Before starting construction and planting seedlings on a plot of land where moisture collects and puddles form, it is necessary to drain such a plot and equip it with a drainage system. Otherwise, wastewater and groundwater will erode the foundation of the house and buildings, destroy the root system of plants, and waterlog the soil.

A properly equipped drainage system that uses drainage pipes (drains) and drainage wells can prevent possible troubles.

What are drainage wells for and what are they?

A private house or cottage is often located in an area prone to waterlogging; its foundations can gradually collapse under the influence of groundwater. Also, owners are often faced with the fact that there is no sewerage system, which means there is nowhere to put the water from the septic tank. There is a possible threat of flooding of residential and non-residential buildings, especially such as a cellar, garage, bathhouse, garden and vegetable garden. In these cases, a drainage well, and possibly an entire drainage system, is needed.

Collecting excess water in an underground container, by gravity or pumping, with constant or periodic removal - this is the meaning of a drainage well. The system is installed once and will work for the entire period of operation of the house. But during use, the drain well requires periodic cleaning. To do this, silt deposits are lifted from the bottom of a clogged well with a stream of water, followed by pumping or draining them.

The drainage well device can be of three types :

- Inspection (inspection) and drainage wells for sewerage, located at the places where drainage pipes turn and intersect or every 40-50 meters of drains, periodically clean them, and if there is no drainage, pump them out. To construct such wells, it is often enough to use a pipe with a diameter of 34 cm or more.

Inspection well at the intersection of drainage pipes Source rinnipool.ru

- Collectors (water intakes) are the final points for draining water, most often only surface water (storm water, melting water, stream water), with its pumping into a sewer system, reservoir, or use for household needs. They are characterized by a rather large volume, often an impenetrable bottom, and a built-in staircase is common for them. The placement of the pump and maintenance procedures impose restrictions on their diameter - at least 70 - 100 cm.

- Backfill (absorption, filtration) , they are located in places where they want to get rid of puddles, for example after washing cars. Around them it is planned to pour a large mass of rock, crushed stone, and screenings, both for supplying water to the well and for draining it through its bottom into deep water horizons. In particular, the bottom of the grouting well is covered with a layer of crushed stone 30 cm thick. In this device, partial bacterial and mechanical treatment of wastewater occurs, with periodic washing or mechanical extraction of silt and sand.

This is what the diagram of a filtration well looks like Source flotenk.ru

In cases of mixed type wells, their functions overlap, and the structure of the drainage well changes.

Thus, a water intake well can discharge water into a grouting well. In this case, it does not require a sealed bottom and can do without a pump, but it still needs periodic inspection and cleaning, like an inspection well.

Location on the site

Before planning the construction of a well on a site, be sure to follow the rules for its location relative to other objects. All distances and standards are indicated in SNiP. If you do not comply with all these standards, the SES will not issue a construction permit.

The storage system is sealed, water does not enter the ground. The minimum distance for a storage well is 5 m from the foundation of a residential premises. But it is better to increase this interval to 10 m, if the territory allows. This will prevent the penetration of unpleasant odors into the house and protect the foundation from destruction. The distance will allow you to create the required slope of the pipes during excavation work and will help the entire sewer system operate properly.

Manufacturing materials

The traditional material for the walls of drainage wells is reinforced concrete rings. Reinforced concrete is also used as a bottom material (a reinforced concrete disc is placed at the bottom of the hole, at the base of the future drainage well) and a cover (with a hole for a hatch). Reinforced concrete is quite cheap, strong, and durable.

However, the installation of ready-made reinforced concrete requires the use of lifting equipment or large labor costs; the joints formed during installation can be difficult to seal.

See also: Catalog of companies that specialize in installation and design of sewerage systems

Installation of reinforced concrete rings will not be possible without the use of special equipment Source gidroguru.com

These structures are usually installed by first digging a large pit. And after installing the first ring and installing asbestos, ceramic, cast iron or other heavy and fragile pipes, it is gradually covered with soil using bulldozers and excavators.

This is a rather expensive technology that disturbs the top layer of soil. Recently, wells made of plastic and composite materials are increasingly being used.

Application of large diameter plastic pipes

A modern solution for creating a drain well is the use of large-diameter pipes made of various types of plastic. The following are the features of plastic pipes:

- The design is seamless, which ensures a high level of tightness.

- Plastic does not react to exposure to high humidity, unlike many other materials. Therefore, it is ideal for creating a drainage well.

- Plastic is made from petroleum products, which ensures resistance to various substances.

- The pipes in question do not respond to low temperatures and can be used if the temperature of the wastewater is very high.

- The low weight means that there is no need to prepare the base for the creation of the structure in question. In addition, the light weight of the pipe simplifies its transportation and installation.

- Modern production standards determine that pipes can withstand significant pressure from the environment or wastewater.

However, there are also a few disadvantages to consider. An example is the following information:

- If the soil is not properly stable, it can have a significant impact on the pipe structure, resulting in cracks or deformation.

- The indicator of possible pressure exerted by the accumulated liquid or soil is also relatively low. Therefore, plastic pipes are practically not used in cases where the structure is deeply buried.

- Plastic is susceptible to certain chemicals. Therefore, they should not be used in the case of wastewater disposal from industrial buildings.

A fairly large list of advantages is determined by the fact that today almost everyone in suburban areas uses large-diameter plastic pipes as a well.

Video description

About the installation of plastic drainage wells in the video:

Advantages of a plastic drainage well

Instead of massive reinforced concrete rings with steps and pipes in which a person can easily fit, composite and plastic thin-walled devices, including small diameter ones, are increasingly being used. In this case, you can immediately install a ready-made well on the site.

This approach allows you to quickly and cheaply equip and maintain the drainage of a private house, garage, or bathhouse.

Drainage wells made of plastic are distinguished by the fact that the installation of a drainage well, dismantling and reinstallation of the new system and light pipes leading to it (usually also plastic) can be done by one person without the involvement of special equipment and without serious disruption of the landscape.

Plastic wells will require fewer resources to install Source giropark.ru

Where to begin?

Of course, before starting construction, it is necessary to draw up a detailed diagram of the sewage system of a country house. Only under this condition can you avoid mistakes and not do the same work several times.

At the initial planning stage, the following activities are carried out:

- It is necessary to determine the location of the drainage well. It is better if it is a platform that is located below the level of the house.

- Now you need to determine the point where the downhill sewer pipe will exit the house.

- Next comes the stage of drawing up a diagram to scale indicating the dimensions of the pipes. In this case, you need to calculate the number of connections. The quality of the system depends on how accurate the measurements are. In addition, at this stage it becomes clear what materials and in what quantities need to be purchased.

Installation sequence

How to install a drainage well:

- Pouring the concrete bottom of the well if its tightness is necessary.

- Installation of a composite or solid well.

- Laying and inserting inlet and outlet pipes.

- Arrangement of such parts as a ladder, cover, hatch, pump.

- Using a level, check the verticality of the well and the horizontal slopes of the pipes.

What tools and materials will workers need?

The main responsible and time-consuming work when installing a drainage well is making a tie-in and its subsequent sealing. In addition, it is necessary to dig holes and trenches, adjust pipes to length, adjust their slope to gravity, and adjust the depth and height of the well.

Based on this, a grinder (angle grinder) is required for work. If the material of the well is concrete or composite, asbestos and ceramic pipes are used, then the grinder requires diamond discs for concrete and a sledgehammer. If the well and pipes are plastic, metal discs and a hammer are enough. In addition, you definitely need a level, which can be supplemented with a plumb line, a level, as well as a tape measure, cord, shovels, trowel, and bucket. For digging narrow trenches, a convenient device is made from a piece of tin, twisted into the shape of a truncated cone and nailed to a stick.

Trenches for pipes and a hole for a well can be dug manually, but it is unlikely to cost less than calling an excavator Source deilo.ru

To seal the cut-ins and level the bottom, giving it the shape of pipe trays, use cement mortar, or, if dealing with plastic, use glue, plaster or tape, or sealant.

Requirements

When choosing a material, you should take into account the basic requirements for wells. Let's take the following points as an example:

- High tightness.

- Long service life.

- High strength.

- Easy to maintain.

- Ease of installation work.

The most suitable materials are selected to meet these requirements.

Where to place the drainage well

As for the inspection well, it is usually located a couple of meters from the lower (or conventionally lower) corner of a residential building, which is surrounded by drainage pipes. In such a well, most often there are three inserts for pipes: two drainage and one drain (this pipe can drain water into a sewer, a reservoir, into loose soil down a slope, or into a drainage well of another type). It can be very small, and then to check its condition it is enough to have a tiny removable hatch and a sludge dipstick (like a car one, which is used to measure the oil level).

A collector well is necessary if the soil is clayey and does not absorb water well. It is located a couple of meters from the lower (or conditionally lower) corner of the site or behind it, in cooperation with neighbors. They immediately provide for how to safely descend into the well in an emergency. Let's say it's raining, and a bag of garbage is stuck in the drain hole, what should you do? They also find out what useful volume the collector needs (practice shows that it is better to immediately take it with a reserve).

The volume of the collector well should not be small Source vi.decorexpro.com

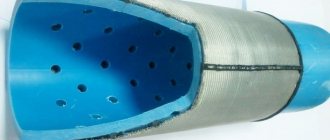

A grouting well is usually installed after a septic tank, if there is no sewerage or other drainage area nearby, and the volume of discharge of household or cleaning waste is small (about 1 m³ per day). Concrete is practically unsuitable for such a structure - it is better to take composite, metal, or plastic. Before backfilling, such a well is lined with soft material, protecting it from damage by blocks of stones and rubble, and after backfilling it is perforated by drilling holes in the lower part from the inside.

Types of wells for sewer systems

Before you figure out how to make a sewer well, you need to find out what types of these structures will need to be included in the diagram.

The system may include the following types of wells:

- Perepadny;

- Observation;

- Turning;

- Cumulative;

- Filtration.

It often happens that one structure is built to simultaneously perform several functions.

As a rule, the structure of a sewer well consists of a working chamber and a neck covered with a hatch. What design features do certain types of these structures have?

If the sewerage pipeline is long enough, then you cannot do without the installation of inspection wells. Their functions are to provide monitoring of the system and ease of cleaning in case of blockage.

Advice! According to the rules, the distance from the sewer outlet from the house to the first inspection well should not exceed 12 meters. But it should not be placed closer than three meters from the foundation. Subsequent inspection wells are located at a distance of 15 meters from each other.

A rotary well is installed if it is impossible to ensure a straight line arrangement of the pipeline. At the place where the pipe turns, a well is installed that can simultaneously be used as an inspection well.

What type of pump should be used to pump out drainage water?

A pump is a common attribute of all types of wells. To pump out drainage water, both stationary and periodically used pumps are used. For continuous operation, select a pump of small capacity but sufficient power, such as a submersible drainage or drainage float pump.

A powerful and efficient pump is used to periodically pump out silt and sand deposits. If a pump is used to pump out a pond, extract sand, or deepen the bottom of a port, it is probably suitable for getting rid of sediment from a drainage well.

A submersible pump for a well will help you easily pump out liquid from an overflowing container Source abad.uz

Pumps suitable for removing sediments are called differently: mud pump, submersible pump, fecal pump, centrifugal pump, sand pump, hydraulic pump - the question is not the principle of operation or name, but whether this device is intended for pumping out sediments, including silt, sand and even small pebbles.

In principle, any pump according to the technical passport “drainage” should pump out accumulated deposits, but for this it may not have enough power (say, the “Malysh” pump) or steam. Two pumps are usually used to remove deposits. Also, a container of about 200 - 300 liters may be required. The sequence of work is as follows:

- A mud pump pumps water out of a drainage well.

- A water-type pump supplies, as powerfully as possible, clean or settled water from a container or other source.

- A mud pump (for example, Pumpex SK series, Makita, Kärcher, Grandfoss), switched on when the water flow starts, pumps out the turbid water, carrying away sediments.

- Another option for cleaning sediments: a team scoops out sediments with buckets, trowels, and shovels by hand.

The manual cleaning method is the cheapest, but not the cleanest Source megapolis-tula.ru

In any case, drainage storage wells require maintenance using pumps (the water still needs to be pumped out before manual cleaning).

Features of the design

Local sewerage is designed to collect wastewater generated during domestic use. The sewage system of a private house, depending on the design, can be of three types:

- storage well;

- drain hole;

- multi-chamber septic tank.

These sewerage options in a private house differ in scale and shape. However, they all share common required design elements, including:

- a neck that can be closed with a hatch or lid;

- work compartment;

- sealed or draining bottom.