Cork insulation is a natural material with good properties, due to which it is often used in the construction of various objects. The coating is considered universal because it can be applied to any surface if it is necessary to improve their heat and sound insulation qualities. Cork material has different thicknesses, this parameter directly affects thermal conductivity and sound permeability. When choosing, the insulation properties are taken into account, but we must not forget about the disadvantages.

Cork production and its structure

Cork insulation is based on the bark of the cork oak (Quércus súber), which is distributed only in a few countries: Tunisia, Morocco, Algeria, Italy, Spain, France and Portugal. Half of the total volume of this raw material is generated by plantations in Portugal, where this industry is of national importance. All countries producing natural cork export about 170 thousand tons of this rather rare material per year, which, in conditions of high demand, keeps its prices at a consistently high level.

Cork oak bark was used as insulation back in the Middle Ages by Spanish monks, who used it to decorate the floors of their cells. Mass industrial production of pressed cork chips (agglomerate) dates back to 1891, when this method was officially patented in the USA. The largest supplier of this material is the Amorim Group, all of whose branches are located in Portugal. The company began its path to success back in 1870; at the moment, more than 40 large industrial productions are united under this brand.

The microstructure of cork bark is a series of hard capsules connected in series, having the shape of an irregular polyhedron. The closest analogue of such a structure would be a honeycomb. Each capsule has a complex structure consisting of several layers:

- On the outside, it is covered with two layers of fiber, giving it structure.

- This is followed by a hollow chamber filled with a gas mixture close to atmospheric air (the only difference is the significantly reduced carbon dioxide content).

- Next is a drop of tree resin - suberin, which makes up the majority of all cork material.

- The core of the capsule also consists of celluloses, which gives it internal rigidity.

There are about 40 million of these capsules per 1 cm3 of cork raw material, which creates a unique membrane structure that has virtually no disadvantages. Internal cavities significantly reduce the thermal conductivity of this material, which makes it a high-quality insulation. At the same time, the high concentration of resin almost completely prevents the absorption of moisture, which is the main factor influencing the destruction of most thermal insulators.

In percentage terms, the composition of the cork looks like this:

- Suberin - 60%.

- Cellulose - 20%.

- Lignin, which binds rigid cellulose structures - 12%.

- Water - 5%

- Other impurities (tannins, cyrin, etc.) - 3%.

Raw cork raw materials have the following technical characteristics:

- Thermal conductivity - 0.04 ± 0.1 W/m*K.

- Water absorption percentage ≤13% of total mass.

- Density - 245 ± 5 kg/m3.

- The maximum withstand pressure is 1 t/cm2.

- Hardening at low temperatures, which quickly disappears when exposed to heat.

Moreover, all types of cork insulation have high levels of sound insulation and fire safety. Excellent sound absorption allows this material to be used as a separate means for creating special acoustic conditions. Also, the cork does not support combustion even when exposed to an open flame.

Environmentally friendly thermal insulation for the home

Mineral wool and fiberglass

Safe insulation for walls and ceilings

Glass wool is widely represented on the Russian market by products under the Knauf, Izover and Ursa brands. These insulation materials are made from quartz sand and contain about 40% recycled glass. In fiberglass and basalt mineral wool (Isover, Isorok, Izobond and others), a small amount of formaldehyde or acrylic binders are used as a binder, as in URSA PureOne mineral wool.

During installation, inorganic thermal insulation - mineral wool and fiberglass - has significant disadvantages. When installing basalt slabs and mats indoors, the level of contamination with microscopic fibers significantly exceeds the norm. Particles of these insulation materials do not have a carcinogenic effect, but can cause irritation of the respiratory tract. Their disadvantages include the ability to absorb moisture and the possibility of subsidence.

Ecowool home insulation

Ecowool is also an environmentally friendly insulation material – a fairly new insulation material on the Russian market. The material consists of two-thirds cellulose and shredded waste paper, in addition to recycled paper, straw is also used. During production, substances that prevent combustion are added to cellulose - fire retardants. The advantages of ecowool include the ability to absorb and quickly release moisture.

The disadvantages are that cellulose insulation can rot and mold when constantly wet. Since ecowool consists of waste paper, it is a flammable insulation and cannot be called an insulation that mice do not eat. This environmentally friendly insulation for the floor in a wooden house or walls in a frame house is easy to install and safe for the environment and human health.

Cotton home insulation

Photo. Choosing environmentally friendly insulation

Organic cotton insulation is one of the most environmentally friendly materials available today, as it is made from recycled jeans. Cotton slabs and mats can be laid independently without the use of personal protective equipment. The insulation has excellent sound insulation, so this material is often used when equipping home theaters.

Cotton is a flammable material, so during production, fire retardants are added to the insulation - substances that prevent combustion and the spread of fire. When installing cotton insulation, its slabs are quite difficult to cut, and laying the material will take a little longer than when working with mineral wool. When installing fiber insulation, remember to use a vapor barrier to protect against moisture.

Linen home insulation

Flax mats have recently appeared in Russia under the Ecoteplin brand. From an environmental point of view, flax mats are an absolutely clean insulation material that does not emit toxic substances during operation. Linen, due to its natural origin, is safe for health and can be used in premises where safety requirements are especially high, for example, in hospitals and preschool institutions.

According to the manufacturer, the service life of linen thermal insulation is about 60 years, the material retains its original properties throughout its entire service life. The insulation is not exposed to fungus and mold, and does not settle over time. Linen thermal insulation is difficult to ignite and does not support combustion, and in terms of thermal resistance it significantly exceeds the glass wool discussed earlier.

Sprayed polyurethane foam (PPU)

Photo. Thermal insulation of PPU frame house

Sprayed polyurethane foam is a safe material, since clean water acts as a foaming agent. Due to the absence of cold bridges and seams in the thermal insulation layer, a 1.5-fold reduction in heat loss is achieved compared to traditional slab and roll materials. PPU (sprayed polyurethane foam) reduces the risk of condensation and mold appearing on the treated surface.

The disadvantages of this thermal insulation include its relative high cost; PU foam is applied to the surface using special equipment. Hydrofluorocarbons may have adverse effects on humans during application. Also, the disadvantages of insulation include the fact that polyurethane foam is destroyed under the influence of direct ultraviolet rays, thermal insulation quickly ignites and spreads fire.

Varieties of heat-insulating materials based on natural cork

Natural cork raw materials can act as a heat insulator. But at an extremely high cost, it is more advisable to use special materials based on it, which include expansite (black agglomerate) and impregnated plates (white agglomerate). Cork bark is best used as a decorative finish for floors and walls. Its thin layer will not provide complete thermal insulation, but its original appearance can decorate any interior.

Both of these materials are produced on the basis of cork raw materials crushed into granules. The technology for producing black agglomerate involves heating to 300°C, which triggers the process of sublimation of suberin and, as a result, produces a homogeneous mass. By increasing the volume of internal cavities, the initial volume can increase up to 30%, which has a positive effect on the thermal conductivity and cost of the material.

The international format for this material is 1000 by 500 mm slabs. But depending on the brand, its thickness can vary from 10 to 300 mm. Thin sheets up to 50 mm are rolled into rolls, while thicker ones are supplied in the form of ready-to-use slabs. Due to swelling, the density of the expansite decreases to 120 ± 10 kg/m3, but the thermal conductivity remains at the same level - 0.04 W/m*K. This type of thermal insulation can be used at temperatures ranging from −200 to +150 °C, which allows it to be used even for insulating unheated floors and walls.

The technology for producing white agglomerate is much simpler: cork granules are pressed with the addition of natural adhesives. The standard format is slabs 900 by 600 and 1000 by 500 mm. If the sheet thickness does not exceed 50 mm, impregnated plates are also rolled into rolls. Density ranges from 110 to 260 kg/m3, average thermal conductivity is 0.05 W/m*K.

Specifications

The characteristics of insulation depend not only on the properties of the material, but also on the form of its manufacture. Therefore, if we talk about this material as a whole, we can outline its average characteristics:

- the density of the material is 110-130 kg/cm3;

- specific gravity 200 kg/m3;

- thermal conductivity 0.04 ± 0.1 W/m*K;

- vapor permeability 0.2 mg/m*hour*Pa

- fire resistance class M3.

It is important to know that manufacturers of cork insulation claim that it is not subject to aging . Therefore, it will serve as long as the building itself lasts.

Varieties

The cork is produced in the form:

- agglomerate – white and black;

- roll material;

- dense slabs.

White agglomerate

This type of insulation is used for interior work and does not require finishing; it is obtained from the bark of tree branches. Under the influence of high temperature, the crushed material is pressed using glue. The plates have:

- fire resistance class M3;

- high density up to 130 kg/m3;

- minimum percentage of humidity;

- and high sound absorption coefficient.

Due to its light weight and thickness, white agglomerate is suitable for internal insulation, interior decoration and as a soundproofing material.

Black agglomerate

Black cork insulation is used for interior work; it is produced in the form of slabs. It consists of compressed granules. They are heated and partially charred, which gives the material a dark color.

Black agglomerate is intended for insulation of roofs, walls, suspended ceilings, floors, and also as a soundproofing material. The panels do not absorb moisture, they are resistant to the formation of harmful bacteria and mold. Material properties:

- density from 95 to 130 kg/m3;

- thermal conductivity -0.040 W/μ;

- low vapor permeability;

Roll version

It comes in different grain sizes and thicknesses. On average, the length of the roll is 25 square meters. m., it is used as a substrate for parquet, laminate and as insulation for walls.

Rolled cork is not used for heated floors. The material has high thermal insulation properties and therefore the heat from the source will warm the ceiling, and not the floor and air in the room.

Tile

This is a thicker type of material, used for external and internal work when installing roofs, for insulating foundations and external walls. Used for country houses and high-rise buildings.

Tiles can be single-layer or consist of two layers. The latter option is available painted, tinted or varnished. Two-layer tiles do not require finishing and can be used in the interior of an apartment or house.

Properties

It should be noted that cork is a material with many features. Its advantages:

- low thermal conductivity;

- absolute environmental friendliness and natural origin;

- perfectly absorbs noise, so it is often used to insulate roofs made of “noisy” materials (galvanized steel, copper);

- a light weight;

- ease of processing;

- pleasant to the touch, has a beautiful texture;

- elasticity, resistance to deformation and the ability to restore shape after prolonged deformation.

A relative disadvantage will be instability to mechanical damage from sharp objects and punctures.

The material is afraid of moisture - it absorbs it, but when dried it does not lose its shape and qualities. The material is also resistant to bacteria, fungi, and insects, but this can be solved with special impregnation.

Structure

Cork is obtained from the bark of the cork tree. Due to the peculiarities of the internal structure, it has excellent heat-insulating and noise-absorbing properties. In order to become ready for use, it undergoes special processing, which makes it even more effective, but the basis of its qualities will not be the processing, but the original internal structure. When creating such insulation, a minimum amount of chemicals and impurities is used.

Cork insulation is not cheap. The reason for this is the prevalence of cork oak in narrow areas, as well as its absolute environmental purity. What makes it an excellent insulator is its internal structure: inside it consists of countless microscopic hermetically sealed chambers filled with inert nitrogen and other gases. This device makes even a very thin plate of material an excellent heat insulator and gives it elasticity.

Myth 1 - Insulating a wall from the inside with cork is expensive

You can buy cork panels at a price of 650 - 700 rubles. for 1 sq. m. But when using them, you can immediately find a solution to the problem of how to insulate the wall from the inside, as well as make the wall aesthetic. But let's look at alternative options:

1. Use of thermal insulators and conventional finishing.

Penoplex and other synthetic heat insulators and, for example, wallpaper.

Firstly, cork is completely natural, but these materials are not. Secondly, additional thermal insulation materials take up space - at least 3-6 cm from each wall. Thirdly, in terms of money, such insulation of the wall from the inside will be more expensive, taking into account the cost of the heat insulator and special structures, wallpaper, installation work (if specialists install it).

2. Decorative paint or plaster.

It will not solve the problems of thermal insulation, freezing and cold walls, it will require preparation and leveling of the walls, so the final cost per 1 sq. m may be even higher than for cork panels, especially if the work is carried out by specialists.

3. Wallpaper - cheap, if it falls off from the freezing wall, you can re-glue it.

First of all, not all wallpaper is cheap. Secondly, it is under them that mold often grows on freezing walls. Thirdly, wallpaper usually has to be changed after 5-6 years. But wall plug is an eternal material. Thanks to the protective wax coating, the panels are easy to clean; any stains can be removed with an eraser or detergent without abrasives. Cork wall coverings do not fall off thanks to special contact adhesive, do not lose their external characteristics, and last for more than 15-20 years.

Myth 3 - Cork is not a practical material

You can even include a few misconceptions here:

- Does it absorb odors? No, it's covered with wax.

- It can be easily damaged - children will throw something, a champagne cork will fly off. You can damage a cork panel only on purpose, by taking a nail, for example. Normal use is not scary for her.

- Can't be washed. Can! Wash, wipe, use non-aggressive detergents. The plug is not afraid of water, flooding, or condensation.

- Difficult to glue. Easy, even easier than wallpaper, because the 600x300 mm format is much more convenient than stripes the entire height of the wall.

Warm, comfortable, elegant, environmentally friendly cork panels are an ideal option for the home.

Cork 3D panels

Are you still thinking? Then the last argument. Invest in a wall plug and forget about renovations for years to come. Wall panels will serve not only to insulate the walls from the inside, but also for beauty. Choose a shade and texture that you like, let the walls be the backdrop for other details with which you can update the interior in the future. Cork panels are a repair once and almost forever, no re-gluing every 5 years. Wet cleaning and they are as good as new. Now it’s worth taking a look at the range.

Using cork insulation

Cork insulation is made in various forms: rolls, slabs or even in the form of a laminate, which is used as a finishing floor covering. Before installation, the cork material is acclimatized at room conditions.

They cover and protect walls, roofs, floors and even foundations from heat loss with cork.

For wall insulation

Rolled materials and tiles are used here as insulating cork material. They can be glued under wallpaper. Roll and tile material is available in thicknesses from 2 to 10 mm. You can use any material for walls; the greater the thickness, the better the heat in the room is retained.

Insulation and finishing of the balcony with cork

The general method of insulating walls is as follows.

- The surface of the walls is cleaned. Wallpaper is removed because the glue can cause it to soften and fall off.

- Defective parts and irregularities are leveled and primed.

- After the primed surface has dried, installation of insulation on the walls begins.

- Roll insulation is pasted on like wallpaper. For better adhesion, coat both the walls and the surface of the insulation. Wait a couple of minutes until the material dries slightly, only then apply it to the surface of the wall.

- To glue insulation in the form of slabs, markings are first made. The walls are divided into two equal parts and lines are drawn horizontally and vertically. The first tile is glued in the middle of the wall, and the subsequent ones are either perpendicular to the floor surface or parallel to it.

For better gluing of the agglomerate, special glue, contact or acrylic-based, is used. Universal acrylic adhesive is used for installing insulation on walls, and contact adhesive is used for floors. The difference between these compositions is that acrylic is applied to one of the surfaces, and contact is applied to both.

For floor insulation

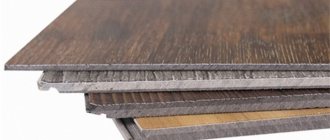

Cork agglomerate is also suitable for insulating floors in the house. Rolled cork acts as a substrate for the finishing floor covering (laminate, parquet, linoleum), because it allows you to distribute the load over the entire sheet.

Floor insulation with cork material

Important! For laminate and parquet, cork insulation cannot be used as a substrate with a thickness of more than 2-3 mm. This is explained by the fact that the greatest difference in base heights for these coatings is 2-3 mm per square meter. With large thicknesses, strong deformations of individual sections of the base are formed over time, which leads to breakage of the locking joints.

Before installation, the floor is cleaned of dirt. If the old coating is durable, you can leave it. On a dry, prepared surface, markings are made from the central point of the room perpendicular to the walls.

Tiled insulation is laid perpendicular to the entrance from the center of the room. In this case, an adhesive composition is used to connect the slabs to the surface.

The rolled material is cut into pieces of the required size with a margin and laid away from one of the walls. There is no need to use glue to fix the strips to the surface. The rolls are secured together with tape, after which the finished floor is laid on them.

Insulation with cork and expansite is expensive, but thanks to the heat-insulating properties, it is possible to create a good heat-protective contour of the room with a small thickness of the material. In addition, this material is also used as a finishing material, which makes it possible to save money.

Application area

In modern house construction, cork is used in thermal insulation of various surfaces, including walls, floor structures, floors, roofing systems and basements.

Rolled cork is in demand as a heat and sound insulating layer when installing a heated floor system. Rolled sheets are often used as a backing for laminate and parquet flooring. Sheet models of the product - mats and slabs - are relevant as the optimal heat insulator for wall structures.

Dense cork panels of considerable thickness are used in the construction of foundations and basements, roofing systems and attics. Sprayed crumbs are in demand as a functional façade decor: the coating serves as heat and sound insulation for external walls, while being distinguished by its original aesthetics and presentability.

Cork insulation technology

Installation of plugs for thermal insulation of walls and floors is carried out taking into account the characteristics of the material:

- Rolled products must be unrolled before laying so that the web can rest and straighten in the appropriate temperature environment. Otherwise, installation difficulties will arise, since when rolled up the cork takes on a characteristic shape;

- It is easier to work with sheet cork than with the rolled version. However, you will have to follow the technology of fitting individual fragments, which is especially difficult in corner areas.

When choosing an adhesive for laying cork, take into account that different compositions provide different adhesion abilities. The properties of fixing substances determine such aspects as the speed of installation work and the permissible time frame for the start of operation of the facility.

Tools and materials

When laying cork to insulate walls inside an apartment, the following set of tools and materials is required:

- sander;

- jigsaw, sharp knife;

- primer;

- tape measure, marker;

- laser level or painting cord;

- glue, spatula;

- sealant;

- water-based varnish, roller or brush.

To insulate with cork, you will need a grinder.

You also need to prepare the required amount of cork insulation of the desired brand.

Necessary calculations

When planning to insulate walls with cork from inside the apartment, calculations should be made based on the area and features of the surface being equipped. It is also important to make markings to ensure the correct lines for laying the insulation coating:

- on the wall, a perfectly straight vertical line is struck from the corner using a laser tool or painting cord;

- stepping back from the upper boundary of the wall under the ceiling, determine the horizontal.

If thermal insulation from tiled cork is planned, horizontal lines are marked across the entire area of the wall, since the coating is laid from the lower perimeter. Installation of roll sheets is carried out similarly to gluing wallpaper.

Insulation and finishing of walls and ceilings

Cork insulation is installed end-to-end. Roll sheets prepared along the length are glued starting from the vertical line. The sheet insulator is laid from the bottom of the wall. Moreover, horizontal lines determine the location of the rows of tile cork. Ceiling insulation is carried out according to a similar scheme.

The adhesive is applied according to the manufacturer's instructions, on both surfaces or only on one - on the tiles or the base being installed. The gaps are filled with a special sealant for cork coverings. After complete drying, finishing work is performed. Most often, cork on the wall and ceiling is treated with a colorless water-based varnish.

Despite the high cost of the material, cork insulation is in demand due to its high performance and decorative characteristics. The service life of insulation is commensurate with the resource of the structure itself, which makes cork relevant for insulating the walls of apartments and country houses.

Main advantages of the material

The excellent thermal insulation qualities and environmental safety of cork insulation are complemented by the following positive qualities :

- strength and light weight;

- does not change volume when humidity changes;

- does not ignite;

- when exposed to moisture, mold does not form on the material;

- does not rot;

- not destroyed by rodents;

- simple installation;

- has dielectric properties and does not accumulate static electricity.

Disadvantages of cork insulation

There are practically no significant disadvantages to this type of insulation. Only a few weaknesses of the material are noted:

- The insulating substrate of the wall may be damaged if this type of finish is used at industrial facilities and provided that metal cutting or other types of processing of this material will be carried out in the room. The fact is that metal shavings contribute to the deterioration of the thermal insulation qualities of the cork. Solid particles clog the pores of the insulation. Prolonged use in such conditions will lead to damage to the structure of the cork coating.

- Insulation, characterized by low density (95-130 kg/m³), allows vibration waves to pass through. This means that it cannot be used as a barrier to prevent vibration noise from penetrating into the object. To protect against vibrations, it is better to consider cork insulation with a density of 130 kg/m³ or more.

- High price. Considering the excellent insulation properties of cork, as well as the absence of synthetic additives in the composition, one would expect that such insulation would be offered at a high price. However, one must take into account the long service life of the cork, which allows the use of such a finish without the need for periodic replacement.

The material protects against noise if the main condition is met - the high frequency range is provided (1.5 kHz).

How to get rid of impact noise

Here you need to approach the problem from the other side; the task is not to absorb the sound wave that is bothering you, but to push it away. Building materials that are porous will help well: polyethylene foam, cork backing or extruded polystyrene foam.

The difficulty is that such insulation should be laid on the floor of the apartment located above you, and this is only possible if you have good relations with your neighbors. Such ceiling sound insulation will be the most effective; a multi-layer floating floor will be created, which is not difficult to lay with your own hands.

Soundproofing walls with cork in an apartment, how it’s done

To ensure effective sound absorption, it is recommended to use several types of soundproofing coatings, characterized by different structures. Among them may be cork material. It is recommended to install it on the inside of the room where the noise source is located. If technical covering made of balsa wood is installed, it should be mounted on a rough base. Decorative material is laid last, as it is used as a finishing touch. Cork can be laid on walls in several layers.

Is it possible to insulate from the outside?

Cork coating is also used for facades, as it has the following advantages:

- helps conserve heat;

- reduces noise levels;

- does not collapse under the influence of temperature changes and precipitation;

- has a service life of about 25 years.

To finish the facades, liquid cork is used, which is applied to the surface in several layers using a sprayer. The material has a wide color palette and is not demanding in maintenance.

Criterias of choice

When choosing a plug for insulating an apartment, take into account the following points:

- application features. Depending on the planned work, choose cork in rolls or in the form of sheet material;

- cork thickness parameters. Priority is given to material of maximum thickness if a heat and sound insulation system of a high level of reliability is required;

- manufacturer. Portugal is considered the recognized market leader in the production and sale of cork; well-known brands from Mediterranean countries also offer these products;

- price. White agglomerate is relatively cheaper than black. The cost of a rolled cork starts from 135 RUR/m², depending on the thickness. Sheet insulation is sold at an average price of 600 rubles/m².

When visually inspecting a material, such characteristics as surface smoothness, uniformity of structure, and elasticity require attention. It is worth considering that high-quality cork insulation does not crumble, and it is also not easy to break off a piece of the product.

Release form

The agglomerate can be presented in the form of rolled webs and sheet products. The length of roll products is 10,000 mm with a width of 1000 and 1400 mm. The thickness of the canvas varies from 2 mm to 10 mm.

Sheet cork covering in the form of slabs and mats is widely used in the construction of wall structures as an effective heat and sound insulation resource. Dense versions of the material - panels for insulating attic and basement floors - are equipped with a locking system to facilitate installation work.

Linear dimensions of sheet cork:

- 915x610 mm;

- 935x640 mm;

- 1000x500 mm.

The thickness of the slabs varies in the range of 2-320 mm and up to 500 mm for black agglomerate.

The best manufacturers of cork insulation

The main suppliers of cork agglomerate to our country are Portuguese manufacturers. Among the leading companies in the insulation materials market are the following brands:

- Amorim, the oldest manufacturer leading the global market . The average cost of materials is presented in the range - for panels from 600 rubles / sq. meter, the cost of packaging roll material starts from 1200 rubles.

- Wicanders, the company's product range includes cork insulation for wallpaper and decorative cork coverings. The cost of insulation starts from 1,300 rubles per roll.

- Izora specializes in the production of panels designed to insulate walls, roofs and floors. The average price, depending on the type of agglomerate, is 600-450 rubles/sq.m. meter.

- Sedacor. The main products are cork insulation in rolls and sheets. Packaging sheet insulation (6 square meters) will cost the buyer approximately 900 rubles, and the cost of roll insulation starts from 135 rubles. per sq. meter.

Many potential buyers of cork insulation are confused by the high cost of this material. In fact, this is its main disadvantage . The cost of building a house that is insulated with cork agglomerate can increase by 8-10% compared to using synthetic insulation.

It is not recommended for use in rooms where high humidity is constantly present, since even after treating the insulation with compounds that improve its moisture resistance, it remains sensitive to moisture. Moreover, it has the ability to accumulate it.

To install the cork covering, you need to purchase a special glue . Its cost is high, which significantly increases the cost of insulating a house.

However, if you take into account the quality of balsa wood insulation, its unlimited service life and the absence of harm to the health of its owners, the cost turns out to be not so high. Therefore, many consumers who care not only about maintaining heat, but also about the health of their family, are increasingly using cork insulation in the construction of their homes.

All about cork agglomerate - the best insulation for the home, watch the video:

Agglomerate of Spanish quality in the Basque Trading House

The search for high-quality thermal insulation material often ends in nothing. Many place strict demands on him, which not every “candidate” can withstand. If polystyrene foam, glass wool or expanded polystyrene were previously rejected, then it’s time to choose cork agglomerate. First of all, it has an environmentally friendly composition. One hundred percent “natural product”, perfect for insulating interior home spaces. And not only. The agglomerate perfectly withstands subzero temperatures and precipitation without losing its properties. Therefore, using such insulation for installation outside is also a good idea. You can order it and purchase it inexpensively at the Bask Trading House.

About the advantages of the product

The cork tree from which building materials are made is an African plant. It also grows in the Mediterranean. Such products cannot be cheap: significant production costs plus considerable transportation costs. However, cork insulation has many advantages, so the extra investment will very soon pay off. Among the main advantages of the agglomerate:

- highest thermal insulation qualities;

- extraordinary sound-absorbing properties;

- unique durability: does not rot, cannot be damaged by rodents;

- high fire resistance (practically does not burn);

- resistance to deformation.

Confirming the environmental friendliness of the agglomerate, we can say that there are no chemical compounds in its composition. There is no need to worry about the safety of your home: it will be at its best. At the same time, each buyer receives an unplanned “addition” to insulation - excellent sound insulation of the internal walls of the house with high-quality cork covering. As they say, two in one.

Widespread use

Agglomerate is a universal material. It is also used as a decorative decoration for a room. If you get creative, you can cover the floor, walls and ceiling. Then agglomerated corks will replace plaster and wallpaper. Such repairs will last for ten years, or even more. After all, agglomerate is valued for its wear-resistant and durable qualities. Having decorated the apartment with such material, it is easy to get rid of the annoying noise from the neighbors. It can’t be any other way: there’s nothing better than excellent sound insulation from cork for walls, and the price will quickly justify itself.

Where else can you use a unique building material? On flat roofs, gluing it to supporting structures. On the facades of houses - on top of the existing plaster. If cork is chosen as the finishing material, the thermal insulation will be excellent. Do you want to lay laminate flooring? To reduce noise and increase heat, a substrate is required. You can’t do this without cork agglomerate. Rolled fabric is the best way out. It is faster to lay it by spreading strips along its entire length. In addition, the cortical base will eliminate small defects on the floor.

Quality product and

Agglomerate cork is produced in the form of rolls and slabs. offers the latest. Looking at the catalog, you can see an agglomerated cork board in black and light shades. Both agglomerate options have standard sizes accepted on the European market. The price is consistent with Spanish quality. To make cork wall insulation effective, you cannot do without a black agglomerated slab. Its positive properties are:

- has the required density;

- provides ease of cutting and ease of installation;

- does not require leveling before installation;

- has a small size and light weight.

The roll in this regard is less convenient to handle. There is no other optimal option than a stove.