People have tried to heat their homes since ancient times. At first it was just an open fire, then safer stoves of various designs appeared. In the modern world, compact units operating on different types of fuel are used for autonomous heating of residential and industrial facilities, but the most convenient is a gas unit. Let's figure out what the structure of a gas boiler is.

The main element of any heating system is the boiler. This is a compact device in which the energy of fuel combustion is converted into heat, which heats the coolant entering the heating system. Externally, modern boilers look like an ordinary cabinet. But the internal structure of the unit is quite complex.

General instructions for use

Before you start using a gas boiler, you must connect it to the gas network, heating pipes, cold and hot water supply (if the unit is double-circuit and is also intended for preparing hot water), and electrical network, which must meet the technical characteristics of the machine.

Gas connections are made only by certified gas service workers. The water is connected and the boiler is started for the first time by representatives of a specialized organization for servicing heating systems. When connecting, strictly adhere to the requirements of the warranty card and operating instructions, otherwise the warranty will be void. A gas boiler can only be used for the purposes for which it is intended.

Table of the required boiler room volume depending on the boiler power.

The manufacturer is not responsible for improper operation of the boiler, violation of operating rules and for damage associated with this. This will also void the warranty.

Installation, service and other work must be carried out in full accordance with the regulatory and technical documentation and user manual. Only original spare parts must be used.

If a malfunction is detected in the operation and/or breakdown of the unit, you must immediately turn off the gas supply at the tap and call a qualified specialist. It is strictly prohibited to carry out any work on the gas boiler yourself.

When performing any work on or near air ducts and chimneys, it is necessary to turn off the device and turn off the gas. After completing the work, before turning on the boiler, you should check the functionality of the air ducts and chimneys.

When the gas boiler is turned off for a long time

- turn off the gas tap;

- when the boiler automation is powered from the mains and there is an electric water pump, disconnect them from the line;

- turn off the taps of the cold and hot water supply system, heating system;

- if the heating system is filled with water and the ambient temperature is expected to drop below 0°C, the water must be drained from the heating system;

- The final shutdown of the unit should be entrusted to a specialist.

When cleaning the boiler, turn it off. The device can be cleaned with damp cloth rags, a mild detergent, and soapy water. Do not use aggressive chemicals for cleaning, including detergents, insecticides, and other toxic substances.

The use and storage of flammable substances in the same room as a gas unit is strictly prohibited.

Principle of operation

The operating principle of a gas heating boiler is quite simple. Through the return pipeline from the heating network inside the house, cooled water is supplied by a circulation pump to the input of the heating circuit heat exchanger.

At low coolant temperatures, an electromechanical valve opens, supplying fuel to the injector. The igniter ignites the gas and the combustion process begins. The boiler constantly operates on the heating circuit.

The DHW circuit begins to function when the tap on the mixer is opened. This thermal scheme of the boiler operation in the summer makes it similar to the operation of a conventional gas water heater.

How does a condensing boiler work?

The name “condensing” boiler units was acquired due to the fact that they implement a technology for obtaining additional thermal energy by modifying the aggregate state of condensate from steam located in the flue gases.

Operating principle of a condensing boiler

During the combustion of natural gas in a condensing gas boiler, water vapor is created, which in traditional units evaporates and is released into the atmosphere through a chimney.

Experts have developed an additional device in the boiler - a water economizer, in which steam in the flue gases turns into condensate, while releasing additional heat, which is transferred to the coolant in the economizer.

The temperature at which the condensate is converted is called the dew point of +55 C, and the technological process is called condensation. This temperature corresponds to the parameters of the return network water entering the boiler from the heating system. If it is more than +60 C, then the condensing boiler will work like a traditional device with low efficiency.

In addition, condensate creates a very aggressive environment containing acids. Therefore, its collection and disposal will require a special neutralization system, which the liquid must undergo before it can be discharged into the city sewer.

Condensing boiler. Photo source: allbuildingtips.com

In general, a convection gas boiler is an expensive device, however, fuel savings of up to 20% allow it to pay for itself within five years.

The principle of operation of a double-circuit gas boiler

The operating principle of a double-circuit boiler unit is designed for 2 thermal modes:

- heating;

- DHW.

In heating mode, the operation of the boiler is practically no different from a single-boiler boiler. Starting the burner involves a fairly long start-up period in order to increase the temperature in the heating circuit to operating levels. When the main mode is reached, the flow of fuel to the burner stops.

The internal air temperature sensor allows you to automatically regulate the temperature and sends a signal to open the gas when the permissible level decreases.

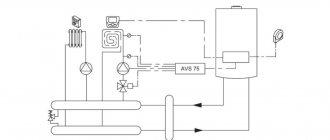

Modern double-circuit Baksi boilers, in addition to an internal temperature sensor, are equipped with a special weather-dependent automatic system that regulates the operation of the boiler based on the outside air temperature outside the building window. The burner increases the temperature of the heating water, the circulation of which through the pipelines of the heating system is ensured by a circulation pump. A three-way valve built into the system switches the movement of coolant through the heating circuit or into the DHW system.

Today's double-circuit heating boilers are equipped with automatic control and safety systems. In emergency situations, flame and draft sensors are capable of shutting off the gas supply to the boiler through an electromagnetic valve, thereby preventing the creation of an increased concentration of gas in the boiler room.

This mechanism not only shuts off the gas supply, but also informs others about the danger using sound and light alarms, and also starts exhaust ventilation to reduce the content of methane and carbon monoxide in the air.

Requirements for use

Before you start using the boiler, you need to make sure of some very important points. The heating system must have the right amount of fluid. The boiler itself must be connected to the atmosphere through an expansion tank. The safety valve and burner field must be in working order. The latter should be freed from foreign objects and other debris. The boiler valve must be opened.

Before starting ignition, it is necessary to remove the protective film, if any, from the burner. How is ignition carried out? First you need to make sure that there is no smell of gas in the room. In addition, such phenomena as an open pipeline supply valve and the presence of draft in the chimney are unacceptable. Immediately before ignition, the burner viewing window opens. The burners bring fire to the middle of the field. If ignition has occurred, a slight pop should appear. As a rule, this happens within 5-7 seconds.

If, after these steps, ignition still does not occur, then you should immediately turn off the valve and ventilate the room. The next attempt can be made no earlier than 10 minutes later. This is what the operating rules say.

The temperature during boiler operation must not fall below 65°C, as this may lead to condensation.

It is important to ensure that no specific gas odor arises in the room during work. At the same time, the temperature cannot be higher than 90°C

The boiler burner must be periodically cleaned of dirt.

This is what the basic operating instructions for this unit look like. It is important to be careful when using a gas boiler and not to deviate from the rules of use. Use it correctly!

Bottom line

Now it’s clear why the gas boiler often turns on. And that the frequency of turning on and off the burner of a gas heating boiler is a very variable and very individual value. This directly depends on a large number of factors. Manufacturers guarantee that the boiler will provide the specified temperature range, regardless of whether the burner is turned on or off. At the same time, the intensity of fuel combustion helps prevent its overconsumption due to clocking.

The operating mode of the gas boiler is selected strictly in accordance with the time of year and the required thermal index in the room. To avoid very frequent switching on and off of equipment, you need to determine the correct location for installing the thermostat and stabilize temperature intervals. And also adjust the gas burner and resolve the issue with the thermal capacity of the heating circuit.

Accommodation requirements

These requirements will directly apply to the room in which the gas boiler is to be located. What does the instruction manual say about this? Thus, the room must have a total area of more than 7.5 m². Ceiling height - at least 2.2 m.

Diagram of a gas boiler from Vaillant.

In addition, the room must have a window that can be opened if necessary. It should go outside. This is required by fire safety.

As for the door in this room, it should open in the direction of movement from the room. There should be no switches in the room itself. They should be moved outside the room.

A ventilation system (supply and exhaust) is required. Approximately 15 m² of air per 1 m² of gas burned is required. Three air exchanges are also needed.

When installing the boiler itself in a room, fire safety precautions must be strictly observed. So, from the boiler to the combustible elements of the room, you need to measure a distance of no less than 25 cm. As for non-combustible elements, a distance of 5 cm is allowed here.

The distance between the chimney and combustible parts is 40 cm, and between the chimney and non-combustible parts - 15 cm.

The gas boiler must be installed on a perfectly flat surface on which there are no slopes

This is important for safe use.

How combustion products are removed

This process is implemented in 2 ways. Natural or forced draft is used. If the hood is not strong enough, then there is a danger of carbon monoxide entering the room with corresponding consequences.

The installation of a chimney for boilers must occur as described in SNiP 2.04.05-91 and DBN V.2.5-20-2001. The boiler pipe is connected directly to it if natural draft is used. Products made from steel sandwich pipes, bricks or ceramics, which are discharged through the roof, are good for this. They are heat-resistant and create strong draft, ensuring the release of fuel combustion products into the atmosphere. This output design is typical for an open circuit.

The removal of combustion products is carried out through natural draft using a chimney.

If the boiler is equipped with a fan to forcefully remove harmful compounds, then a coaxial chimney is used. It is designed in the form of 2 pipes of different diameters, nested inside each other. An exhaust air stream containing harmful impurities is created in the internal cavity, which must be removed.

At the same time, fresh fuel enters the combustion chamber through the external circuit to maintain combustion. Since the gases are removed mechanically, it is enough to place the coaxial pipe outside through a hole in the wall.

Service life

The service life of gas equipment is determined in the technical passport of the boiler and ranges from 10 to 15 years. However, with regular maintenance and prevention, it can last much longer. The regulatory services may establish additional requirements for service life.

This may be due to the presence (or absence) of spare parts that are needed in the process of maintaining full operation of the boiler. If during the repair some part is required, and the manufacturer has stopped producing them, it may be necessary to replace the boiler as a whole with a more modern one and one equipped with spare parts.

Circulation pump operation

What the performance indicators of the circulation pump will be depends, first of all, on the power at which the boiler operates, and this device does not have much influence on the operation of the entire system. It is very important that the pipes through which the coolant circulates are made of high-quality material, for example, steel or good plastic.

First start

Before starting the gas water heating boiler for the first time, it is necessary to check the correct installation and installation, in compliance with all instructions. The installed boiler must be inspected by a gas service inspector and sealed. After which you can begin preparing for the first launch. Before starting, the automation is configured with the required parameters set, following the operating instructions supplied with the boiler.

We recommend: Replacing a gas water heater in an apartment: standards and requirements for replacing a gas water heater

Filling the system with coolant

Step one is to fill the system with water or another coolant. The entire circulation circuit is checked for the presence or absence of “air” plugs in the system.

If present, air pockets must be vented by slowly releasing air through a special valve. Most often this is found on heating elements. Etching must be carried out with caution, with the readiness to close the valve in time.

Checking the supply lines

Step two is to check gas pipes, valves, and shut-off valves for leaks. The inspection is carried out by a gas service employee. But if you smell a specific gas smell, you can check it yourself before a specialist arrives and find the leak. For this, use a regular soap solution.

By applying it to welds, at the joints of pipes and shut-off valves, you can detect gas leaks.

Putting the boiler into operation

Step three is the direct start of the gas water heating boiler itself. Carry out strictly according to the attached instructions. If you can’t figure it out on your own, then it’s better to contact specialists who have access to this type of work.

Boiler shutdown

At the end of the heating season, if the boiler is not planned for use in the hot water supply system, then it must be turned off for a long period. To do this, follow a few simple steps:

- turn off the gas supply, make sure that the burner in the boiler goes out completely;

- turn off the power supply to automatic ignition and automation;

- shut off the water supply to heating and water supply.

No special additional actions are required. Do not drain the entire coolant circulation system to avoid corrosion.

How to eliminate boiler clocking in heating mode

Adjusting the minimum power of the Gepard or Panther boiler through the service menu

At the first stage, in the service menu, as described above, we find line d.0 , press the “mode” button and look at the value of the boiler power parameter, kW, on the display. In our example, the factory setting =15 was visible. It is necessary to set a new boiler power value equal to the power of the heating devices connected to the boiler. This setting will only work in heating mode.

For our example, using the “-” button we set a new boiler power value = 9 (the minimum possible setting corresponds to 8.5 kW.). The newly established value of the minimum boiler power (8.5 kW) is still very different from the power of the heating devices (4 kW).

If the power of the heating system corresponds to the operating range of boiler power

The maximum power of the heating system in the house may fall within the operating power range of the boiler specified in the instructions. For example, the total maximum power of radiators in a house is 14 kW. The operating power range of the Protherm Gepard 23 MTV boiler is 8.5 - 23.3 kW. To eliminate boiler clocking in this case, we act similarly to what was described above, but with the only difference: at the first stage, in line d.00 we set parameter =14.

I recommend trying to set the boiler power to 20 - 30% less than the heating circuit power, for example, d.00 = 11 kW. This power should be enough to compensate for heat losses at home, since the power of radiators is usually chosen with some reserve.

Increasing the anticycling time

At the second stage, we increase the anticycling time in line d.02 of the service menu.

Factory setting d.02 = 20 minutes. According to the schedule (see above), we determine that, for the heating water temperature set on the display of 70 ° C, restarting the burner is possible after 4 - 5 minutes, not earlier.

In line d.02 we set a new value for the anticycling time, for our example the maximum possible = 60 minutes. Line d.67 displays the time in minutes until the boiler is turned on again. Breaks in burner operation became approximately 10 minutes long. Twice as much as with the factory setting, which is still too often.

Increasing the anti-cycling time results in the burner turning on later, at a lower heating water temperature. The heat flow from the boiler to the heating circuit is reduced.

Thus, by selecting the settings of the boiler power and anti-cycling time through the service menu, we ensure that the cycle duration between turning on the boiler burner is at least 15 minutes. That is, the boiler should be turned on no more than four times within one hour.

I note that not all brands of gas boilers have the ability to adjust the anti-cycling time. In this case, you only have to select the boiler power settings.

On some brands of gas boilers, the rotation speed (performance) of the circulation pump is set manually using a switch on the pump. To reduce the boiler clock, it is recommended to increase the pump speed.

Setting up a Gepard or Panther gas boiler for power below the minimum

At the third stage , the minimum power is adjusted .

Such adjustment is not necessary in all cases, but only when the first and second stages do not bring the required result. As in our case, when the power of the heating system (4 kW) is significantly less than the minimum power of the boiler with the factory setting (8.5 kW).

It should be noted that adjusting the boiler power using the method described below is also useful in other cases, since it allows, through an experiment, to adjust the heating power of the boiler in accordance with the actual power of the heating circuit. The actual power is usually less than the calculated one.

Before carrying out work on setting the minimum burner power, you must:

- Fully open thermostatic and other valves on radiators and set the room thermostat to maximum temperature. The thermostat that controls the heated floors is set to the maximum permissible temperature so as not to overheat the floors.

- In the user menu of the boiler, set the maximum operating temperature, which is set by the owners in the coldest weather, adding another +5 °C. Usually this is not less than 65 °C. If the owners do not remember it, or on a new boiler, set the factory setting of the maximum temperature of 75 ° C in the menu. The boiler burner will have to automatically turn off at a temperature 5 °C higher, i.e. at 80 °C.

- Cool the heating circuit to a heating water temperature below 30 °C.

Next, we start the burner in heating mode, select line d.52 , press the “mode” button and see on the display the value of the gas valve stepper motor position parameter in the factory minimum power mode.

By removing the front cover of the boiler, we visually observe the size of the flame in the burner. In our example, the factory setting was displayed on the display, the number = 72, and the flame height in the burner was quite high.

Using the “-” button we set a new parameter value in line d.52, for example =20. 3 seconds after the change, when the new value is automatically confirmed, we observe a significant decrease in the flame height in the burner. This indicates that the useful power of the boiler with the specified setting will be greatly reduced.

Next, observe on the display the increase in temperature in the direct heating pipeline at the outlet of the boiler. Typically, the temperature increase stops when it reaches a value less than the set value, for example 52 °C. The boiler is running, but the temperature does not increase (or changes very, very slowly). This means that a power balance has been achieved between the boiler and the heating system at this established water temperature. At this moment, we increase the parameter in line d.52 of the service menu, set a new value = 30 - the temperature begins to rise again and stops again, for example at 63 ° C. Again we add the parameter value in line d.52 =35 and so select the parameter until the temperature stops at a value slightly higher than the maximum, for example 77 °C. In this way, a balance is achieved between the power of the boiler and the heating circuit at maximum operating temperature. The boiler power will be set to the minimum level required to operate with the connected heating circuit. In this case, the cyclic operation of the boiler will be minimal.

If the radiators do not warm up well in height, the temperature difference in the forward and return pipes at a maximum temperature is more than 15-20°, then increase the response pressure of the bypass valve. Read below on how to adjust the bypass valve. The water temperature in the forward and return pipelines can be seen on the display if you enter the service menu, lines d.40 and d.41.

In case of adjusting the bypass valve, the gas valve setting in line d.52 must be repeated.

In our example, the burner heated the water to a maximum temperature of 77 oC with a minimum parameter value in line d.52 equal to =28 (factory setting was =72). With a lower parameter value, the burner could not heat the water to the specified temperature. And at a higher value, the burner heated the water to 80°C and the boiler automatic switched off the combustion.

It should be noted that the method described above for adjusting the gas valve, which allows you to balance the boiler power with the power of the heating circuit through an experiment, is not included in the recommendations of the boiler manufacturer. This is the idea of the author of the article, successfully implemented when setting up autonomous heating systems with gas boilers.

Factory setting of the gas valve

Honeywell gas valve. 1 - fitting for measuring the gas pressure at the outlet to the burner; 2 - fitting for measuring inlet pressure.

The boiler manufacturer prescribes setting the minimum power on the gas valve as follows:

In line d.00 of the service menu, set parameter =9, which limits the boiler power to the minimum level specified in the instructions. Turn on the boiler in heating mode.

A pressure gauge tube is connected to the upper fitting at the gas valve outlet. Before connecting, it is necessary to unscrew the locking screw on the fitting 1-2 turns.

Call line d.52 of the service menu. And using the + and - the value of the line parameter d.52 , set the minimum pressure at the gas valve outlet specified in the boiler operating manual. For example, for a Gepard 23 MTV boiler, the minimum pressure in front of the burner is 1.5 mbar or 15.5 mm water column.

This setting will ensure that the boiler operates with the minimum power specified by the manufacturer - 8.5 kW. The boiler manufacturer's service instructions do not answer the obvious question of what to do if the power of the heating circuit connected to the boiler is less.

In our example, after setting and setting parameter =28 in line d.52 , measuring the pressure at the outlet of the gas valve in front of the burner showed a value of 4 mm.water column.

A home mechanic can roughly assess whether the gas valve settings correspond to the factory settings without resorting to measuring the gas pressure on the valve.

To do this, set parameter =9 in line d.00 of the menu and turn on the boiler in the minimum heating power mode. Record gas meter readings. After 15 minutes (1/4 hour), the meter readings are recorded again and the gas consumption during this time is determined. For example, we determined the gas consumption from the meter to be 0.289 m3/15 min. This value is multiplied by 4 and the gas consumption calculated for 1 hour in the minimum power mode is 1.156 m3/hour. Compare the obtained value with the data from the factory instructions. For example, the standard gas consumption in minimum power mode for the Gepard 23 MTV boiler is 1.15 m3/hour. Gas consumption according to the meter readings approximately corresponds to the factory norm. We conclude that setting the gas valve in minimum power mode meets the requirements of the factory instructions. If not, then the gas consumption is adjusted by changing the parameter in line d.52.

Similarly, based on gas consumption, you can evaluate the setting of the gas valve at maximum power by switching the boiler to DHW mode.

U-shaped pressure gauge

A simple pressure gauge for measuring a gas valve can be made from a clear plastic tube, filled with water and bent into a U shape. One end of the tube is placed over the valve fitting and the other is left open. A ruler is used to measure the difference in water levels in the branches of the tube. The measured distance will be equal to the pressure in millimeters of water column - mm.water column.

A tube with an internal diameter of 8 mm can be tightly pulled onto the gas valve fitting. For a tube of a different diameter you will have to select an adapter.

At the end of the measurements, do not forget to carefully tighten the screw on the measuring fitting and check its tightness.

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the Proterm Wolf KSO floor-standing boiler. These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.

Schematic diagram of a gas boiler with an open combustion chamber.

Figure 3

1 Safety relief valve (3 bar) 2 Gas fittings 3 Primary filter 4 Ignition transformer 5 Injection burner 6 Temperature sensor PL (NTC) 7 Ignition electrodes 8 Combustion chamber 9 Primary heat exchanger 10 Draft stabilizer 11 Flue gas thermostat 12 Expansion tank 13 Ionization electrode 14 OL temperature sensor (NTC) 15 Automatic air vent valve 16 Circulation pump 17 Heating system pressure sensor 18 Bypass with adjustable bypass valve 19 Three-way priority valve 20 Secondary plate-type heat exchanger 21 Cold water flow sensor 22 Cold water filter 23 Make-up valve 24 Drain tap

A PL – flow line B Hot water outlet C Gas inlet D Cold water inlet E OL – return line F Drain pipe

Safety regulations

Remember, gas is a common cause of explosions and fires. Therefore, treat fire safety techniques with respect, follow the requirements and instructions.

Frequently encountered dangerous malfunctions and methods of elimination according to safety rules:

- flame failure is a moment during which the flame extinguished, but the gas supply did not stop. The solution is to turn off the gas supply and open the room in which the boiler is located for ventilation. During ventilation, it is strictly forbidden to use open fire, turn on and off electrical appliances, lighters, etc.;

- decrease in the filling of the circulation circuit with water - occurs when there is a water leak. If a leak is detected, turn off the boiler, but under no circumstances start filling the circulation circuit. Wait until it cools down completely, find the leak, and fix it. After which you will have to fill the circulation circuit again;

- the draft in the chimney has disappeared - stop the boiler and clean the chimney. Ventilate the room. When the draft resumes, return the boiler to operation;

- The pilot light goes out - turn off the boiler, carry out the switching procedure according to the passport and the attached instructions.

Do not forget that a gas boiler is a high-risk device; such equipment must be operated strictly according to the instructions, in compliance with full fire safety measures.

What to do if problems occur

Let's look at breakdown situations using the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may arise that require prompt correction.

The following problems may appear in Baksi models:

- the burner does not light;

- during operation, popping noises are heard in the firebox;

- the boiler overheated;

- the device is very noisy;

- The sensor has failed.

The probable causes of breakdowns are associated both with violations of operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality coolant;

- the pressure in the gas pipeline has decreased;

- voltage drop in the electrical network;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

Low gas pressure

The gas pressure in the gas main varies significantly depending on the time of year. In winter, when the maximum number of consumers is turned on, gas pressure often approaches the minimum permissible. Old-style domestic equipment may completely shut down in such situations due to low pressure.

Modern boilers still function, but they can no longer produce their full power. This is not as noticeable when heating the heating system as when the boiler is operating to heat hot water, when consumers notice that the water coming from the tap is lukewarm. Only a service engineer who has a special knowledge of the equipment. And if the static pressure is 130 mm. vd. Art. at the inlet to the gas valve, then we can immediately assume that there will not be enough gas in the dynamics, and the boiler will not produce its full power if necessary. With a further decrease in pressure, the power of the equipment will also decrease.

This value can be determined from a graph of the dependence of thermal power on gas pressure at the burner, provided by the equipment manufacturer. They are considered the most resistant to a decrease in gas pressure. In the event of a drop in blue fuel pressure, the service engineer is unable to influence the situation and must contact the gas utility.

Classification by power level of gas boilers

There are several power levels for gas boilers:

- A single-stage gas boiler operates at the same power level.

- Two-stage gas boiler. The full power of the equipment is needed throughout the heating season, so this model is more economical and helps to increase the service life of the unit.

- The most efficient boilers with the ability to modulate power.

Gas boilers differ in efficiency and operating principle due to the following factors:

- Case material – cast iron or steel;

- Ignition type – piezo ignition or electric;

- The heat exchanger is made of copper, cast iron or steel.

An autonomous heating system cannot have such troubles as irregular operation of centralized heating. If you choose the right heat generator, the room will have a comfortable climate and energy costs will be minimal.

You can buy a gas boiler in our online store.

Requirements for the chimney and other parts

The chimney needs to be made of steel, preferably stainless. There must be cleanout hatches and the ability to drain condensate. At the bottom of the chimney there is a pocket intended for deposits.

We recommend: GSM module for boiler - functions, models and prices, setup instructions

The outside of the chimney is subject to additional thermal insulation. The insulation material must be protected from precipitation and condensation.

The chimney should be 2-3 cm higher than the boiler outlet. The height of the chimney must be at least 5 m. The chimney is installed in the receiving plate of the vapor trap. In this case, condensate should not get inside the boiler.

The pipe cut should not fall on the wind support area.

What about an atmospheric expansion tank? It must be installed at the highest point of the entire structure. It is preferable that it be located inside the room.

The boiler supply pipeline must be equipped with a safety group and a thermometer. The boiler itself is strongly not recommended to be installed in openings, niches and other similar hard-to-reach places.

Regulation of gas supply to the boiler and water circulation in the system

If you screw the gas burner on, the gas will flow in a smaller volume, the flame will become smaller and the resulting temperature will be lower.

In modern boilers, this process occurs automatically: the temperature is controlled and switches to the required mode independently. If the burner goes out, the incoming gas will not be able to burn and will pose a danger to the premises and its occupants. There are auto mechanisms that can regulate this process and determine whether the system is ready to supply gas. If not, the gas simply does not flow. To heat the room faster by circulating water in the heating system, boilers are equipped with pumps. Thus, depending on the type, class and model of the boiler, the following can be installed in it:

- pump;

- control system;

- safety system;

- protection and diagnostic systems.

Most modern models are equipped with automatic gas supply, emergency protection and temperature control: they independently monitor the operation of the pump, the current state of the thermal level and switch modes and states without manual intervention. The person who bought the boiler does not have to interfere with its independent operation, unless, of course, the device is working properly. And in case of failure of one or another unit or mechanism, maintenance of gas boilers is provided.

Number of circuits in a gas boiler

A gas boiler can have one or two circuits. Let's take a closer look at each type:

- A single-circuit boiler is used only for heating the room. In order to heat water for household needs, you will need to install a boiler. A more economical option is a instantaneous water heater, and the optimal option is an indirect heating boiler.

- A double-circuit gas boiler heats the room and heats the water.

If you need a large amount of hot water, then a double-circuit boiler will not cope with it. The best option would be to install a single-circuit boiler with a built-in boiler of the required volume.

What can you save on when using a gas boiler?

Saving and its reasonable calculation is a particularly pressing issue when it comes to heating and choosing a boiler. In terms of savings, expert reviews of floor-standing boilers agree - floor-standing ones are less resource-consuming.

Competent installation

Experts also agree that efficient, reliable and economical operation of the boiler is only possible with proper organization of not only the installation of the boiler itself, but also the entire heating system

In addition, it is important to take into account all measures to prevent equipment failure, since repairs and servicing of gas boilers are also significant material costs, which in turn can also be reduced by promptly contacting a gas boiler service center, as well as by drawing up a service agreement gas boiler.

Do-it-yourself boiler cleaning

Washing heat exchangers yourself can also reduce costs if you choose the appropriate type of device that allows you to do this procedure yourself. It is important, also from the point of view of economy, that the gas boiler in a private house must be grounded. You can get acquainted with the main types of gas boilers for heating a private home here. Even if the boiler has been in operation for a long time, but this requirement has not been met, it should not be neglected: it is worth learning how to ground a gas boiler in a private house and carry out this procedure.

Choosing a gas boiler

A means of saving is the choice of boiler itself. Cheap, more expensive, with or without automation, what you can win at the very beginning and in subsequent operation - all this is important to take into account and calculate. A striking example of the ambiguity of calculating savings on heating can be the purchase of an AGV type boiler (gas water heating unit), which means the cheapest type of old, Soviet-style boiler with primitive automation. The standard AGV gas boiler has a very low price, but also low efficiency, but does not require electricity. Only an accurate calculation will help determine the degree of savings when using this device. You can read about domestic gas boilers in our article “Russian-made gas boilers: varieties and properties”. It is also important to determine the potential problems of certain boilers when choosing the optimal model. For example, a MORA gas boiler will constantly suffer faults until it fails in conditions of instability of the electrical voltage, with the slightest setting errors and lack of water in the system. And the reviews for the Master Gas Seoul gas boiler are contradictory at first glance, but they provide information about the vulnerabilities of this model - the accumulation of combustion waste in the boiler, which leads to noisy fan operation, leaks and unstable water temperature during supply, while with its main functions, heating, this model copes well. Probably, every budget model has features of this kind that, under certain conditions, may not appear, thus justifying savings on the purchase, and with knowledge of the structure of the boiler, as well as the strengths and weaknesses of each model, you can not remain indifferent and not let the situation go left to chance, but to manage the level of comfort and the amount of costs when operating heating equipment.

To begin with, you need a reasonable choice of power

Attempts to optimize the operation of the heating system will be completely pointless if the rated power of the boiler is far from the required one. Moreover, it doesn’t matter which way.

- With a clear lack of power from the heating unit, with the onset of cold weather in some rooms, or even in the entire house at once, it will be clearly cool, to say the least. Moreover, it is impossible to eliminate this drawback with any settings - “you can’t jump over your head.” All that remains is to rely on additional electric heaters and plan to replace the boiler with a more powerful one in the foreseeable future.

- With an overly powerful boiler, it would seem that the owners have a trump card on their hands - a solid operational reserve! But this is only at first glance …

The problem is that thermal equipment is mainly designed and calculated for power close to the upper limit of the rating range. It is under such conditions that the boiler will show all the advantages inherent in it by the designers. A reduction in power is possible (this is what the range is indicated for), but this is inevitably accompanied by a decrease in efficiency.

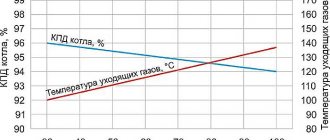

Range of total (Q) and useful (P) boiler power. Please note that the minimum and not the maximum, but the nominal limits are shown. That is, the optimal mode with maximum efficiency is to operate the boiler at the highest power levels.

By the way, indicate the decrease in efficiency with a decrease in power in the passport or on the product nameplate. This information is usually only available in the service instructions.

For example, the instructions for the “Protherm Gepard 23 MTV” boiler directly state that with a rated power of 23.3 kW, the efficiency indicator (η) reaches 93.2%. And if the equipment operates at the lower end of the power range (8.5 kW), then the efficiency drops to 79.4%. That is, in reality, it turns out that when operating in low power mode there is a significant loss of performance - a considerable part (more than 20%!) of the expended energy simply burns out, without bringing any benefit to the consumer.

I don’t even want to think about the efficiency value if the real demand of the heating system is less than the lower limit of the power range... However, such “curiosities” do occur.

And to avoid them, it is necessary to purchase a boiler with power indicators that are adequate to the real needs of the existing or planned heating system. That is, to carry out preliminary calculations.

For such calculations, a ratio is often proposed: 100 W per square meter of heated area. However, this “algorithm” does not take into account the specific climate of the region of residence and the location of the building on the ground, nor the characteristics of the house itself and each of its premises. And therefore, a considerable mistake in one direction or another is likely.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Therefore, let me offer you another solution to begin with - a special calculator for determining the required thermal power. It evaluates each room of the house, taking into account many criteria. The sum of all heated rooms will give a very accurate idea of the total thermal power of the system. In addition, the obtained value for the room will allow you to correctly select heat exchange devices for it - radiators, convectors, etc.

Below is an explanation of the calculation procedure.

Calculator for calculating the thermal power of a heating system

Go to calculations

Explanations for calculations

We repeat - the calculation is carried out for each of the premises of the house or apartment individually. The sum will give the total heating power requirement.

To simplify your task and save the results obtained for the future, you can, armed with a plan of your property, draw up a plate in which you can indicate, line by line, all heated premises. And then determine according to the plan and write down all the necessary data for each of the rooms. This will be, perhaps, the most difficult part of the calculations, since the calculator will take care of the rest.

On a copy of the plan, you can indicate the directions of the cardinal points (here the wide blue arrow shows the North) and, if information is available, the predominant direction of cold winter winds (“wind rose” for the winter).

An example of a sign is shown below - it is not tied to the plan taken solely as an example, just as a proposed design option. And now we will briefly go through the requested data.

| Name of the room, its area, ceiling height. Insulation of the floor, which is located above and below | The number of external walls, their orientation to the cardinal points and relative to the winter “wind rose”. Quality of wall insulation. | Number, type and size of windows | The presence of doors to the street or to an unheated room | Required thermal power |

| 1. Hallway. 3.18 m². Ceiling 2.8 m. Floor laid on the ground. Above is an insulated attic. | One, South. Average degree of insulation. Leeward side | No | One | 0.52 kW |

| 2. Hall. 6.2 m². Ceiling 2.9 m. Insulated floor on the ground. Above is an insulated attic | No | No | No | 0.62 kW |

| 3. Kitchen-dining room. 14.9 m². Ceiling 2.9 m. Well-insulated floor on the ground. Upstairs is an insulated attic. | Two. South, west. Average degree of insulation. Leeward side | Two, single-chamber double-glazed windows, 1200 × 900 mm | No | 2.22 kW |

| 4. Children's room. 18.3 m². Ceiling 2.8 m. Well-insulated floor on the ground. Above is an insulated attic | Two, North - West. Full insulation. Windward | Two, double-glazed windows, 1400 × 1000 mm | No | 2.6 kW |

| 5. Bedroom. 13.8 m². Ceiling 2.8 m. Well-insulated floor on the ground. Above is an insulated attic | Two, North, East. Full insulation. Windward side | Single, double-glazed window, 1400 × 1000 mm | No | 1.73 kW |

| 6. Living room. 18.0 m². Ceiling 2.8 m. Well-insulated floor. Above is an insulated attic | Two, East, South. Full insulation. Parallel to the wind direction | Four, double-glazed window, 1500 × 1200 mm | No | 2.59 kW |

| 7. Combined bathroom. 4.12 m². Ceiling 2.8 m. Well-insulated floor. Above is an insulated attic. | One, North. Full insulation. Windward side | One. Wooden frame with double glazing. 400 × 500 mm | No | 0.59 kW |

| TOTAL: | ||||

| Area 78.5 m² | 10.87 kW ≈ 11 kW |

So, for the calculations you will need to clarify and indicate the following data in the calculator for each of the premises:

- What temperature is typical for the region in the coldest decade of winter. It is clear that this indicator will be the same for calculating all rooms - it simply characterizes the climatic features of the area. So there is no point in putting it in the table - you can specify it during the first calculation, and then simply not change it.

Important - this should be a minimum, but normal temperature for your region.

- The area of the room and the height of the ceilings - there is nothing to explain here.

- The number of external walls, that is, the reverse side in contact with the street or a cold unheated room.

- The side of the world towards which the outer wall faces. The idea is that walls in the South or South-West can receive a “solar charge”, unlike their “antipodes” in the North and North-East, which never see the Sun.

- If the direction of the prevailing cold winds in winter is known, then this factor can also be taken into account. If there is no such inflation, leave it at default, but then the calculation will proceed as for the most unfavorable, quickly cooling windward side.

- When assessing the degree of wall insulation, one should proceed from the fact that the thermal insulation that is completed on the basis of thermal engineering calculations is considered complete. If there is no such confidence, then it is better to leave the medium level - this approximately corresponds to brickwork of two bricks (approximately 500 mm) or a log house with a wall thickness of at least 200 mm. Well, the walls of a residential building should not be uninsulated - you will simply go broke on heating!

- Next, you have to choose from the proposed lists the option of insulating the floor or adjacent to the rooms above and below.

- An entire block of fields is dedicated to windows. You have to indicate their quantity and quality - choose from the list of proposed options. In addition, the calculator asks for size. The glazing area is automatically calculated and compared with the area of the room, on the basis of which a correction factor is introduced into the calculation.

- Finally, the number of doors leading from the room to the street or to a cold (unheated) room is indicated. This is understandable: each opening of the door means an influx of a considerable volume of cold air, which requires a certain compensation.

After that, press the calculation button - and the result for a specific room is ready. There is no need to add anything to it - the operational reserve is already included in the fact that the calculation was carried out for the most unfavorable conditions.

The total value for all rooms of a house or apartment is a guideline for purchasing a heating boiler. For example, in the table above it turned out to be 10.87 kW. They select a model that, of course, has slightly more power, but best of all is the closest one in the direction of increase. That is, in this example, let’s say, choosing a boiler with a capacity of 11.6 kW would be appropriate.

* * * * * * *

What to do if, for some reason, a boiler with too much power has already been installed, and its replacement is not planned for the foreseeable future. Is it possible to optimize the operation of the heating system?

It turns out, yes, many modern models allow you to make adjustments, those that, if they do not bring the boiler to the optimal mode, will at least bring it to a level as close as possible to the nominal values.

Basic recommendations for the operation and repair of gas boilers

- Do not open the gas valve under any circumstances. All work related to gas must be performed by a specialist. You shouldn't put your life in danger.

- As a last resort, if you have basic knowledge about the operation of gas boilers , you can check the filter at the gas pipeline inlet. Before doing this, be sure to turn off the tap, unscrew it and check the gasket.

- 80% of problems during operation of a gas boiler occur due to phase zeroing when the wire plug is incorrectly connected to the socket. For example, one of the family members unplugged the boiler and unknowingly put the plug back in the wrong position. First of all, you should pay attention to this and try to put the fork in the correct position. If this is the problem, the system will reset the error and the boiler will start working. This completes the repair of the gas boiler. In order not to get confused about the correct phase setting, you can make marks on the plug and socket with a marker, mark the pin and the corresponding hole.

- It is necessary to check the gas pressure; this can be done visually, for example, by the boiling time of the kettle. If the kettle boils longer than usual, half an hour instead of ten minutes, then the pressure is low.

- Coolant circulation. Filters are installed at the inlet to protect the boiler from debris and scale that enters it from old or low-quality systems during operation of the gas boiler. A layer of dirt forms inside the pipes, and circulation in the boiler is disrupted. In this case, you need to make sure that the system is not clogged with debris - unscrew the filter and check it. In case of contamination, rinse the filter thoroughly and replace it.

- Be sure to check the chimney. Various contaminants may appear inside the pipe during operation of a gas boiler, for example, wasps can nest comfortably in it or build a hive right in the chimney. In addition, if water enters the chimney from the outside, ice may form, preventing air from escaping. A sign that the problem is in the chimney will be a strong spread of flame when the boiler is turned on. In this case, the pipe must be cleaned and the ice removed. Clean the chimney pipe regularly.

- Before first use and throughout the operation of the gas boiler, you should turn the rotor of the circulation pump as follows: unscrew the washer, place a piece of cloth and use a screwdriver to turn the rotor clockwise. Due to the tightness of the pump, movement will be difficult, but after that the work will be restored.

- Check the operation of pressure, temperature sensors, etc., after turning off the boiler. Make sure the contacts are connected - disconnect the wire from the sensor and insert it back, this way the electrical connection is restored.

- There is a burner inside the boiler that requires regular cleaning. This can be done using sandpaper, carefully clean the ionization and ignition contacts and the burner field from plaque.

- If during operation of a gas boiler there is loud noise and vibration coming from it, it is necessary to check the fan, which may become clogged from dust getting into it. If there is dirt on the fan blades, operation will be disrupted. Contamination must be eliminated to restore normal air circulation and normal operation of the gas boiler. Lubricate the bearings. If the fan continues to spin poorly, then the bearings need to be replaced.

- The system is equipped with a press control - a mechanism that serves to close the circuit when the fan is turned on, which protects the boiler from fire. Two tubes supplying pressure and vacuum are connected to it. This element also needs to be checked. When the fan is turned on, a click is heard, indicating that the contacts in the press control are closed. If the fan malfunctions, the press control will also be faulty.

We recommend: Fiber cement panels: what they are, pros and cons, characteristics, manufacturers, reviews, installation

Why does a gas boiler turn on often: reasons

When connecting a gas heating boiler, you must carefully observe all the nuances of connecting the unit to the heating system. The service life of the equipment depends entirely on this. All gas boilers must be turned off and on periodically in order to maintain the required comfortable temperature. If the boiler turns on too often, it means there is a problem with the system. It is necessary to identify the reason for the device clocking.

Clocking is the frequency of switching on of a device that provides heating of the thermal fluid. If no external devices are connected to the unit, the frequency of the time interval between turning on the boiler does not exceed 10 minutes. And by default, such indicators are only three minutes.

Frequent turning off and turning on of the boiler is not normal for the operation of the device.

To significantly save gas consumption, it is necessary to choose a method of continuous operation of the unit with compensation for heat losses. The main reasons leading to device clocking:

- Boiler overheating due to high power;

- Gas is supplied at an insufficiently high pressure level;

- Incorrect operation of the thermostat;

- Malfunction of the pumping device;

- The filter is clogged with dust, dirt, soot, and scale.

If the room is small, sometimes there is excessive gas consumption. Based on this, when purchasing the boiler itself, do not be lazy to correctly evaluate its technical parameters and all the points that play an important role during operation. It is worth noting that the devices of different models often have significant differences. This implies that it is necessary to be extremely careful in studying the instructions before installing the equipment.

The boiler is operating at too high a power

Operating a gas boiler at maximum power levels ensures rapid heating, but in addition to this, pulsed operation of the boiler. The degree of heating depends on the characteristics of the gas burner. When hot return flow arrives, the boiler turns off. After the return has cooled, the boiler starts up again. The problem of frequently turning on a gas boiler during the off-season is especially pressing.

Buying a room thermostat will help you cope with this problem. If the room temperature reaches the required value, the boiler will “receive” this data from the thermostat. Then it will turn on much less often and work for a longer time.

The most important factor is to find out the most suitable power of the device, depending on the climate where you live, the total area of your home and how well your home is insulated. Condensing boilers used in heating systems with extremely low temperature conditions are in great demand. These impeccable models of units provide heating of the coolant in the return circuit at values of 60°C.

Automatic control of burner power of heating boilers

Exceeding the permissible power value

When purchasing a gas boiler for autonomous heating, the power of the device is taken into account depending on the area of the room. If the power is excessively high, the unit increases the temperature as quickly as possible and turns off. This is repeated with noticeable frequency every day, thereby causing irreparable damage to the elements of the heating system. The service life will noticeably decrease, and heating will become extremely unprofitable.

Insufficient gas pressure

Depending on the time of year, the level of gas pressure in the device varies. With the onset of winter, a huge number of residents are connected to centralized heating, due to this, pressure levels in the system are reduced to minimum values. In this case, the boiler continues to work properly, but the service life of the equipment is reduced significantly. Currently, several methods of fuel modulation are used:

- direct relationship between flow and constant temperature - hydraulic modulation;

- indirect relationship based on a temperature sensor - electronic type modulation;

- current in a closed circuit with a signal to the control unit - ionization type modulation.

Errors in automation operation

Another common cause of device malfunctions is incorrect functioning of the automation. The thermostat and temperature sensor are installed on the outlet pipe of the primary heat exchanger. These elements monitor temperature readings and protect equipment from overheating.

Gas boiler automation

Errors that adversely affect the operation of automation:

- Weak contact or lack of pulse from the gas sensor;

- Errors in signal receipt and false alerts about device overheating;

- Reduced pressure in the system;

- Incorrect installation of the device;

- Poor performance of the ventilation system;

- Thermal sensor malfunction;

- Malfunction or malfunction of the temperature sensor;

- Incorrect ignition.

It will be quite difficult to troubleshoot problems on your own without the proper experience and level of training. We strongly recommend that you seek the help of specialists.

Causes of low pressure in the line

Incorrect operation of a gas boiler may be due to low pressure in the line.

- Dirty filter. It is necessary to remove blockages and clean the filter from dirt.

- The fuel meter is broken or damaged. It is easy to recognize by hearing a characteristic hum. The values on the automation vary, and the needle may remain stationary. In this case, you also cannot do without the help of a specialist.

- Response of protection sensors in the event of a gas leak. The automatic system, when a threat is detected, instantly turns off and blocks the gas supply. You may smell gas in your home. You must immediately completely disconnect the unit from the network and call specialists from the gas service.

Power surges

Gas boilers, or rather, their electronics, operate directly from electricity. The boiler has a built-in power voltage sensor. When disconnected from the electrical current supply or a malfunction in the network, the device turns off and turns on when the voltage returns to normal. In order to protect the unit, a UPS is installed. The uninterruptible power supply will continue to operate for some time after the power is turned off.

Incorrect thermostat installation

When installing the thermostat, you cannot make a single mistake. Thermostats are divided into two types: built-in and remote. Incorrect installation of the remote device leads to incorrect functioning of the heating equipment. The ideal option would be to install it in a room that cools down the fastest.

Installation of a remote gas boiler temperature sensor

There are two types of thermostats: built-in and remote type. The first option is not distinguished by its mobile properties. It is very important to install remote models correctly. It is advisable to carry out installation not in the coldest room, but in one that cools quickly. This will have a positive effect on the operation of the heating system. The installation of thermostats is strictly prohibited:

- in the basements of houses;

- near window and door openings;

- next to household appliances;

- at a small distance from the ceiling or floor;

- under direct exposure to sunlight.

Installation of thermostats in kitchens is not recommended.

The filter is clogged

When the filtration unit is contaminated, there is a sharp decrease in heat in the boiler unit. The result is that a small amount of liquid heats up too quickly. The boiler stops operating normally until the installation has completely cooled down. Then the device turns on, as if realizing that the return is still cool.

The thermal fluid passing through the heating system through public pipelines can contain colossal amounts of dirt and various impurities. For this reason, it is advisable to install a mesh model water filter in front of the circulation pump.

The gas boiler should turn on after the system has completely cooled, but the sensors receive information that there is no overheating, and then the sensor turns on. And this happens countless times during the day. Clogging occurs due to the presence of dirt and other impurities in the water passing through the utility pipeline.

Incorrect installation of the circulation pump

The circulation pump promotes proper water circulation. It arranges the work so that the water flows back into the boiler, already at a warm temperature, reducing the further heating stage. When a circulation pump is connected, gas and electricity consumption is noticeably reduced. An unprofessional installation of the circulation system will cause the unit to constantly turn on and off. In this case, the device goes out, lights up and goes out again. Then the boiler makes characteristic sounds.

Chimney blockage

Various objects that can be blown in by the wind, as well as birds, leaves, and debris often get into the chimney from the street side. This causes the pipe to become clogged. And in winter, the chimney may become covered with a crust of ice. The reason is the presence of condensation, because during the entire period of operation, steam is generated in the heating system, which enters the street through the chimney.

Icing can occur for several reasons:

- The steam temperature reaches 100 ºС. In models of modern boilers, this unpleasant feature is becoming increasingly common, leading to inconvenience.

- The chimney is very long, the steam simply does not have time to escape and freezes in the pipe itself.

- Reduced draft in the pipe due to narrowing of the hog.

- There is very little fresh air coming in.

- The chimney and pipe were made incorrectly.

If you get rid of the above problems, you can avoid significant problems and breakdowns in the heating system. After all, in winter there is a high probability that there will be a lot of moisture, and all of it will literally freeze into a crust of ice. A large amount of moisture will again freeze onto this crust, preventing waste resources from escaping. If ice appears, you need to get rid of it immediately. It is advisable to insulate the pipe itself. A clogged chimney will provoke endless turning on and off of the boiler, but the biggest danger lies in insufficient draft, then carbon monoxide will enter the room. And this is unsafe for the health and even the lives of residents.

Narrow pipe diameter

Often, a decrease in clearance in the pipeline system occurs due to blockages. If the riser is clogged, we see an increased resistance of sections of the heating system and a decrease in the amount of circulating coolant. When a blockage is detected, hydraulic, pneumatic flushing or cleaning is used to increase the diameter of the pipes.

Before starting the process, you need to make sure it is tight, disassemble and clean it. Hydraulic flushing involves creating a huge pressure of water flow through the pipeline system. The applied liquid, along with the dirt, is thrown into the drainage system. In order to increase the flow rate, you can use a mains, circulation or other type of pump.

Pipeline cleaning is carried out in cases where it is impossible to remove the blockage using standard flushing. For this purpose, the clogged narrowed section of the pipeline is turned off, after which the coolant is drained. To clean disconnected pipes, a thick and fairly elastic wire with a fixed brush is used. At the final stage of getting rid of pipes from narrowings, the heating system is assembled in the reverse order.

Why does a gas boiler click: 5 main reasons and ways to eliminate them

Pump faults

Users of gas boilers sometimes encounter various problems with the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the internal part. To prevent such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axle is forced to rotate using a flat screwdriver.

Free-standing equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is due to the presence of high temperature conditions at the boiler outlet, which can cause damage to the device. Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

How is the work inside the boiler regulated?

If the boiler is turned on and in working condition, sensors built into the control system check the temperature of the heating system and transmit the results to the thermostat.

A thermostat is a device responsible for automatically regulating a heating device in terms of maintaining the temperature set by the consumer. Sensors are an integral part of the thermostat. If the temperature based on the measurement results is below normal, the automatic system switches the heating device to heating mode, the water is heated in the heat exchanger and, using a pump, if any, is supplied to the pipes, distributing heat throughout the room.

The heating system is closed, that is, water, which acts as a coolant, constantly circulates through the pipes without changing its volume.

If the volume is disrupted, the entire system may not function correctly. Usually this is noticed in one way or another, for example, if a gas boiler is noisy, this may be evidence of a lack of water in the heating system, which in turn leads to overheating of the boiler. In such cases, check the thermostat adjustment (the device responsible for maintaining a constant temperature), if it is normal, check the water level and add it if necessary, providing the system with the necessary volume for normal functioning.

Hydraulic block of the boiler.

Figure 7

1 – Gas valve 2 – Safety relief valve 3 – Plate-type secondary heat exchanger 4 – Flowing water flow sensor 5 – Automatic air vent 6 – Screw providing access to the motor shaft to unlock it 7 – 2-stage pump 8 – Adjustment bypass valve 9 – Three-way valve motor 10 – Make-up valve

Condensation in the impulse tube

Symptoms of this situation - when there is a request for heating or domestic hot water, the burner does not ignite, but the circulation pump and fan turn on. There may be several reasons, from malfunctions of equipment components (fan, differential smoke relay, electronic board), to the influence of external factors, moisture ingress or condensation. Water in the boiler can be formed due to an incorrect slope of the coaxial set (for traditional boilers it should be negative, that is, 2-3° down from the boiler). The operation of the fan in the boiler unit is controlled by the control board using a device such as a differential smoke relay (or presosstat ). It is connected to the fan by pulsed silicone tubes (or one), depending on the manufacturer and operating scheme.

The pressure switch measures the pressure difference between the outlet of the blower side of the fan and the pressure inside the sealed combustion chamber. When the fan is turned on, a pressure difference is created in the pressure switch cavity, while the diaphragm acts through the rod on the microswitch and switches it. The cold air that enters for combustion is slightly heated by hot flue gases passing through the inner pipe to the outside. By acting on the chamber elements, it leads to their cooling and, under certain conditions, condensation of water vapor occurs. Even a small drop of condensate formed in the impulse tube can lead to equipment shutdown, because it will interfere with the transmission of the impulse to the pressure switch.

If this situation occurs, you must call a service engineer for repairs. But if the engineer cannot immediately arrive at the site, you can use a temporary solution - dry it with a household hairdryer. After opening the plug in the boiler, turn on the hairdryer and let it work for about a quarter of an hour. Thus, the combustion chamber warms up, which leads to evaporation of condensate. As a rule, this problem is solved by installing, instead of one connecting impulse tube, a set consisting of a tee and three tubes, where two are connecting impulse tubes, and condensate is drained through the third, or Just put on some insulation that will prevent the tube from cooling down significantly. This design is already used in many boiler models already in the factory version.

The main components of a wall-mounted boiler with a closed combustion chamber.

Figure 4

1 Safety relief valve (3 bar) 2 Gas valve 3 Primary filter 4 Ignition transformer 5 Injection burner 6 Temperature sensor (NTC) 7 Ignition electrodes 8 Combustion chamber 9 Primary heat exchanger 10 Sealed vacuum chamber 11 Differential combustion products flow relay 12 Fan 13 Coaxial air inlet-removal system for combustion products 14 Expansion tank 15 Ionization electrode 16 Temperature sensor OL (NTC) 17 Automatic air vent valve 18 Pump 19 Pressure sensor 20 Bypass with adjustable bypass valve 21 Three-way priority valve 22 Plate heat exchanger 23 Cold flow sensor water 24 Cold water filter 25 Charge valve 26 Drain tap A Supply line (FL) B Hot water outlet C Gas inlet D Cold water inlet E Return line (RL) F Drain pipe