Heating boilers have long gone beyond the category of outlandish novelties and have become a popular and profitable option for heating residential or public premises.

Practice has shown that the most economical and comfortable for the owner is a gas boiler.

It is capable of operating in automatic mode, consumes fuel economically, is reliable and durable.

There are two main designs of gas boilers - single- and double-circuit.

The debate about which option is better still continues and requires careful consideration.

What is a wall-mounted single-circuit gas boiler and what is the difference from a double-circuit one?

A wall-mounted boiler is a heating unit. which is installed on a solid (load-bearing) wall. This installation method requires light weight and size, which is a plus in a residential environment.

A single-circuit boiler is a device that heats, prepares and supplies coolant to the heating circuit. Double-circuit boilers, in addition to the basic function, are capable of preparing hot water for domestic needs.

At first glance, it is much more convenient to use a double-circuit boiler. The opportunity to have not only heating, but also hot water from one device is very attractive for any owner.

However, there are some objections here:

- the performance of double-circuit domestic hot water units is low and cannot satisfy high demands;

- the supply of hot water is unstable - many users note serious fluctuations in the temperature of the hot water supply while taking a shower, associated with the inclusion of another plumbing fixture;

- most single-circuit models can work in conjunction with external water heaters, which makes them capable of full DHW supply,

NOTE!

Many experts recommend considering your hot water needs first. If they are tall enough, the family is large or a new addition is expected, you should immediately choose single-circuit boilers with external water heaters.

Additional functions

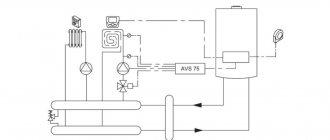

Each heating unit has its own electronic unit with a set of standard functions for regulating and monitoring the operation of a gas boiler. But in addition, for an additional fee, you can install additional equipment that will significantly expand the control capabilities of the heat supply system.

Kinds:

- Room control modules. For more comfortable regulation of indoor temperature, additional control units are installed in some rooms. In fact, they are the same as the electronic module on the boiler, but with a smaller set of functions.

- Temperature sensors. In order to ensure maximum comfort and at the same time achieve minimum gas consumption, you need to program automatic adjustments of the control system. This cannot be done without the use of temperature sensors, which are installed inside and outside each room. This type of control is called weather-dependent; savings from it can reach 20-30%.

- Remote control systems. You can organize remote monitoring of the operation of the heating system and, if necessary, make the necessary adjustments to its operation. This will require the installation of an appropriate device, most often a GSM module. In fact, this is the same mobile phone or modem with a SIM card.

Device

The main components of a single-circuit gas wall-mounted boiler are:

- gas burner, which is connected to the primary heat exchanger;

- turbocharger fan;

- circulation pump;

- three-way valve;

- gas equipment;

- control board and self-diagnosis sensor system.

IMPORTANT!

The design of atmospheric boilers does not include a turbofan, and non-volatile installations have neither a circulation pump nor a control board. Such boilers operate only on mechanics, like a regular gas stove.

Top 3. BAXI ECO-4s 1.24F

Rating (2021): 4.09

18 reviews from resources were taken into account: Yandex.Market, Otzovik, IRecommend

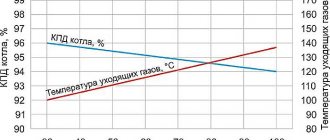

Increased efficiency The boiler efficiency is 93%, which is several percent higher than similar models with similar parameters.

- Characteristics

Average price: 41,600 rub.

- Country: Italy (produced in Hungary)

- Thermal power (kW): 24

- Heated area (sq.m): 250

- Control type: electronic

- Installation: wall

- Fuel consumption (cubic m/hour): 2.73

- Circuit water pressure (bar): 3

One of the important parameters when choosing a boiler is efficiency. It is calculated using a complex scheme from the ratio of thermal power, pressure created and fuel consumption. On average, this value is 87-90%, which is the norm. But BAXI ECO-4s went further: its efficiency is 93%, and this is the best result among models with similar characteristics. The boiler itself is wall-mounted, with electronic control. It requires a network connection as the burner is controlled by smart electronics. The tank is completely copper, which is why we see such a not very attractive price tag. But it will last for many years and will not develop fistulas that require repair or replacement.

Advantages and disadvantages

- Full copper tank

- Smart Electronics Control

- Best efficiency

- Expensive device

Operating principle

The operating principle of a single-circuit gas boiler is based on flow-through heating of the coolant using a gas burner.

The liquid that has cooled during circulation enters the boiler, where it is immediately sent to the heat exchanger . Passing through it, it receives the maximum possible heating for the current operating mode.

The coolant then flows into a three-way valve, where it is partially mixed with colder liquid from the return flow. This procedure allows you to achieve the set temperature and provide heating mode.

The prepared coolant is again sent to the heating circuit to undergo the next cycle.

Differences in ignition type

There are two main types of ignition:

With all its advantages, the use of piezo ignition has one significant drawback - maintaining the igniter burning requires increased gas consumption, which for not very wealthy citizens can hit the wallet.

- Piezoelectric - a small gas igniter operates on board the wall-mounted boiler, ignited using a piezoelectric element;

- Electric - there is a high-voltage generator on board with two electrodes, between which a spark jumps.

The latter type of ignition is economical and safe - there is no need to burn gas.

Kinds

Wall-mounted single-circuit boilers are produced in various design options, which can be divided according to the following characteristics:

By type and material of heat exchanger:

- steel _ Stainless steel is used, which has average capabilities and efficiency. Such units are usually installed on units in the middle and low price range.

- copper _ This unit demonstrates increased heat transfer, durability and efficiency. Installed on expensive models from the most famous manufacturers.

On single-circuit boilers, as a rule, one structural type of heat exchanger is used - tubular. It is a spiral of steel or copper tube, which is heated by a burner flame.

The coolant passing inside manages to get a high temperature and exits to the next nodes completely ready for further work.

By type of burners and combustion chambers:

- atmospheric _ These are open type burners that use air directly from the room. To remove flue gases, they need to be connected to a traditional type chimney with natural draft;

- turbocharged _ These units are closed, so a turbofan provides fresh air and smoke displacement. Their combustion process is more stable, and there are never problems with smoke removal. The only problem may be a fan failure or a power outage.

According to the method of energy transfer:

- convection _ These are boilers that operate on the usual principle of heating the coolant using a burner.

- condensation _ A relatively new design, which uses a two-stage method of heating the coolant. First, it is heated from the heat obtained from the condensation of flue gases, and only after that it enters the heat exchanger, where it finally receives the set temperature. This technique allows you to significantly reduce gas consumption, since the coolant is already heated and does not require too intensive preparation . However, for the operation of condensing boilers, specific conditions are required - the condensation temperature must exceed the return flow temperature. This is only possible on underfloor heating systems, or when the temperature difference between inside and outside is no more than 20°. This is impossible in Russia.

NOTE!

When purchasing a condensing boiler, you should not trust the declared efficiency, which is 107-109%. This is a common marketing ploy. We must first understand how this unit works.

Protherm Medved 50 PLO

It is a floor heating system with an atmospheric burner and an open fuel chamber. The maximum power of the boiler unit is 44.5 kW. The design of this mini-boiler room includes a built-in 110 liter boiler. to create a domestic hot water system in the house. A special feature of the boiler is the manufacturer’s use of a reliable and durable cast iron heat exchanger. According to the manufacturer, its service life reaches 20 years. Main advantages: low fuel consumption 5.2 m3/h; protection class IP 40; Efficiency 92%. Disadvantages: does not work in low pressure gas lines. Cost – 70 thousand rubles.

Most popular manufacturers

The most famous and popular manufacturers of wall-mounted single-circuit boilers include:

- Vaillant;

- Viessmann;

- Buderus;

- BAXI;

- MORA-TOP;

- Protherm;

- Navien;

- Bosh;

- Ariston;

- Thermex, etc.

It is difficult and impractical to list all manufacturers. There are many of them, some companies are subsidiaries of more well-known concerns. In addition, new companies are constantly appearing on the market, which expands the range and makes the choice for the user more diverse.

How to calculate power?

Calculating power using scientific methods is quite complicated. The heat loss of the building is determined, the thermal contour is calculated, and the influence of openings or other openings is taken into account.

The process is difficult even for professionals, not to mention untrained people . Therefore, a simple and fairly reliable technique is usually used. One kilowatt of thermal power can heat an area of 10 square meters. m.

Therefore, to determine the boiler power, you need to divide the area of the room by 10. For example, for 180 sq m you need 18 kW of power.

Attention! You should not choose overly weak or overly powerful boilers. In this case, the reserve works to the detriment - the unit operates in the wrong mode and fails faster .

Requirements for placement of attachments

The following standards and regulations must be observed when installing wall-mounted boilers:

- Room area - at least 4 square meters. m. Ceiling height - from 2 m. Doorway width - from 0.8 m. A window with an area of 0.3 sq. m. is required. m. It is not allowed to place gas equipment in the living room, bathroom and toilet.

- It is necessary to organize a flow of fresh air into the room in which the equipment is planned to be placed.

- There must be at least 10 cm between the boiler and the wall, the surface of which is not treated with a fire-resistant coating. If there is protection, this requirement is not necessary to comply with. The distance from the floor to the attachments is 0.8-1.6 m.

- Plastic pipes must not be used to supply gas to the boiler.

- The height of the chimney is from 5 m. It can have no more than 3 bends.

- When installing volatile heating equipment, it is necessary to properly organize the electricity supply system, providing current and thermal protection.

- The boiler room must have a gas leak detector.

- The distance between devices operating on natural fuel is at least 20 cm.

Depending on the boiler model, these requirements can be tightened or relaxed.

Rating of TOP 5 single-circuit wall-mounted boilers

Let's consider the most popular models of gas single-circuit wall-mounted boilers:

MORA-TOP Meteor Plus PK24ST

A well-known manufacturer of heating equipment from the Czech Republic, MORA-TOP produces a wide range of gas boilers. The Meteor Plus PK24ST model is an atmospheric unit that requires connection to a classic type chimney.

The boiler power is 23 kW, which allows heating rooms up to 230 sq.m. Wall mounting facilitates access to connecting pipes and simplifies maintenance of the unit.

Main characteristics:

- coolant temperature - 30-90°;

- system pressure - up to 3 bar;

- gas consumption - 2.67 m3/hour;

- dimensions - 400x750x380 mm;

- weight - 31 kg.

The boiler is equipped with multi-stage protection against external influences, overheating, backdraft and other undesirable conditions.

It is possible to connect external control and a storage boiler for DHW supply.

Buderus Logamax U072-18

Buderus is part of the Bosh holding, which significantly expands its capabilities. Heating boilers of this brand are distinguished by their reliability and high quality combined with relatively low prices.

The Buderus Logamax U072-18 model, thanks to its power of 18 kW, is capable of heating 180 sq. m of residential or public space. The boiler has a copper heat exchanger, a closed burner, and multi-stage protection against all overloads or external influences.

Options:

- coolant temperature - 40-82°;

- system pressure - up to 3 bar;

- gas consumption - 2.1 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 34 kg.

To create a full-fledged hot water supply line, you need to connect an external boiler. For this purpose, the boiler already has a 3-way valve and a circulation pump .

The capacity of the expansion tank is 8 liters, allowing it to overcome temperature fluctuations in the coolant volume.

BAXI LUNA-3 1.310 Fi

The Italian company BAXI is known as a manufacturer of high-quality and durable heating equipment. Currently, the factories of this company are distributed throughout Europe, and the head office is located in the Netherlands.

The double-circuit wall-mounted boiler BAXI LUNA-3 1.310 Fi has a power of 31 kW, designed to serve an area of 310 sq.m.

The copper heat exchanger allows for maximum heat transfer efficiency. The closed type burner eliminates flame failure due to sudden gusts of wind or strong drafts.

Boiler characteristics:

- coolant temperature - 30-85°;

- system pressure - up to 3 bar;

- gas consumption - 3.52 m3/hour;

- dimensions - 450x763x345 mm;

- weight - 38 kg.

The manufacturer sets a 10-year service life for its products, subject to compliance with all operating requirements and timely maintenance.

The warranty on the unit is 2 years.

Protherm Panther 25 KTO (2015)

Protherm is a subsidiary of the Vaillant Group. It was formed as a special division for the production of inexpensive budget-class gas boilers.

However, existing requirements and strict European standards have done their job - Protherm products are not inferior in quality to the products of the parent company . The Protherm Panther 25 KTO boiler (2015) has a power of 25 kW and is capable of heating 250 sq.m. usable area.

Its characteristics:

- coolant temperature - 30-85°;

- system pressure - up to 3 bar;

- gas consumption - 2.8 m3/hour;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

It is noteworthy that Protherm boiler groups are named after groups of animals.

Thus, wall-mounted gas boilers represent a “cat” line, where all series have corresponding names - Lynx, Panther, Jaguar, etc..

Viessmann Vitopend 100-W A1HB002

A sample of a gas boiler from the leader of the European heating industry - Viessmann. The company's policy does not consider the possibility of reducing the quality or reliability of its products.

The Vitopend 100-W A1HB002 model clearly demonstrates the approach of the company’s engineers to the creation of heating units. Boiler with a closed burner, power 29.9 kW (for heating 300 sq.m. area).

Its parameters:

- coolant temperature - 40-80°;

- system pressure - up to 3 bar;

- gas consumption - 3.47 m3/hour;

- dimensions - 450x725x360 mm;

- weight - 38 kg.

Experts note that gas consumption is too high for such power. However, when connecting an external water heater, fuel consumption practically does not increase.

This makes the boiler a good option, capable of providing the room not only with heat, but also with hot water supply when an additional unit is connected.

Vaillant AtmoVit INT 164-564/1-5

Designed for heating a small private house or cottage with a total area of up to 120 m2.

Equipped with a single-stage atmospheric burner, cast iron heat exchanger, electronic ignition and flame level control sensor. A special feature of this model is the design of the burner with ceramic rods and a fuel flow regulator. The open chamber and lack of pressurization make it impossible to install it in a room not equipped with ventilation and a smoke removal system with natural draft. The advantages of this heating system: high efficiency - 94%; possibility of connecting an indirect heating boiler; the presence of automatic self-diagnosis. Average cost 7 thousand.e. Disadvantage: VRC 420S regulators are not included in the package.

Lemax Premium 20 is a Russian-made single-circuit energy-independent boiler unit with a capacity of 20 kW. The installation is equipped with a steel body, 2 mm thick, an atmospheric burner and an open fuel chamber. A special feature of this device is the innovative design of the heat exchanger, protected from overheating and coated with a special enamel that prevents corrosion. Advantages of this device: the presence of an air flow regulator, self-diagnosis functions. Efficiency – 90%. Average cost – 21 thousand rubles. Disadvantages: frequent problems with ignition, general shortcomings.

Conclusion: in terms of price-quality-functionality ratio, Vaillant AtmoVit INT 164-564/1-5 is unanimously recognized as the best floor-standing boiler.