Why do you need to prime the floor?

Concrete pavement is the most common type of floor surface. This popularity is explained by a large number of advantages, but it is also important to take into account the disadvantages of concrete. It does not have waterproofing properties, so its porous structure quickly absorbs moisture, under the influence of which deformation processes begin to develop.

The expected effect of a self-leveling floor may never occur, because failure to use a primer can lead to the formation of fungi, unpleasant odors, and mold. If a large amount of water forms, the self-leveling floor may rise, which will lead to the need for repeated repairs.

To avoid undesirable consequences, it is better to do everything correctly from the beginning and prime the rough base before you start pouring the self-leveling floor.

Leveling the surface

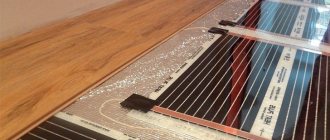

The most important quality of the floor before decking is its evenness. Just a flat surface will not fit under the laminate; it must be perfectly flat. If the floor cannot be leveled, you will either have to pour a new one, or use the so-called liquid floor or self-leveling mixture. The quality of the flooring depends on the evenness of the surface.

When the floor is ready, you need to determine exactly where the cables and wiring will go under the laminate. This is a very important stage.

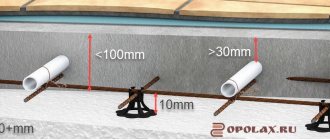

Concrete preparation is one of the types of floor leveling. This method consists of three key elements: screed, bentonite and plywood.

- First, you need to apply a concrete screed to the surface. It will fill and eliminate possible large irregularities.

- The next step is to apply a layer of bentonite or other self-leveling mixture. If this process is ignored, the floor will collapse very quickly.

- Plywood is laid over the concrete. When choosing, you need to choose a moisture-resistant material, because it is the most durable.

- Now all that remains is to choose a substrate and lay the laminate. However, we must remember that the concrete screed requires curing for about a month (minimum 28 days).

Raised floors have an advantage over concrete leveling. The main advantage is saving time. Such floorings do not require waiting or curing time. Another plus is efficiency. Concrete or other self-leveling material is quite expensive. Logs or plywood will cost much less.

The procedure for laying a raised floor is not very complicated:

- First, a structure is installed, into which logs or plywood must then be laid. This design has special holes with bolts that adjust its height. Installation is carried out using dowels.

- When the structure is ready, the bars can be laid. If the floor is still not very level, this can be corrected using the rack bolts. You just need to tighten them up and you can achieve the required quality of the floor.

There will always be space between the subfloor and the raised floor in which various cables and electrical wiring can be routed. This will solve a lot of problems. Such structures can be easily disassembled and reassembled. The adjustable height of the floor allows even water pipes to be hidden underneath.

Today, raised floor modules can be purchased ready-made. You just need to select the required dimensions and install the structure. If any element is damaged, it can be easily replaced. This is a very practical choice that is suitable not only for apartments, but also for offices, and even industrial premises.

Is it possible to pour a self-leveling floor without a primer, possible consequences

Theoretically speaking, the process of forming a self-leveling floor can occur without prior priming. But if we consider this possibility from a practical point of view, all masters agree that soil is a must. It guarantees long-term use of the surface. Otherwise, the new floor may not last even a year, as various defects will begin to form on its surface.

Application of a primer provides:

- high level of adhesion of the screed to the base;

- dust removal;

- reducing the absorbency of the base, in other words, the base of the floor will not quickly absorb moisture from the screed, thereby allowing enough time for complete drying;

- antifungal properties;

Combination with floor coverings

Each person has their own taste preferences. During renovations, many people quite actively use tiles, which can be used to decorate a wide variety of surfaces without any problems. In this case, you need to figure out whether it is necessary to prime the floor before laying the tiles and how to act in this situation. In this case, soil mixtures are applied to significantly improve the adhesion between the cladding and the base. Of course, you can lay tiles on cement mortar the old fashioned way, but practice shows that the corresponding method is clearly inferior in many respects to modern soil mixtures.

Quite common floor coverings today are linoleum and laminate. In this case, it is also impossible to do without preliminary preparation of the foundation. It is not enough to know whether it is necessary to prime the floor before laying linoleum, because you still need to approach the corresponding process correctly. Linoleum is known to have an attractive appearance and low cost compared to other coating options. Thanks to pre-priming, the corresponding material will also experience a significant improvement in its own technical parameters.

When to use a deep penetration primer

This type of primer is used during the process of pouring the floor, in rooms with high levels of humidity and frequent changes in temperature conditions. Such premises include baths, saunas, and swimming pools. Since the floor here is in constant contact with water, standard soil for a domestic space is not enough; it is the deep penetration effect that is important. Application of the composition makes it possible to clog the wide pores of concrete, thereby creating an additional protective layer responsible for the safety of the coating.

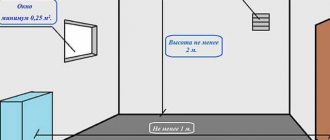

Base requirements

There are a number of requirements that apply to all types of bases for this floor covering. These include:

- Evenness. The maximum permissible difference in height is 2 mm per 2 linear meters of surface length.

- Purity. Fine sand and dirt particles remaining under the laminate create an unpleasant squeaking sound when moving on it.

- Uniform slope. This parameter should not exceed 4 mm per 2 m2 of room.

- Dryness. Any substrate must be allowed to dry thoroughly before applying primer. Otherwise, this may lead to swelling of the coating.

Primer selection criteria

In order to correctly select the optimal type of primer, you need to carefully analyze the selection criteria:

- Type of base – concrete, cement screed, tile, wood. For each of these coatings, there are different types of primers, characterized by special compositions. Particular attention should be paid to the last two bases, as they have a weak level of adhesion and strength.

- Room type. For office and domestic premises with a normal microclimate, it is optimal to give preference to concrete contact, but for premises characterized by a high degree of humidity, it is worth purchasing deep penetration soil.

- Price. The choice based on this criterion is quite subjective, but you should not focus on options that are too cheap; they may be of dubious quality.

- Easy to use and easy to apply. This criterion is especially important for those who will independently carry out the priming process without experience or skills in this type of activity.

Main tasks to be solved

When arranging a covering, a primer for floor screed can solve a number of problems. Some of them are important for the quality arrangement of the connected foundation. Others guarantee that the surface of the substrate will not swell. The average list of application purposes looks like this:

- The main task that a floor primer solves under a screed is to bind the surface and create a structure of uniform absorption. Under such conditions, mortars can penetrate into the surface of the base, forming a reliable bond for the transmission of mechanical loads;

- primer under floor screed can have a strengthening effect. Treatment with such a composition is extremely useful if a new coating is laid on an existing concrete base in which destruction processes have begun;

- Screed on wood, plywood or other hydrosensitive material requires treating the base with primers with water-repellent properties. They form a thin protective film on the surface. In this case, there is no danger that cracks will appear in the concrete screed due to swelling of the base.

The rarest problem solved by priming the floor before a bonded screed is to enhance adhesion. It is needed when the solution is laid on a solid, smooth base. In this case, using special primers, a rough surface is obtained that ensures good adhesion.

Adhesion enhancing primers belong to a special class of surface treatment products. Technologically, they are an adhesive with a high content of large particles. In expensive compositions, this is quartz sand, which has a complex shape of elements, which significantly increases the surface roughness after drying and the degree of adhesion of solutions applied to it.

What primers are used?

Today, the building materials market offers a wide range of primers for self-leveling floors. All of them are presented by different manufacturers, have different composition and cost.

Among the most popular types of soils are:

biocidal – has a high degree of penetration, long service life, and is also characterized by antifungal properties;

polyurethane - has economical consumption, but the cost of such a substance is slightly higher than its analogues. Among the main advantages are protection against the formation of oily stains and excellent adhesion to the tiled surface.

silicone – has the highest degree of water repellency. When applied to the base, it quickly penetrates deep inside, displacing existing moisture. After it dries, all pores are reliably protected from re-entry of moisture.

concrete contact – has increased adhesion and a crystallizing effect. Can be used for rooms with normal microclimate, does not have a high level of protection against humidity.

hydrophobic - demonstrates high adhesion, but its contact with alkali is not desirable, as this may lead to the need to update the layer.

Security measures

When working with any primer mixture, we must not forget that it is a chemical product. Experts strongly recommend using thick gloves when working with such compounds. Try to avoid getting the solution on exposed skin. Sometimes craftsmen don’t get by with ordinary gloves - they specially purchase painting overalls. Some people find them inconvenient, but in terms of security this flaw is not so important.

Do not forget that many types of primers are quite difficult to wash off from different surfaces. If you accidentally get your hands dirty with these compounds, they will remain dirty for several days. Polystyrene primer compounds are rightfully recognized as the most toxic and hazardous to health. You need to work with them especially carefully and prudently. Under no circumstances should you finish the floor with this mixture in a completely enclosed room. Experts recommend wearing special masks and the highest possible gloves when working with polystyrene primers.

To learn how to prime a floor, watch the following video.

Primer technology

Regardless of the type of primer mixture chosen, the technology for its application is carried out in accordance with the following steps:

- Consideration of the characteristics of the base . Carrying out an inspection allows you to choose the optimal soil composition, taking into account the base material, as well as the type of self-leveling floor. In some situations, it is possible to use two types of soil on one base.

- Preparing the base . Before applying the mixture, the floor surface must first be cleaned, leveled, sanded, and all visible defects must be eliminated.

- Application of primer . The application process occurs using a roller, brush, or a special spray apparatus.

- Applying the second layer . During the drying process, you should pay attention to the uniformity of this process. If there are areas where drying occurs faster, then a recoat may be necessary.

Recent Entries

A primer is a specific liquid material that is designed to significantly improve the adhesion of various coatings. It is easy to understand whether the floor needs to be primed, because after the appropriate procedure, you can lay various coatings with confidence in the durability. In addition to its main function, the primer can slow down the process of water absorption. As a result, the screed will maintain its uniformity for as long as possible, and will also reduce the likelihood of its subsequent cracking.

Laying on a wooden base

Before laying laminate flooring on an old wooden base, you need to make sure that the boards have not rotted and are suitable for further use. Otherwise, they need to be replaced. Small unevenness can be smoothed out by scraping, but a significant difference in level can only be corrected by laying OSB boards or similar materials. They are fastened to the floor with self-tapping screws, the heads of which are recessed into the coating by 2-3 mm.

Deflection of boards when subjected to mechanical impact is unacceptable and must be eliminated. The reason may be incorrect spacing between the joists, which can be corrected by increasing the thickness of the boards. Another solution to the problem could be to lay another layer of material perpendicular to the existing one, and secure a sheet of plywood on top.

The creaking of a wooden floor will be heard even after installing laminate flooring on it. Therefore, this defect must be eliminated.

The next preparatory step will be applying a primer.

Types of protective coating for wood flooring

To treat wooden surfaces, a universal acrylic mixture can be used, as well as specialized solutions, which include:

- alkyd mixture,

- polystyrene primer, which must be used very carefully and only in a well-ventilated area, since it contains toxic substances,

- shellac mixture - intended only for fresh coniferous wood. It prevents resin from reaching the surface of the material.

After treatment with a primer, the floor surface is lined with a substrate and covered with laminate elements so that they are directed perpendicular to the boards.

Laying on a concrete base

In the case when the concrete was carefully leveled when pouring, and the mixture included fine crushed stone, minor unevenness and differences can be corrected by applying a self-leveling mixture. This procedure is carried out in several stages:

- Treating small cracks with tile adhesive.

- Coating the surface with a deep penetration primer.

- Diluting the finished mixture according to the instructions to the consistency of homemade sour cream, without lumps and foreign mechanical impurities.

- Pouring the solution. The process must be started from the highest place, and after the mixture is distributed by gravity over the entire surface of the floor, level it with a wide spatula.

- Rolling out air bubbles from the leveling mass using a roller.

This completes the process. Now the solution needs to be allowed to dry for several days, and only then can you begin laying the laminate.

But most often, the concrete base has significant unevenness, bevels, cracks and other flaws, the leveling of which can require a large amount of quite expensive leveling compound. In this case, it is more advisable to make a concrete screed.

Before installing the covering, the floor surface should be treated with a primer. This will strengthen the base and prevent it from crumbling during operation.

Types of protective coating for concrete

Not all types of primers are suitable for treating concrete bases. Therefore, in this case you need to choose the following:

- An acrylic mixture that is universal and suitable for both concrete and wood, plasterboard, and synthetic materials.

- Epoxy mortar is used to protect concrete surfaces. It reliably protects from moisture and is resistant to many chemicals.

If necessary, antiseptic additives must be added to these mixtures to prevent the development of pathogenic and fungal microflora.

After applying one coat of primer, you need to wait 6-8 hours and apply a second coat. This is done so that the surface of the base base is well saturated, and small particles of cement and sand do not lag behind it.

A backing made of foamed polyethylene or cork is laid on the primed surface. It will create additional protection from moisture, provide thermal insulation and reduce the level of noise entering the room. After this, you can begin installing the laminate.