Updated: 04/22/2021 16:52:38

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Vibration pumps got their name due to the principle of operation, where liquid is pumped due to the internal vibrations of a vibrator, which simultaneously creates a vacuum and excess pressure. Thanks to it, water is sucked in and pushed out. This made it possible to narrow the shape of the pump, compared to vortex pumps, and make them waterproof so that they can be completely immersed in liquid. Vibrating devices are used to pump water from basements, wells, boreholes and reservoirs. Let's figure out how to choose such a pump and consider 6 models that have proven themselves in practice.

Pumps and their types

Different types of water pumps are designed for pumping liquid from various containers. To extract moisture from wells and boreholes, surface and submersible types of electric pumps are used. The difference between submersible and surface ones is primarily in how they are positioned relative to the water source during pumping. The second difference is the depth from which water is extracted. Surface ones are used to raise moisture from a level up to 8 meters below the axis of the apparatus, submersible - from depths greater than 8 meters. During operation, surface pumps draw in liquid, while submersible pumps push water upward.

Submersible mechanisms are highly productive, have efficient cooling, have different designs and are divided into:

- Vibrating, with which water is pumped by a vibration mechanism;

- Centrifugal, in which water in the working chamber is pumped by the force of centrifugal acceleration.

Naturally, due to their simple design and relatively low price, these types of mechanisms are popular and widely used for various purposes. So which pump is better to choose - vibration or centrifugal? What to pay attention to and how to make the right choice? The information below will help.

Recommendations

If you do not take into account the possibility of theft, then if the well is sufficiently insulated, the pump can easily overwinter inside. To insulate it, it is recommended to make an additional overlap at a depth of about a meter from the ground surface.

A light frame made of bars is attached to the walls of the well shaft, on top of which foam sheets are laid. All joints between the edges of the sheets and the walls of the shaft are filled with polyurethane foam. After this, the threat of freezing of the pump located in the well will disappear completely.

Vibration pump

The operation of the electric pump occurs due to the fact that a field is induced around the core with alternating current supplied to the turns of the coil, changing direction 50 times per second. Naturally, in one direction of the magnetic field the armature is attracted to the core, in the other it is repelled. Armature vibrations are generated and transmitted by the rod to the piston of the working chamber. It moves back and forth along the axis, while water is either drawn into the chamber through the receiving holes or pushed into the pressure line. The outlet of water from the working chamber through the inlet is blocked by check valves.

Advantages

- Unpretentious operation and maintenance due to the simplicity of the design;

- No need to worry about lubrication due to the absence of rotating and bearing parts;

- Less wear and tear, since parts do not heat up;

- They work in water containing mineral salts and alkalis;

- Work in water of any temperature;

- Low power consumption for operation;

- According to manufacturers, they have a long service life (users, naturally, differ in their opinions).

Flaws

The generation of vibrations in a water source when pumping is the main disadvantage. In addition to the unsuitability of the vibration pump for pumping wells, of course, there are other disadvantages:

- The vibration pump coil overheats even during short-term idle operation (5-30 seconds is enough). It is recommended to purchase vibration modifications with a thermal protection option. For example, the “Baby” modification turns off when the coil heats up and turns on after it cools down.

- Vibration mechanisms respond very negatively to changes in mains voltage: performance drops by 50% when the voltage drops by 10%. Naturally, voltage surges cause an increase in load on the mechanical parts and components of the device. Therefore, a voltage stabilizer is needed when the device is connected to the network. According to the passport, to avoid overheating: after an hour of work, you need to rest for 20-30 minutes. When installing a stabilizer, the operating time can be increased.

- Naturally, constant vibration during pumping leads to loosening of the threads in the joints of the parts. You have to check them from time to time.

- Rubber parts wear out quickly when the vibration pump operates with contaminated water. It is advisable to protect the suction pipe with a mesh filter.

- The presence of steel bolts in the body that quickly rust in water.

What are they used for?

Due to the characteristics of vibration pumps and the underground structure of the water source, vibration pumps are not used to equip borehole sources. The fact is that the well is equipped with a casing pipe, at the bottom of which there is a mesh filter, which leaves solid particles contained in underground water “overboard”. Naturally, during pumping, a sand cone is formed around the filter from particles of different fractions that have not passed through the filter cells. This cone becomes an additional natural filter for groundwater.

When vibration equipment is used to pump out a well source, solid particles are separated into fractions in a multi-fraction cone. Small particles fall down to the filter mesh, large particles rise up. Naturally, grains of sand with sizes close to the size of the filter mesh holes clog them, and the rate of entry into the casing and the volume of pumped liquid decrease as a result. If the grains of sand are smaller than the filter cells, they end up in the pumped water, and then events develop in two directions:

- The well is “sandy” - the source water supplied by the vibration mechanism becomes cloudy;

- The well silts up - small particles gradually clog the lower internal space of the pipe and the vibration pump located in it.

The second situation is serious - silting of the pipe. There are also two options here:

- The device can be removed from the pipe (you can, of course, disassemble it into parts and clean it yourself, but to clean the pipe, contact specialized specialists);

- The mechanism will get stuck when removing the source from the casing, after which, of course, you will have to fork out money for a new well (the worst case scenario).

In addition to these problems, another one very often occurs - vibration pumps become the culprits in the process of ground movements and destruction around the pipe. The casing collapses. Naturally, if the house is located next to it, the foundation sags.

From the above it is clear that the vibration pump is not used as a downhole pump. For well pumping, vibration-type equipment is suitable. Even if the water level drops and it enters the intake pipe with silt and sand rising from the bottom, it is enough to turn off the mechanism and wait until the well is filled and the suspended matter settles.

The vibrations generated by the vibrating pump come to the rescue when you need to pump a new well or increase the flow rate of a water source. In this case, they are used to obtain the desired result.

Naturally, in addition to pumping from a well, vibration modifications are used to supply liquid from various containers, for example, tanks, ponds, and flooded rooms.

Choosing a vibration pump

The main choice is technical

The main parameters of any type of pumping apparatus are:

- Q – volumetric fluid supply,

- N – power consumption,

- p – pressure,

- N – pressure,

- h – efficiency.

Naturally, the main function also determines the technical characteristics by which the modification of the working mechanism is selected. The technical parameters are primarily:

1. Height of water rise - pressure (H). This modification characteristic is specified upon purchase. The required pressure is calculated by adding the distance from the top of the well to the water surface of the source, the immersion depth of the mechanism, the length of the main pipes (x0.1), of course, multiplying the resulting sum by a factor of 1.2, which takes into account losses. Modifications with pressure ranging from minimum - 40 m to high - 90 m are sold. Of course, the closer the source is to the house, the higher the actual water pressure in the house will be. If the pressure is insufficient, there will be no moisture at the analysis points. (The “Baby” modification creates a pressure of 56.6 m, the pressure of the Chinese modification “Patriot NP” is up to 80 m, the pressure of the borehole “Vodojet” is up to 110 m).

2. Of course, the performance of the electric pump (Q) is the main indicator. Naturally, it must correspond to the planned load and not exceed the flow rate of the water source. There are three categories of pumping devices based on performance: [p]

3. Optimal immersion depth (h is the same for all manufacturers - 7 m).

4. Power (N) is the energy consumption of the pump to create pressure and flow (flow is the volume of liquid pumped by the pump per unit time). In most cases it does not exceed 300 W.

5. The maximum pressure (p) created by vibration pumps is 0.4 mPa.

Subtleties of choice

Following is noteworthy:

- Is there an adapter that allows you to attach a hose/pipe with a diameter of 19 or 25 mm to the vibration pump;

- How convenient is the threaded connection?

- Is the vibration pump cable long enough to avoid splicing it in the cavity of the source casing pipe (the length should be enough to reach the nearest power supply);

- What kind of insulation does the cable have (naturally, the best insulation is rubber, with which the mechanism can be confidently used at any outdoor temperature in any season).

Water intake from above or below is fundamental

Some vibration modifications have an inlet pipe in the upper part of the housing, some - in the lower part.

If you choose a submersible vibration pump with a top position, you will not have to worry about dirt or sand getting in the water supplied. A device of this modification is placed above the bottom of a water source with a minimum height margin of 30 cm.

To pump out liquid from a well being constructed, increase the flow rate of wells, or pump new ones, vibrating pumps are used that take water from below. In this case, you need to ensure a minimum height reserve under the vibration pump of 90-100 cm, and you need to provide the vibration pump with thermal protection in case it may overheat if left without water (this is necessary, and it does not matter where the suction valve is located).

Housing material

Naturally, to the previous vibration mechanisms with aluminum casings, modifications with plastic casings that are not subject to corrosion have been added. It's hard to recommend anything here. Therefore, the choice of “which is better” depends on the buyer’s decision.

Video description

Instructions for properly rewinding windings in this video:

- If you find out that the housing is intact and the resistance is at the required level, you need to clean the pump (bleed it out).

To do this, you just need to strongly inhale air into the supply hole, and then into the reverse, intake hole. The air flow should flow freely in both directions and not get stuck anywhere.

If you blow into the hole, the valve should close quickly, thereby blocking the oxygen supply. If this does not happen, it means that the adjustment of the device has been completely disrupted.

- The next step is to simply shake the device well.

There should not be any strange sounds inside it. If you hear a non-characteristic ringing, this means that some kind of detachment has occurred or one of the parts has simply fallen off.

Pump Baby after assembly Source etalon-bt.ru

Experts advise lowering the pump into a container of water. You can also add 100 g of acetic acid 9%. If you don’t have it, then lemon will do. Leave the pump in this solution for 7-8 hours.

Then it is washed under running cold running water. Thanks to this solution, limescale deposits can be removed.

- Now you need to check the valve.

There should be a small gap of up to 1 mm from it to the device. Unscrew the hose and lower the pump into the water. Turn it on. If the pump is working properly, then without a valve a stream of water will rise high. A properly operating pump will have a height of from 50 cm to 1 m. Thanks to this experiment, you will be able to judge the pressure.

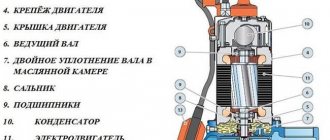

Centrifugal pump

How does it work

The water entering the working chamber, captured by the blades of the rotating impeller, takes over the rotation from them and, leaning to the periphery by centrifugal force, exits the working chamber with pressure into the main line through the outlet pipe. Naturally, new water is sucked into the continuously vacated space of the working chamber by the force of vacuum, drawn into rotation by the moving blades and flows after the liquid that has gone to the periphery of the working chamber. Of course, the process is continuous, so no pulsations occur in the pipeline - there is an even flow of water under pressure.

The power of the submersible mechanism, of course, is increased by increasing the number of working chambers running sequentially - in cascade. The more working chambers, the longer the cylinder of the pumping mechanism.

Advantages

- Centrifugal type modifications are universal due to the peculiarities of their operation;

- There are no pulsations in the pipeline and near the device,

- Quiet pumping (an important quality);

- High operational reliability;

- Affordable, although higher price;

- Easy to operate and maintain (easy to repair with your own hands);

- Very reliable;

- Wide area where they are successfully used.

Flaws

- The need for maintenance and its complexity associated with the presence of a large number of working chambers;

- The electric pump is particularly sensitive to voltage changes, requiring connection through a stabilizer,

- Sensitivity to fluid contamination.

Naturally, centrifugal-type devices are used for various purposes. They do not have the main disadvantage of vibration ones, so, of course, they are suitable and are successfully used by site owners for pumping water from wells. In addition to modifications for supplying drinking water, there are fecal and drainage devices.

Ways to improve efficiency and ease of use

Of course, a centrifugal apparatus is used to work more efficiently and conveniently if it is equipped with additional technical devices. These are:

- A valve that prevents water drawn into the working cavity from flowing back;

- Coarse filters that prevent solids from entering the pump;

- Signaling and protective device that protects the electric motor from possible overheating;

- Float switch for automatic operation of the mechanism;

- Touch sensors turn off or turn on the device when there is no water in the source and when it is replenished, when the water level drops/rises to a set height (the pump does not run dry and does not overheat).

How to choose the right one

Centrifugal devices are characterized by high productivity, rare maintenance, an operational life of 4-5 years, and work in water wells of any type.

When choosing a centrifugal pump, of course, they take into account the same parameters as vibration pumps, and also pay attention to the following factors:

Water pollution - Since a pump is purchased to pump out a specific well, you need to know the flow rate and dynamic level of the well, and, of course, it is equally important to know the degree of purity of its water and what kind of soil is present at the bottom. Consequently, the modification of the water apparatus must comply with the degree of purity of the water masses for which it is purchased. That is, you need to know what size particles are contained in the liquid. The accompanying documents for the device, of course, contain information about the highest concentration of contaminants that it can handle (mg/l) or indicate what size solid particles can be. Of course, submersible devices are in most cases equipped with filters that mechanically purify the water. However, if such a device is operated in an unsuitable environment, the filter becomes clogged too quickly and requires frequent cleaning. The complexity of operation is obvious.

Length of the power cable – It should be sufficient without extension.

What is the diameter of the pump outlet pipe. Accordingly, he will need to purchase the required number of pipes to construct a water main from the depths of the well.

Since the pumping device will “hang” at great depths, a reliable cable of the required length is necessary.

Additional equipment is also an important parameter. The water level alarm sensor guarantees that the device will stop operating when the water level drops to a critical level. However, a float type sensor cannot always be installed in water wells. In this case, you need to pay attention to the degree of protection of the submersible device. It is necessary that it turns off when switching to “dry running” or when overheating. Many models have a mechanical fluid filtration system and a manufacturer-built check valve.

Devices can come with all of the above add-ons and more. It is often cheaper to buy as a set than to purchase each of the add-ons separately.

The brand and price of the submersible device are also important selection criteria. It is more advisable to contact a specialized store that sells products from well-known quality brands, and a warranty is attached to the purchase. You can choose hydraulic devices from brands such as Aquarius, Gilex, Elitech, as well as imported ones.

When choosing, it is important to find out whether there is a warranty service network and other details for resolving issues related to the purchase.

And of course, the diameter of the product must match the diameter of the well pipe.

Many buyers, preoccupied with the choice and the question “which is better,” read reviews about this technique on websites and forums on the Internet. In this case, of course, it is better to turn to specialists you can trust.

In addition to vibrating and centrifugal submersible devices, there are two more types on the market.

Important little things

Quite often, it is the most important details regarding the operating conditions of the equipment that are usually written in the instructions in the smallest print. And it is these little things that you should pay attention to when purchasing equipment and installing it.

As for both submerged and surface models, a check valve must be included in the general well layout scheme, which prevents the outflow of water from the pipeline. However, for submerged models, the malfunction of such an element or its absence when used with a rubber or plastic hose is not critical; during operation, water is still pushed out of the pump and then follows the hose. But for surface models, the presence of such equipment is extremely important; in addition, when periodically using a surface pump without a check valve at the end of the PVC pipe, you will have to constantly have 5-10 liters of water on hand to pour into the neck of the pump before each new start of the engine.

And of course, safety - submerged models have a high class of insulation, both of the cable and of the electrical equipment itself, which cannot be said about surface models with an open electric motor.

Vortex pumps

The design of the devices is somewhat similar to centrifugal ones; their main working chamber is equipped with a rotating wheel with blades. The shape of the working chamber and wheel blades of the devices differs from centrifugal ones. In addition to centrifugal swirling of water, they also create powerful turbulence, as a result of which a powerful liquid pressure is organized at the outlet (3-9 times more than centrifugal ones). This achieves a reduction in the number of working chambers without reducing pressure and productivity.

The simplicity of the design was reflected in the price of the submersible device. Its cost is lower. Such devices will not be damaged by air entering during pumping, which is why they are used in production. Vortex turbulent stations are used for pumping dispersion mixtures saturated with gases.

The disadvantage is sensitivity to fluid contamination. Also, these are the fastest-wearing units (you need to take care of replacing parts). For these reasons, they are not very popular among summer residents.

Second stage: disassembling the device

Let's find out how to properly disassemble the Baby pump before a thorough inspection.

It is advisable to disassemble the pump according to the instructions. Some people are unable to complete this procedure because the screws included in the structure rust and oxidize so badly that they simply cannot be removed from the body. In this case, of course, you should contact professionals.

Disassembling the Baby pump is carried out according to the following scheme Source vodatyt.ru

If you still manage to disconnect the screws, then you can see for yourself what’s wrong.

After the pump is disassembled into two parts, the electrical part is inspected, and then the mechanical part.

Screw Pumps

A screw submersible device operates on the principle of an Archimedes screw. A working screw (rotor made of steel) of complex configuration touches the edges of an elastomer cylinder so that cavities of varying shapes are formed. The cylinder and screw together are called a gerotor pair. Whatever position the rotor is in, the total volume of the chamber cavities is the same. When the screw rotates, water moves to the outlet pipe, located in the cavities formed by the gerotor pair. Water enters the main evenly, and the outlet pressure is constant. The mechanism of this modification can pump liquids of different viscosities. Medium-priced samples with a productivity of 1500-2000 l/hour are capable of creating a pressure of 40-60 m.

The advantage is that it is insensitive to voltage surges (a stabilizer is not used during operation).

Among the main disadvantages of this type of device is the large number of friction areas that form in the chamber during operation. The system is very sensitive to water contamination. Incoming sand is an abrasive. The parts wear out quickly, and the gerotor pair needs to be replaced. This type of pump is not popular, although it is suitable for water wells. There is also no data on service life, since this type of pump modification is new on the market.

Which is better?

All vibration pumps are in the same price range from 30 USD. up to 40 – 50 USD Their cost is so insignificant compared to the costs of constructing a well or borehole that it is not worth saving and buying a frankly low-quality product.

The domestic market is flooded with good models of Russian, Ukrainian and Belarusian production. But there are practically no foreign units: Italian, German, or they are not in demand. Don't buy a vibration pump made in China, save a little and just throw away the money.

- Brook

- Baby

- Aquarius

Brook

One of the most common and reliable domestic pumps. Models with this name are manufactured by different factories: the Russian JSC Livgidromash (Rucheek), the Belarusian JSC Technopribor (Rucheek 1). It has an upper water intake chamber, has a pressure of up to 60 m. But pay attention, the Rucheek pump in tests produced 598 l/hour and raised it to a height of 50 m, and Rucheek 1 only 300 l/hour to a height of 30 m. The name is practically the same, but characteristics are different. Although both are equipped with good thermal protection.

Baby

He also gained good fame among the owners of summer cottages. The “Malysh” pump is produced by “AEK Dynamo” (Moscow), “Electrodvigatel” (Bavleny), as well as other manufacturers. All of them are of fairly high quality, but it is necessary to clarify the characteristics, since there are models with an upper water intake, and others with a lower one. But you don’t have to worry about thermal protection; all models have it. This largely determines the reliability of the Kid and his good reputation.

Special equipment

If you ask yourself which model of all types of pumping equipment is more suitable for providing high-quality water to your home and site, then you need to choose devices that are additionally equipped with special elements to protect the engine from overheating - temperature-sensitive switches.

For wells with great depth, it is advisable to buy special downhole equipment - deep-well pumping equipment (not a single type of submersible pump can cope with delivering water to the surface from great depths). This type of equipment is produced specifically for deep wells, and is a complex design for uninterrupted supply of water to the surface. It is distinguished by its reliability, power, durability and is considered the optimal solution for autonomous water supply to large houses and areas with various points of consumption.