in its volume can lead to rupture of the heat exchanger, or, in the most serious case, provoke an explosion.

To eliminate this possibility, an expansion tank is used in the design of boilers. It absorbs excess water volume, compensating for its increase when heated .

An increase in pressure most often indicates a problem with the expansion tank. Its design consists of a container and an elastic membrane installed approximately in the middle.

When the liquid begins to flow, the membrane sag and makes room for excess water..

When the volume decreases, it returns to its previous position. If the membrane is torn or not firmly attached to the expansion tank stacks, the coolant will fill the entire volume of the tank.

When expanding, the water will have nowhere to go, which will provoke a constant increase in pressure. The solution to the problem is to restore the condition of the membrane or replace the expansion tank with another, serviceable copy .

Using a chemical solution through a booster

To perform this cleaning method, it is necessary to use special equipment - a booster, with which an acidic washing solution is pumped into the heat exchanger.

Then, over a long period of time, it is necessary to drive the solution through the pipes several times. The result will be that the deposit will dissolve and will be removed from the equipment along with the liquid used for flushing.

After flushing, the throughput and thermal conductivity of the gas boiler will increase. An acidic solution can dissolve any stubborn contaminant, which can be carbonate salt deposits or ferric iron deposits. A small amount of acid remains in the pipes, which is neutralized. To do this, use a special solution, which is launched into the heat exchanger after the washing is completed.

What causes blood pressure to drop?

A drop in pressure (the boiler goes out) indicates the appearance of leaks. It is necessary to check the condition of pipelines, threaded connections, gaskets and other external elements of the heating system . If there is no visible damage, you should look for problems with the boiler.

The main problem element may be the heat exchanger. Welded joints sometimes crack or break due to frequent temperature changes. Sectional cast iron heat exchangers used on powerful floor-standing models are risk factors at section connections.

In addition, the pressure relief valve may be triggered or jammed open..

Threaded connections of pipes can also lose their tightness due to drying out or destruction of gaskets, non-threaded connections, etc. All detected problems are eliminated in accordance with their specifics.

Do-it-yourself repair of double-circuit boilers

Double-circuit boilers should be repaired especially often, since they work in intensive mode, heating rooms and storing hot water for domestic needs.

NOTE

During the repair of gas boilers, structures will almost always need to be dismantled. You need to carry it out carefully, remembering the connection sequence, so that later you can correctly assemble all the elements of the system.

Repair of a wall-mounted gas boiler (cleaning and flushing the heat exchanger with special means) is clearly shown here:

Connecting a room thermostat

A room thermostat is a convenient and useful device that allows you to regulate the temperature of the air, not the coolant, in the heating system. The default sensor monitors the outlet temperature of the heating agent.

This does not give a correct picture of the state of the microclimate in the room. For example, when the outside temperature rises, the room becomes hot .

But the sensor cannot track this, and the extract air temperature is within the limits specified by the mode, so from the point of view of the system, everything goes fine, in accordance with the boiler settings.

If a room thermostat is used, the burner will turn off much earlier, which will improve the microclimate in the room and significantly reduce gas consumption.

To connect the room thermostat, you need to set the boiler's own element to the maximum temperature.

It will only work as an overheat limiter . The external unit is connected at one end to the automation unit, and at the other to the boiler thermostat. By default, a jumper is installed between the contacts, which must be removed and the thermostat connected.

IMPORTANT!

It is necessary to use the appropriate brands, for example - CEWAL RQ10. Installation of a thermostat is only possible on boilers marked N (with the SIT 820 NOVA automation unit).

How to repair a boiler yourself: step-by-step instructions

Once a specific breakdown has been accurately diagnosed, you can begin to fix it. Of course, if you are sure that this is a feasible task that does not require special skills and equipment.

Preparatory stage

- First of all, you need to disconnect the device from the power supply and also turn off the gas valve tightly. Even if the repair is not related to elements in direct contact with fuel, this condition is mandatory.

- If it is difficult to estimate the time of restoration work, and it could theoretically take several hours, you should completely drain the water from the heating system or pour in an antifreeze solution (if it is not there). The fact is that during the repair the air temperature in the room may drop to negative values, and the water will freeze.

- Safety precautions: along with turning off the gas valve and de-energizing the system, you should also remember that before repairs, the working surface must cool to an acceptable level. Otherwise, touching it may cause burns.

Cleaning the heat exchanger

If the boiler overheats, this may indicate 2 reasons:

- The automation that controls the operation of the device is faulty.

- The heat exchanger is clogged (soot deposits).

Automation can be repaired only with the help of special equipment, which in most cases is not available in the house. But it is quite possible to clean the heat exchanger yourself.

The sequence of actions is as follows:

- Turn off the boiler and allow it to cool.

- The taps are turned off.

- Remove the front cover.

- Dump the remaining water (open a hot water tap or a valve inside the mechanism to drain water from the heating system).

- Remove the heat exchanger.

- The heat exchanger is cleaned first mechanically, then in a solution of vinegar and citric acid, taken in equal quantities (you can use a tablespoon per liter of water). Instead of a solution, you can also use special formulations purchased in the store.

- The heat exchanger is kept in this mixture for 1-2 hours until completely cleaned.

- Then rinse with running water and wipe dry.

- Put the heat exchanger back, close the lid, and fasten all the parts.

Chimney cleaning

Reduced draft and overheating of a gas boiler can certainly be associated with a clogged chimney. It is in this part of the system that the largest amount of soot accumulates. However, dirt accumulation is quite rare since the gas does not produce a large amount of waste.