Question:

Good afternoon I already asked about the advantages of aluminum radiators and you gave a complete answer. Recently I saw steel radiators in a store, they are also affordable and I would like to hear about the pros and cons of this heating system. Thanks for the answer!

Answer:

Creating a temperature level that is comfortable for living is the task of a modern heating system. Today it is mostly water. Its main elements, which bear full responsibility for the stability and efficiency of heating, are radiators. They play a key role in heat transfer, so choosing them from a large list is an important step towards comfort.

Cast iron, copper, aluminum, bimetal, steel are the structural basis, among which you have to choose. It is easy for a potential buyer to get confused in the presented list. The reason for this is a lack of technical knowledge. Placing trust in the seller's recommendations is a wrong decision. They are far from always perfect in such matters, and their main goal: to sell stale or expensive goods, should be taken into account.

It is wiser to understand the issue of choosing radiators yourself. To do this, you do not need to delve into the technical parameters; it is enough to consider the advantages and disadvantages of each radiator. They are no longer in theory, but highlighted by practical operation, based on real reviews from people. It’s worth starting to study the facts with the simplest steel radiator in its design. It has been operating in a water heating system for decades and has good performance.

Distinctive features

The buyer will never be able to distinguish between an aluminum alloy and a bimetallic one when choosing, because visually they are simply identical sections of radiators, covered with identical paint and varnish material. Therefore, you cannot do without a sales consultant and studying documents for goods in a shopping center. As for the fundamental differences, here the buyer will be faced with a number of physical and technical characteristics of each material.

Manufacturing option

Aluminum products are sections assembled together, assembled with special fasteners and gaskets. Nipples and seals ensure the tightness of the structure. The technology increases heat transfer to 50 cm2.

- Casting. The technology allows, under pressure, to obtain products with excellent resistance to any external or internal (water hammer) influence. Molded batteries are very precise in shape.

- Extrusion. This option is cheaper than the previous one, but the material characteristics are worse.

Light metal option Source tengrinews.kz

Bimetallic radiators are made from two types of raw materials. The ribbed body is made of aluminum. A core of pipes is installed inside the structure, through which the coolant from the heating system passes. Most often, containers are made of steel, less often – copper. The diameter of the structure is smaller than that of models made of one type of metal.

Design features Source santehservis.dp.ua

By heat transfer

Before distinguishing an aluminum radiator from a bimetallic one, you need to understand the features of the comparison indicator. Heat transfer is a criterion indicating the amount of thermal energy that a battery transfers to the air per hour. The higher the parameter, the faster the room heats up.

The heat output of aluminum radiators is from 200 W, 50% of the energy comes in the form of radiation, the rest by convection. The ribbed inner surface of the sections increases readings. After turning on the heating, a standard-sized room will warm up in 10-15 minutes, which saves time and fuel in a country house.

Radiator in the room Source lucheeotoplenie.ru

Due to the design features of bimetallic radiators, heat transfer is lower. The steel core reduces the overall performance by 1/5 of that of an all-aluminum model. The energy carrier in batteries made of two metals does not provide instant heating of the room.

For resistance to water hammer

Water hammer is a physical phenomenon in which the pressure in a particular area increases sharply. When water moves in the heating pipes, obstacles appear, which leads to an abrupt stop. Under the influence of the pumping force, the pressure inside the system increases. The liquid rushes to areas with less resistance, and this leads to damage (bursts) of utility networks.

Device in the room Source trubamaster.ru

Aluminum radiators are resistant to water hammer within 6-16 atmospheres. If there are sudden surges in the heating system, the batteries will burst, and boiling water will begin to flood the apartment and neighbors. Craftsmen do not recommend using such models in old panel houses.

Bimetallic structures have a strong steel core inside. The material is resistant to high pressure, so it will withstand water hammer within 20-40 atmospheres. Radiators are reliable and safe for use in old and new high-rise buildings.

Corrosion resistance

The water in the city heating system consists of many chemical additives that improve thermal conductivity. The components are safe for outdated cast iron models, but negative consequences are possible in modern ones. Impurities are deposited on the walls of the batteries, which leads to corrosion.

Aluminum radiators can withstand pH levels up to 8 units. In old multi-story buildings, the indicator in the pipes is in the range of 10-12. As the parameters increase, destructive reactions begin at the connecting points, which lead to depressurization.

Heating system design Source ukrxoztorg.com.ua

Bimetallic radiators are less demanding on the pH level of water than aluminum types. Due to the design, only the core comes into contact with moisture. Steel has low activity in relation to the chemical structure of the liquid in the heating system. In high-quality models, manufacturers additionally protect the inner surface with an anti-corrosion layer.

Relative to temperature

Cast iron radiators operated with temperatures within 150 C. Aluminum batteries can withstand hot water up to 110 C. To prevent this problem, a built-in thermostat is often installed in the design to regulate modes. The maximum value for bimetallic species is 130 C.

For ease of installation

Due to their low weight, both varieties have basic installation. During installation, massive brackets are not used, as for cast iron models. The equipment can be mounted on a plasterboard partition without fear of destruction or subsidence.

Aluminum structures can crack or become deformed if installation instructions are not followed. Alloy options are more resistant to mechanical influence. To prevent devices from malfunctioning, installation should be entrusted to specialists.

By service life

The durability of the equipment depends on the type of construction. Bimetallic radiators, subject to installation rules and regular maintenance, will last at least 25 years. The most expensive aluminum models will last within 10-15 years under the same conditions.

By price

Bimetallic radiators contain steel, so the finished product is 20-30% more expensive than aluminum structures. Often the price tag of a branded one-component model is lower than that of a “nameless” bimetal structure. The difference in price appears due to the high cost of operation.

Specifications

Aluminum heating radiators have technical characteristics that allow complex heating of rooms, transferring one half of the heat by radiation from the battery panel, and the second by convection air flows.

One section of such radiators has the following indicators:

- depth – 70-110 millimeters;

- panel area – 0.5 m²;

- coolant capacity inside the battery – 0.4-0.6 liters;

- thermal power – 120 W;

- weight – maximum 2 kilograms;

- coolant temperature – 90 degrees.

Pros and cons of radiators

The experience of professionals suggests that there is no universal heating equipment. When choosing batteries, users pay attention to design and price, but exclude technical features. Before you distinguish an aluminum radiator from a bimetallic one, you need to understand the pros and cons of both types.

Aluminum

Batteries are made from an alloy of metal and silicon. Silumin retains the positive characteristics of aluminum, while increasing resistance to adverse conditions. The advantages of the equipment include:

- High heat transfer coefficient. After turning on the heating, aluminum radiators will warm up the room in a few minutes. The devices are very hot to the touch, so they are often hidden under protective screens to prevent accidental burns.

- Compactness. The dimensions and weight of the battery are much smaller than those of cast iron. When installed correctly, the structure does not protrude beyond the window sill.

- Affordable price. The equipment has low cost.

- Changing the number of sections. In cast models, elements can be added or removed.

- Temperature regulation. The user independently adjusts the comfortable parameters for the room.

- Stylish design. The elegant design will fit into the interior of any room.

The models are very dependent on water quality. Hydrogen accumulates in aluminum radiators. If gas is not periodically removed from the heating system, an explosion is possible. Special air vents break down quickly, so you need to regularly monitor the condition of the filters. If the pH level in the liquid becomes within 8 units, then there is a risk of corrosion. Rust corrodes the joints, which manifests itself in the form of leaks.

Warm compact design Source vchaspik.ua

Installation of aluminum batteries should be carried out by professionals. At the slightest violation of installation rules, radiators become deformed and fail. When connecting to pipes made of another metal, a corrosive reaction is possible, so similar or plastic types are used.

Bimetallic

Steel and aluminum are used in the production of heating equipment. The upper body provides thermal conductivity, the internal parts are responsible for resistance to destructive reactions and water hammer. The positive aspects of bimetallic radiators include:

- Long service life. Due to the internal steel pipe, the device does not lose its original characteristics for 25 years.

- High maximum temperature. Bimetal can withstand 130 C (aluminum - 110).

- Resistant to pressure surges. It does not collapse under water hammer up to 40 atmospheres, although in the heating system of a high-rise building the indicator does not rise above 20.

- High quality coverage. Models are painted in 2 stages (paint, polymer epoxy), which increases the tightness and decorativeness of the structure. A boring color can be repainted.

- Use in damp areas. The external sheet covering protects the equipment from corrosion.

- Easy installation. Sections can be extended on site.

A reliable bimetallic battery is not destroyed by the chemical composition of water in the pipes. The weak point of the radiator is simultaneous contact with liquid and air, which provokes corrosion on the steel surface. The danger arises when draining moisture at the end of the heating season or when the system in the dacha is standing still.

The bimetallic model has a smaller pipe cross-section than the aluminum one. Due to the complex design, the internal usable area is reduced. Small particles from the heating line under the influence of high temperature clog the narrow opening.

Model in the interior of a room Source santreyd.ru

Steel and aluminum have different thermal expansion coefficients. Due to the mismatch in the system, loud crackling sounds occur. Bimetallic radiators have good heat transfer. When the heat is turned on, the room heats up quickly and evenly. Due to the complex manufacturing technology, the price of the models is much higher than that of aluminum types of the same size.

Baseboard heating

This type of heating devices appeared in our country not so long ago. These are devices very similar to copper-aluminum radiators: the same copper tube on which copper or aluminum convective plates are placed. They just have a different connection method, layout and different dimensions. Heating elements can be inserted into heating modules (tubes with plates) or they can be assembled into closed circuits through which the coolant circulates. They are located along the floor along the perimeter of the walls, covered with metal decorative overlays. The width is about 3 cm, the height is 12-20 cm, depending on the power. Exactly low radiators.

This is what baseboard heating looks like. No more other heating devices

Advantages, disadvantages

The advantage is that most of the heat (70-80%) is transferred by thermal radiation. The heat rising from warm baseboards heats up the walls first. They then begin to radiate heat. Therefore, a more uniform temperature is observed in the room, and warm air does not accumulate at the top.

Another plus is its very compact size and quite high heat output: one meter produces 180-280 W at average temperatures. In addition, they are not conspicuous and provide wide scope for design solutions.

The only downside is the high price.

Which to choose

Despite the apparent similarities, both types of batteries have different characteristics. Some are suitable for high-rise buildings, others for country buildings with individual heating. When choosing aluminum or bimetallic radiators, you need to understand what is best for an apartment and what is best for a private house.

To the apartment

Multi-storey buildings are connected to central heating. The pressure in the pipes can change dramatically, ranging from minimum to maximum values. Instability leads to water hammer, which not all metals can withstand.

The water temperature in the system changes dramatically throughout the day or the entire heating season. The chemical structure of the coolant in a high-rise is not ideal. The liquid contains reagents, abrasive substances, and the pH level is higher than the maximum norm (8 units). Components accumulate on the internal walls of equipment, which leads to depressurization and ruptures.

Option for apartments Source djoul.ua

When choosing aluminum or bimetallic radiators, you need to know which model made of two metals is better for an apartment. The structure with a steel core will withstand high pressure testing and operating pressure, avoiding accidents. To minimize the aggressiveness of the chemical composition of water, you need to choose devices with stainless steel coating of internal parts.

Bimetallic sectional models are recommended for installation in apartments of new high-rise buildings. The devices, which are undemanding to the quality of the coolant, are easy to install. For old buildings, preference is given to monolithic options. Due to the reinforced design, the batteries will withstand the maximum load and will not burst from a powerful water hammer. The heating equipment is protected from leaks by a solid steel core.

Convenient bimetal model Source skspec24.ru

To a country house

Understanding the difference between an aluminum radiator and a bimetallic radiator, it is easy to choose a solution for a cottage. In a suburban building there is an individual heating system (boiler), which provides constant pressure. The readings in the pipes do not exceed 10 atmospheres, so there are no sudden changes or water hammer.

Aluminum model for a cottage Source rapidly.ru

Positive properties of aluminum batteries

Aluminum radiators are light and durable, easy to transport and install. In addition, they also have a number of important advantages:

- small sizes (shorter in width compared to cast iron);

- very high level of heat transfer;

- operating pressure corresponding to the needs of modern heating systems;

- you can select a product with a certain number of sections according to the heated area;

- good heat transfer, which means efficiency;

- the ability to adjust the temperature using built-in thermostats;

- excellent aesthetic appearance.

The advantages of aluminum radiators over bimetallic ones are their lower price, which is very important for the consumer.

How to distinguish

Externally, both types of batteries are very similar, so problems arise when choosing. Knowing how to visually distinguish an aluminum radiator from a bimetallic one, you can independently choose the appropriate model for your home or apartment. There are signs that allow you to quickly determine the type of equipment you need.

Section options Source otoplenie-expert.com

Pure aluminum batteries are lighter in weight than bimetal structures. Sections of the same size and shape will vary in weight. The steel core is 0.5 kg heavier than one-piece models.

How to choose a design Source yandex.ua

In order not to confuse structures made of different materials, professionals recommend inspecting the threads. In a bimetallic radiator, in areas where water passes through, the integrity of the structure is noticeable. A silvery layer of aluminum is visible on the gray surface of the steel pipe. There is a color transition between the two metals.

Understanding how to distinguish an aluminum radiator from a bimetallic one visually, you can determine the desired model by ear. If you knock on steel, the sound will be loud. The one-piece design produces a dull tone. The check is carried out with a wooden pencil, nail or plastic pen.

How not to make a mistake with the view Source pirco.ru

A magnet will help you find out the type of material. The internal steel filling attracts the device, but aluminum has no attraction. The device is brought closer to the center of the structure, where the metal pipe is located.

Comparison by other functions

Modern heater models are equipped with additional functions. Both radiators and convectors have them:

- electronic control system;

- various operating modes;

- built-in ionizer;

- humidifier.

An oil heater has something that a convector does not - quick drying of clothes and shoes. For an electric convector, there is an attachment for drying; it performs its function, but takes much longer.

Convector vs oil heater | Which heater to choose for your home?

Product packaging

To make the right choice of aluminum radiators, you need to monitor the product package.

Standard kit includes:

- left-hand and right-hand plugs;

- Mayevsky valve (is a valve for bleeding air from the heating system);

- brackets;

- racks;

- gaskets for sealing;

- Ball Valves.

The connection of aluminum radiators should only be carried out by specialists who have permission for such activities. It is strictly not recommended to do this work on your own. As for installing batteries, this must be done in accordance with the technical instructions supplied with the products.

Prices: summary table

| Model | Heat transfer per section, Vit | Working pressure, atm | Breaking pressure, atm | Average price per section | Price for 1,000 W of power |

| Royal Thermo Biliner Alum 500 | 175 | 16 | 48 | 760 | 4 300 |

| Royal Thermo Revolution 500 | 170 | 20 | 50 | 850 | 5 000 |

| Global VOX R 500 | Up to 276 | 16 | 48 | 720 | 5 000 |

| Rifar Alum 500 | 186 | 15 | 50 | 750 | 4 000 |

| Radena 500 | 195 | 15 | 40 | 960 | 4 900 |

| ROMMER Al Optima 500 | 133 | 12 | 24 | 388 | 3 000 |

| Mandarino 500 | 210 | 15 | 25 | 1600 | 7 000 |

When choosing aluminum radiators, we primarily focus on technical characteristics and operating conditions. The right choice will allow you to avoid troubles in the form of structural destruction and flooding of premises, which can result in high repair costs.

Calculation of the number of sections

To effectively heat a particular room, a certain number of battery sections will be required. If there are not enough of them, the system will not be able to warm up the home in winter. To correctly calculate the quantity, there are special formulas.

The first option is by area. This method is used if the ceiling height in the room is standard, not higher than 2.6 m.

The formula looks like this: N = S × 100/Q, where:

- S is the area of the room;

- Q is the thermal power parameter of section 1;

- N is the required number of sections.

It is recommended to round up, with a margin.

The second option is a calculation for a room with a non-standard ceiling height, by volume. Based on the recommendations of SNiP, heating 1 m3 of area requires 41 W of equipment power. The formula is: N = V × 41/Q. The letter “V” indicates the volume of the room.

Even if the calculations were made incorrectly, you should not be upset. Aluminum batteries can be expanded, that is, additional sections can be added to them. To do this, you will need a special key for radiators, and the blocks themselves are connected using steel nipples.

Manufacturers of steel appliances

On the heating equipment market, steel radiators are represented by models from many manufacturers, but the manufacturing technology practically does not differ, and the cost may differ slightly.

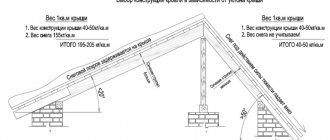

Steel tubular radiators are assembled from stamped sections welded together by spot welding

The price of a product is determined by its size, brand, design. It is often possible to purchase a high-quality domestic device that is not inferior in its characteristics to a world-famous brand.

Among the domestic companies whose products are in stable demand in our market are the following:

- Lidea;

- Prado;

- Conrad.

Lideya devices are manufactured in Belarus. They are equipped with 1-2-3 panels, the volume of coolant in which is in the range of 0.9-6.55 liters and depends on the size. Radiator power with one panel is 2.1 kW, with two panels – 3.9 kW, with three panels – 5.6 kW. Steel thickness 1.2 mm, operating pressure 8.9 bar.

Prado heating equipment is manufactured in Izhevsk. It is equipped with 1-2 panels, the volume of coolant varies between 0.8-5.7 liters. As for power, a radiator with one panel has 1.4 kW, with two panels it has 2.3 kW. Steel thickness 1.4 mm, operating pressure 8.8 bar.

Conrad batteries are manufactured in St. Petersburg. They are equipped with 1-2 panels, the volume of coolant in which is 0.85-5.2 liters and depends on the size. The power of the device with one panel is 1.35 kW, with two panels – 2.3 kW. Steel thickness 1.4 mm, working pressure 10 bar.

Among European manufacturers of tubular steel batteries, German and Italian companies have proven themselves well: Charleston , Kermi , Arbonia , Israp Tesi .

Also the most popular are panel heating radiators made in Germany by Kermi and Buderu s, and by the Finnish company PURMO . Almost in no way inferior to them in quality and popularity are Delonghi from Italy, as well as Korado of Czech origin.

Models of panel and tubular radiators made in Europe have different dimensions and power. Technical characteristics are presented in the passport of each model.

A well-known brand will cost an order of magnitude more than equipment from less popular companies. But purchasing a branded device guarantees the purchase of a device of appropriate European quality

Steel radiators are among the most popular heating devices. Due to their presentable appearance, affordable price and high heat output, they are widely used in offices, houses and apartments. The maximum service life of steel radiators is achieved in autonomous heating systems.