Register Login

Publication date: May 3, 2019

The creation of the first samples of amorphous film batteries became a new discovery in the field of alternative sources of electrical energy. Over the course of several years, the model was improved, achieving outstanding technical and operational characteristics from a simple design. Experts involved in energy research say that very soon amorphous solar panels will take a leading position in their segment and will be put into mass production.

Description

At this time they are already represented by the third generation. The advantage of the second is considered to be low cost with power identical to crystalline modules. Therefore, they are the ones that have become widespread. Silicon required to produce them is 10 times less.

Models belonging to the third generation are characterized by an increased operating period and efficiency increased to 12%.

Important: photovoltaic modules, thin-film modules are considered the main candidate for mass production, possible in the near future, despite the shortcomings and the fact that today the leadership is held by crystalline analogues (80% of the market).

About technology

To make a thin-film solar structure, semiconductor compounds are sputtered onto a flexible substrate (usually a polymer).

At first, they used exclusively amorphous silicon for this. But, I was not satisfied with the low efficiency of photocells - about 4-5%.

After the advent of selenide and telluride - innovative materials, it was possible to achieve a higher efficiency rate - up to 12%.

Generations of amorphous panels

Very soon, the rapid development of amorphous film modules may change the current market situation.

Today they are represented by three generations:

- The first category includes single-junction ones, the disadvantage of which was their short service life: after 10 years of operation they became unusable. In addition, their efficiency was extremely low - 5%;

- they are the same, but with twice the efficiency (8%) and a longer service life;

- third-generation devices can fully compete with analogues, since they have a fairly high efficiency - about 12%. They will last much longer than their predecessors.

In addition to them, there are combined options that form both crystalline and amorphous elements. However, their cost is high, so they are not widely used.

Vacuum method

The method involves the use of vacuum chambers or electron guns for deposition of diselends from vapor.

In principle, any approach can be used, for example, ion sputtering, but all methods have their own difficulties, such as the formation of a film both on the substrate and on the inner surface of the chamber. Another difficulty is associated with the supply of indium, which is actively used for the manufacture of flat panel monitors.

For such devices, the efficiency can exceed 20%.

Although panels of this type are actively developing, their demand is small and does not exceed 2%.

Films made using cadmium telluride have gained great popularity. Their efficiency is 16% (versus 18%). Amorphous silicon batteries are very popular. Their efficiency was increased to 10%.

Advantages

Thin-film amorphous panels have many advantages over their crystalline counterparts:

- better performance at high operating temperatures. Due to their lesser dependence on heat, they are more efficient than crystalline ones in warm weather. It is clear that they lose power when heated, but not as much as conventional solar panels, for which it can be reduced by 20%.

They are capable of generating electricity in low light conditions, therefore they are more effective in comparison with their crystalline counterparts in rainy weather, twilight and snowfall.

Amorphous systems continue to generate electricity when classical crystalline structures stop generating it. They produce 20% more of it than their analogues.

- allow hidden installation;

- cost less because production costs are low. The favorable cost of each Watt is also explained by the injection of significant investments, which makes it possible to increase their output and reduce the price;

- high flexibility and low thickness make installation, repair and maintenance easier;

- less dependent on shading and dirt on the front surface, while the performance of silicon devices is reduced by 25%;

- Minimum defects. The process of creating the modules in question is very simple. Due to the absence of the need for soldering to connect the modules to each other (they are formed immediately into a single structure), there are fewer defects in the finished products.

The disadvantages, as you can see, are more than offset by the advantages of the panels.

Comments:

Megavolt

I read that they released solar batteries in the shape of a round cone, they produce 20% more than conventional batteries. Does anyone know about this technology?

Electrician

Megavolt, let's calculate))) The efficiency of film batteries (namely, they are rolled into a cone) = 10%. We add 20% of 10% to them and get as much as 12% with an increase in cost of at least three times! Breakthrough in savings!

Semyon

Electrician, I also watched this story. It immediately seemed suspicious to me that the entire scientific breakthrough consisted of giving batteries some kind of shape. As if no one had guessed before that the sun was out of place... As always - conspiracy theories and collusion.

Leave a comment Cancel reply

Related Posts

Selecting a battery for a solar power plant

Types of solar-powered garden lamps and lanterns, how and where to use them.

Types of controllers for solar panels and how to choose

The principle of operation of solar panels.

Disadvantages of amorphous modules

The main negative feature of amorphous silicon solar cells is considered to be low efficiency, which is half that of silicon analogues (under conditions close to ideal).

In addition, they have other disadvantages:

- significantly larger dimensions than analogues;

- protected on both sides by glass, they acquire a significant final mass. The disadvantage, by the way, is gradually leveled out thanks to the development of technology.

Silicon panels have no less disadvantages.

Why efficiency is so important

Efficiency comes into play when calculating the amount of space you can use for a solar panel system. With comparable sizes of the described modules from Amerisolar AS-6P30 280W (1.63 square meters) and NeOn 340 W from LG (1.71 square meters), the difference in power per square meter at the output will be 15.6%. On the one hand, this may not seem very effective, given the price difference of more than double, but in the case of limited space or a more aggressive external environment, it may shift your choice in favor of this well-known manufacturer.

The increased efficiency emphasizes not only the efficiency of the manufacturing technology, but also the high-quality materials used in manufacturing. This can affect the operating life of the devices and the resistance of the panels to so-called degradation. Don't forget about the manufacturer's warranty. Having representative offices and warranty services in almost every corner of the world, LG will be able to boast a more loyal approach to customers and fulfillment of its obligations.

Disadvantages of Silicon Devices

This material is very expensive, since for the required degree of purification it needs to go through several stages of purification. When cutting it, a large amount turns into waste - chips.

In addition, not all energy is converted into electrical energy under the influence of light: it is partially reflected back from the surface, the other part, without being absorbed or converted, passes “outside”.

We recommend:

- Solar panels work at night and in cloudy weather

- Monocrystalline solar panels: comparison with analogues, advantages, price - TOP-6

- Thin-film solar cells: advantages and disadvantages, price, characteristics

In addition, it can lead to thermal vibrations in the crystal lattice and is wasted on the recombination process, i.e. destruction of electrons with “holes”, which is accompanied by the release of heat.

All this negatively affects the efficiency of solar cells, reducing it to 15% (in rare cases to 22%).

What is a solar battery

A solar battery (SB) is several photovoltaic modules combined into one device using electrical conductors.

And if the battery consists of modules (which are also called panels), then each module is formed from several solar cells (which are called cells). The solar cell is the key element that is at the heart of batteries and entire solar systems.

The photo shows solar cells of various formats.

Here is the assembled photovoltaic panel.

In practice, photovoltaic cells are used in conjunction with additional equipment that serves to convert current, for its accumulation and subsequent distribution among consumers. The home solar power station kit includes the following devices:

- Photovoltaic panels are the main element of the system, generating electricity when sunlight hits it.

- A rechargeable battery is an energy storage device that allows you to provide consumers with alternative electricity even during those hours when the solar system does not generate it (for example, at night).

- The controller is a device responsible for timely recharging of batteries, while simultaneously protecting the batteries from overcharging and deep discharge.

- An inverter is an electrical energy converter that allows you to produce alternating current at the output with the required frequency and voltage.

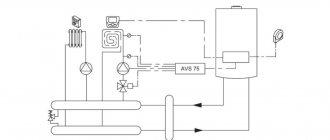

Schematically, a power supply system powered by solar panels looks like this.

The circuit is quite simple, but in order for it to work effectively, it is necessary to correctly calculate the operating parameters of all devices involved in it.

Area of use

It is recommended to use this type of solar modules for:

- high cloudiness;

- hot weather, when the modules heat up to 60 degrees;

- no restrictions on the area of the structure and its weight;

- if necessary, integration directly into the building.

In addition, amorphous solar panels can be installed in window openings (instead of glass) and mounted on building facades, which opens up unlimited possibilities for designers. But, the elements must differ in a certain degree of transparency (for glass it is 5-20%, without losing a percentage of electricity generation).

Where can I buy

You can purchase solar panels either in a specialized store or online in an online store. In the second case, the budget option for purchasing products on the Aliexpress website deserves special attention. For some panels there is an option for shipment from a warehouse in the Russian Federation; they can be received as quickly as possible; to do this, when ordering, select “Delivery from the Russian Federation”:

| Mini solar panel with voltage from 2 to 12 Volts | 100 Watt 12 Volt Flexible Solar Panel | 300 Watt Flexible Solar Panel Set |

| Dokio Portable Solar Panel 18V 200W | Lamp with built-in solar panel power supply | Polycrystalline solar panel 40 Watt, 18 Volt |

Manufacturing

Only thoroughly purified silicon is suitable for the manufacture of a semiconductor converter. Its shape, as a rule, is a cylinder with a diameter of only tens of millimeters.

It is cut into the thinnest disks, microns in thickness, which are then alloyed, applying metal and other impurities to the surface.

In a silicon wafer, areas are formed that are saturated differently with “holes” and electrons. In other words, having “hole” p-conductivity and n-electronic conductivity.

By “holes” we mean a metal from which electrons have been partially removed by impurities, i.e. this is the “positive” zone, or p-conductivity.

By combining the composition, the order of the applied layers and their thickness, hetero- or pn-junctions are obtained, i.e. The plates have the ability to produce electricity when irradiated with light.

Based on this principle, the first FETs were created - photoelectric converters, the efficiency of which reached almost 30% under normal conditions and about 22% at high temperatures.

Average prices

The cost of solar panels is one of the criteria for their selection.

The retail price for the models discussed above, produced by Chinese and sold through specialized organizations, is:

- Solar battery 60P – 3400.00 rubles;

- Solar battery 100P – 4980.00 rubles;

- Solar battery TopRaySolar TPS-FLEX-50W (50.0 W) – 6790.00 rubles;

- Solar battery TopRaySolar TPS-FLEX-80W (80.0 W) – 10,410.00 rubles;

- Solar battery TopRaySolar TPS-FLEX-100W (100.0 W) – 12,440.00 rubles;

- Solar battery TopRaySolar 100M (100.0 W) – 5210.00 rubles;

- Solar battery TopRaySolar TPS-FLEX-100W (100.0 W) – 12,440.00 rubles.

The cost of devices from other manufacturers with similar technical parameters lies in the same price range, so there is always the opportunity to make your own choice, in accordance with individual wishes.

Production of amorphous FEP

The raw material for the main layer is silane-silicon hydrogen (SiH4). After treating silicon with hydrogen, hydrogenated silicon is obtained.

In a closed chamber, the silane is exposed to a glowing electrical discharge before being applied to amorphous silicon. Evaporating, silicon vapors are deposited on the substrate. The layer is micron thick.

Since the production is waste-free, the cost of the finished product is low. Modules can be made with an area of several square meters.

Hydrogenation achieves semiconductor properties in the thinnest films.