Thanks to electricity, homes have light, water and heating, and people have the opportunity to use many household appliances that significantly improve the quality of life. At the same time, current poses a huge danger if an emergency occurs during the operation of machinery and equipment connected to the circuit. A properly installed socket with grounding will eliminate the risk of electric shock. To perform installation correctly and safely, you do not need professional skills or equipment. A set of home tools and basic knowledge of physics is enough.

What is grounding

Connecting wires for grounding in a socket

Electric current is a flow of electrons moving along a conductor under the influence of a magnetic field that creates a potential difference. By the nature of substances, particles move from a positive potential (+), which is called a phase and is applied to technology, to a negative potential (-), called zero. A person, consisting of 70% water, is an ideal conductor of current. The earth has absolute zero potential. If there is a separate line and a buried circuit, it will absorb both leakage and static charge, which will take the path of least resistance bypassing the human body.

What role does it play?

In accordance with the updated GOST, all private houses and apartments must be equipped with grounded sockets with special contacts for the wire that absorbs current leaks in devices. Many do not attach importance to this decision and in vain. In household appliances, internal wires often come off or burn out, after which they touch the body. A Euro socket with grounding takes voltage from the surface of the equipment, discharging it along a separate line into a structure buried in the ground. The resistance of this line is less than that of the human body. This eliminates the possibility of accidents due to faulty electrical wiring of household appliances. Thus, the hidden wiring socket with grounding ensures that the leakage current is reduced to a safe level.

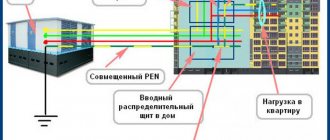

What is the difference between grounding and neutralizing

The difference between grounding and grounding

Not all residential buildings have grounding in sockets. At the same time, there is a need to protect residents from electric shock when using household appliances, especially those equipped with a steel body and installed in wet areas. For this purpose, grounding is used - connecting the body of the electrical installation to the neutral wire. According to its purpose, this solution performs a protective function - preventing a person from being injured by leakage current.

The difference with grounding is that in the event of grounding, when current flows through the body, a short circuit occurs, which leads to the operation of automatic devices installed both on the line and in the device itself. Injury to a person is excluded from the very beginning, since a broken device will be de-energized even before contact with it. You can connect it to the network only after the fault has been eliminated.

Test method

Checking the ground loop is carried out according to a single algorithm:

- Cleaning the tire area for good contact.

- Driving 2 additional pins into the ground 50 cm.

- Connecting the busbars to the pins using the device clamps according to the diagram.

- Perform measurements according to the instructions for the device.

Place electrode “C” at a distance 5 times the length of the vertical ground electrode. Remove pins from underground utilities for data accuracy.

Technology for working with the M-416 device

Checking wires with the M416 device for resistance compliance

If a visual inspection does not reveal any faults on the ground line, you can find out the condition of the circuit using the M-416 device. The work is carried out as follows:

- Power supplies are checked. The device must have 3 batteries of 1.5 V each.

- The device is placed horizontally on a flat surface.

- Calibration in progress. The range switch is set to the “5Ω Control” mode.

- The arrow is set to the zero position. You need to press the red button and turn the rotor handle. The scale displays 5±0.3 Ohm.

- The meter is located at a minimum distance from the ground electrode. This will help prevent the resistance of the connecting wires from affecting the overall result.

- The test is carried out according to the diagram under the cover of the device. The main and auxiliary electrodes will need to be driven into the soil to a depth of 50 cm.

- Calculations are being carried out. If the resistance is less than 10 Ohms, the total must be multiplied by 1, and the switch must be moved to x1. If the measurement result is more than 10 ohms, the switch is switched to x5, x20, x100.

Distinctive features of a grounded outlet

External difference between an outlet with a grounding contact

In order not to make a mistake when making a purchase, you need to know what an outlet with a grounding contact looks like. In appearance, it is practically no different from analogues with phase and zero. The cover of the product is white, black or brown. The module can be single or double with connectors for plugs with a diameter of 3.6 mm.

The modules have the following technical characteristics:

- voltage - 220-250 V;

- current strength - 8 A, 16 A;

- power - 3.6 kW, 7.2 kW;

- fastening - internal and external.

Some models are equipped with stabilizers with an indicator display and an emergency shutdown device.

The external difference between sockets with grounding is the presence of metal springs on the sides of the socket that contact the plug terminals. The springs are brought out to the third contact located in the middle between phase and zero, to which the grounding cable is connected.

Determining the purpose of conductors

When working with electrical wiring, be sure to double-check the assignment of the outlet conductors. There is no guarantee that the electrician or the previous owner of the premises did not mix up the wires. Therefore, if the tester shows a voltage of 220 V relative to a terminal that appears to be grounding, this does not mean that it is such.

This means that one of the contacts is a phase, and the second is a zero or ground. If the tester shows 0, then there is a neutral and ground conductor. It is impossible to understand exactly what is what.

If you are not 100% sure of the purpose of the grounding terminal, the sockets operate differently. First you need to exclude the presence of two phases. Check the voltage between all contacts. If the device does not show 380 V anywhere, but only 220, it means that one phase conductor is connected to the socket. Now you need to start looking for grounding.

First you need to disconnect the grounding conductor in the floor panel. It is connected through a bolted connection to a special bus welded to the body of the electrical panel.

After this, the voltage between the socket connectors is measured.

If the device shows 220 V, then the socket contacts are the phase and neutral wires, and the ground terminal really is. Now knowing exactly where the ground is, you can determine the remaining connectors, but first you need to reconnect the “ground” to the ground bus.

If the multimeter shows 0, then the ground has been connected to one of the socket contacts, and the second is neutral or phase. Now we take measurements between the socket and ground contact of the socket. If there is no voltage, then this socket is the real ground.

The readings at 220 V speak for themselves.

When it is prohibited to connect grounding to sockets

There are a number of rules regarding the safety of electrification of premises. Their violation can mean only one thing - the creation of a situation fraught with electric shock to people.

It is prohibited to connect a hidden wiring socket to grounding in the following cases:

- Damage or rupture of the wire leading to the steel frame buried in the ground.

- The presence of a jumper between the neutral and ground lines.

- Output of the third wire to house communications - water, gas or heating pipes.

Connections can be made only after defects in the electrical wiring have been eliminated.

Useful video on the topic

A lot of interesting information is in the video.

Leave a comment Cancel reply

Related Posts

How do ABB automatic machines differ from their competitors?

DIY triple socket installation. How to carry out the work.

What is a Legrand pass-through switch, features of its connection diagram.

Installing a socket or switch in a plasterboard wall, brief instructions

How to choose the right outlet

Internal grounded outlet

To select the right outlet, it is necessary to study and evaluate a number of factors that will affect its reliability and functionality.

You should focus on the following criteria:

- Type of metal. Stainless steel parts have the best characteristics.

- Power. A good option is a two-socket 16 A device.

- Case material. It is better to choose ceramics, which are resistant to heat and corrosion.

- Type. If you install an indoor unit, you can save space. The open method saves effort and time.

When choosing, every little detail matters, including the color and design of the product.

Checking stable operation

The presence of three holes in a socket alone is not a sufficient guarantee of safety. The system will only work if the wiring in the residential premises is built taking into account modern requirements.

To carry out testing activities, you will need an indicator screwdriver and an ampere-volt-ohmmeter.

The verification technology is as follows:

- Unscrew the connector and make sure there are three wires of different colors;

- Carry out a visual inspection of the cores for damage, ensure their integrity and suitability for use;

- If you are unwilling or unable to open the case, you need to use an indicator screwdriver;

- The light bulb should light up only once - at the moment of touching the “phase”;

- If all conditions are met, it is the turn of the ampere-volt-ohmmeter. One probe of the switched-on device is fixed in the “ground” hole, and the second is touched in turn to “zero” and “phase”;

- If the device display shows zeros when connecting “phase” and “ground”, you need to sound the alarm: there is no protection at all.

- It is also a malfunction if two phases are detected immediately.

Installation of a grounded outlet

Multimeter

Installation should be carried out in a de-energized room wearing protective gloves and goggles.

To work you will need:

- multimeter;

- screwdriver;

- steel slats;

- pliers;

- wire cutters;

- knife;

If you need to hide the cable in the wall, you need a grinder and a hammer drill. You should work while standing on a dielectric mat.

How to find out if there is a ground in an outlet

The yellow-green wire indicates the presence of a ground in the outlet.

Installing a socket with three contacts only makes sense if it is connected to a ground loop. This can be determined in several ways that are accessible even to a beginner.

- Visually check the connection of the third yellow-green wire.

- Measure the resistance between phase and ground. If it is, the connection is available.

- Connect the wires from the lamp in the socket. Its combustion is evidence of the integrity of the line and the serviceability of the circuit.

Indirect signs of a lack of grounding are crackling sounds in the speakers and weak electric shocks from operating devices with a steel body.

Installation of the overhead option

Surface-mounted socket with grounding

Surface-mounted points are installed on walls made of solid wood, plasterboard and plywood.

The sequence of actions is as follows:

- Mark the location of the socket and cable.

- Connect the wires.

- Disassemble the device body and loosen the bolts.

- Clean and connect the wires to the contacts.

- Screw the base to the surface.

- Assemble the socket and check the strength of its fixation.

Open wiring can be hidden in pipes, plastic channels, or run along strings or insulators.

Connecting the internal version

Correct connection of an indoor outlet

Before connecting a three-wire grounding cable to an outlet, you need to check its integrity. It should not have external damage, creases or melted areas.

The work is performed in this order:

- Carry out markings.

- Make grooves and a hole for the mounting box.

- Remove dust and crumbs from the openings, treat the walls with a primer.

- Lay the cable, bringing it out of the hole by 15-20 cm.

- Wall up the installation box. It must be placed flush with the wall.

- Connect the wires to the contacts.

- Secure the device using screws and sliding tabs.

After this, you can supply electricity to the room.

Connecting wires

The stability of the device depends on the correct connection of the wires. It should be remembered that copper tends to oxidize over time, which reduces the quality of contacts. To avoid this, the ends of the cores, freed from insulation by 10 mm, are soldered. After this, they need to be inserted into the holes until they stop and pressed as tightly as possible with the bolts. The reliability of the fixation is checked by lightly pulling the wires.

Checking the correct connection

After installation and before supplying electricity, it is necessary to check the correct connection.

This procedure consists of monitoring the following elements:

- mounting box;

- compliance of wires and terminals;

- integrity of line to contour;

- housing fastening strength;

- reliability of lid fixation.

If the enclosure has additional options, they must be connected to the phase.

Double socket

Connecting a double socket with grounding

Installing a device with two sets of connectors is practically no different from installing single products. The contacts are connected into one common circuit, which removes leakage current from both consumers, regardless of where they are connected. In this case, it should be taken into account that the current indicated on the cover is the total for both installations.

The only difference is the size of the mounting box. Depending on the design of the product, it can also be double. The opening is made by drilling holes or sawing rectangular openings in the wall. The connection is made in the usual way.

Multimeter reading options

Any device, indicator screwdriver or tester, must be checked for functionality and only then used. The insulation must be intact, without cracks or tears. The tip of the probe should be separated from the holder by a dielectric washer to protect it from accidental touches.

The body of the measuring device must be intact. Before measurement, the plugs are inserted into the sockets of the device, which correspond to the measurement of alternating voltage. After making sure that the device is working properly, you need to switch it to the AC voltage measurement mode with a scale of 750 V. This is necessary in case of measuring line voltage when two phases were connected to the socket by mistake.

This method of testing an outlet is suitable if the tester is confident that the ground contact is indeed ground. Then the task is to find zero. One probe touches the ground contact, and the second is inserted into any socket of the socket. The following options may be available:

- the device shows 220 V, which means the contact is phase;

- if 0 or a few volts, then this is the neutral wire.

A reading of a few volts says it's zero. But how to determine zero when the house is supplied with electricity through a TN - C power supply system and re-grounded next to the building? After all, in this case, the device readings will be zero.

To make sure that this conductor is neutral, you need to disconnect the grounding in the entrance electrical panel. Then measure the voltage between the socket contacts of the socket. The device shows 220 V - the zero of the socket has been found. The multimeter does not show anything - grounding has been detected.

If the device reads 220 V on each contact relative to the grounding one, you need to make an additional measurement between the two sockets of the socket. The device shows 0, which means one phase is connected to both sockets. Otherwise, the device will show 380 V, which means there are two phases on the outlet.