From the author: Hello, friends! Home air heaters create warmth and comfort in the house when there is frost and cold wind outside. After installing a new heating system, apartment owners often do not know how to turn on the gas convector. Of course, you can study the instructions, but the best way is to see everything with your own eyes using a video or get information from experienced users. Additionally, you need to familiarize yourself with the safety precautions and operating rules of the device.

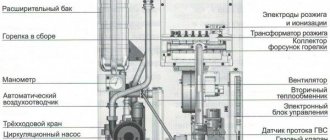

Gas convector device

The operation of the device is based on the law of natural air heat exchange. From the external environment, the device draws in oxygen necessary to maintain the combustion function. Gaseous substances harmful to human health escape through a special adapter.

Weather conditions do not affect the operation of the device. The smell of gas and combustion products is not felt due to the fact that the process takes place in a sealed chamber. A gas convector is a prefabricated structure consisting of a large number of parts:

- back wall,

- sealed housing,

- front casing,

- air exchanger,

- pipes, screeds,

- fastenings and mounting products.

The body is made of cast iron or steel with a heat-resistant coating. The decorative grille protects people from accidentally touching the hot surface of the device. Warm air passes through it, warming the room. The air exchanger is installed on the outside of the wall. The windproof design ensures trouble-free operation of the device.

The safety of the convector operation is maintained automatically:

- if the draft is weak or the ignition burner goes out, the gas supply is interrupted,

- set the desired temperature on the control panel,

- gas flows evenly, regardless of the pressure in the gas pipeline,

- The burner is ignited using a piezo igniter.

Color combinations

Stylists advise taking into account the following nuances:

- direction in the interior;

- combination of shades;

- illumination

It is much easier to choose a palette if the style for the kitchen and living room has already been selected. For example, neoclassicism and Provence have their own combinations. In a classic interior, designers combine pastel colors, pale colors, which are slightly diluted with dark shades.

In French country houses you can often see soft blue, pink, and pistachio colors. Art Deco designers make up objects and finishing materials in black and white, sometimes beige and brown or silver and black. The main thing is to choose a shade for the walls. White will become universal, it will expand the space, and later you can paint them with any paint.

However, in the cooking area, white ceases to look fresh. Beige or gray shades would be more practical. This background will highlight the other colors. In a monochrome interior, designers recommend gluing wallpaper in an unusual color or with a photo print.

Installation of a heating device

On the wall where it is planned to mount the convector, make a hole corresponding to the parameters of this model. The further actions of the masters are as follows.

- A coaxial telescopic pipe is inserted into the prepared tunnel.

- The wall must be made of material that is not subject to combustion. If the interior is made of wood, drywall or other combustible materials, it must be insulated.

- The pipe is installed perpendicular to the convector with a rigid fastening.

- The back of the device is screwed to it.

- The convector is attached to the wall.

- The telescopic pipe is positioned so that only the fungus is visible from the outside.

- The remaining cracks are sealed with heat-resistant foam and cement mortar.

It is necessary to ensure that emissions from the convector do not fall on footpaths, since the escaping gases have a high temperature.

Raised beds

Recently, raised beds have become especially popular. With this method of their formation, the upper level of the bed is raised above the ground by 20-50 cm and placed in a separate box. This method has a number of advantages over a vegetable garden located in the same plane with the ground, namely:

- ease of care for the garden bed, since there is no need to bend over to carry out normal procedures (planting, weeding, loosening);

- you can create a bed from specially brought soil if the land on the site is not suitable for gardening purposes;

- much fewer weeds and pests settle in the garden bed;

- beds enclosed in separate high boxes look unusual and, with proper organization of space, become an independent aesthetic object.

Preparation for use

Before starting to operate the air heater, you need to check:

- gas burner manifold fasteners,

- tightness of gas connections,

- accuracy of thermostat operation,

- security system in the room and the device itself.

Attention! Never attempt to reset factory programmed settings. They are designed for convector operation on natural gas. To carry out the necessary adjustments (for liquefied gas or other types of fuel), contact a specialized service center.

Conclusions and useful video on the topic

The video will talk about how to make a propane gas burner yourself:

Having at hand a small supply of tools, a gas burner diagram and the necessary materials, every home craftsman can assemble a propane burner

It is important to follow fire safety rules and use only high-quality materials approved for use in the domestic gas supply system. But if you are not confident in your own abilities, it is better to purchase such a device in a store

If you had to assemble a propane burner yourself, please share your knowledge with our readers and tell us which option you chose. Why was he chosen and were there any difficulties during the work process? Perhaps you have a diagram of the device and a photo of the finished homemade product - include visual information in the discussion of the material.

Switching procedure

To ignite the pilot burner, you need to move the main regulator from the “OFF” to “ON” position. Press and hold the control knob for a few seconds until the pilot light comes on. Check to see if the wick lights after you release the control knob. If the light goes out, repeat the operation. To further understand how to turn on and operate the device, watch the video.

Set the temperature control to the desired position - from 13 to 38 degrees. Each of the seven values corresponds to a specific indoor air heating temperature. The gas convector can be left in standby mode when only the wick is lit and the main flame is extinguished. To turn off the device, just press the “OFF” button.

Attention! After the end of the heating season, the gas supply to the device should be completely shut off.

To do this, close the valve on the gas pipeline.

Precautionary measures

The use of household appliances requires compliance with safety precautions. Be careful and listen to the advice of manufacturers:

- You cannot use a convector that has a damaged viewing window,

- if the device goes out spontaneously, do not re-ignite it earlier than after 3 minutes,

- To prevent burns, the convector is protected with a protective grille.

It is strictly prohibited:

- dry things on a running appliance,

- turn the device on and off for children and people with limited legal capacity,

- operate the device with the outer casing removed,

- repair the device yourself,

- place flammable objects at a distance of less than 1 m from it,

- leave it on if signs of a gas leak are detected.

If there is an unpleasant odor in your home, take immediate precautions:

- turn off the gas supply,

- extinguish all sources of open fire,

- do not touch switches and mobile phones,

- ventilate the room

- urgently call the emergency gas service,

- Contact a gas convector service center.

Building regulations

Pipes may be laid in the outer walls of the building, but the diameter of the outer casing should not be less than the thickness of the fence. Vertical deviation is allowed no more than 30°, horizontal deviation - 1 m. Cutting is done where the pipe passes through the ceiling structure.

Chimney distance standards:

- to fireproof structures - 5 cm;

- to fire-resistant (plastered walls and wooden ceilings) - 25 cm;

- to fire-resistant ones, covered with asbestos sheets and galvanized - 10 cm, if the insulation protrudes beyond the edge of the channel by 15 cm on both sides.

The chimney is checked for density if the device uses the principle of self-production. The chimney end hole above the roof is closed. If smoke accumulates in adjacent ducts or adjacent rooms, the chimney duct is loose or not isolated.

The requirements for smoke ducts are:

- density sufficient to prevent the passage of gases and smoke;

- the diameter coincides with the outlet pipe of the heating unit;

- Permitted materials are used during construction;

- chimneys provide the required draft force;

- there should be no blockages or blockages inside the pipes;

- are not installed in the area of wind pressure.

Features of use

The operating principle of the device is based on the physical phenomenon of convection. Streams of cold air penetrate through the lower grilles, heat up from the heat exchanger and rise to the ceiling. Constantly circulating air quickly heats the room. When installing convectors, there is no need to install heating pipes in the apartment.

Several convectors are installed in a large house. A main gas pipeline must be connected to each of them. One device heats a room with a volume of up to 130 cubic meters. It maintains a given temperature regime with a minimum gas flow rate - from 0.22 to 0.48 m3/hour, depending on the model.

The efficiency of the devices reaches 88%. In comparison, gas boilers operate with efficiency of up to 98%. The performance is improved for devices with fans, but at the same time the noise level in the room increases. When heating and cooling, steel convectors emit a characteristic crackling sound (the metal expands or contracts). Cast iron casings do not produce any sounds.

Gas appliances come in two types: wall-mounted and floor-mounted, fireplace type. They are fastened in the same way, have a common principle of operation, but the latter are larger in size.

Advantages

The convector chimney has a number of advantages that make it a worthy alternative to conventional cast iron or bimetallic radiators and even an entire water heating system in small country houses, summer kitchens and bathhouses.

- Versatility - coaxial convector chimneys are suitable for a conventional wood stove, and for solid fuel or gas boilers.

- Increasing the productivity of a heating device through the use of secondary thermal energy of heated smoke, gases and water vapor.

- Efficiency - the design can heat three rooms at once: the one in which the boiler is located, as well as one or two adjacent ones.

- Durability - thanks to the use of durable metals and alloys in the manufacture of the casing, the service life of the structure can reach decades.

- Fire safety - the chimney-convector device isolates the heat source, protecting surrounding materials from overheating. Due to this, such chimneys can be installed in wood-burning bathhouses and houses made of timber.

- Protection from infrared radiation - the metal casing acts as a screen that absorbs excess heat.

Another advantage of the design is increased strength and increased service life of furnace equipment as a whole. Coaxial convector chimneys are made of durable alloy steel. It resists the effects of high temperatures and aggressive acids contained in exhaust smoke.

LPG convector

The air heater can be converted to operate on bottled (liquefied) gas. For this purpose, special nozzles and a gearbox are purchased. If there are several such convectors in the house, then a special room will be equipped on the outside of the house for storing propane cylinders.

A comfortable temperature in the house is achieved using the built-in thermostat. It prevents the air in the room from overheating, while gas is consumed more efficiently.

Important! Gas combustion products will not enter the airspace of the room if they are vented into the chimney.

Before buying an air heater, calculate the required power to heat the volume of the room in which you plan to install it. Be sure to take into account the height of the ceilings, otherwise the device may not meet your expectations. The best location for convectors is under the windows. In this case, cold air does not have time to penetrate into the room.

Sometimes these devices are used as an additional source of heat in severe frosts. Approximately 0.095 kg of liquefied gas is burned per 1 kW of heat transfer power per day. Keep in mind that a cast iron heat exchanger in a gas convector lasts much longer than a steel one. Its service life can last up to 50 years, but such a device costs much more. Manufacturers provide a factory warranty of up to 5 years. Make sure that when purchasing the device in the store, all documents are filled out, including the warranty card.

Review of popular models and their prices

The range of wall converters available on the modern market is not that wide. Several large companies that supply high-quality products stand out from the crowd.

The following models are the most popular today:

- Gas convector Alpine Air NGS 20F – has a wall-mounted configuration, is equipped with a closed combustion chamber and an improved gas exhaust system. With a power of 2.2 kW, it is capable of heating rooms with an area of up to 40 cubic meters. m. It has established itself as a reliable and durable heating device, capable of operating even in the harshest climatic conditions. The price for the NGS 20F model varies between 20-23 thousand rubles.

- Alpine Air NGS-40F is another interesting solution from the same company, this time at 4 kW. Technologically it follows the design of its “younger brother” and is equipped with an excellent cast-iron heat exchanger. The heated volume has increased to 70 cubic meters, but the price does not lag behind - 26-30 thousand.

- Hosseven HDU-3 is a budget solution from a well-known Turkish company. The HDU-3 is a 2.7 kW wall convector with a steel heat exchanger and provides an efficiency of up to 89% - one of the best results in its category. A closed combustion chamber, a coaxial exhaust tube and an affordable price (from 13,000 to 14,500 rubles) are the main advantages of the model.

- Hosseven HDU-5DKV is a high-performance convector that can be purchased for 21-23 thousand rubles. It has a cast iron heat exchanger with an electrically independent fan and an improved closed burner, thanks to which it produces 4.5 kW of power. The efficiency of the device reached 91%.

Of course, the list of convectors worthy of attention is not limited to these models. It includes products from such brands as Karma, ATON, Emax, AKOG, KORDI, etc.

Distinctive features

Convectors operating on liquefied gas have a horizontal or vertical chimney. Vertical systems have more power, but have installation limitations - they cannot be installed everywhere. Models with a fan provide accelerated air circulation in the room.

Installation of the device follows the same principle as in the case of natural gas, but it is necessary to provide an additional hole to connect it to a cylinder located outside the room.

Important! During the first hours of operation of the convector, an unpleasant odor is felt in the room. This burns the lubricating oil. Ventilate the room and the air will be refreshed.

To start the device, the operations described above are carried out sequentially. The only difference is that instead of a tap on the gas pipe, they open a valve on the propane tank. An important distinctive feature of liquefied gas appliances is the ability to heat rooms located away from gas pipelines.

Work specifics

Today, heat exchangers of various types are produced. In general, the features of their operation, as well as the design characteristics, are similar. The structural properties of such an element:

- Full body available.

- Presence of outlet and outlet pipes.

- Braking mechanism for combustion products. Its role is played by valves with cutouts that are installed on the axles.

The flaps can be turned. A zigzag chimney of varying lengths is formed. The valves can be adjusted to ensure the ratio of draft and heat transfer is as efficient as possible. Safety standards are met.

In this video you will learn how to make a heat exchanger:

How to fix the problem

Malfunctions in the operation of the devices occur very rarely. The main reasons for unstable operation of the device:

- burner contamination,

- clogging of jets,

- dampening of contacts.

Experts advise carrying out preventive measures at least once every 24 months. Craftsmen carry out the necessary repair work:

- weld the damaged body,

- restore the automation system,

- switch the device to liquefied gas.

Attention! Only a certified technician from the gas industry or service center can carry out repairs on gas convectors.

The main task of the specialist is to eliminate the cause of the problem. To do this, replace the damaged node or block. Such repairs are done quickly at a low cost. At the final stage, the operation of the equipment is tested in different modes and the functioning of security systems is checked. Experts inspect the gas pipeline to prevent gas leaks.

Main characteristics of the device

Gas convectors have many advantages that allow them to be used in residential buildings, factories and shops. This:

- moderate cost,

- can be turned on only in one room if there are several devices installed in the house,

- The device provides significant gas savings,

- uniform distribution of warm air,

- ease of operation,

- reliability and long service life,

- can be used during a power outage,

- no installation of additional sources required,

- affordable installation and maintenance of the convector.

When choosing a heating system for a new apartment, consider installing gas convectors using natural or liquefied gas. Let your home be warm and cozy.

Criterias of choice

When choosing a convector for specific application conditions, the following main characteristics of the equipment are primarily taken into account:

- Installation method.

- Fan.

- Combustion chamber design.

- Power and gas consumption.

- Heat exchanger material.

- Automation.

Let us consider in detail the features of each parameter.

Installation method

Modern convectors are divided into two types according to installation method:

- Wall mounted . Fixed to the surface of the main wall. They are lightweight and compact in size. The exhaust device is equipped with a rigid pipe through a hole in the wall. Maximum power – 10 kW.

Wall-mounted propane convector Source oboiman.ru