Currently, the market offers a wide variety of water meter models from different manufacturers and in different price categories. How to avoid mistakes when choosing the diameter of a water meter and not throw money away when buying water meters that do not meet your requirements will be discussed in this article.

When buying water meters, a mandatory condition is to buy it new and from a reliable company with all obligations. Never - not from “private individuals” and not on the market, no matter how the sellers assure that there will be no problems with the “vodokanal”. It is possible that after purchasing and installing such a device, the controller of the water utility or management company will simply refuse to register it, seal it, and thereby accept it for registration. Forging a passport with seals and quality control stamps costs nothing in our time.

When purchasing a water meter from a reliable organization, be sure to check the product passport, in particular, the presence of marks on factory verification, established verification periods and manufacturer’s warranty obligations. Each meter must have its own individual serial number.

Which company makes it?

The production and trade of meters is carried out by JSC Teplovodomer .

The company is located in Mytishchi, Moscow region. In addition to these products, energy consumption metering devices are produced for apartments, private houses and industrial premises.

During the production of flow meters, quality control is carried out for compliance with Federal Law No. 261 of November 23, 2009 , which sets out the rules for installing energy-saving equipment to increase savings efficiency.

It is possible to manufacture meters in different diameters with different functional characteristics, accuracy classes, and water protection.

Why do you need water metering?

Despite the obviousness of the answer, many segments of the population are in no hurry to install metering devices until there is an official order. This inertia is caused by the fact that over many years, when water utility services cost mere pennies, we did not pay attention to consumption standards. With rising prices for utilities, this expense item has increased significantly. Based on this, we can list all the advantages of installing a hot and cold water flow meter:

- Let's start with the fact that companies providing water supply services, a priori, will not operate at a loss. Consequently, they will try to shift all their expenses onto the shoulders of consumers. When you see a broken main that has been leaking water near your home for weeks, know that its costs are paid by those who pay according to consumption rates.

- Excessive consumption rates. The second factor is directly related to the first, but we highlighted it separately to show its scale. Let's take St. Petersburg, for example, according to the 2021 regulation, cold water consumption per person is 220 liters per day, hot water - 150 liters. Let us repeat, for each person registered in the apartment. This is even higher than SNiP standards.

- The owners went on vacation and were not at home, it happens, but the receipt must be paid.

- Owners of private houses may have noticed that the receipt has added the cost of “irrigation”, which is directly related to the area of the plot, and it does not matter whether something is growing there or a garage is installed. Moreover, in the latter case, you can find an additional point for water consumption for washing the car.

The listed factors are quite sufficient to explain the need to install water meters.

Pros and cons of water meters

The advantages of flow meters include:

- Application in various areas - residential premises, offices and production.

- Variants of different accuracy classes are offered.

Flow meters for cold water supply can withstand temperature conditions up to 50ºС, for hot water – up to 150ºС.- There are universal type metering devices on sale.

- Simplified data collection - sealed casing, dedicated dial, scoreboard lockable if necessary.

- Installation of a radio pad during the first start-up and during operation to transmit readings via radio channel.

- The materials included in the casing strengthen the structure.

- Crimping test under pressure of 2.4 MPa.

The disadvantages include:

- They cannot be installed on pipelines for measuring wastewater, as they are designed for ordinary water according to SanPin 2.1.4.1074-01 and SNiP 41-02-2003.

- The degree of protection IP-68 is made to order, which is more expensive than conventional models.

Each model may have its own disadvantages due to the type of installation and operating parameters.

Selection rules

When deciding which water meter is best to choose, you need to proceed from the following number of factors:

- Technical requirements.

The water meter must first of all meet a given set of operating parameters for a particular water supply system:

- Temperature.

- Pipe diameter.

- Body length.

- System pressure.

- Allowable flow limit.

- Error.

- Integrity of the package.

- Price.

One of the important selection criteria for most consumers. More expensive models, as a rule, have the same set of characteristics as cheaper ones. Therefore, there is no point in overpaying just for the prestige of the manufacturer.

A water meter quickly pays for itself Source stroyday.ru

- Reliability. The build quality must allow the device to be used for the entire service life declared by the manufacturer without unexpected accidents.

- Factory warranty.

- Period between checks.

- Compliance with operating conditions. The device must be designed for low water quality, the presence of particles in the water mass and other factors characteristic of domestic water supply systems.

Recommendation! A correct idea of how to choose a water meter comes from knowledge of its material. It is better not to deal with devices with a silumin body. Models made of brass or bronze are quite reliable. Water meters in constant contact with water exhibit maximum durability if made of stainless steel. Reliable electronic analogues are produced in a polymer shell.

Models

The company offers several types of metering devices, differing in mounting method and appearance.

When assessing technical performance, various characteristics are used, including:

- consumption,

- sensitivity,

- installation method and other conditions.

The passport for each modification provides an extended overview, which further describes the decoding of classes and parameters of use.

When analyzing meter models, you should take into account the design option, depending on the type of reading taken. When a magnetic contact sensing mechanism is provided, the cost increases.

To apply modifications, you will need to additionally install a computer, recorder and other devices. The passport for the devices indicates the price of one pulse .

Winged

They are used for commercial and household purposes. They are located in apartments, private houses, offices and commercial premises in the manufacturing sector. There is a design with a nominal diameter diameter (DN) of 25, 32, 40 mm.

Externally, they are a round type flow meter with a data indicator in the form of a roller and pointer mechanisms. The first is responsible for providing information about consumption in cubic meters, the second - in shares.

Peculiarities:

- several markings - VSKhN corresponds to the simplified type model with space for a radio patch, VSKhNd for meters with pulse data collection;

- If necessary, it can be ordered complete with IP protection.

Winged models can withstand wear, which is confirmed by test results in accordance with GOST R 50193.3-93. Performance indicators are presented in the table:

| Options | DN-25 | DN-32 | DN-40 |

| Minimum flow rate Class A/B/C | 0,014/0,063 | 0,24/0,1 | 0,3/0,16 |

| Flow rate when maximum error changes Class A/B | 0,35/0,1 | 0,6/0,16 | 1,00/0,26 |

| Consumption during continuous operation Qn Class A/B | 3,5 | 6 | 10 |

| Maximum Qmax Class A/B | 7 | 12 | 20 |

| Threshold sensitivity, m3/h | 0,0105 | 0,018 | 0,03 |

| Roller pointer limit, m3 | 99999 | ||

| Minimum division, m3 | 0,00005 | ||

| Pipe mounting type | Threaded | ||

| Weight, g | 2000 | 2200 | 2500 |

| Average service life, not less | 12 years | ||

| Period between verifications | 6 years | ||

| price, rub. | From 5200 | From 5700 | From 6700 |

It is worth choosing VSKhN vane flowmeters based on the diameter of the pipeline. DN-25 is installed in residential buildings, and DN-32, DN-40 is suitable for industrial pipelines .

Models DN-15, DN-20 belong to the group of residential flow meters designed for use with a small amount of passing water. They should be checked once every 6 years when used for at least 12 years.

Turbine

They are used in measuring cold water in buildings for permanent/temporary residence, workshops where waste exceeds 15 m3 in 24 hours.

A design feature is the replacement of the impeller with a rotating “turbine” inserted in a vertical position towards the cold water direction. It is responsible for the volume of the aquatic environment.

Models are available with a diameter in the range of 40-250 mm. It is planned to manufacture VSKhN meters of the turbine type with the installation of a radio pad and pulse options for remote data collection.

Operational characteristics are described in the table:

| Parameter | Values of VSKhN turbine flow meters |

| Diameter, mm | 40, 50, 65, 80, 100, 125, 150, 200, 250 |

| Lowest consumption Class B | 0,45-10,0 |

| Transient flow Class B | 0,90-16,0 |

| Nominal flow Class B | 30-1100 |

| Highest consumption Class B | 60-1600 |

| Sensitive flow rate during continuous turbine operation m3/h | 0,15-3,0 |

| Type of connection | Flanged |

| Weight, kg | From 7.9 to 75.1 |

| Period between verifications | 6 years |

| Duration of operation | 12 years |

| price, rub. | From 7900 to 44300 |

When choosing one model or another, you should focus on the diameter of the pipeline . The space where the flow meter will be installed is important. For frequently used pipes with a diameter of 40 mm, a DN-40 turbine type with a weight of 7.9 kg is suitable.

The popular models from the series are DN-40, DN-50 and DN-200. Their performance characteristics vary in flow range, price and dimensions.

A filter plate is placed in the inlet pipe of the device to prevent sedimentation of suspended particles. This increases the service life of the flow meter.

The labeling of VSKhN turbine-type devices may contain information about the manufacturer.

They are produced both in Russia (Teplovodomer Rossiya) and in Poland (Apator PoWoGaz) . The cost of the models does not differ.

Class C

They are used for measuring the volume of water consumed in domestic, public and highly specialized premises.

Class C indicates precision control when resistance to magnetic signals, physical force and repeated rotations is provided.

Models are available designed to accommodate a radio pad . If desired, you can purchase a modification with a pulse output. Externally they resemble vane flowmeters.

Performance characteristics:

| Parameter | Nominal values |

| Diameter, mm | 15, 20, 25, 32, 40 |

| Minimum consumption Class B | 0,025-0,16 |

| Flow rate when maximum error Qt changes Class B | 0,04-0,26 |

| Nominal Qn Class B | 1,5-10,0 |

| Flow at maximum Qmax Class B | 3,5-20,0 |

| Sensitivity threshold m3/h | 0,0075-0,03 |

| Pipe installation type | Threaded |

| Weight, kg | 0,5-2,5 |

| Time interval between verifications | 72 months |

| Operational period | 12 years |

| price, rub. | From 1180 to 8760 |

One of the features of the series is the presence of a strainer at the inlet of the water meter, which prevents the penetration of pollutants into the measuring mechanism.

When choosing between models of VSKhN meters with metrological class C, the consumer must take into account the scope of application and the internal diameter of the pipeline.

The minimum diameter is 15 mm, which is convenient to place in residential buildings and apartment complexes . The maximum size of the flow meter used is 40 mm. The latter is used in industrial water supply. If necessary, metering devices with a pulse output are purchased to correctly collect information.

IP68 rated

If it is necessary to place metering devices in dirty rooms or in spaces where there is high humidity or possible flooding, models with protection class IP68 are selected.

The flow meter mechanism can withstand aquatic environments (flooding to a depth below 1 m) . The protective cover prevents the penetration of dust. Flow meters with an output for measuring with a pulse tip are offered for sale.

In areas with a smaller volume of cold water, the VSH models DN 15-20 are produced. For pipelines with a diameter of 25, 32, 40 mm, it is possible to manufacture threaded meters, and for pipes with a diameter of 40-250 mm, it is possible to use flanged meters.

Specifications:

| Parameter | Flow meter type | |

| Diameter, mm | Threaded DN-25, DN-30, DN-40 | Flanged DN 40-250 |

| Minimum Qmin Class A/B (B for flanged) | 0,14-0,3 | 0,45-1,0 |

| Adapter Qt Class A/B (B for flanged) | 0,35-1,0 | 0,9-16,0 |

| Flow during continuous operation, Qn Class A/B (B for flanged) | 3,5-10,0 | 30-1100 |

| Maximum Qmax Class A/B (B for flanged) | 7,0-20,0 | 60-1600 |

| Threshold sensitivity, m3/h | 0,0105-0,03 | 0,15-3,0 |

| Water consumption at a pressure drop of 0.1 kgf/cm2 | — | 26-800 |

| Weight, kg | 2,0-2,5 | — |

| Verification period | After 6 years | |

| Operational period | 12 years | — |

| price, rub. | From 5700 to 45500 | |

Threaded ones are installed more often in apartments, houses and utility rooms. With a flange installation method, the flow meter is popular in the manufacturing sector and utilities.

A popular model with IP-68 protection for household objects is the DN-25 VSKhN. Suitable for pipes with a diameter of 25 mm with threaded fastening. The maximum flow rate is 7 m3/hour.

An interesting representative of the series with a diameter of 40 mm is a threaded type, which can be used on production pipelines where this type of fastening is necessary (maximum flow 20 m3).

Another model VSKHN-40f IP-68 with an installation length of 200 mm and a higher flow rate of 60 m3/hour is used in cold water supply systems of medium and large consumption with a flanged metering device.

Meters of IP-68 class with threaded mounting are manufactured under the Teplovodomer brand, and flanged meters are manufactured in Poland (Apator PoWoGaz).

Combined

They are a combination of a vane and turbine water meter, where there is a reed switch sensor . Available in class IP-54 or IP-68.

Scope of use: cold water measurements on industrial supply pipes, public utilities and automatic flow metering points.

Their design is created specifically for places where there is a variable flow , which changes periodically over time or under the influence of environmental conditions.

Specifications:

| Parameter | Nominal value |

| Nominal diameter, DN | 50/20, 65/20, 80/20, 100/20, 150/40 |

| Nominal flow | 50-400 |

| Maximum consumption | 90-600 |

| Transition flow | 0,2-0,8 |

| Consumption at a minimum | 0,05-0,2 |

| Limit sensitivity m3/h | 0,015-0,1 |

| Consumption at pressure drop 0.1 kgf/cm2 | 12-118 |

| Weight, kg | 17,6/18,7-74,6/76,9 |

| Interval between verifications | 6 years |

| Average usage time | 12 years |

| price, rub. | From 37000 to 150000 |

When choosing, a diameter is determined that allows operation over the entire flow range, based on the type of room. The diameter of the pipelines located at the facility is also taken into account.

Of the entire series, the VSKhN DN-50/20 meter with a flow rate of up to 90 m3/h is considered compact. Another popular option is the VSKHN DN-100/20, which is IP-68 rated, magnetically protected and can withstand depths of more than 1 m. Its maximum flow rate is 300 m3/h.

The VSKhN DN-150/40 model, supplied in IP-54 or IP-68 class, is presented with the maximum diameter value. Their consumption is the same, ranging from 0.2-600 m3 per hour.

Combined cold water metering devices are more often used in social premises , where such flow meters must be present in order to control increased flow during a fire. These include kindergartens, schools, business centers and offices.

Electromagnetic

They are electromagnetic type flow converters. When used, cold water is converted into electrical signals (frequency, impulse, current). Available in a modified form with an indication unit - built-in or remote.

Features include:

- Long-term operation in unusual situations (vibration, increased humidity, temperature).

- Fastening to different pipes – vertical and horizontal.

- Elimination of temperature error.

- Converting elements are provided for additional hydraulic resistance.

Performance indicators are presented below:

| Parameter | Standard |

| DN | 15, 20, 25, 32, 40, 50, 65, 80, 100, 150, 200 |

| Converter type | B |

| Sensitivity | 0,01-2,0 |

| Min flow | 0,02-4,0 |

| Transition flow | 0,033-6,7 (0,05-10,0) |

| Max flow | 5-1000 |

| Regular verification | After 4 years |

| Average use | At least 12 years |

| Price | From 19,700 to 93,000 rubles. |

For low flow rates, the Master Flow DN-15 model with an installation length of 135 mm (up to 5 m3) is suitable. For a pipeline with a diameter of 40 mm, “Master Flow” DN-40 is used, operating in the flow range of 0.3-45 m3. For industrial premises, a dimensional model DN-200 (up to 1000 m3) is purchased.

Installation principle

Now let's move on to the main question - how to install a water meter in a private house? You need to start by contacting the water supply organization in order to submit an application indicating the request and the location of installation of the water meter with its further registration.

In this case, you need to ask two questions:

- Is it possible to install a water meter in a private house with your own hands, or must this be done by employees of Vodokanal or another organization that has a license to carry out this type of work.

- What water meters can be installed. The thing is that in each region there is a list of models that can be installed. Therefore, you need to familiarize yourself with this list. If you purchased a device in advance that is not on this list, you will have to either buy a new one to avoid problems, or license it, running around to various organizations where you will have to pay for the services provided. So it’s better to first familiarize yourself with the list, and only after that purchase the counter itself.

As practice shows, in many regions there are no strict restrictions on who will carry out installation work. Therefore, taking into account your financial situation and trying to save money, you can do everything yourself.

But in the end, you will still have to call the controller to register the device, because in the process of putting it under control, the water meter is first of all sealed. It would be ideal if Vodokanal workers do everything. It won't cost that much, but it's already a 100% guarantee.

Well construction

So, how is the meter installed? You need to start by digging a well. Usually, to do this, they dig a hole 1.2 × 1.2 m with a depth of 1 m. There is one very important requirement, which concerns the correct operation of the water meter in winter.

It is important that the temperature in the well does not drop below +5C, so you need to think about how to insulate the well.

Considering that the well structure will be lined with bricks or blocks, plus, it will be necessary to lay thermal insulation material, the pit itself will have to be expanded to dimensions: 1.7 × 1.7 × 1.3 m.

True, you will have to take into account the level of the pipe, which is a branch from the main water pipeline towards the house. That is, the depth of the pit may be deeper. In any case, the distance from the bottom of the pit to the pipe should not be less than 10 cm.

In this case, you will have to take into account that the bottom of the well will have to be concreted, since a solid foundation is needed under the walls of the structure. A concrete screed thickness of 10 cm is sufficient because the loads on it will be insignificant.

Next, the walls of the well rise. After which you can proceed to installing a water meter. To do this, the pipeline is cut at a distance of 20 cm from the entrance. Next, the size of the installed shut-off valves, coarse filter and the water meter itself is measured. And in this place the pipe is also cut.

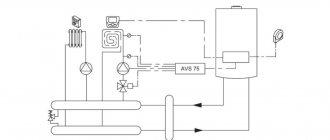

Installation

Now you can proceed to installation.

- First of all, a valve or ball valve is installed.

- Next, the filter is installed.

- After that the counter itself.

- And the last one is the check valve.

It is clear that a valve is necessary to shut off the water supply for various cases: repairs, accidents, prevention, and so on. The filter partially purifies the water, which extends the life of the water meter. The latter counts the volume of water consumed. Why do you need a check valve?

Its function is to block the reverse flow of water from the internal water supply system of a private house.

For example, if there is a need to change the water meter or clean a clogged filter, then first of all the valve is closed, and the check valve blocks the route through which water can flow back.

It is clear that its functions can be performed by exactly the same valve or ball valve. Many owners of private houses do this. But the valve does everything automatically with a spring-loaded mechanism, and the valve has to be turned to close the pipeline.

All connections between the water supply elements inside the well must be threaded, that is, detachable. There is no need to use welding here, because one of the main requirements for water supply networks is their maintainability.

That is, repair operations carried out inside the well should not be a big problem for the owner of the house.

Attention! And one more point regarding the thermal insulation of the well - the top cover also needs to be insulated. Many people forget about this, and end up with a decrease in temperature inside the well tank.

So, if all the rules for installing a water meter in a private house have been followed, you can call a representative of the water supply sewer system to check the installation and seal the water meter.

Of course, you must first independently test the assembled structure to ensure there are no leaks through the joints and the correct operation of the water meter itself.

Therefore, the valve must be opened carefully; high water pressure can create an impact on the impeller of the water meter and damage it. After this, any consumer is opened to see whether the counting mechanism rotates or not.

After making sure that everything works and there are no leaks at the connections, you can call a Vodokanal employee.

Installation and fastening

During installation the following rules are observed:

Vane meters with a diameter of more than 25 mm are placed only in a horizontal position. Turbine ones are fixed in any spatial position.- There must always be water at the installation site of the pipeline.

- There must be a straight pipe section with a length of at least 5 pipeline diameters before the flow meter. There must be at least 1 diameter after the placement location. If there is a factory set of connectors, the rule may not be observed.

Each model is supplied with a technical data sheet, which describes the installation diagram in detail. In general, it does not differ from the instructions for similar metering devices.

Unauthorized access to equipment for measuring cold water consumption is ensured by a seal .

In conventional versions, it is installed on an adjusting screw, but for pulsed ones it is necessary to place it on the output.

TOP 10

A quick and trouble-free way to find a solution to the question of what is the best water meter, which one to choose - a rating of the most popular models. The 10 most popular representatives are presented in the following list:

- ECONOMY.

Product from a domestic manufacturer. Maximum adapted to operating conditions in Russian conditions, taking into account the main features of both main and private water supply systems. It is distinguished by accuracy, durability, and reliability.

- Betar SHV 15.

Inexpensive model for controlling cold water - no higher than 40 degrees. at pressures up to 10 bar. Characterized by durability and the ability to be mounted at any angle.

- ITELMA WFW20 D080.

A device for monitoring the operation of a water supply system with the ability to transmit data at a distance by connecting a pulse sensor. It has a long service life, protection from magnetic fields and leaks.

- Decast Metronic VSKM 90-15 DG.

This specimen was included in the rating of water meters as one of the inexpensive, but at the same time practical and durable devices. Operates on direct and return lines at temperatures up to 90 degrees and a pressure of 1 MPa. Serves for at least 10 years.

How to take readings?

Vane and turbine meters are characterized by a visual overview of water consumption, when the user sees the cubes and their shares. A roller pointer is used to take readings.

The numbers on the VSKhN meters are clear, making it easier to collect readings. The sealed system ensures no fogging.

Using the example of a vane model, you can display the results for flow rate taking into account the following features:

- if the black numbers on the five rollers are not activated until the readings are taken, the amount of water is calculated in cubic fractions - tenths, hundredths and thousandths;

- when the user notes a change in the black numbers on the rollers, the flow rate is more than 1 cu. meters;

- The dial indicator contains information in ten-thousandth parts.

The combined meter has two displays, which provide information on the water consumed. Based on the supply source, the user sees data on temporary and permanent flow.

For electromagnetic flow meters, the data block is remote or built-in, depending on the model purchased. The display shows the current volume.

terms of Use

All meters in this series can be used not only in cold water supply systems. If the coolant temperature does not exceed +50 degrees Celsius, then the products can be used to calculate the water flow in the heating circuit of the building. In addition, the device can be installed as a hot water meter if the liquid temperature does not exceed the limit value.

Meter models differ in diameter, overall length and overall size, which must be taken into account when selecting a location for installing a water metering unit.

Where to buy and what to look for when buying?

You can order products from the official website , where the current price is presented on the date of purchase.

Having chosen the required model, the client sees the cost in euros and rubles. The sale of VSKhN metering devices is carried out through suppliers of control and measuring instruments. The price of products will be 1-5% higher.

When ordering, the client provides information on the product - designation and class. Please remember that the set of connectors is not included in the delivery package. They are purchased separately.

Why do you need a VSKh meter?

It is necessary to account for cold water consumption. Current legislation does not allow the use of tap water without consumption meters. In many cases, this option for paying for liquids is more fair, because if the entire cost of water supplied by a utility company were distributed equally among residents, thrifty citizens would overpay significant amounts of money.

With this calculation option, water utility losses that occurred as a result of accidents will also not be taken into account, which will also reduce the cost of money for homeowners.

Video description

Video – TOP 7 water meters for 2021:

- Gardena Water Smart.

Mid-priced model. Equipped with a digital information display. Designed for installation only at the outlet of the water intake point. Works in 4 modes.

- “Norma” STV-50 (flange).

Premium category device. Designed to account for both cold and hot water.

- Zenner ETWI-N DN 15.

One of the best water meters for measuring hot and cold flow at an affordable price. Capable of withstanding a sharp surge in pressure up to 1.6 MPa.

- Valtec ½.

Budget, long-term counter, equipped with a pulse output. Does not show errors during the first two periods of testing.

- METER SVU-15.

A cheap water meter from a domestic manufacturer that operates up to 100 degrees. Equipped with protection against leaks and magnetic disturbances.

- PULSE.

Inexpensive Russian model. Widespread on sale.

Good to know! The rating of water meters is compiled taking into account such important criteria as the ratio of the price of the product to its quality, popularity among users, expert opinion, equipment, availability of spare parts, degree of installation complexity, sensitivity to magnetic interference and the quality of the main components separately.