Repairing the floor in the kitchen requires the consideration of several issues, where the main thing is the choice of flooring. There are a large number of profile products on the modern market, among which laminate occupies a special place. Should it be used in the kitchen or replaced with another material? If you pay attention to the recommendations of professionals, you can draw a conclusion about the suitability of the material for a given room. The main thing is to choose and install the flooring correctly. To understand the features of the product and choose the right product, taking into account the types, properties, pros and cons, we recommend that you evaluate the presented article.

Laminate for the kitchen

Laminate in the kitchen: is it possible or not?

The answer is yes, provided several conditions are met. The type of laminate, coating class, as well as compliance with installation technology are important here. The most acceptable option is considered to be a material of class no lower than 33 with a thickness of 8-12 millimeters. There must be a strong protective layer on top that will resist moisture. The surface should be textured to ensure comfortable movement and no risk of slipping. The joints are treated with specialized compounds that are required to repel water, which is done after installation.

Difference between moisture-resistant and water-resistant laminate

Currently, there are 3 main types of laminate, which are divided into categories. Not all flooring is suitable for the kitchen, so you need to understand the specifics. Usually stands out among standard variations.

| View | Description |

| Regular laminate | This is a specialized consumable material that is capable of absorbing liquid or condensate no more than 8-16% of the volume. To ensure the water resistance of the product, it is impregnated with specialized compounds and glued to a moisture-resistant base using glue. |

| Moisture resistant | It has a lower percentage of water absorption, which ranges from 2-8%. The floor covering is protected from leakage for a short period of time, which protects the element from swelling. The main protection is a special polymer film. |

| Waterproof | Assumes moisture transmission of no more than two percent. Can be completely immersed in water, which will not make the material unusable. The presented variation is the most suitable for use. |

You can purchase regular, moisture-resistant and water-resistant laminates

To create the first two types of products, wood or cellulose fiber is used by pressing under high pressure. To give greater density, specialized additives are added to the fiberboard.

Important! The latter provides additional properties, including excellent sound and heat insulation.

What does laminate consist of - design features

Most manufacturing companies have their own laminate production technologies, but they are united by constant general principles. For example, the structure:

- The stabilizing layer is the very first one in contact with the base. Serves as a substrate that protects against moisture and also serves as sound insulation.

- Base layer or base . He is the one responsible for the load. The base can be: HDF - high-density fiberboard, MDF - medium-density fiberboard and high-strength plastic board.

- Decorative layer - responsible for the pattern, which most often imitates wood in a longitudinal section.

- Layer-protection . The resin coating provides the workpiece with high resistance to mechanical wear and stress. Laminate gets its name from the way the boards are coated with resins.

In addition to the base layers, there are a number of auxiliary layers that provide the material with various properties. For example, antistatic and relief.

Is it possible to turn ordinary laminate into waterproof?

To create special water resistance properties, you can do it quite simply and cheaply. To do this, during installation you will need to lay the floor covering without using a backing. Typically, an adhesive mass is used for this, and then the top is treated with polyurethane varnish. Such a product will have excellent technical characteristics, and due to its high porosity it will provide resistance to liquids. Nevertheless, experts recommend waterproofing the base, which will eliminate the problem of water accumulation in the lamellas.

As for the disadvantages of such a life hack, the low resistance to high loads stands out. In conditions of high traffic, faster abrasion is observed, and, consequently, a decrease in service life. Usually the difference in operational applicability is almost 2 times. It is imperative that the floor covering be restored and repaired during use.

polyurethane varnish

To turn a regular laminate into a waterproof one, glue and polyurethane varnish are used - they are used to treat the coating

Flooring installation

First, lay out the backing. It is necessary for shock absorption of locks, for partial absorption of noise and thermal insulation. The substrate sheets are laid without overlapping the adjacent one; tape can be used to connect them.

The first panel is placed in the right corner perpendicular to the window. We secure the second board to the end of the first using an end lock at an angle of 20-30° and smoothly place it on the floor. Insert strips separating the panels from the wall every 50 cm.

When you reach the wall, the last lamella in the row will need to be cut to the desired size, previously measured with a tape measure. This can be done with a jigsaw. Laying the second row begins with the remainder of the last panel of the first row. This results in a displacement of the transverse joints in adjacent rows (“brickwork”).

The lamella of the second row is inserted into the lock along the board in the first row, the angle of inclination is 20-30o, then we lower it to the floor. After laying the second row, the end of the outer panel must be tapped with a hammer through a special extension until a closer connection is made.

Fitting the second row of boards

The last row of covering usually has to be cut along to the required width of the lamellas in order to fit them into the space remaining to the wall.

A hole in the slab is cut around the pipe with a diameter 20mm larger than the pipe diameter. Subsequently, it is hidden with a rosette matching the color of the floor covering.

Upon completion of installation, install the baseboard around the perimeter of the kitchen. It will close the technological gap and complete the design of the floor.

Which laminate is ideal for the kitchen?

Of the types under consideration, only waterproof brands that are highly resistant to this negative factor are suitable for the kitchen. Similar products are also made using wood-cellulose fibers, but the crowning feature is considered to be impregnation using composite materials. Such a coating ideally retains moisture and creates ideal conditions for resisting water. It is important to understand that the joints and the reverse side do not have such protection, so manufacturers do not recommend prolonged interaction with liquid.

Over time, products wear out, which leads to a decrease in resistance levels. Film abrasion, problems with locking joints - all this requires timely repairs and high-quality maintenance.

For the kitchen you should only choose a laminate that is not afraid of water

Degree of wear resistance and impact resistance

The wear resistance of laminate is a source of pride for manufacturers. Today, the top layer of the material is able to withstand significant loads without loss of performance or decorative appeal.

In factory laboratories, the material is tested for abrasion by grinding it with abrasive materials for a certain time, and the indicators in this regard are very high.

The impact resistance of a material is determined by the material of the supporting layer. The softest and, accordingly, fragile types are based on MDF or fiberboard. The more durable material consists of HPL (High Pressure Laminate), which is tightly pressed using special resins and additives that enhance the strength of the coating.

When choosing material for the kitchen, you should take into account the characteristics of your lifestyle. Kitchen is not the same in different families . In one case, this is a fairly large loaded room, in the other - a small room where 1-2 people appear, and the coating does not experience any special loads.

Therefore, the choice of class and degree of strength belongs to the user himself, who will not want to overpay for unused capabilities.

Lamella structure

There are 2 types of waterproof laminate on the modern market.

- A matrix that is made using polymers.

- Composite laminate, which is created using pressed cellulose. Various polyurethane and polyethylene compounds are added to the latter.

The cheapest and most affordable laminate is considered to be the one made from polymer-wood composite materials. A similar line is created according to standards that allow it to resist liquid for 5 hours. Please note that such a coating has good thermal insulation. Among the disadvantages, one can point out the short matrix, which causes greater fragility during installation. To carry out installation, it is imperative to create a flat floor, as well as to ensure careful connection of the locks. Please note that such a product, in terms of technical parameters, is often compared to a decking board.

A cheaper waterproof laminate is considered to be one made using polymer-wood composite materials.

As for the polymer waterproof laminate, it is produced on the basis of polyvinyl chloride. Its shape is set using high pressure through special molds. Please note that the intermediate layer is made from polypropylene or polyethylene. The upper part is made using paper, PVC or other film. Products of this type have impressive strength. You can check by creating physical activity or changing temperature conditions.

Important! On such a floor you can not only use aggressive detergents, but also completely fill it with water for 20 hours.

moisture resistant laminate

Outer row

When we have reached the final wall during the installation process, all that remains is to lay the last row. Usually the outermost row does not consist of the entire width of the panels - all of them will have to be sawn lengthwise.

Apart from the longitudinal cut, the installation is no different. The only issue is that it is not very convenient to join due to the presence of a wall. To apply mechanical force from the wall to the edge panel, a pry bar or large chisel is well suited; they are used as a lever.

Sometimes the last row is only 1-2 cm wide. You have to saw off a narrow strip from entire panels, this happens quite often. There is nothing negative about this.

It is more convenient to first assemble the outer strip along its entire length and only then carefully insert it into the locks of the previous row

The assembled last row may need to be tapped - this is done without a hammer, by inserting a pry bar or chisel into the gap from the wall. Usually this is enough. If you still need more force, I use the clamp from the kit and a hammer.

It is necessary to knock out locks at the last strip no matter how wide it is. When the strip is too narrow, it needs to be further trimmed from top to bottom (second part of the photo). Only then will the locks come together in the correct position.

It's time to end on this note. Today we did not discuss diagonal installation and installation without thresholds - in fact, there are no special differences, only nuances. Due to the resulting publication being too long, we will address these issues in future articles.

Rate this publication:

- Currently 4.33

Rating: 4.3 (9 votes)

Laminate classes

Not all classrooms are suitable for kitchen use. Typically, products from classes 31 to 33 are used here, as they have excellent technical parameters. But you need to know some essential nuances.

- Class 31 has a service life of up to 12 years. Typically used in commercial and residential buildings with average traffic.

- 32nd grade. It has a service life of up to 15 years and has increased scratch resistance. Typically used in buildings with higher than average traffic. Features a higher price tag.

- 33rd grade. Experts recommend using it in rooms that have a high level of traffic, which indicates excellent stability. The service life reaches 20 years, there are no cracks from old age, and does not swell with prolonged interaction with water.

For the kitchen you should use laminates of class 31-33 - not lower

How to choose a coating by strength class

How to choose laminate for the kitchen? First of all, you need to focus on the strength class.

This class is designated by two numbers. For household use, coatings of classes 21, 22, 23 are intended - in order of increasing resistance. According to this classification, class 23 laminate can be installed in the kitchen; it is inexpensive, but it will last no more than 4 years, since it consists of only three layers.

In fact, household laminate of classes 21 and 22 is no longer sold in stores. The reason is lack of demand. In Russia, the commercial type is more popular.

Material of commercial classes is considered more durable - 31, 32, 33. But wear resistance class 31 is more suitable for bedrooms and living rooms, and for the kitchen it is better to choose classes 32, 33, 34+. This floor can last in the kitchen for about 25 years. You can read more about laminate classes on Wikipedia.

Commercial coatings consist of five layers:

- Moisture-resistant film at the base;

- High density wood board;

- Decorative layer made of durable paper;

- Acrylic resin to protect the decor;

- Moisture-resistant top film.

What to look for when choosing laminate flooring for the kitchen?

There are several items that should be evaluated before selecting specialty products.

- Physical endurance class. The higher the resistance, the longer the floor covering will last. Typically, class 32 is suitable for the kitchen, corridor and other rooms. In the absence of force majeure, the material will last up to 15 years. Variations with resistance classes 33 and 34 are more expensive and durable.

- Moisture resistance. It is important to ensure that the specialized material is waterproof. This is important for rooms where there is an increased risk of spilling liquid on the floor. Typically, laminate packages will feature a drop of water, a tap, or the words waterproof, water resistance, and others.

- Lock type. There are 2 types of locks on the modern market. The first is called Click, which differs in the ability to collect and parse. The second is called Lock and involves gluing products together. Click is considered more reliable and practical from the standpoint of operation and installation. The floor is easier to install, and its service life is much higher than its analogue. The Lock variation is cheaper, but such locks are more difficult to install and also require a level base.

Which laminate is better - with Click or Lock locks?

- Brand and warranty. You should not buy the cheapest and little-known laminate. If you have financial problems, then it is better to use a solution from a reputable manufacturer than to take risks and buy products that will not last long. As an alternative, it is better to look at linoleum with a wood texture.

- Thickness. Another parameter that is important to track. The greater the characteristic, the greater the load the floor covering can withstand. For the kitchen, it is advisable not to take product variations that have a thickness below 9 mm.

For the kitchen it is better to use a fairly thick chamfered laminate. To make the floor look more unique and beautiful, it is better to choose products without a chamfer. This will also provide a functional addition.

- Formaldehyde emission. Environmental safety and harmlessness to humans is an important parameter. Pay attention to the marking, there should be the letters E1 or E0.

- Noise absorption. Not all floor coverings have good sound insulation properties. If it is possible to order more expensive material, then pay attention to the Sound Protect variation with a thickness of 1-2 mm. Otherwise, take a closer look at the substrate.

- Anti-slip. The absence of slipping allows you to create safe conditions for human life. Typically, rough terrain is used for this.

It is important that the laminate is anti-slip

Seam sealant

In general, I would recommend refraining from buying sealant, because often something that is closer in properties to glue is sold under the guise of sealant. It is not recommended to glue locks together; this can lead to unpredictable defects during operation. If the panels stick together, it will be extremely difficult to disassemble part of the covering to replace some boards without damaging the locks and edges!

Sealant is needed to protect locks from moisture. Some manufacturers impregnate locks with something like paraffin, in which case there is no need for sealant. This type of laminate is not difficult to recognize by picking the lock with your fingernail. If the locks are not impregnated, when installing even in a dry room, there is a risk that the floor will creak.

If you nevertheless purchased a laminate with non-impregnated locks, it’s okay, you just need to be more careful in choosing a sealant by contacting a competent sales consultant. Having purchased a sealant, you can test its properties by coating and testing two pieces of laminate. After a couple of days, separate them. If the lock opens freely, the sealant remains elastic and can be easily removed - everything is in order.

Alternatively, instead of sealant, you can use impregnation for locks and treat each panel with this solution before installation.

Cons and pros

Using laminate flooring in the kitchen provides the following significant advantages.

- The flooring, which is made using high-quality materials and technology, is not subject to physical damage, temperature changes, and is not afraid of moisture.

- The product has a higher temperature compared to tiles. Causes pleasant sensations directly when walking barefoot. If you add underfloor heating, there is no alternative to laminate.

- There are no dents or other deformations due to installed furniture, appliances, etc.

The laminate does not deform from walking on it or installing furniture

Among other points, it is necessary to point out the ideal aesthetic properties, because the appearance is similar to natural wood. At the same time, a person does not overpay and receives the ideal material for easy and affordable installation.

We must not forget about the shortcomings. The following main items may be included here.

- Exposure to water. With prolonged exposure, the product swells and swells. To solve the problem presented, additional processing is required, which involves filling the seams using sealants. Risks are reduced, but the problem is not fully resolved.

- Some people often confuse water-resistant and moisture-resistant laminate flooring. They are fundamentally different and behave differently when in contact with water. Moisture-resistant material cannot withstand prolonged loads from water, which leads to swelling. This occurs due to liquid getting into the joints. If deformation has occurred, it will not be possible to restore the aesthetic appearance. As for the waterproof product, it is insured against such troubles.

- Loud knocking sound when walking. The floor covering creates a characteristic ringing sound when walking. This is especially felt when there is a clicking noise from pets. If you don't put the backing on yet, a drum effect appears. To solve the problem, you should definitely use special substrates. They absorb steps and also eliminate minor unevenness in the floor.

If you do not put a backing under the laminate, walking on it, especially with shoes, will be accompanied by loud sounds

- Chips and scuffs. Flooring products are simpler compared to parquet. But this does not mean that there are no problems here. An incorrectly hung door or improper support of equipment can lead to deformation and damage to the surface. Sometimes wax pencils come to the rescue in this direction.

Choice of coating colors

Color is a matter of personal taste. Of course, there are selection criteria based on the color of the kitchen unit, the style of wall decoration, etc. But the priority in this case has always been and will be the personal view of the kitchen owner on this or that material, its color and the general sensations that a person has that serve as a measure of the suitability of the coating.

All recommendations in this case are ineffective, although there are many tips on how to choose the color of laminate for a large or small kitchen . Thus, it is believed that material that is too dark over a large area begins to dominate and attract the eye.

A light coating is more neutral in this regard. In addition, dark surfaces make dust, scratches or crumbs of debris more noticeable, which constantly appear in the kitchen while cooking. One way or another, the choice is a personal matter for the owner.

Compatibility with heated floors

Warm floors go well with laminate, provided that a number of conditions are met.

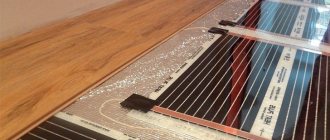

- Specialized flooring cannot be laid directly on electric floor heating systems. This is due to uneven heating of the surface, which leads to the creation of cracks. It is better to use film or water systems.

- The temperature should be increased gradually. It is extremely important not to allow the temperature to rise above 28 degrees. Be sure to install a rheostat and specialized sensors to regulate the temperature.

- During the heating season, it is advisable to use additional devices that will humidify the air. In the kitchen, the laminate should not dry out, so the humidity level should be at 50%.

Laminate can be combined with underfloor heating systems, but the temperature cannot be increased too much - it can become deformed

Reviews

We have collected for you some of the most detailed reviews about laminate flooring, where people describe real experiences using this coating. Below each review are comments from our experts.

Indeed, laminate flooring with a strength of 32 can withstand even the toughest conditions. However, keep in mind that over 10 years its price has increased significantly. However, if you are ready for the costs, they will be worth it.

The color of the laminate really determines a lot. Thus, owners of laminates that are too light often complain about dust, but with “variegated” laminates you really can’t see anything. But this does not mean that it does not need to be removed.

This review is interesting because of the remark about the hood. It not only removes unpleasant odors in the kitchen, but also helps control the humidity in the room. This allows you to extend the durability of the laminate.

And again we return to the fact that the main thing is quality. We did not find any negative reviews about the durable and thick laminate, but there were quite a lot of praise.

Design Features

When working on the style, it is important to assess the size of the board. Typically, rectangular variations are used for the kitchen, the length of which is 1200 mm. The width should not exceed 200 mm. It is important to note that there are various variations on the market, with a wide variety of elements in width and length.

The second position is associated with the presence or absence of a chamfer. If the product is sharpened to look like wood, then the latter has special grooves. They set a non-standard effect and allow you to specify a non-standard design.

Important! When choosing, pay attention to the markings 2V and 4V, which indicate the number of sides with a chamfer.

It is important to pay attention to the design of the laminate - it is often designed to look like wood, which looks quite beautiful

As for design, wood-look variations are currently popular. That is why solutions called “oak”, “ash” and so on are presented on the market. Each option has a nuance. For example, oak has more than 50 of them. The pattern on the planks may differ. The more expensive the material, the more varied the pattern will be presented. Products imitated with natural stone deserve special consideration, as they allow for heat retention and a non-standard design.

Stone or concrete under the tiles

Tiled laminate looks great in any kitchen interior, the main thing is to choose a harmonious design. Scandinavian, Mediterranean, hi-tech, modern, minimalism, ecological, ethnic style - in all these styles, tiled floors are found quite often.

Under the stone

The design of laminate flooring in the kitchen “under concrete” is suitable for styles: loft and industrial, rustic, bauhaus, boho, neo-brutalism, grunge, constructivism, military, minimalism, onto-art, pin-up, techno, hi-tech, modern, ethnic style, retro.

Under concrete

How to calculate the quantity?

When ordering laminate, be sure to take extra. Usually the calculation is 5% more than the declared area. If the consumable material remains, it can be used to repair the surface. Another important feature is associated with the type of masonry. If the installation is carried out diagonally, and you will be working on the floor yourself, then you will need up to 15% more products.

waterproof laminate

How to correctly calculate the required amount of laminate

DIY installation

Almost everyone can make a kitchen apron from laminate with their own hands.

It is very important to follow the sequence of actions and perform everything carefully and carefully

All installation steps are divided into several stages:

- Preparatory work. The surface of the walls must be covered with putty. It eliminates all irregularities and defects. The wall should be leveled and prepared for subsequent installation.

- Installation of sheathing. Self-assembly of the structure is not difficult. It is advisable to take small blocks of 4x4 cm and attach them to the wall at a distance of 50 cm from each other. The sheathing can be assembled either over the entire wall or over part of it.

- Installation of laminate to the sheathing. The laminate sheet is secured with screws, plastic dowels or screws to a lath covered with concrete screed or linoleum. In certain cases, special glue is used. When joining elements to each other, all connections are covered with sealant, which increases the degree of protection from external influences. Always start attaching the plates from the bottom.

- Final works. It is best to cover the edges of a laminate kitchen apron with decorative corners made of polymer materials.

How is laminated board laid?

When carrying out work, several nuances should be worked out, which are presented below.

- Be sure to purchase flooring with a reserve. Please note that the same color from different batches may differ in shades. A large supply will be required for non-standard installation.

- Be sure to read the instructions before working with the product. Manufacturers always provide nuances regarding correct installation and operation.

- The task should be carried out in the direction of the light from the window opening. This will ensure that the gaps that appear between the panels are masked.

- The most difficult installation method is considered to be diagonal. A simpler solution is to lay it along the window opening, as well as across the room itself.

Laying laminate diagonally is quite difficult - it’s easier to lay it along the walls

- When carrying out work, be sure to prepare the subfloor. This will create a more even surface. It is advisable to supplement the subfloor with waterproofing.

- If the kitchen is small, then the best solution is to use a plain material. As for different colors, they reduce the area of the room.

- To ensure that the result meets your expectations, be sure to follow the instructions recommended by the manufacturer. This will avoid problems.

- The floor covering can be used both on a wooden floor and on a concrete screed. Be sure to evaluate humidity parameters and elevation changes.

Laminate can be laid both on the subfloor and on the old coating, if it is level enough

The tips presented will be enough to get a truly high-quality result.

Laying lining material

To arrange the floor in the kitchen, two types of linings are used - coniferous mats and cork cloth. The material is laid on concrete in rows with mandatory bandaging of the seams. The joints must be glued with tape so that under load the lining material does not spread to the walls of the room.

The standard thickness of the lining is only 8 mm, therefore, if the work is carried out with the dismantling of the subfloor, sometimes you have to lay out two layers in order to guess the height of the laminate relative to the threshold level.

Installation work under heated floors

As noted earlier, laminate can be used in conjunction with heated floors. To do this, you need to implement the following tips.

- Electrical systems must not be used. Since the film heats up as quickly and unevenly as possible, the floor covering dries out and undergoes deformation. The best option is water or infrared TP.

- The product does not tolerate sudden temperature changes. That is why it is necessary to smoothly regulate the temperature. Special sensors and a rheostat should be used to regulate the heating procedure.

Laminate does not “like” temperature changes - adjust the temperature smoothly

- Try not to exceed the temperature above 28 degrees. Otherwise, fragility and brittleness increases.

- During operation, it is advisable to acquire air humidifiers. It is important to maintain humidity at least 50 percent. Otherwise, cracks will appear on the floor.

If you put these tips into practice, you will be using laminate flooring for many years.

infrared film

How to arrange a transition

The combination of tiles and laminate requires solving the issue of transition from one type of floor to another. There are several ways to join floor coverings:

- using a cork gasket;

Cork gasket.

- covering the seam with an aluminum decorative strip used to fix linoleum near the walls;

Aluminum strip.

- sealing the seam with sealant;

- arranging a podium along the joint line;

- masking the connection of two types of flooring with a PVC overlay.

Vinyl overlay.

In this case, the connecting line should pass at a distance of one and a half steps of the cook (usually the mistress of the house) from the tabletop. This is a guarantee that when taking a step back, the cook will not trip over the threshold. The podium is set up in the same way. The tiles are 2-3 cm higher. Rarely, but it happens the other way around when the laminate is higher.

Attention: advice from the site staff - the seam line should not cross the main direction of movement of residents. Kitchen visitors should move parallel to the joint. In this case, the risk of tripping is zero.

Combination options

Both types of floors, regardless of the space occupied, color and texture, actively influence the perception of the interior. But there is a nuance: the floor covering adjacent to the furniture always more intensely shades and enhances the decorative effect of the furniture in the interior. Therefore, you need to pay special attention to the tiles and select them in contrast to the laminate or in similar color tones.

So, beige tile color goes well with brown or terracotta laminate. It does not draw attention to itself, but visually neutralizes high humidity and temperature in the kitchen, creates a calm, relaxing atmosphere, and has a calming effect on the nervous system.

The method of sealing seams should show kitchen visitors the floor as a single whole, although assembled from two different materials in color and texture.

Some tips for use and care

Correct selection and installation according to technology will guarantee long-term use. Typically, the service life of the product is at least 15 years. Use a few tips to create truly effective flooring conditions.

- Try to minimize the amount of wet cleaning in the kitchen. Use an alternative such as vacuuming or sweeping with a broom. This will allow less contact with water, thereby preserving the structure of the consumable material.

In order for the laminate flooring in the kitchen to “live” for a long time, it is better not to carry out wet cleaning too often

- If you need to carry out wet cleaning, then use a mop with a soft cloth that collects liquid well. It should be cleaned with a slightly damp cloth; after completing the task, it is advisable to treat the surface with a dry cloth.

- Do not use aggressive detergents. Typically, for wet cleaning, a practical solution is considered to be a regular soap solution or specialized chemicals for wooden floors. It is advisable not to use variations of abrasive type chemicals, they scratch the floor and shorten the service life.

- If a stain appears on the surface, it should be removed immediately. Dirt must not be allowed to eat into the material, otherwise it will be impossible to remove it. Regular stains can be removed using the above mentioned products; more severe stains will require an acetone solution. Apply it to the surface and then leave for 2-3 minutes. Next, remove the liquid using a rag and soap solution.

- Spilled water? Quickly absorb moisture using any fabric materials. It is necessary to get rid of the problem by wiping the surface dry. Otherwise, there is a risk of swelling at the joints.

- For furniture with sharp legs, special covers should be provided. This will protect the surface from scratches. Also, to preserve surfaces, there are special polishes that are coated with a thin layer on the surface. In professional practice, mastic and wax are not used, which is associated with the appearance of a slippery surface. Such products spoil the structure of the material.

- To paint over scratches, it is better to use a special wax pencil. In some cases, you will have to use acrylic putty, which will help disguise larger chips. Please note that the material takes at least 24 hours to dry.

If scratches appear on the laminate, they can be removed using a special wax pencil

- It is advisable to treat scratches after they appear. This will help reduce the risk of moisture penetrating into the material. Otherwise, deformation should be expected.

Important! Caring for laminate flooring is not such a problem, and the lack of complexity is seductive and makes you think about choosing such a floor covering.

Wood decor

Imitation wood is the most common decor for laminate flooring in the kitchen. Modern printing technologies provide highly realistic drawings. Precious wood species are imitated, for example, wenge, walnut, zebrawood, ash, merbau, pine. Out of competition - oak in varying degrees of staining (aged, oiled, bleached, varnished, tinted and natural).

The more expensive the material, the more attention is paid to the image and structure of the wood. Age rings, color transitions, wood pores and fibers can be clearly distinguished on the slats.

Manufacturers and price tag

Regular inexpensive laminate class 33 is sold in online stores at a price of 450 rubles per square meter. If you purchase it with a moisture-resistant finish and for heated floors, then the price tag is in the range of 700-1500 rubles, depending on the brand. Popular European materials are supplied to the regional market at a price of 1000-2500 rubles per square meter. The following collections are ideal for the kitchen:

- Tarkett (Woodstock Family, Estetica, Robinson);

- Kronotex (Mammut and Amazone);

- Imperial (Lumia, Lux and Exclusive);

- Pergo (Sensation);

- Ritter (Charlemagne, Nefertiti);

- Kronospan (De Facto, Symbio, Salzburg).

Typically, the cost per square meter of laminate varies from 700 to 2500 rubles, depending on the class and manufacturer

Reviews about laminate flooring in the kitchen

“We installed moisture-resistant laminate in the kitchen, and for 10 years there have been no problems. We took the inexpensive class 32. Experts recommended putting tiles under the headset, which was done. This was associated with greater resistance to wear and moisture, as well as increased protection from grease. The floor survived the flood, so I don’t want any other floor covering” (Inga, Moscow).

“Laminate flooring was installed in the kitchen 5 years ago after a major renovation. During this time, there are practically no problems with swelling; there is a slight swelling at the sink. If water spills, I try to clean it up immediately. There is also a desire to create such a floor covering in the new apartment, however, my husband insists on laying tiles in the work area” (Anna, Krasnogorsk).

Many people are happy that they chose laminate flooring for their kitchen.

“We installed laminate throughout the entire apartment during the renovation. We took inexpensive, Chinese consumables of class 32. The laminate copes quite well with the tasks. We often drop spoons and other utensils, the child often spills liquid, but so far there are no problems” (Marina, Zelenodolsk).

“Laminate flooring is an opportunity to create comfort and coziness in your home. It has taken root well in the kitchen, creating aesthetic beauty and comfort in the form of warm walking on it. You can compare it with a wooden floor” (Vasily, Voronezh).

“I don’t want anything more than laminate. An ideal floor covering that is cheap, beautiful and resistant to most negative factors. If you properly care for it and remove the water on time, then no consequences are observed. It can be practically cleaned with ordinary detergents” (Antonina, St. Petersburg).

Many people notice that laminate, despite its low cost, is of fairly high quality and copes well with various negative factors.

“A child and laminate flooring in the house mean comfort and safety. There is no cold floor, the baby can walk in any room. I spilled water many times, nothing bad happened, the main thing is to choose the right material” (Galina, Sverdlovsk).

Preliminary calculation and selection of tools

The process of laying laminate flooring in the kitchen has one remarkable feature: if the calculation of the number of lamellas is made with an error, then the covering can be laid with one missing board, which will have to be hidden under the kitchen unit. It is clear that such a scheme significantly reduces the value and strength of a laminate floor. Most often, they resort to it if expensive imported installation material was brought to order, and one strip was missing. Considering the enormous weight of the furniture cabinets in the kitchen, nothing will happen to the floor.

To calculate the number of slats, you will need to know the dimensions of the kitchen and the dimensions of one strip. The calculation sequence is as follows:

- We divide the longitudinal size of the kitchen by the length of one strip of laminate, we get the number of pieces, for example, 6.2;

- We divide the width of the room by the transverse dimension of the lamella, we get the number of rows, for example, 17.7;

- We round and multiply 7x18 = 126, with 8 pieces in a package we get 17 packs.

It is best to buy kitchen material in advance and store it in a cool, dry place. You can begin laying laminate flooring only after completing all renovation work in the kitchen.

To work, you will need a jigsaw, a tape measure, a construction square, a construction knife, a hammer, a set of dowels with plugs, tape and lining material.