Home » Automation and controls » Why and how automation is needed on old-style gas boilers

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

…

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

Why do you need gas automation?

Old-style boilers were manufactured in accordance with the gas parameters and heating system features that were in use several decades ago. These are, for example, models KChM, AOGV. At the same time, their durability allows them to be used for many years to come. But the problem with automation is that quite often it breaks down. In such a situation, there are three options:

- diagnose existing automation and replace the necessary parts;

- equip a reliable and high-quality unit with a modern automatic system;

- buy a new boiler.

The difference, of course, is in the price of the issue, the effort and time of the owner.

Let's consider the cheapest option - troubleshooting gas automation on an old boiler. However, first, let’s figure out why an automatic system is provided in the coolant in general.

Gas automation allows you to regulate and maintain the required level of coolant temperature, and also serves to automatically stop the gas supply in an emergency situation. Installing automation on an old gas boiler will allow you to be sure that if the burner flame goes out, then after a short time the system will work to stop the gas supply without your participation.

Attention! Automation, in addition to regulating and maintaining the temperature at a given level, ensures the safety of using the heating device and allows you to save on heat consumption.

If you want to change the automation, keep in mind that domestic manufacturers produce models that are suitable for almost any old coolant. Imported automation cannot be installed on everything. In addition, when installing foreign automation on old-style gas boilers, not all of its functions may work - the design features of the boiler will not allow it.

…

On a note! The choice of automation for gas boilers is varied. The most popular is the system from Italian manufacturers, for example, SIT. American automation (Honeywell) holds second place in popularity. There is a large selection of Russian (SABK, "Orion") and Ukrainian, "Iskra", "Plamya", APOK-1).

The boiler does not turn on or ignite

With the development of modern low-rise construction and gas networks, the boiler has become a common household appliance in every house or apartment. Basically, after installation, the boiler does not cause users any trouble. Modern boilers operate completely autonomously and require only regular maintenance or inspection.

In our opinion, the average operating time of units before the first breakdown is from 4 to 6 years. Some users encounter problems even after 9 years, and some, on the contrary, earlier. In this material I will tell you what can be done if the boiler simply does not turn on, and I will also consider the most common malfunctions of gas boilers.

The concept of “does not turn on” can mean completely different problems:

- There is no indication (the display is not lit)

- The boiler does not light up

- The boiler does not operate in any particular mode

Therefore, these different situations should be considered separately in detail. Please note that to eliminate some malfunctions, user intervention is sufficient, but in some cases it is necessary to call a qualified specialist.

The boiler does not turn on - there is no indication

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all you need to make sure that power is supplied to the boiler. Typically, the electrical connection of the boiler is carried out through a separate “automatic machine” - check whether it is turned on or not.

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room with gas boilers are flame attenuation in the burner and gas pollution in the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- the flame on the igniter goes out;

- leakage of the pulse system.

When these situations arise, the automation is triggered to stop the gas supply and prevent the room from becoming gas-filled. Therefore, installing high-quality automation on an old gas boiler is basic safety rules when using it to heat a room and heat water.

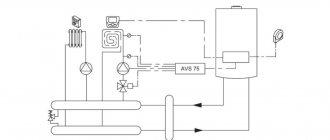

All automation of any brand and any manufacturer has one operating principle and basic elements. Only their designs will differ. Old automatic machines “Plamya”, “Arbat”, SABC, AGUK and others work according to the following principle. When the coolant cools below the temperature set by the user, the gas supply sensor is activated. The burner starts heating the water. After the sensor reaches the user-specified temperature, the gas sensor automatically turns off.

On a note! When using modern automation, it is possible to save heat up to 30%. Old-style automation is non-volatile and does not require electricity. Its adjustment, connection and disconnection are carried out by a person. Commands are transmitted using electromagnetic pulses.

The video explains how the automation of gas boilers AOGV and KSTG works.

…

Causes

The key reason is scale on the heat exchanger tubes, which significantly narrows their clearance. As a result, at the same gas flow rate, the heat transfer process is significantly reduced.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Do not use tap water to fill the heating system. When it heats up, scale forms, which will have to be cleaned periodically. Softened water, which can be purchased in specialized stores, is better suited for these purposes.

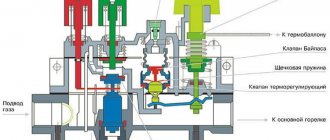

Basic elements of automation

The main elements of automation for a gas boiler are:

- thermostat;

- shut-off valve;

- traction sensor;

- flame sensor;

- igniter tube;

- igniter;

- burners.

Let's try to clearly explain how automation for a gas boiler works, breaking it down into its main elements and talking about their functions.

The gas passes through a gas purification filter. Next it goes to the solenoid valve, which regulates the fuel supply to the burner. Temperature and draft sensors are located next to the valve, monitoring the indicators and signaling if they exceed acceptable standards. Also, the automation kit for gas boilers includes a thermostat with a bellows and a rod, designed to set the desired temperature. A special button is used to adjust the indicators. When the water is heated to the temperature set by the user, the thermostat is activated, the gas supply to the burner is stopped, while the igniter continues to operate. When the water cools by 10-15 degrees, the gas supply is resumed. The burner lights up from the igniter. The automation is started manually.

How to solve?

Usually the problem is solved by cleaning the heat exchanger with special acid compounds. Secondarily, the condition of the heating system is assessed and excess air is removed from the radiators.

Jokes with gas equipment are bad, so all repair work should be carried out only by specialists in this industry. If you have the slightest suspicion that the boiler is not working as it was before, then you should not hesitate to call the experts.

Experts also recommend:

- Do not ignore the annual scheduled technical inspection of the serviceability of gas equipment. The technicians will clean the heat exchanger and look inside the boiler. If there are any malfunctions, they will be eliminated. This will maximize the life of the boiler and also protect your life from possible risks.

- Never repair a boiler yourself using manuals found on the Internet. This does not guarantee full serviceability of the equipment, which is fraught with negative consequences.

- Pay attention to the nuances of operating the model you choose. Don’t be lazy to study the documentation, which describes in detail the sequence of actions in a given situation.

In conclusion, it is worth noting that all problems in gas equipment sooner or later make themselves felt. Operation of faulty equipment can lead to a gas explosion, which is extremely dangerous to life. Observe all safety precautions and do not ignore the rules for operating gas equipment.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

How to solve?

If the pump is working properly, but there is no heat in the house due to significant gas consumption, then you need to clean the heat exchanger. The procedure is performed only by specialists who use special liquids of high acidity.

Incorrect errors on the screen

The boiler went out for some reason, and a code appeared on the display. Naturally, the first thought is to look at the instruction manual, but what to do if such a code is not there?

Flushing

How to clean the heat exchanger of a gas boiler from scale with your own hands? If there is a small amount of plaque inside, you can get by with manual washing using a citric acid solution.

If there is a thick layer of scale, you will need a washing unit that will circulate the detergent for several hours. A 10-liter tank with a pump is suitable for this purpose (you can use a circulation pump from the circuit). Two hoses from the pump are connected to two heat exchanger pipes.

There are three cleaning methods:

- mechanical;

- chemical;

- hydrodynamic.

In the first case, you can use a brush, scraper, or vacuum cleaner to remove plaque. Heat exchanger parts are pre-soaked in cleaning solutions.

During chemical treatment, an acid wash solution is pumped into the system using a booster and driven through a heat exchanger for several hours. Acidic solutions are good at removing ferrous and carbonate sediment. At the end of cleaning, the product is drained and a neutralizing agent is added.

The hydrodynamic method is the injection of water with abrasives into the system under pressure. In this way, the internal surfaces are cleaned mechanically, but the cleaning efficiency is higher than when processed manually. Flushing can be done without dismantling the system, but it is quite expensive. When cleaning yourself, you need to monitor the pressure in the circuits to avoid rupture of the heat exchanger.

Other models

In practice, cleaning burners follows the same principles. The differences lie in their removal and reassembly.

The following examples are provided:

For example, the Helios AOGV 4 parapet apparatus is equipped with Eurosvit 360 automation and burners of the European brands Bray and Polidoro.

The burner set is removed following the example of the Zhitomir process. A pump is used to clean the nozzle, and hard brushes are used to clean the surfaces.

The Conord line stands out in particular.

The automation variations here are:

- AGU-T-M (Russia),

- "Eurosvit" (Italy),

- Honeywell (USA).

The most popular is the second variation:

It includes a sectional burner, Polidoro tubes, igniter, thermocouple, gas valve, temperature indicator and wires.

A similar system is available in the Lemax Premium 12.5 model.

Only the burner here is micro-flare. The mechanism is very easily removed by removing the top cover and lightly unscrewing the fixing bolts.

Its analogues are also found in the Siberia models.

Ecological burners "Vorgas" are used here.

Does not lag behind in this regard. Here its models Novella Maxima 108 N RAI and Mynute Boiler stand out.

Honeywell automation looks like this:

It has a similar operating principle to the Eurosvit system. The differences lie in the materials of some components.

It is often found in wall-mounted modifications, for example in Baksi Fortech 24

It also has an ecological burner that leaves no combustion products.

An equally popular device is the Ariston ALTEAS X 24 FF NG.

Many Daewoo models operate with similar automation. For example – DGB 200 MSC.

Whatever model or brand you have, strictly follow the suggested instructions for removing and reinstalling the burner block. Clean it thoroughly with the right products 1-2 times a year. Maintain other mechanisms as well. And then your boiler will work properly for a long period.

I. GENERAL PROVISIONS

1.1 This instruction contains requirements for ensuring the safe operation of steam and hot water boilers and is compiled on the basis of the standard instructions of the Russian State Mining and Technical Supervision Authority.

1.2. Persons at least 18 years of age who have undergone special training, a medical examination, and have a certificate with a photo for the right to service boilers running on natural gas are allowed to service boilers.

1.3. Re-inspection of boiler room personnel is carried out at least once every 12 months.

1.4. When entering duty, personnel are required to familiarize themselves with the entries in the log, check the serviceability of the equipment and all boilers installed in the boiler room, gas equipment, serviceability of lighting and telephone. Acceptance and delivery of duty must be documented by the senior operator with an entry in the shift log indicating the results of inspection of boilers and related equipment (pressure gauges, safety valves, power supply devices, automation equipment and gas equipment).

1.5. Acceptance and delivery of shifts during the liquidation of an accident is not permitted.

1.6. Unauthorized persons are allowed access to the boiler room by the head of the enterprise.

1.7. The boiler room, boilers and all equipment, passages must be kept in good condition and proper cleanliness.

1.8. Doors exiting the boiler room should open outward easily.

1.9. Repairs to boiler elements may only be carried out in the absence of pressure. Before opening hatches and hatches located within the water space, the water from the boiler elements must be drained.

1.10. Work inside the furnaces and flue ducts of the boiler may only be carried out at a temperature not exceeding 50°C with the written permission of the person responsible for the good condition and safe operation of the boilers.

1.11. Before starting repair work, the firebox and flues must be well ventilated, illuminated and reliably protected from possible penetration of gases and dust from gas ducts and operating boilers.

1.12. Before closing hatches and manholes, it is necessary to check whether there are people or foreign objects inside the boiler.

1.13. Before starting work, the firebox or flues must be well ventilated, illuminated and reliably protected from possible penetration of gases and dust from the flues of operating boilers.

1.14. Before allowing people for repair work, the boiler must be turned off along all lines through which it can be put under pressure (the main steam line and its drains, feed lines, fuel oil or gas pipeline, periodic purge line).

1.15. A permit was issued in two copies indicating the following security measures:

- Plugs installed;

- The fan motor is de-energized and a poster “Do not turn on - people are working!” is hung on the starter;

- Lighting 12V;

- Work in overalls and safety shoes.

Settings failed

Settings are a “trouble” that can affect the owners of almost all energy-dependent boiler systems, regardless of the manufacturer and brand of equipment. The problem may be a voltage drop that caused the settings to fail. But, more often than not, the boiler begins to work inadequately after the intervention of the owner or “would-be repairmen” from the nearest workshop.

Advice: Repairing the control board of a gas boiler yourself is a thankless task: any problem related to electronics can lead to failure of the boiler installation or, worse, to an emergency. Entrust the competent adjustment of the boiler to professionals.

The situation with Zhytomyr

This brand is famous for its devices with piezo ignition. For an example of burner cleaning, the Zhytomyr 3 model, equipped with EURO SIT technology, is used.

The following list of tools is required for the operation:

- Screwdriver. A flat tip is required.

- Open-end wrenches.

- A regular brush and its analogues for cleaning metal products.

- Yorshik.

After blocking the gas with a key, remove the screw securing the boiler door. It is removed entirely. This way the core of the unit becomes open.

The main burner is concentrated in its lower zone. To remove it and subsequently clean it, you need:

- Disconnect the cable from which the piezoelectric element and electric ignition operate.

- Use a key to remove the thermocouple and its clamp from the valve.

- Mark with a marker the distance of immersion of the nozzle into the burner itself. This will make it easier to return it to the correct position.

- Unscrew the nut securing the valve to the burner. Communication goes through a copper tube.

- Carry out the same manipulations with the ignition electrode.

- Using a screwdriver, remove the two fixing nuts of the other burner (pilot). There is a gasket underneath. If it is damaged or deformed, replace it.

- Remove the nozzle from the burner. If the process is difficult, gently tap around this part with a key.

To dismantle the main burner, the screw connecting it to the boiler body is released. Then it is removed. To do this, you need to grab its lower part and the copper tube and sharply pull it out of the valve.

The screw that fixes the insertion distance of the nozzle part is loosened.

For the cleaning itself, a brush and a brush are used. Carbon deposits are carefully removed.

A vacuum cleaner is used to clean the holes. All work affects both external and internal components.

This algorithm is also suitable for the procedure with the burner of the Dani AOGV series devices, for example -11.5; 23.2 and 29.

You can do the same with many similar units: Aton AOGV 16-EM, ZhMZ-AOGV 17, etc.

The injectors also need to be cleaned. Carbon deposits from the top side are removed with a brush. A wire or thin needle is used to clean the holes.

After this, all the parts are assembled using the reverse algorithm.

Cleaning methods

Cleaning is carried out in two ways: mechanical and chemical

Mechanical cleaning

The cleaning method is imperfect and involves mechanical action. Soot should be carefully removed so as not to damage the internal surface of the boiler and parts, which can subsequently lead to metal corrosion. Often the tools come with the boiler - these are pipe cleaners, brushes and scrapers. It is also possible to use air cleaning, when warm air is supplied under pressure.

Dry cleaning

It is recommended to apply cleaning agents while wearing PPE (personal protective equipment); rubber-based gloves are usually used, this will protect the skin from interaction with harmful substances. Chemicals clean not only soot, but also metal, which can further lead to its destruction. This method is best used on minor dirt and small areas of contamination.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean soot from a diesel boiler.

It is used in boilers with a small thickness of contamination, as well as when speed of execution is required. Equipment for such washing consists of:

- pump and

- containers with water supplied under high pressure.

Thanks to this cleaning, soot and soot are removed quite quickly, but this method can only be used by specialists and is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (using the example of cleaning a Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Next, connect a booster hose to one of them to supply the reagent.

- We connect the second pipe to the second end of the hose. The spent reagent will be removed through it. This closes the system and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Rinse the heat exchanger itself with sufficient water.

Booster is a device for chemical cleaning. Thanks to it, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, since the old one gradually reduces its properties. This method is most often carried out by specialists.

Air turbine

Bearings are the most problematic part of any fan. Due to the increase in the coefficient of friction in the bearing, heating increases and the rotation speed of the rotor, and therefore the blades, significantly decreases. There is another reason for the heating of the housing associated with a decrease in the performance of the air turbine - interturn short circuit.

In the first case, you can carry out the repair yourself by unscrewing the device and lubricating the bearing with “graphite” or any other high-temperature-resistant lubricant. In case of problems with the motor winding, it is unlikely that it will be possible to solve this issue without the intervention of specialists.