When developing a sewerage system for a new house or during its major renovation, the most important stage is the selection of materials, at which the calculation of the main parameters takes place, which, in turn, is used to select the diameter of the sewer pipe.

The main parameters when designing a sewer system, in addition to the diameter, are the following:

- slope, which ensures normal operation of wastewater drainage;

- turns: their number, angle of rotation;

- methods by which pipes are connected to each other, to fittings and plumbing fixtures.

Pipes and fittings of various diameters for domestic sewerage systems

Types of pipes

There are 2 main materials for making pipes: plastic and metal. The first, in turn, is divided into 3 types:

- polyvinyl chloride (PVC);

- polyethylene (PET);

- polypropylene (PP).

All of them can be easily found on the market.

The standard diameter of sewer pipes is indicated in the technical specifications and most often it ranges from 5 to 12 cm. But there are types of sewer pipes with a smaller diameter, which are also made according to technical specifications. conditions, which will facilitate their selection for different systems.

Pipes are divided into categories, depending on the highway on which they will be used (each diameter is 16 cm):

- SN-2. Such pipes are made of lightweight material, therefore they are used in areas with minimal load (domestic sewerage indoors, residential areas without traffic load).

- SN-4. They are denser than the previous ones, so they are purchased for a sewer system that needs to be installed under a highway, where traffic is not very strong.

- SN-8. The densest pipes, which are also used under highways, neighborhood highways, in factories and where there is frequent traffic.

Types of pipes Source domstrousam.ru

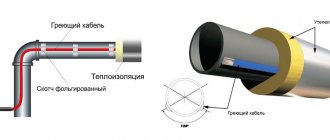

During the installation of the system, not only pipes are used, but also various connections and adapters:

- Turns that allow you to change direction.

- Adapters and splitters for forks.

- Gearboxes that connect pipes with different circumferences to each other.

- Compensators that reduce the effect of high temperatures.

- Couplings and clamps.

It is important to remember that the sewer must have a minimum number of bends and forks. This will make the structure more stable and reduce the cost of the entire installation. When installing PVC sewer systems, keep in mind that most of the cost is in the connections, not the pipes.

Types of connections Source infotruby.ru

Method for determining the optimal sewer slope

To determine the required angle of inclination of the pipes, it is necessary to calculate all sections using the reference information presented above. In fact, you need to know exactly the length of the pipe, its diameter and the slope value for this diameter.

In some reference tables, the required angles of inclination for a specific diameter are indicated as a fraction or in hundredths (corresponds to GOST). For example, the value (1: 20) is 0.05 and corresponds to a slope of 5 centimeters per linear meter.

To calculate the total slope of the pipe, you need to multiply its length (for example, 5 meters) by the angle of inclination (for example, 0.05), taken from a special table:

5 × 0.05 = 0.25 - total slope of 25 centimeters.

Advantages and disadvantages of PVC

PVC has a number of advantages, thanks to which they have proven themselves well in the market:

- Resistant to corrosion.

- Immune to damage by microorganisms.

- A large assortment.

- Availability of various diameters.

- Resistant to temperature differences and pressure changes, as well as chemicals.

- Can handle heavy loads.

- Do not deteriorate after prolonged use.

- Simply mounted to any sewer.

- They do not emit harmful fumes.

- Due to the fact that PVC pipes have a smooth surface, they are less susceptible to the formation of build-up or sediment.

- Do not allow electric current to pass through.

- Light enough.

- Inexpensive compared to other materials.

The main difference between plastic pipes and metal ones is that the former have a larger range, and the latter are most often made of cast iron. One of the disadvantages is that PVC is not as durable as its competitor, but will last at least 50 years.

See also: Catalog of house projects with 2 or 3 bathrooms.

Installation of sewerage in a bathroom

With this publication we are opening a series of articles on “piping in the bathroom”, where the issue of installing rough plumbing in the bathroom and toilet will be addressed. The first stage is the design and installation of the sewer system.

Why sewer? Yes, because all subsequent wiring depends on it. If water supply pipes are usually not difficult to extend to any point in the bathroom, then with sewer pipes it is a little more difficult. The presence or absence of boxes depends on the drain pipes; due to the need to maintain a slope towards the riser, you need to take into account all the little things, including the height and location of the bathtub. In other words, the entire layout of rough plumbing directly depends on the sewer pipes.

Properties of pipes and their purpose

The place where pipes are used directly depends on their physical properties. Polyvinyl chloride is one of the types of plastic that does not deform from high temperatures, is frost-resistant, and does not lose its properties when heated and frozen. The main purpose of PVC is to install them in water supply and drainage systems, and the place where they can be used depends on the thickness and density of the walls:

- sewerage;

- pressure system;

- gravity drain.

PVC sewerage Source nomitech.ru

Pipes are divided into these subtypes only after they have undergone certain processing. Plasticized PVC PVC-U is considered one of the best in terms of its parameters, which determine the location where such a pipe can be used. The following indicators are characteristic of PVC:

- Good strength against mechanical damage and three-layer production technology, as well as external corrugation, thanks to which it can be installed deep underground.

- Resistance to external factors.

- The highest wastewater temperature that such a pipe can withstand is +65 °C, the lowest is -10 °C.

It can also be noted that the weight of 1 m of plastic pipe is only 2 kg, and the greatest strength is 50 MPa.

Laying underground Source experttrub.ru

Polypropylene drain elements

To regulate the quality of production, which produces plastic sewer pipes of various sizes, the table TU 4926-002-88742502-00 is used. According to the conditions specified in the document, the diameter of the finished product can be 50, 100 and 150 mm. The wall thickness parameter varies from 3 to 5 mm and depends on the value of the circumference. Such products can be used when installing risers, or for organizing a discharge line from a plumbing fixture.

It may be mentioned that well-known global manufacturing companies use polypropylene in the manufacturing process of industrial pipes. The circumference of such products can reach 1.2 meters.

PVC pipe sizes for various premises

When choosing a pipe, an important parameter is its diameter, which may differ depending on the purpose. It is also important to remember that the sewer system will function without problems if the size is selected correctly.

There is a table of the diameter of PVC sewer pipes, which indicates parameters that will help simplify the choice of material:

| Device | PVC diameter, cm | ||

| Bath | 0,40 | ||

| Shower room | 0,40 | ||

| Washing | 0,30-0,40 | ||

| Combined drain | 0,50 | ||

| Bidet | 0,30-0,40 | ||

| Toilet | 0,100 | ||

| Sink | 0,40 | ||

| Central riser | 0,100 | ||

| Branches from the riser | 0,65-0,75 | ||

The pipeline parameters include:

- diameters on both sides;

- internal and nominal cross-section;

There is also a table of PVC sewer pipe sizes presented below.

| DN(cm) | DS min(cm) | Wall thickness | Bell length | |||

| e (cm) | e2 min (cm) | e3 min (cm) | A min (cm) | C max (cm) | ||

| 0,32 | 0,32 | 0,18 | 0,16 | 0,10 | 0,24 | 0,18 |

| 0,4 | 0,40 | 0,18 | 0,16 | 0,10 | 0,26 | 0,18 |

| 0,5 | 0,50 | 0,18 | 0,16 | 0,10 | 0,28 | 0,18 |

| 0,75 | 0,75 | 0,19 | 0,17 | 0,11 | 0,33 | 0,18 |

| 0,11 | 0,110 | 0,27 | 0,24 | 0,15 | 0,36 | 0,22 |

This table of sizes of plastic sewer pipes will help you decide how much material you need to take and what kind of material.

Extended table for choosing diameter Source vse-o-kanalizacii.ru

List of sewer fittings

Only fittings are capable of combining pipes of different types and sizes. Used to connect branches and when turning a structure. The reliability of the system's sealing depends on correctly selected connecting parts.

| Name of the connecting element | Functionality |

| Tee 110×110 mm | Large fitting, used to connect to the central riser and toilet. |

| Reduction 110×50 mm | A special type of fitting that connects pipes with a diameter of 50 mm to a diameter of 110 mm. |

| Bends | Elbows designed to change the direction of pipelines. Suitable for all sewer sizes. Can be installed at an angle of 90° or 45°. |

| Tees | Several pipes are connected into one system. Can be all sizes identical or different. |

| Audit | Designed for places with an increased risk of contamination, equipped with special removable covers. |

| Stubs | They are selected for a certain pipeline diameter and installed at the ends. |

Switching from cast iron to plastic

There are situations when cast iron is installed in the sewerage system and it needs to be changed to PVC. In this case, you must first dismantle the old drainage system:

- Cast iron is cut from the top at a distance of 7.5-10.5 cm from the ceiling, and approximately 80 cm from the tee is left below, the rest is removed with a metal disc. These actions need to be done only until the middle of the structure.

- After this, the rest of the cast iron is removed with a chisel (to do this, it must be inserted into the drilled place and hit with a hammer, then it will fly apart).

- Otherwise, you can take a crowbar or a hammer drill to clear the cement from the pipe, and then use the chisel again.

- After this part of the cast iron is removed, it is necessary to remove the remaining concrete from below and saw off the lower part from the tee, leaving 3-7 cm.

What a joint looks like Source yelpcdn.com

Installation features

Actually, most of the information has already been told, all that remains is to assemble the purchased components in accordance with the design idea.

Pipes are assembled from the riser (inlet pipe) towards the consumer. In other words, the pipes that are closest to the drainage point into the common house riser are installed first.

At each connection, the pipe should fit into the socket of the previous one by approximately 50 mm. If the cuff in the socket is too tight and you cannot insert the outlet, then you need to lubricate the cuff with liquid soap or detergent - things will go much easier.

Plastic pipes are cut using any available means: a grinder, a hacksaw. You can even do the cutting with a regular wood hacksaw. The main thing is to clean the cut edge from all kinds of burrs - burrs inside the pipe will cause blockage, and burrs on the outside will prevent the parts from being assembled properly.

Briefly about the main thing

There are 2 types of pipes: metal and plastic. The former are made only from cast iron, and the latter from three types of raw materials: polyvinyl chloride (PVC); polyethylene (PET); polypropylene (PP).

When installing a drainage system, PVC is most often used, which greatly facilitates the operation of the sewerage system. These pipes can withstand heavy loads (road and neighborhood highways), can serve at temperatures down to minus 10 ° C, and are also treated on both sides so that no sediment remains on the smooth surface after rain or mechanical stress. Also, such a pipe can be easily installed in place of an old cast iron one. They come in several types in diameter and are connected to each other by adapters.

| Additionally The exhibition of houses “Low-Rise Country” expresses sincere gratitude to the specialists for their assistance in creating the material. – supplier of water supply and heat supply systems for any facilities, from the world's leading brands. The company also develops and installs automated metering systems for energy consumption. If you need more detailed advice, you can use the following contacts: website: www.makipa.ru email: phone: +7 (495) 134-48-01 |

Ratings 0

Read later

Options

The standard marking for cast iron pipelines is from DN 50 to DN 400. Products that do not have sockets, that is, with smooth sides, have an increased margin of safety. Their length is three meters. SMU pipes can be produced in lengths of 15 cm or more.

The wall thickness of a cast iron pipe is almost identical to plastic products and is 4-5 mm. However, despite similar dimensions in length, wall thickness and diameter, the weight of the metal structure is 10 times greater than the weight of the plastic pipeline. For clarity, a meter of metal product will weigh about 15 kilograms. Accordingly, a plastic pipe of identical dimensions will weigh only 1.5 kilograms.

SDR Ratio

This abbreviation is often found in labeling codes. Spelled as SDR . Indicates the standard dimensional ratio, in English - Standard Dimension Ratio.

This is the ratio of the outer diameter of the pipe to its wall thickness. For example, let's find the SDR for the indicators:

D=200, S=4.9

Here D is the outer diameter and S is the wall thickness. Both values are in mm. The calculation formula is:

SDR=D/S=200/4.9=40.81

Round up for a whole number and get:

SDR 41

The lower the coefficient, the thicker the pipe wall. This means it is stronger.

Material

PVC - polyvinyl chloride. It can be found everywhere. It serves as the basis for insulating electrical wires. It is used to make furniture edges. Vinyl covers the front side of decorative wallpaper.

The main advantage of the material is its accessibility. But there are disadvantages. Plastic does not tolerate frosts in central Russia. At -15 degrees Celsius it “dumbs” and becomes brittle. And if you heat PVC to +66 °C, it will begin to lose its shape. The melting point is only +100 °C.

But these characteristics are quite sufficient for the installation and operation of sewage systems. Indoor and outdoor.