Connecting a dacha to a centralized water supply system is in most cases problematic, and sometimes simply impossible. Therefore, summer residents use autonomous water supply systems to obtain water for household and drinking needs. But not everyone has a drilled well on their property. Many people get their water from a well.

- Why does a well need to be insulated?

- When is it necessary to insulate a well?

- Why is freezing water dangerous?

- Insulation materials

- A set of measures for insulating a well

- Reports of our work

What you need to know about water and wells in winter?

Our guaranteed depth without freezing is approximately 150cm. The layer of earth below has a constant positive temperature. This is the basis for the use of heat pumps and non-freezing recessed eco-greenhouses.

Springs at a depth of one and a half meters and below seem icy in summer, but in fact they also have a low positive temperature. Springs and fast-flowing rivers do not freeze even when they reach the surface.

Therefore, in a sand well with a good debit, water will not freeze even in severe frosts and without shelter. With medium, a crust of ice may form, but the water flow will be sufficient for selection through pipes. The water in a sand well with low flow rate and in a clay well does not freeze in winter. But if the walls of the well freeze, water from the vein in winter simply will not be able to get into the well. Until spring.

Installation stages

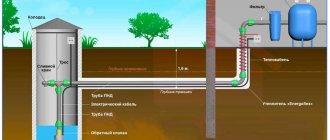

You need to start arranging a water supply by designing the system and drawing up drawings. The diagram should clearly show the paths that water will take from the water intake point to the distribution points in the house.

Branching pipes indoors can be done in several ways:

- Collector - a separate pipe is connected to each water intake point.

- Sequential - the entire pipeline is installed along the entire building and several branches extend from it to water intake points.

It is recommended to resort to the latter method if the volumes of water consumed are small and no more than three people live in the house.

If the building has a washing machine and dishwasher, there are watering hoses and more than three people live in it, it is better to install a collector water supply system that can create optimal pressure in the water column and provide good pressure from the tap.

Stages of winter water supply installation:

- System design. Selection and acquisition of equipment and materials.

- Preparation of trenches for pipes. A layer of sand and gravel is compacted at the bottom of the recess.

- Installation of pumping equipment, hydraulic accumulator.

- Connection of a pumping station, hydraulic accumulator with a pipe.

- Inserting an intake pipeline into a well shaft.

- Installation of insulated pipes from the well to the dacha.

- Wiring of an autonomous water supply system indoors.

The installation of the pipeline is carried out using special pipes - these are special short pipes with threads on both sides. Pressed against pipes using fitting adapters or flanges.

To prevent leaks, the joint between the parts must be carefully treated with sealant. Polyethylene pipes are connected using fittings or soldering. Additionally, adhesive joints are treated with silicone sealant. It is strictly forbidden to use bitumen and mastic.

The cost of laying a winter water supply system for a summer residence depends on the area and model of pumping equipment. The average price ranges from 15,000 – 20,000 rubles.

How to prevent the water in the well from freezing in winter?

When constructing a well, you should insulate the upper rings above the surface of the ground and in the ground to a depth of up to a meter, as well as the lid. The underlying heat of the soil and water is usually sufficient to prevent freezing. If the rate of water flow is low, care should be taken to ensure that there is a sufficient water level in the well and that the walls at the level of the water vein are not exposed when drawing. In this case, with severe frost and poor insulation, the soil may freeze from the walls of the well and block the water. How to ensure a sufficient volume of water in a well with a small debit is described in detail in the article If there is little water in the well.

You can cover not only roses with snow, but also wells

By the way, look closely at the green cover in the photo above. This is the so-called modern type of well, which, other things being equal, almost does not freeze. The old classic look of the well top not only lost its functionality. It is much more difficult to insulate it than a new one. That is, it makes direct sense to change the design of the well, and use the old top to create a decorative well on the site.

Why is freezing of wells dangerous?

It is a mistake to think that well insulation is only necessary when it is used year-round. Many summer residents and seasonal residents of country houses sincerely do not understand why insulate a well that no one uses in winter anyway. Meanwhile, such seasonal wells also need effective thermal insulation!

Otherwise, a variety of problems may arise that make the operation of the well difficult or completely impossible:

- the formation of an ice plug in the water supply system;

- displacement of the rings resulting from the expansion of frozen water in the surrounding soils;

- failure of the ice plug and damage to pumping equipment;

- divergence of the joints of reinforced concrete rings when water gets between the seams.

Wells that are not protected from low temperatures require repair work much more often. And in terms of financial costs, repair measures are often more significant than carrying out one-time insulation work.

Image gallery

Photo from

A good reason to insulate a well

Ice plug in an uninsulated well

Destruction of concrete well walls

Shift of concrete well rings

If a water supply system based on a well is installed in a suburban area, then in addition to the shaft itself, it is necessary to insulate the pipes to protect the supply line of the system from low temperatures.

If the well runs out of water in winter, how long will it take to fill it?

In underground springs there is water all year round (item 1). If it does not fill up because the walls of the well and the soil are frozen, the flow of water will resume as soon as they thaw.

If the problems in paragraphs. 5, 6 and 7 arise constantly and are not solved by insulation and/or changing the design of the finial, there is a radical solution. No, this is not a new well. This is a top in the form of a small building. A beautiful closed gazebo, if the well is in sight, or an outbuilding. This completely replaces insulation, plus it eliminates freezing of the soil at some distance around the well. As a result, water supply improves in winter and you get additional MAF. And if there is a need for some work (for example, replacing a hose, pump, etc.), they can be done in warmth and with light. An example of such a top is given at the end of the article about modern well design.

Insulation options

Insulating a well

Modern industry offers several types of materials for insulating wells for the winter. Among them, the most popular are:

- Penofol. This is a sheet of foamed plastic, covered on one side with foil or metallized polymer. Has excellent thermal insulation properties. Unfortunately, it is soft and cannot withstand heavy loads associated with soil pressure, so it is rarely used.

- Styrofoam. Foamed polystyrene is an inexpensive and very popular material. It is easy to install with your own hands and is quite rigid. It is produced in large sheets; for installation, you will have to cut them into narrow strips so that they fit better into the round concrete rings.

- Polyurethane foam. The liquid composition is sprayed onto a concrete or brick surface, foams and hardens in a continuous layer. The consistency is similar to polyurethane foam. The best solution for thermal insulation of a reinforced concrete ring. It is distinguished by the high cost of equipment. Molded modules made of polyurethane foam. The so-called “shell” for insulating well rings consists of two halves - half-cylinders; they are easy to install and secure. The joints are sealed with construction foam.

- Many homeowners still use traditional insulation methods - filling with expanded clay, sawdust, etc. Given the relative cheapness of materials, these methods are significantly less effective. Mineral wool is not suitable for insulating wells due to its hygroscopicity.

What is the best way to insulate a well?

Extruded polystyrene foam (pink) - it bends well, the thickness is suitable, the price is reasonable. If the well has a plastic cover, you can blow it out from the inside with foam. Now insulation in the form of foam cylinders has appeared on sale - they stick to concrete without cracks, but prices are still high. I don’t recommend polystyrene - it crumbles unpleasantly. Even if it doesn’t fall into the water, collecting them around the site is not a pleasant task. There is also good news - the functionality of a modern well has made the upper ring above the ground unnecessary. This means that the issue of insulating both the walls and the lid has been significantly simplified.

Thank you for your attention. It's time to drink a cup of aromatic tea. From that same unfreezing well...

Reports of our work

- Insulation of the source shaft. Marfino November 8, 2016

- Insulation of the shaft and cover. Village Goluboe September 28, 2016

- Mine insulation. Bolshoye Snopovo August 23, 2016

- Guarantee of the quality of our services

- Samples of contracts for our services

- Service areas

Order in 1 minute Online consultation

Laying depth of winter water supply pipeline

It depends on the region. For example, in St. Petersburg and Moscow, the calculated depth is 1.2-1.4 meters, the pipe is laid 30 cm lower. However, in reality, the soil freezes so deeply only in harsh conditions: there is sand on the site, the groundwater is high, there is no snow or it is being cleared. Often the soil freezes deeply under a house if it stands on stilts or a columnar foundation.

The actual freezing depth in these regions rarely exceeds 60 cm in depth. But we still lay the pipe at a depth of 1.5 meters, and we control this moment using the installer’s photo report.

If you do not know the standard freezing depth of the soil, it can be calculated using the formula. You will find it in document SP 22.13330.2011:

5.5.3 The standard depth of seasonal soil freezing dfn, m, in the absence of long-term observation data, should be determined on the basis of thermal engineering calculations. For areas where the freezing depth does not exceed 2.5 m, its standard value can be determined by the formula:

where Mt is a dimensionless coefficient, numerically equal to the sum of the absolute values of average monthly negative temperatures for the winter in a given area, taken according to SNiP 23-01, and in the absence of data for a specific point or construction area - according to the results of observations of a hydrometeorological station located in similar conditions with the construction area; d0 is the value taken equal to 0.23 m for loams and clays; sandy loam, fine and dusty sands - 0.28 m; gravelly, large and medium-sized sands - 0.30 m; coarse soils - 0.34 m. The d0 value for soils of heterogeneous composition is determined as the weighted average within the freezing depth. The standard depth of soil freezing in areas where dfn > 2.5 m, as well as in mountainous areas (where the terrain, engineering-geological and climatic conditions change sharply), should be determined by thermal engineering calculations in accordance with the requirements of SP 25.13330.

Let's calculate the standard freezing depth in St. Petersburg. Open SP 131 13330.2012, table 5.1: Average monthly and annual air temperatures. It states that in St. Petersburg the average subzero temperature persists for four months: December (-3.9°C), January (-6.6°C), February (-6.3°C), March (-1. 5°C). We add these values and calculate the root. It turns out 4.3. Multiply this by d0.

For clays: 4.3x0.23 = 0.99.

For sandy loam and fine sand: 4.3x0.28 = 1.2.

0.99 and 1.2 are the standard freezing depth in meters.

For Moscow the numbers will be as follows:

For clays: 4.8x0.23 = 1.1.

For sandy loam and fine sand: 4.8x0.28 = 1.3.

Types of well houses and their tasks

The primary task of a well house is to protect water from various substances - dust, leaves and other similar contaminants. This requires a tight-fitting lid. Open wells are only possible for technical water - for irrigation. Water from them cannot be used for other purposes. So if you plan to at least wash dishes, the well must be closed tightly.

The lid on the well must lie tightly

Protection from precipitation of any kind is also necessary: rain and melt waters carry with them very dirty water with fertilizers dissolved in it, animal waste, various debris and impurities. If it gets into the well, it can cause serious contamination. To protect against precipitation, they make a canopy, most often a gable one - this makes it easier to remove precipitation.

Another purpose of the well house is to protect from strangers or, in any case, to ensure safety for children. To do this, they make latches or cut in locks.

Option for a closed well house

To make it easier to raise water, they install racks and gates - in the simplest case, a rotating log with a handle to which a chain is attached. And all this together should still please the eyes of the owners, but at the same time require minimal care.

Open or closed

As you can see in the photo, the well house can be open or closed. It’s cheaper and easier to make an open one: the well ring can be trimmed with stone or wood, the lid, racks and canopy can be made of wood or metal - whatever will cost less. A minimum of materials is required for this structure. There is only one “but” - in winter the water in such a well can freeze. If you don't plan to use it in cold weather, no problem.

But for winter use, an insulated well house is required. But even then it can be made open:

- buy a polystyrene foam “shell” for the well - they are of a suitable size, secure it, and then lay the finishing on top of it;

- The overlap of the ring and the lid should be made of several layers of wood, and the boards should be laid in different directions, overlapping the joints.

Closed well house

Another option is to make an enclosed house. It is slightly larger in size than a well ring. The existing air gap is already a good heat insulator, but the protection can be further improved by filling the gaps with foam, for example.

What to make from

Choosing an appearance sometimes takes a long time. The fair half of humanity especially “suffers” from the desire to decorate a well, going through numerous design options and spending a lot of time doing this. In fact, everything is simple: if you have a house and a well is located nearby, you should decorate it in the same style and, if possible, in the same color. Agree, it looks good.

It is better to decorate the well in the same style as the house

What to do if the house is brick or plastered? Choose a finish that matches the style of the site. If this is one of the first buildings on the site, just do it as you like.

The question often arises: to make it from metal or wood. Wooden ones certainly look beautiful. But without proper care, they quickly lose all their attractiveness and become gray and ugly. If you are not afraid of the prospect of regularly, at least once a year, updating the protective coating (remove the old paint, then paint it again), make it from wood. If this is not for you, make it from metal. The entire structure or just the frame is your choice. What’s bad about this option: a frame made of galvanized metal profiles, covered with siding. Especially if the house is decorated in exactly the same way.

Siding well house

As you understand, there are a lot of options. First choose the type - open-closed, then materials and finishes to your taste, understand the design, make a house for the well with your own hands.

Method two. We thermally insulate the upper ring of the structure

Every specialist will tell you that in order to prevent freezing of a well, you need to reduce the thermal conductivity of its upper ring. This method of thermal insulation is performed in two ways:

- by means of polystyrene foam;

- using polyurethane foam.

Let's look at the first method first.

We use polystyrene foam for the ring “under a fur coat”

Here you should prepare the following consumables for work:

- polyurethane foam;

- paint;

- plaster;

- insulating blocks made of polystyrene foam, which are connected using a tongue-and-groove system.

On a note! According to this technology, the first ring on top will be completely insulated, while the second only partially. Now to work!

Step one. Work should begin with preparatory activities. Dig a pit 20 centimeters wide and approximately 0.5 meters deep around the ring. Then thoroughly clean the surfaces from dirt and install the first “fur coat” ball. At this time, make sure that the density of all connections is maximum! Blow out the joints with foam to seal them. Having finished with the first level, proceed to assembling the second and gluing it to the ring. Blow out the gaps that have formed between the layers with foam.

Step two. Next, begin plastering the surface of the rings. This will protect the foam from the negative effects of the sun's rays, which, as we know, worsen the thermal insulation properties of this material. After the plaster has completely dried, apply paint to it - this will prevent the finish from getting wet.

Step three. All that remains is to fill the pit and thoroughly compact the earth.

Penoplex, we insulate the foundation reliably and correctly

We recommend that you read our article on insulating the foundation yourself. You can find out more here

We use polyurethane foam for the ring “under a fur coat”

If you chose polyurethane foam as insulation, then follow these steps. First, dig a similar pit (as in the previous method of insulating a well for the winter), and then build a wooden frame around the first ring. But this is in general terms; let’s analyze the procedure in more detail. Prepare the following materials for work:

- paint;

- dowels;

- polyurethane foam sprayer;

- collapsible metal formwork;

- plaster;

- a piece of plastic film;

- wooden bars.

Step one. Traditionally, start by digging a pit, but narrower (maximum 10 centimeters). After this, install bars around the first ring in increments of approximately 40 centimeters. Cover the edges of the trench with formwork made of thin sheet steel, which will exactly follow all the contours. Cover the formwork with the prepared film. For what? This is explained by the fact that the adhesion of foam plastic is very significant, and therefore dismantling the formwork is impossible.

Step two. Having finished building the formwork, you will notice that a void has formed between it and the ring - this is what needs to be filled with insulation. Upon completion of pouring, the polyurethane foam will increase in volume, and the trench will therefore be filled as densely as possible.

After this, you need to wait until the material is completely dry. As soon as this happens, dismantle the formwork. Plaster the finished surface and apply a layer of paint to it. Fill the void left after formwork with earth and compact it thoroughly.

On a note! It is also advisable to cover the well with a lid, which was described in one of the previous paragraphs of the article.

How much does it cost to lay a winter water supply system per 1 linear meter?

installs water supply in:

— Moscow and Moscow region.

— St. Petersburg and Leningrad region.

The cost of laying a pipeline that can be used in winter depends on the region: in St. Petersburg the price of this service is 1000 rubles per linear meter, in Moscow - 1300 per linear meter. The difference in price is due to the difference in labor costs.

We dig water mains mostly by hand. This is cheaper for the client, and besides, the equipment does not damage the site. This is especially important if it is already landscaped.

Bypass drain system

The drainage system can be provided in the house using a bypass. The bypass is installed directly in front of the automation and hydraulic accumulator. It is designed in such a way that when the pump is turned off, water drains from the pipe to the check valve, but remains in the internal system. A tap is installed on the bypass line itself. When it is opened, water is drained from the internal system too.

A check valve is usually installed on a horizontal section of pipe. A tap is installed on the bypass line; when it is opened, water is also drained from the system.

The best thermal insulators

According to their thermophysical characteristics and availability, the best thermal insulation materials are: polystyrene foam, polystyrene foam, roofing felt, film, polyurethane foam or hard plastic segments.

Another inexpensive thermal insulator is penofol - insulation with a foil surface. Its advantage is ease of installation, but its disadvantage is instability to mechanical damage.

| Material | Advantages | Flaws |

| Polyurethane foam | Tightness, resistance to deformation and destructive effects of moisture, high performance, durability. | The need for annual painting of the insulating surface layer. |

| Expanded polystyrene | Waterproof, frost-resistant, easy to install, durable, affordable price. | Lack of resistance to ultraviolet radiation. |

| Mineral wool | Good thermal insulation, affordable price. | Low water-repellent properties. |

More expensive options are solid wood, brick, but in this case you can get insulation and decorate the well shaft.