Complete water supply in a private house is ensured by installing a pump in a well. Water can be taken from the mine by two devices, a surface and a submersible device.

Each option involves the use of centrifugal or vibration units. The use of a surface device is limited to the depth of the aquifer, no more than 10 meters, and a submersible pump is capable of extracting water from a depth of 60 meters.

Required materials and tools

In order to quickly install a submersible or surface apparatus in a well, install a water pipeline into the house and install automation for starting and monitoring the water supply, it is necessary to carry out preparatory work.

Purchase materials and equipment that will be needed to install the system:

- submersible or surface pump;

- set of automation equipment with hydraulic accumulator;

- pressure hose;

- distribution tee for submersible version;

- check valve;

- coarse filter for surface version;

- fitting;

- insulation;

- geotextiles;

- stainless steel cable;

- cable for supplying electricity to the pump;

- auxiliary materials for fastening and waterproofing.

To carry out installation work you will need the following tools and equipment:

- Shovels, crowbar.

- Bulgarian.

- welder.

- Electric drill.

- Screwdriver.

- Roulette.

- Set of open end and socket wrenches.

Equipment replacement

Sooner or later everything goes wrong. Therefore, it is necessary to foresee the possibility of repair and maintenance in advance. In the simplest case, the owner simply pulls out the entire structure by the halyard and performs the necessary manipulations on the surface. In stationary systems, it is desirable to have access to the connection point of the line to the flexible hose. Usually, a well of larger diameter is equipped for this purpose, allowing the master to go down there. When working, be sure to turn off the power supply.

Correct connection

Installation of the submersible apparatus and installation of the surface apparatus are carried out with a connected pressure pipe. Despite the difference in use, both hoses, pressure and suction, in their parameters must meet the requirements:

- rigidity - pressure differences should not affect the shape of the pipe;

- wear resistance - abrasive elements in water should not damage it;

- frost resistance – not to deform during operation at low temperatures;

- environmental safety - the drinking hose must be made of materials that do not emit toxic substances;

- operating temperature range from +1 °C to +40 °C.

Products made of polyvinyl chloride (metal-plastic and polypropylene) shown in advertising photos meet these requirements. Hoses are used to lift water and move it into a house or storage tank in the country, and they are fixed to the pipes of the pump, tee, or adapter using fittings.

Drainage pump units for draining a well

How to troubleshoot pumping station problems yourself

Cleaning or repairing the well shaft is carried out when it is drained. The drainage pump copes with the task most effectively. Devices of this type are rarely used for pumping clean water.

Submersible drainage pump

There are two types:

- Submersible - installed at the bottom of the well shaft. Having small weight and dimensions, they have great productivity. Due to their design, they can be used in both dirty and clean water. They fail when air enters the system; to avoid this, it is recommended to install a float switch that turns off the device when the water level drops. According to the specifics, the work is divided into centrifugal and vibration.

- Surface - installed away from the well on a prepared site. It does not require constant monitoring of the water level since only the suction pipe is lowered into the well. Such pumps have increased reliability. The engine does not come into contact with liquid, which significantly extends their service life. The disadvantage is working with shallow wells (up to 10 m) and high noise levels.

Surface pump for clean water

To ensure that the pump motor does not overheat and fail, a thermal relay is additionally installed on it. It monitors the increase in engine temperature and turns it off if the system overheats.

An aquasensor is also a good assistant for submersible pumps. Using this regulator, the user can set the required water pumping level, upon reaching which the pump turns off automatically. The minimum level indicator can be set at 5 mm.

Important! Drainage pumps are used in water with a temperature of no more than 35-40° C and are not suitable for pumping out hot water.

How to hang and secure with your own hands

To prevent the device from ending up at the bottom during operation, it is necessary to securely fasten it with a hose to the wall of the shaft on a metal structure.

- A square-shaped frame with brackets at the corners for fixing to the wall is made from a steel corner using a welding unit.

- Two channels are welded along the diagonals of the square, and a hole is made at their intersection.

- The frame is rigidly fixed on top of the mine casing using brackets.

- A steel cable is passed through the hole in the channel, and a loop is crimped at its end to hold it on the structure.

- The pump is suspended from the safety rope and is used to remove it from the well.

Step-by-step instruction

- First of all, it is necessary to find a pressure pipe at the pumping unit, to which the pipeline is connected, through which the wastewater will be pumped out. The clamp is carefully tightened at the connection point using a screwdriver or pliers.

- Most models are equipped with a float switch. If it is present in the model you choose, then a check valve should be installed on the connected pressure hose, which will prevent water from flowing back into the tank.

- Immediately before installation, you need to check the operation of the unit. Carefully read the instructions for it, manufacturers' recommendations and certificates. Another important point is determining the direction of the shaft. To do this, a household drainage pump is installed on a table or floor and connected to the network. If the movement is to the right, it means the equipment is working correctly.

- The pump unit must be installed exclusively in a vertical position. Make sure that the pressure hose is also directed vertically. Its end is directed into a container where the liquid will subsequently be pumped.

- Finally, the pump is sunk to the bottom of the tank and connected to the power supply.

How to install a submersible machine

At least two people must take part in installing the unit into the source. Installation work of the system from the well to the house is carried out in the following sequence:

- a water supply project is being prepared, taking into account the model of the submersible unit, the automation system, and the required amount of materials for assembling the water pipeline;

- equipment, materials and necessary tools are purchased;

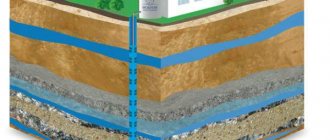

- between the mine and the house we dig a trench under the water pipe, taking into account the cold in your region and 50 cm wide. A layer of coarse sand (20 cm) is poured onto the bottom of the ditch, then a geotextile sheet is spread to protect the pipeline from ground and surface water with abrasive sand;

- On the prepared base, we lay high-pressure pipes made of metal-plastic or polypropylene, which are not susceptible to corrosion, in a trench, having previously been wrapped with heat-insulating material;

- cover the laid lash of the water conduit with a geotextile cloth;

- in the wall of the shaft, at the level of the bottom of the trench, we cut out a hole for the pipe into which we insert the remaining end of the water pipeline; its length should be 30–40 cm. The place where the pipeline enters the well chamber is waterproofed;

- We connect a valve to the submersible electric pump through a fitting, and a high-pressure pipe to it through a coupling. The section of the water pipeline was measured in advance taking into account the depth of the aquifer. We connect a stainless steel safety cable to a special bracket on the pump, and a cable to the electric motor. We secure the wire to the pipe with plastic clamps so that it does not sag;

- above the well we arrange a grid from a metal corner for attaching a safety rope;

- in the shaft, at the end of the water pipe, we fix a tee with a ball valve, which serves for emergency drainage of water. The outlet from the tee, directed into the well, is intended for connecting a pressure pipeline with a pump;

- manually lower the prepared whip with the pump into the source and secure the cable to the bracket. We connect the pipeline from the unit to the tee branch pipe, using plumbing paste to seal it. We lay the cable from the pump along the trench to the house;

- To supply water to the house under the foundation, we install a water pipeline with a cable into the technical room. We connect the hose to the hydraulic accumulator, and connect the cable to the automation;

- We begin commissioning work, start up the unit, and check for leaks. After the test, we dig a trench and begin operating the water supply.

To ensure trouble-free and long-term operation of the system, a PVC hose must be purchased from a specialized store.

Main unit installation requirements

The station itself should also be installed according to certain rules. It is bolted to the base. The base is preferably concrete. A rigid steel frame made of rolled profiles is allowed. Its design is welded or bolted.

It is very useful to install it on a thick sheet of hard rubber - this shock absorber will reduce shock loads when turned on and reduce operating noise.

Much less often for these purposes, spring steel shock absorbers are used, placed under the base, similar to the type of fastening of the eccentric exciter of the vibration table.

But such fastening, at the slightest loosening or violation of the adjustment, can break the mounting sockets on the base of the station and create unnecessary loads on the water fittings - the vibration amplitude is too large. So the best option would be a hard rubber sheet up to 3 centimeters thick. The rigidity is approximately the same as that of a summer car tire tread.

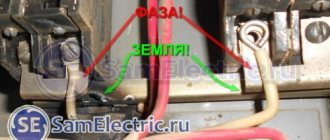

It is important to pay due attention to the electrical part. It is mandatory to connect the station housing to the grounding loop, regardless of the choice of installation location. The use of an RCD (residual current device - the second name for this mechanism is “differential current device”) is very useful - especially if the option with a caisson is chosen or the installation was made directly in the well.

There is no point in overcomplicating the connection diagram. We do only what is necessary

In any case, the station must have an individual protective electrical circuit - at least a circuit breaker with an operating current slightly higher than the rated starting current of the installation.

In addition, the service life of the electrical part of the station is positively affected by the presence of stabilizers, network filters and uninterruptible power supplies. Maybe they won’t be able to have a significant impact on the engine itself, but for the electronics as part of the station’s automation unit, such an addition will be very useful.

Connecting a hydraulic accumulator and automation

To ensure an uninterrupted water supply, it is not enough to know how to connect the device; it is important to protect the pump motor from overheating. In an autonomous water supply system, units with built-in automation are protected from voltage surges and dry operation when there is not enough water in the mine. Monitoring the operation of the pump allows you to regulate the pressure and pressure of the liquid in accordance with the parameters specified in the program.

To provide the house with water automatically, two systems are used: hydropneumatic and electronic.

1 ) In a circuit with a hydraulic accumulator, the hydraulic accumulator capacity with a control relay unit, installed in the technical room, ensures pressure regulation in the pipeline:

- The pressure in the system is monitored by a sensor. When the pressure decreases, when the pump stops sucking in water, the well becomes shallow, the electric sensor transmits a signal to the control relay, which works as a switch, and the unit stops pumping.

Selecting a device type

When collecting drinking water from a remote well, a submersible apparatus is used that is capable of lifting liquid from layers lying at a level of 60-90 m below the soil layer.

Such a pump does not need protection from precipitation and can operate silently and with high performance in any weather, including periods of frost. Installation technology, which involves completely immersing the device in water, reduces the risk of overheating of the mechanisms. The only drawback of the device is the need to lift it for maintenance.

Centrifugal

One of the popular types of submersible pumps, capable of pumping water with sand, while the concentration of the impurity should not exceed 185 g/m³. The plastic or steel pump housing houses a motor that drives a wheel with blades. Depending on the design of the blades, there are 3 types of devices: rotor, turbine and screw. When the impeller rotates, it creates a centrifugal force, under the influence of which the liquid is sucked into the internal chamber and then enters the estate's water supply system.

Such pumps are equipped with automatic equipment to protect against dry running and voltage surges. On drainage models, a float is installed to indicate a decrease in water level.

Centrifugal devices have a particularly strong impeller and are used to clean the well of debris.

Vibrating

In structures for producing water at shallow depths, vibration-type submersible pumps are used. They do not have rotating components, and the movement of fluid in the system occurs due to the influence of the electromagnetic field formed around the core with the winding.

Vibration pump.

When current is applied, the electromagnet attracts the membrane connected to the piston and well water enters the inlet chamber. As soon as the field disappears, the rod returns to its place, closing the inlet valve. At the same time, under the pressure of the piston, the liquid is pushed into the chamber behind it, so that when the magnetic field reappears, it enters the pipeline. The operation of the rod is accompanied by vibration, which can compact the soil over time and thereby reduce the flow of water.

Such models are not characterized by high performance, but they are reliable, quickly installed and do not require maintenance. It is only necessary to check the tightness of the fastenings of the body and rod, since vibration can cause the nuts to unscrew. The equipment cannot be used on floats and placed in close proximity to the bottom.

Preserving the pump for the winter

The main task is to free the pipeline system from water so that it is not torn apart by ice.

Drain taps and pipes are used for this. If the water supply system is equipped with a check valve, it must be opened to allow water to flow back into the well.

The submersible pump should be removed from the well and carried out a routine inspection: if necessary, clean and lubricate it. Many summer residents do not bother themselves with such an event, leaving the mechanism to winter in the depths.

In principle, this should not cause much harm to the equipment, but there is still a danger of it becoming silted, limed, or simply stolen by various “dashing people” who are eager for other people’s goods.

We preserve the pumping station installed on the surface in the same way. We drain the water from the working cavities of the pump itself, from the damper tank and tubes. As for whether to remove the pump from the well and take the pumping equipment with them, each owner decides for himself.

Immersion depth

Before fixing the pump in the well, you need to calculate the depth of its immersion. To do this, you need to know two quantities: static and dynamic water level. The static level is when the volume of water in the well reaches its maximum and its pressure suppresses the pressure of underground sources. The dynamic level is measured depending on the pump power. This is when the amount of water pumped out is equal to the amount incoming. The difference between the static and dynamic levels determines the productivity of the well (its debit).

IMPORTANT! The pump must be submerged at least one meter below the dynamic water level. Both of these values are measured during drilling operations and entered into the well passport

Measuring static depth yourself is quite simple. Do not use the well for 24 hours. Tie a weight to the rope and lower it to the bottom. Then use a tape measure to measure the wet section of the rope.

Both of these values are measured during drilling operations and entered into the well passport. Measuring static depth yourself is quite simple. Do not use the well for 24 hours. Tie a weight to the rope and lower it to the bottom. Then use a tape measure to measure the wet section of the rope.

With dynamic depth, things are more complicated. You need to immerse the pump in the well, turn it on and gradually lower it until the water stops decreasing. After this, measure the depth with a rope and a weight. If the water does not stop decreasing until the well is completely empty, then the pump is too powerful and is not suitable for your case.

Cleaning a heavily silted well

The problem is that if there is a lot of sludge and its consistency is too thick, the intake and working chamber become clogged, which prevents the use of pumps for cleaning wells in normal mode. Enterprising summer residents and residents of private houses have become accustomed to loosening dirt with water pressure. This will require another pump that will supply purified water to the well under pressure.

The essence of the method comes down to the following:

- A container with a capacity of 0.2-0.3 cubic meters is required.

- The hose from the drainage pump is laid so that the raised dirty water falls into the barrel.

- Settling occurs in the tank, as a result of which the raised substance stratifies. On top there is clean water, below there is sand, clay, mud, silt.

- Impurities are removed from the bottom, and water is pumped back into the well using another pump.

Under the influence of the jet, the compacted sludge is washed away, and in the form of suspended particles is supplied to the surface by a drainage pump. The method is simple, but some people do not consider it advisable due to the high costs of purchasing two sets of pumping equipment. They believe that it is cheaper to hire a crew to clean the source manually.

A detailed look at the problem

The submersible pump is always located in the water column, so it has much less chance of freezing. For example, if a well is equipped with an insulated lid on top, and the distance to the surface of the water in it is more than 2 meters, then the maximum thickness of ice in it will be no more than 20-30 cm. And this is provided that no one will use the well all winter, breaking the ice: let’s say it is located on a summer cottage.

Accordingly, there is practically no danger of freezing for the equipment itself immersed in the water column. Another thing is the supply hose. If the hose is equipped with a check valve that prevents water from rolling back into the well, then when frozen, the ice can break it. Therefore, for the winter, the water supply system should be emptied of water if you do not intend to use the well at this time of year. But if you live in a suburban area all year round, then you need to take care of the thermal insulation of pipes and hoses.

Surface-mounted pumping systems should also be carefully insulated if you intend to use them in winter. There are several options for installing them:

- Inside the well shaft, on a special shelf.

- In an insulated booth next to the well.

- In the basement or basement of a residential building.

In all of the above cases, the water mains leading from the water source to the house should be carefully insulated. Pumping systems located outside are also well insulated; electric self-heating cables can be used for these purposes. Provided there is sufficient insulation, pumping systems can easily be used year-round.

Rules for installing the surface version

Surface pumps are not often used for this type of water supply as they are only suitable for shallow hydraulic structures, up to eight meters deep.

And yet, this option has a right to exist, and its installation is no more complicated than installing submersible equipment.

Surface pumps are easier to install and cheaper than submersible models, but they are only effective for wells up to eight meters deep

Mount the device as follows:

- The surface pump is installed in a special caisson or a separate room.

- A hose of suitable length is connected to the suction pipe of the pump.

- A check valve is attached to the other end of the hose (a protective measure to prevent water from draining when the pump stops running).

- A protective strainer is installed on the valve to prevent various contaminants from entering the pump housing.

- The hose is lowered into the well.

At this point, the installation can be considered complete and a test run of the pump can be done. To install such a pump in a well, a special adapter is often used. In this case, the hose is connected to the adapter, and the adapter is connected to the pump. The rest of the installation procedure is exactly the same.

It is a little more difficult to install a surface pump equipped with a remote ejector into a well. In this case, two hoses need to be lowered into the well. In addition to the suction hose, a pressure hose is also installed. It is connected to the side fitting of the ejector using a special outlet.

In addition to the check valve and filter, an ejector must also be installed at the end of the suction hose. It should be remembered that surface pumps are very sensitive to contaminants in the water supplied from the well.

Content

- General installation diagram for the submersible model

- Preparatory stage - laying the pipeline

- Excavation work - trench preparation

- How to properly lay a water pipe

- How to lower a pump string into a well

- Video instruction: assembly and installation of a pump string in a well

Submersible pumping station: the water-lifting device itself, the hydraulic tank and the control unit