What is comfort in the home? This is when it’s warm in winter and cool in summer, walking on a pleasant-to-touch, non-icy floor covering, comfortable furniture and a cozy bed for you and your children. Children fall asleep faster and sleep better when it is warm and comfortable to sleep on soft, children's mattresses https://mebelsait.dp.ua/detskie-matrasy.

When you think about building your own home, you have a desire to make it warm and cozy. Modern gas and electric boilers, converters, etc. cope with heating the house, but they cannot create a cozy atmosphere. That is why stove heating is being actively used again.

The stove is a highlight of the design and an economical heating device. It is much easier to find an experienced stove maker to lay a stove. But this long-forgotten craft has only just begun to gain popularity, and there are very few experienced stove makers.

Therefore, a reasonable question arises: “How to build a brick oven with your own hands?”

Laying out a stove correctly requires a lot of effort, and you will also have to study a lot of instructions for laying brick stoves.

Advantages of a simple stove

All simple type ovens have many unique advantages. For example, a minimum of time is spent on their construction. Some models can be erected in just an hour, while others take 1-2 days to install. Small structures are lightweight, which means they do not require a foundation, which saves time, money and effort. You can choose any place to install the structure; if mobile versions are made without using a binder solution, then it can be disassembled at any time, moved and installed in a new location. Any materials can be used for fuel - pine cones, logs, stems of large plants, and so on.

Option for decorating a fireplace stove Source o-remonte.com

It is also important that such designs have lower fuel cell consumption. For example, compared to potbelly stoves, you will need several times less firewood. If you use the simplest stove without binding stones with clay, you can increase the heat transfer, which will be greater than from an open fire. This is a great option for hiking, but not very convenient if you travel without transport. Since the brick is heavy and capacious, it is inconvenient and difficult to carry.

An additional big advantage is the minimal level of smoke, and the fuel itself practically burns without waste. After good heating, the temperature of the stones can reach 1 thousand degrees, which guarantees not only good and fast heating, but also quick cooking of various dishes.

Russian stove

Large-sized and multifunctional oven. But its size is justified by the presence of free space where you can relax. There is a firebox under the bed where you can cook food. Next to the firebox there is a stove, and just below there is a vent that keeps the fire going. There is also a niche for freshly prepared food.

A Russian stove can easily heat a room larger than 40 square meters. But a full-fledged robot will require a lot of raw materials.

Video description

Another option for creating a stove is shown in the video:

- Further, in the twelfth row, exactly 18 bricks are used.

With their help, the door of the cleaning compartment is closed and the formation of the rear wall of the fireplace chamber continues.

- At the next stage - for the thirteenth row, 19 bricks are used.

When using blocks in a fireplace compartment, they are pulled out and cut away. The same row allows you to raise the walls of the open hob.

- Also 19 bricks are used in the next, twentieth row.

They begin to form a shelf above the fireplace insert. To do this, each brick is pushed 3 cm not only forward, but also to the side. The result is an overhanging row over the firebox.

- Further, in the twenty-first row, 20.5 bricks are used.

With their help, the walls of the cooking compartment are completed and the construction of the fireplace mantel continues.

- Then, in the twenty-second row, 15.5 bricks are laid.

They are reinforced with a steel angle above the cooking chamber. Metal strips are also used above this compartment. They are installed in the middle and rear part, the so-called ceiling of the cooking chamber. The elements are needed to subsequently cover the entire tier.

Swede

Refer to compact options. Length and width – 1 meter. The main function is to heat the room, but you can also cook food on it. The unusual thing about such a stove is that the stove is built in the kitchen, and the rest of the stove will be in another part of the house.

This design is fire hazardous. But the risk of fire is reduced with the help of dampers.

Advantages and disadvantages

Wood-burning stove with hob

The advantages of using wood-burning stove models include:

- versatility - suitable for cooking and heating;

- ease of adjustment of fuel combustion intensity;

- the ability to create a comfortable temperature in a large house;

- ease of installation of ready-made devices and construction of brick ones;

- minimum amount of emissions of harmful substances;

- durability of the structure;

- high efficiency - for models with long-term combustion systems it reaches 82%.

The downside of the units is the use of only one type of fuel and the difficulty of building brick modifications for beginners.

Construction rules

A homemade stove must meet fire safety requirements. Therefore, special attention must be paid to preparation for construction.

- Decide on the location of the oven.

- Prepare the correct drawing.

- Buy quality materials for construction.

- Purchase of tools.

- Create a cost estimate.

Correctly drawn up drawings will become your main assistants, since it is the drawings of a homemade brick oven that help you avoid many mistakes. Ready-made plans can be found on the Internet.

When choosing an installation location, you need to take into account the area of the room and the type of oven. It’s difficult to calculate everything yourself, so it’s easier to use a reduced model of a brick oven, a photo of which is available on the Internet.

Preparatory stage

Any work requires preparation of a place, material, tools, and the stove also requires the spiritual investment of the master.

Any wood-burning stove is made of two types of red brick:

- ceramic - performs an enclosing function, builds an external frame;

- heat-resistant (fireproof) - laid out in the center of the stove, where the temperature is high.

On average, the cost of refractory bricks is 4,200 rubles per 100 pieces.

In addition to the brick, you need to prepare:

- A clay compound used to join bricks together. The cement composition is inappropriate.

- Cast iron doors for the firebox, ash pan, and compartments for cleaning channels.

- Cast iron plate with holes (cooking plate).

- Valves that will shut off the wells when the stove is not in use or is already heated.

- Grate - firewood is laid out on it. Oxygen enters through the holes from below, supporting combustion in the firebox.

Having prepared the material, build a reliable foundation for the stove. The finished structure has an impressive weight. A simple floor will not support the structure. A pit is being dug for the foundation of the stove in compliance with waterproofing standards.

After preparing the foundation for the brick structure, let it dry.

Selection of working tools

Compliance with the technology and the quality of the work performed will also directly depend on the auxiliary measuring instruments and tools that must be used during the work on laying the furnace.

When laying a furnace, measuring, construction and many other auxiliary tools are used:

- Jointing - pours the mortar into the seams and gives the joints an aesthetic appearance. It will come in handy if the stove is left without lining or plaster.

- Trowel.

- Hammer-pick.

- Shovel for mortar.

- Plumb.

- Stove line.

Furnace device diagram

Having chosen one of the ordering diagrams as the basis for assembling a wood-burning stove made of brick, you need to print it out and study it in detail.

Stove makers recommend choosing a Swedish model for your home or cottage. You can build a Russian stove for your home. The choice is up to the owner.

Photos are enlarged, click!

Let's look at the rules for installing a heating and cooking model that is suitable for both home and garden. A practical guide for the home craftsman will be supported by photos.

- Laying out any stove begins with the bottom row, which must be perfectly level. Here you need to use a level, a construction angle. The work starts from the outer contour and moves to the center. The bricks are connected using clay mortar.

- The second row has a functional meaning. It is necessary to fill the vent hole with the door. Having determined the location of the door on the desired side, we lay out the bricks in a checkerboard pattern so that the seams do not line up in a single vertical line. Alternate long and short parts.

- Raise the third row to the upper edge of the blower door, blocking it from above.

- The fourth row has its own peculiarity - the brick is placed on the left and another door is installed in the blower area. This compartment will be responsible for the accumulation and cleaning of ash obtained from the combustion of firewood. The hole will also be located in the fifth row. Therefore, the principle of work is the same. Here it is necessary to provide for chipping the brick so that sharp corners do not interfere with cleaning the compartment.

- From the sixth row, refractory bricks are used. Laying out the firebox begins, where the temperature is the highest. Order drawings usually have a special shading for the location of this material. Therefore, there should not be any difficulties. Using the diagram, you can calculate in advance the amount of all materials. A grate is placed at the base of the row on which the firewood will be placed. It is necessary to trim off rough corners so that the grille lies flat.

- From the seventh row, in addition to the combustion compartment, the channel is rebuilt; it is divided into three wells. Following the scheme, this nuance will not go unnoticed.

- A firebox door is mounted on the horizontal of the 6th row, which is gradually covered with brick from above.

- We gradually approach the cooking compartment of the brick stove, observing the sequence of ordering schemes.

- After completing the masonry of the cooking portal, we move on to the nuances of the heating hearth. How warm the house will be in cold weather depends on the correctness of its construction.

It’s also worth taking the time to study the chimney system, which has its own characteristics in every home.

Conclusion:

It’s also worth taking the time to study the chimney system, which has its own characteristics in every home. Some owners choose the method of embedding a stove into a ready-made pipe, which has separate wells for removing combustion products and filtering air. Sometimes you have to build a separate pipe for a wood-burning stove, which is located away from the exhaust duct. Then the specifics of the work on the construction of the stove at the end of installation will have a different sequence. Create comfort and warmth in your home yourself, so that you can enjoy it later. Be sure to put your heart and soul into the process of building a wood-burning fireplace. The stove will give its warmth to each family member both in the winter cold and in the autumn slush. If you add ingenuity and design ideas for the design of the façade or around the entire perimeter of the fireplace, the stove can become a unique object in the interior of a country house or dacha.

Materials

The heat transfer and durability of the stove will depend on the material used in construction. Therefore this stage is very important.

For cladding, ceramic bricks are used - grade M-500. It is insensitive to temperature changes. And the combustion chamber needs to be laid out only from refractory bricks.

In addition to bricks, the following is used:

- Sifted sand.

- Clay – normal fat content.

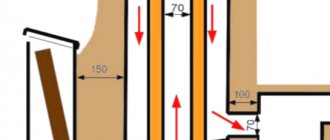

Stove chimneys are multi-turn smoke circuits.

In multi-turn stove chimneys, the smoke channel consists of vertical and horizontal sections connected in series. In such furnaces, flue gases, when moving, overcome a large number of revolutions, which leads to soot settling in the channels. In such furnaces, a cleaning device is a prerequisite. In such a system, the gases are greatly cooled, and the draft in the furnace deteriorates. During the initial period of combustion, the stove smokes. Cooling of flue gases can lead to condensation.

In a multi-turn system, gases must pass through channels, making turns, which leads to resistance to their movement. To overcome resistance, it is necessary to have good draft in the chimney. Such draft can be created by increasing the height of the chimney, which is possible within certain limits. Another way to obtain good draft is to increase the temperature of the gases at the chimney outlet, which will inevitably lead to heat loss and increased fuel consumption. A multi-turn system of stove chimneys makes sense only if they are short in length. Another disadvantage of multi-turn systems is the unequal heating of the furnace in the areas of the first and last channel, and this can lead to cracking of the masonry. But the biggest disadvantage of a stove with multi-turn chimneys is that heating it requires a large amount of fuel, which is not commensurate with the amount of heat generated. Therefore, using a multi-turn system without the improvements described below is generally not recommended.

Foundation for the stove

The basis for a homemade stove is made at the time of construction, since a brick stove requires a strong foundation

First, they dig a hole. It is necessary to take into account that the width and length of the pit must exceed the size of the foundation by 20 cm

Afterwards, the pit is leveled and half filled with sifted sand, compacted well and leveled. Waterproofing is laid on top of the sand, and formwork is installed.

Next, all free space is filled with concrete mortar, bringing it to ground level. Be sure to check the surface for horizontalness using a building level.

After 5-6 days the concrete should harden. After that, the formwork is dismantled, waterproofing is laid and the foundation is brought to the floor. There are two ways to bring the foundation to the floor:

- lay out of brick;

- re-build the formwork, filling it with concrete up to the beginning of the floor. All voids are covered with sand, compacting it.

Concrete mortar recipe - one part of cement contains 2.5 parts of sand and four parts of gravel.

Homemade long-burning bubafon

Using a grinder, cut off the weld seam from the top end of the barrel and smooth out the sharp edges. The result is a cylinder and a lid with a finished flange. Using a hammer or sledgehammer, bend the edges of the cylinder inward. And bend the flange of the lid outward. Turn the cap over and place it on the cylinder. The lid will sit securely in place without slipping.

Using a chisel, cut a hole for the blower pipe in the center of the lid (so that it fits freely into the hole, it is enough to use a diameter of 102 mm).

Assembly diagram for “bubafoni”.

The hole for the plug on the lid can be sealed tightly, but it is better to leave it: by looking inside you can regulate the combustion process.

Then, at the top of the barrel, a place is marked for attaching a piece of the chimney pipe.

The intended hole is cut out and a piece of chimney pipe 20-25 cm long and 150 mm in diameter is welded. You can install a shut-off valve directly inside the pipe. The stove body is ready.

Next in line is the air supply device. For greater rigidity, the edges of the pancake are bent (so that the pancake does not curl from the heat). A hole is cut in the center of the pancake for the blower pipe, and it is welded. If a lid from another barrel is used for the pancake, then the hole for the cork is sealed tightly: during combustion, gases will pass only around the circumference of the pancake. Channels or corners are welded to the pancake from the bottom side. The air supply device is also ready.

It will be inserted inside the cylinder. An adjustment valve of the same diameter as the pipe is placed at the top of the blower pipe. A threaded pin is welded vertically to the inner wall of the pipe; a hole is drilled at the edge of the damper for this pin, ensuring that the damper mounted on the pin closes the pipe exactly.

After installing the damper, tighten it with the wing nut. By loosening the nut, moving the damper towards the edge of the pipe and tightening the nut back, it will be possible to regulate the flow of air into the firebox.

Place the lid on top and the entire stove is ready.

All that remains is to install the chimney pipe. Its diameter must be less than 150 mm, otherwise combustion products will not be completely removed. For good traction, it is better to have a pipe 5 m long. Install it near the stove, preferably on legs. Weld the bottom of the pipe hermetically.

Connect the stove end-to-end to the elbow, which is welded to the chimney pipe, tighten it with a clamp, placing fiberglass under it for tightness. To drain the condensate that collects in the pipe, a ball valve is welded under the pipe elbow (a rod can be used to clear the blockage).

This tap is absolutely necessary, since freezing of the condensate can cause the weld to rupture. Condensation, in addition, can flow into the stove, and through leaks in the connecting clamp - out.

Now you can now heat the “bubafonya” stove. After removing the cover, pull out the air supply device. Place the firewood - the height should not exceed the height of the lower edge of the chimney elbow. If you place firewood vertically, more will go in. You can choose large logs, up to 20 cm in diameter - they will burn without any problems.

A top layer of finely chopped wood chips is formed. Place a rag or paper on top and pour a little kerosene on it. Now the firewood is covered with a pancake of the air supply device, and the stove lid is strung on top. When opening the air damper, throw a piece of lit paper or rag inside the air supply pipe (matches quickly go out due to strong draft).

When the firewood flares up with a characteristic crackling sound, the blower damper is completely closed. Bubafonya can work in this mode without any supervision for days.

This long-burning wood stove produces little ash due to the fact that the wood burns almost completely. The ashes may not be removed for a long time.

As you can see, it is quite possible to construct “Bubafonya” stoves with your own hands. Many craftsmen make them not only from barrels, but also from old gas cylinders and large fire extinguishers. The main requirement for a future furnace is strong steel walls.

This is how you can make a long-burning stove.

Masonry process

The masonry mixture is prepared from sifted sand and clay. The clay is left in water for a couple of hours, after which it is sifted through a sieve. Currently, there is no need to prepare this mixture yourself. A number of companies offer ready-made masonry mixtures in various packaging. Using such masonry mixtures is preferable to making them yourself.

Industrial sieves sift a finer fraction of sand and clay, which makes it possible to obtain a more plastic and homogeneous mixture. This mixture will eliminate the formation of voids and air bubbles in the seams during laying.

First, the outer layer, which consists of bricks, is assembled, and then the middle. There should be no voids in the seams, so fill them with a clay mixture.

The first rows are built using solid bricks. The first row of stitches requires dressing. After the first rows are ready, the brick will have to be cut.

The chopped side of the brick should be inside the masonry. This rule is also used when constructing smoke ducts. The chimney is built from red burnt brick. And the opening of the firebox is created using a metal corner, a “lock” layout.

Before the first fire, it is recommended to wait 3 weeks.

Video description

You can clearly see one of the options for arranging a Swedish stove without a fireplace compartment in the following video:

- The next, tenth row is created with bricks in the amount of 17.5 pieces.

They cover the front part of the place where the oven will be. The blocks are mounted directly on metal strips. Their installation allows you to combine the space above the firebox and oven. In this case, cutouts are first made at the top of the bricks used. They will allow you to subsequently lay the cast iron hob.

On a note! At the same stage, a place is designed where in the future a small door will be installed, allowing the upper part of the fireplace chamber to be cleaned.

- For the next, eleventh row, use 18.5 bricks.

From these they begin to build the walls of the brewing compartment, where there is already a cast iron panel. The brick blocks laid on the right should close the gap between the fixed cooking plate and the already created wall. At the same time, the blocks that are used to create the back wall of the fireplace chamber are pushed forward 4 cm and then pulled together. This allows you to continue creating the inclined surface.