Sheet metal is cut using mechanical and thermal methods. And in the arsenal of craftsmen, an attachment for a drill for cutting metal is increasingly appearing. Each of them has advantages and disadvantages. Some types of equipment are used in factories or private workshops, while others are in demand in home workshops.

Drill attachment for cutting metal - how to choose?

Mechanical cutting methods

The mechanical method is also called cold, since the material is not exposed to high temperatures. The work uses tools whose strength and hardness are higher than those of metal.

- A circular saw. The tool allows you to cut metal at different angles, and with fairly high accuracy. The disadvantage of a circular saw is the shallow cutting depth and large amount of waste.

Circular saw for cutting metal - Hand scissors . This is a simple device that is relatively inexpensive, but requires significant physical effort.

- Grinder or angle grinder. Convenient for cutting reinforcement, thick sheet metal, and other similar products.

Many craftsmen use a grinder for cutting sheet metal. - Machine with band cutter . The machine processes metal at different angles. However, due to the design features, the size of the sheets is extremely limited.

- Guillotine. Such devices are characterized by high productivity. However, they are used only to obtain simple blanks.

Guillotine (locksmith tool) - Hydraulic equipment . This is a new word in metal processing technology. Such equipment provides high cutting accuracy, and the thickness of the workpiece can reach 20 cm or more. Not every master can afford expensive equipment.

Video - Cutting corrugated sheets with a grinder

Popular models and areas of their application

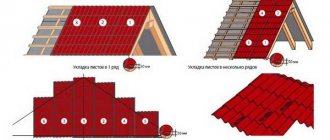

Modern models of drill attachments allow cutting sheet metal not only in a straight line. Using such a convenient and easy-to-use device, you can also make shaped cuts, which is often required when installing roofing structures, ventilation ducts, as well as gutters and other elements of the drainage system.

Using such attachments on a drill, cuts can be made in almost any spatial position. An equally important advantage of these attachments is that they do not require preliminary setup.

This attachment turns the drill into electric scissors that work on the principle of cutting, not carving.

Among the most popular models of drill attachments for cutting metal presented on the domestic market are the following:

- "Cricket" (from);

- Sparky NP 1.8L;

- EDMA NIBBLEX;

- ACCO YT-160A.

Perforated scissors-attachment for electric drill EDMA NIBBLEX for cutting metal and plastic

The differences between models of drill attachments do not lie in the principle of their operation, but in the maximum thickness of the metal being cut and a number of other technical characteristics. Modern models of drill attachments allow you to obtain smooth and neat cuts with sharp, even and uncrimped edges. In this case, the protective coating applied to the surface of the metal sheet is not damaged and fully retains all its functions.

"Cricket"

One of the popular attachments for a drill, which is a compact nibbler (nibbler), is a device called a “Cricket”. This attachment, which allows you to obtain an even and neat cut, can be used for cutting both flat and profile metal sheets.

The “Cricket” scissor attachment is designed to operate from a pneumatic or electric drill (screwdriver) with a power of at least 420 W

Using the Cricket scissor attachment, you can cut not only metal sheets, but thin-sheet products made of polycarbonate and other polymer materials. At the same time, the thickness of the products for cutting which these compact nibblers can be used can be up to:

- 1.5 mm – for steel sheet material;

- 1.2 mm – for stainless steel;

- 2 mm – for copper and aluminum, as well as polymer materials.

Using the “Cricket” drill attachment, you can cut sheet material in horizontal and vertical planes, as well as make internal cuts on the surface of the sheet.

“Cricket” works on the principle of nibbled scissors

It should be borne in mind that in the place of the sheet from where the internal cut will be made, it is necessary to pre-drill a hole.

“Cricket” is a good drill attachment for cutting metal tiles and corrugated sheets. When using this device for cutting metal, the surface of these materials is not deformed, and the cut itself is smooth and neat. The Cricket attachment can easily cope with such complex tasks as artistic cutting and creating large-diameter holes in sheet material.

Thermal methods of metal cutting

Thermal methods, where high temperatures are used as the cutting material, also help to cut metal efficiently:

- gas cutting;

- plasma cutting;

- laser ray.

Plasma and laser installations are progressive equipment.

The latter is the most modern method, which ensures the accuracy and fineness of lines, cleanliness. For these methods, expensive equipment is usually purchased and used mainly on an industrial scale.

Video – Laser cutting of metal

Cutting sheet metal with a steel beaver attachment

Another type of attachment for power tools is also used for cutting sheet metal - this is the Steel Beaver attachment. Many craftsmen call such attachments adapters, but they are not such. After all, this is the final mechanism by which useful work is performed.

The steel beaver also works on the principle of cutting shears, thereby eliminating the occurrence of sparks and overheating of the metal. If the sheet material is processed incorrectly, the manufacturer does not guarantee the quality of the overlap or service life. The Steel Beaver set also includes a replaceable die and a punch. The use of the attachment is recommended in conjunction with a power tool that has the following technical parameters:

- The rotation speed of the chuck must be at least 1500 rpm

- Power not less than 350 W

- Collet

Compared to a grinder, special attachments for drills make it possible to change the cutting angle up to 360 degrees. This is convenient when you need to make a shaped cutout in corrugated sheets or metal tiles. The minimum cutting radius when using attachments is 12 mm. The use of a special device is achieved by high cutting productivity of sheet material.

Why is a drill more convenient than other tools for cutting metal?

A drill is a tool that every craftsman has in his arsenal. However, it is rarely used for cutting metal. But attachments, the variations of which are becoming more and more numerous, allow you to use the tool for these purposes.

Types of drill attachments

The drill has many advantages over the other tools discussed. In particular, this is ease of use, accessibility, and versatility. Models powered by batteries are available. You can work with them when the power grid is unavailable.

Expert opinion: Masalsky A.V.

Editor of the “construction” category on the Stroyday.ru portal. Specialist in engineering systems and drainage.

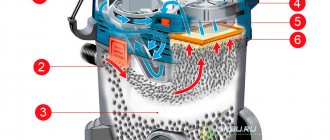

Nozzles are devices that are designed like a punch. Due to the reciprocating movement inside the matrix, the metal rod pierces the sheet. The method is especially convenient when working with materials coated with protective compounds: due to point impact, the top layer is rarely damaged.

The upper cutting part of the nozzle moves up and down, thus cutting the metal and pushing its particles into the slot

The maximum sheet thickness that can be cut with this device depends on the type of metal.

Table 1. Type of metal and average thickness of sheet for cutting.

| Type of metal | Allowable thickness, mm |

| Aluminum | 2 |

| Brass | 1,5 |

| Galvanized metal products | 1,5 |

| Copper sheet | 1,5 |

| Iron | 1,5 |

| Stainless steel | 0,8 |

Reference . More powerful models of the device can cut thicker sheets.

Attachments are used for electric and pneumatic tool models.

What metal can be cut with attachments

There are 2 types of nozzles. Some are designed for cutting certain grades of material (size, thickness), others are universal, they are suitable for processing more than one specific type of metal, which is one of their obvious advantages. These attachments are used to cut the following metals:

- copper;

- brass;

- steel (sheet and stainless);

- aluminum;

- zinc;

- iron.

Popular cutting attachments

Manufacturers have developed many models of attachments. Each model finds its admirer and place of application.

Drills with attachments are increasingly used when cutting metal.

“Steel beaver” (cutting type attachment)

This is a classic nozzle that is used for flat sheets and metal roofing tiles. The unit consists of a shaft that rotates freely in a bearing. The operating principle resembles a crank mechanism. But in this device, energy is spent on rotation.

The ready-to-use steel beaver contains a support section attached to the frame. The moving part makes reciprocating movements during operation. The drill moves relative to the nozzle due to the occurrence of a reactive torque.

Nozzle "Steel beaver"

The “steel beaver” is used mainly for flat products or corrugated sheets with a significant bending radius. This tool allows you to have good control over the cutting line. The protective decorative coating, which is often used to cover metal, does not melt, sparks do not form, and the edge remains without burrs. However, the zinc layer is burned. The cutting line can be as long as the operator requires.

Attention! If there is a need to cut sheets with small diameter bends, it is recommended to use the “Cricket” attachment model.

Table 2. Permissible metal thickness for “steel beaver”.

| Material | Sheet, mm |

| Copper, aluminum | 2,0 |

| Stainless steel | 1,2 |

| Steel | 1,8 |

Structure of the nozzle

The price of the “Steel Beaver” nozzles is from 2100 rubles.

Universal nozzle “Cricket”

The “cricket” operates on the principle of nibblers, and works like a chisel or jigsaw, where the punching rod replaces the file. This makes artistic cutting of metal possible. This device is used for cutting:

- metal tile covering;

- corrugated sheets;

- sheets with profile stamping and stiffening sheets;

- large volumes of smooth steel.

Nozzle “Cricket”

When making a cut, the nozzle does not damage the edges of the metal coated with protection, but rolls it, thanks to which the material is protected from corrosion. Work can be carried out in horizontal and vertical positions.

The advantage of the “cricket” is its high productivity - 1 m/min. Although the grinder works faster, it damages the protective and decorative coating that is used for metal tiles.

Using a drill with such an accessory, you can even cut sheets with complex terrain, since it is convenient to move the cutter in the desired direction. Craftsmen also pay attention to the device due to its low cost. Thus, a domestic “cricket” costs several times less than professional electric nibblers.

The tool also has a drawback. Even with mastery of a drill with an attachment, it is difficult to achieve an even cut. However, this is not critical. The fact is that usually the seams are covered with special shaped parts.

Instructions for using the Cricket attachment

Cutting is carried out in two ways:

- following the surface topography, going around the edges - for the average bending radius;

- when processing metal tiles - along the stiffeners.

Video - This is how Cricket works

The disadvantage of this tool is that quite a lot of waste is generated when cutting.

Advice! Experienced craftsmen do not recommend wearing soft shoes when working with a drill.

Delivery set “Cricket” - from 1800 rubles. According to user reviews, one of the most popular attachments of the “Cricket” type is produced by. Model 14210 produces a thin cut with a width of only 1.6 mm, which saves metal. The kit includes an additional handle. Thanks to its design, the accuracy of work is increased.

Edma Nibblex

This cricket-type attachment is produced by the French company Edma. The tool is used for the following operations:

- straight and curly cuts, including short ones;

- long straight cuts;

- marginal notch;

- working with metal tiles.

Variety of "Cricket" Edma Nibblex

Table 3. Material thickness.

| Type of material | Maximum thickness, mm |

| Steel | From 0.8 to 1.2 |

| Aluminum, vinyl, polyvinyl chloride | 1,5 |

| Polycarbonate | 2,5 |

| Cutting width | 3,1 |

The cost of Edma Nibblex is 7,200 rubles.

TurboShear HD

This attachment works on the principle of scissors. A telescopic mount is installed on it, which makes the device compatible with many models of drills and screwdrivers. With a screwdriver, the nozzle gains greater maneuverability - it can be rotated to any degree and installed in any position, which simplifies the operator’s work. The cost of the set is 12,700 rubles.

Scissors TurboShear HD

Attention! When choosing an attachment, you must take into account the power requirements of the drill.

The nuances of using “cricket”

The choice of “cricket” is determined by a lot of advantages:

- A neat cut. Unlike a grinder, the drill attachment will not leave burrs on the metal surface and will not damage the polymer coating of the material with sparks.

- Lightness of the tool. There is no need to put in a lot of force.

- Compatible with drill and screwdriver. There is no need to purchase extra tools.

- Price. Much cheaper than special equipment for cutting rolled metal, and also saves money on the purchase of consumables such as trimming discs for an angle grinder.

- Easy to use. It is easy to install on the cartridge and also easy to remove.

- Performance. Using a “cricket” you can cut material quite quickly.

- Convenience. Thanks to its shape, it allows you to hold the tool at any angle.

- Ability to cut holes and sections of any shape.

- Versatility. Suitable not only for flat metal sheets, but also for profiled ones.

And yet, certain nuances of working with the nozzle exist. The tool must be held with both hands. That is, the material being cut must either be securely fastened, or the master must work with an assistant.

Like any instrument it requires skill. If you are using it for the first time, it is better to practice first. For the attachment to work effectively, the rotation speed of the drill should be 1500–3000 rpm. But when buying a “cricket”, you still need to clarify its characteristics and requirements - for some, the minimum rotation speed of the cartridge is 2700 rpm.

The “steel beaver” is similar in design and operating principle to the “cricket”. It also does a good job of cutting sheet metal. Curvilinear cuts are made with a minimum radius of up to 12 mm. The difference is that the metal can be thicker - stainless steel up to 1.2 mm.

You also need to take into account that when working with these nozzles, a lot of metal shavings are formed.

Step-by-step instructions: an angle grinder made from a drill, a bolt and a cutting disc

You can make an attachment for a drill for cutting metal yourself from available materials, if you don’t have at least an angle grinder. To do this you will need:

- cutting disc for grinder;

- bolt 100-120 mm long;

- two nuts of the corresponding diameter;

- two metal washers;

- one plastic washer.

Cutting attachment for a drill from a grinder disk.

Assemble the device in the following sequence.

- A plastic washer is inserted into the hole of the disk.

- The head is cut off from the bolt.

- Makers put it on the bolt in the following sequence: nut, metal washer, disk, washer, nut.

- Insert the bolt with the disk into the drill and press firmly.

Drill attachment made from a grinder disc

Attention! When working with handicraft tools, special care should be taken. Therefore, to protect against injury, be sure to wear personal protective equipment.

Safety precautions

Regardless of the brand of drill and attachment, their price and characteristics, it is very important to follow safety precautions.

Drill Safe Practices

This will prevent injury and damage to the material.

- When working with a drill, you need to wear safety glasses and gloves.

- Before starting work, it is important to check the attachment of the nozzle.

- Be sure to check whether the material to be cut is well secured.

- The drill must be held with both hands using special holders.

- When working with a metal cutting attachment, constantly remove falling chips. For example, when installing a roof, a large amount of chips can damage the surface of the metal tile.

- After completing the work, do not touch the treated metal with your hands for some time and remove the attachments, as they may heat up due to friction.

So, when we cut metal sheets up to 2 mm thick, for example, when installing metal tiles or a fence made of corrugated sheets, and the amount of work is small or one-time, then it makes sense to turn your attention to drill attachments.

Master Class. How to make a lathe from a drill

You might be surprised, but a drill can also be used to create a simple lathe. All structural elements are made by hand (with the exception of screws and bearings). There is nothing superfluous - only the most necessary!

Step 1. The first thing you need to do is prepare everything you need for the job.

What you need for a lathe

Step 2. Next, you need to decide what the dimensions of the tabletop will be. It is not necessary to take the sizes given in the example - you can have your own.

Tabletop dimensions

On a note! The dimensions of the tabletop depend on the dimensions of the drill and the dimensions of the workpieces to be processed.

Step 3. After this, the center of the drill is determined. It is placed on the tabletop, then the distance from it (the tabletop) to the center of the chuck is measured. Take a square piece of wood and make a hole in it for the neck of the drill. The center of this hole will be the previously measured distance. This will ensure the drill stays level.

Hole for drill neck

Step 4. All excess is cut off, after which the mount must be put aside for a while.

Excess is cut off

Step 5. We begin assembling two corner pieces, which are a pair of rectangular pieces of wood glued together.

Assembly of corner parts

Corner parts

The smaller part (headstock) will hold the rotating workpiece from the opposite side, and the larger one is the bed, the tool itself will rest on it. It is important that the height of the headstock is approximately 1.5 times greater.

Then guides are created on both workpieces - holes are drilled along the line, which are then connected at an angle.

The holes are connected at an angle

Grandmother and bed

Step 6. 3 important elements are ready. If you want, spray paint them.

Three important details

Step 7. A hole for the bearing is drilled in the headstock (it should not be through). A bolt is inserted into the bearing itself and tightened with a nut. Glue is applied to the seat, then the bearing is installed (it should be with the nut facing out).

First a small hole is drilled

Seat

Applying glue

The bolt is inserted with the nut facing outwards

Step 8. The rail guides are attached to the tabletop. Holes (3 pieces) are drilled for long bolts, the mount for the drill is fixed with self-tapping screws. You also need to install a small wooden rectangle under the handle of the drill. All parts are screwed on.

Slat guides

Drill mount

Rectangle for drill handle

Step 9. The drill itself is fixed with self-tapping screws - it should “sit” rigidly.

Drill inserted

Fixation with self-tapping screws

Step 10. The design is almost ready, all that remains is to make a clamp to hold the workpiece. For this purpose, a round piece is cut out, self-tapping screws are inserted into it, as well as a bolt and nut.

A round piece is being cut out

Self-tapping screws are screwed into it

Ready-made retainer

Step 11. The finished part is mounted in the chuck.

Fastening the latch in the chuck

Lathe testing

Video - How to make a lathe

How to cut profiled sheet material with a nozzle

To connect the attachment to a power tool, the design of the attachment has special protrusions - shanks. Typically, shanks are hexagonal in shape and are clamped into the collet chuck of the power tool. After securing the shank in the power tool chuck, you can begin to work. When performing work, it is important to follow these recommendations:

- If the work is being carried out for the first time, it is recommended to first practice on the remains of sheet materials

- Work is carried out by holding the tool with both hands. This is necessary not only to comply with safety regulations, but also to ensure that the cut is smooth and neat. If you perform work while holding only a drill or screwdriver, the attachment will vibrate strongly, and therefore you will not be able to get an even cut. The exception is Turboshear brand consoles

- It is better to carry out work below (not on the roof) from a safety point of view, although in exceptional cases it is possible to use tools above

- To get the highest quality cut, you need to carry out the work with an assistant. One person holds the sheet to be cut, and the second does the actual work of cutting the material.

- Before starting work, you need to use a marker or pencil to make markings along which to cut thin-sheet material.

In order for the cuts to be neat, even and without defects, you need to learn how to use the tool correctly. This will take practice.

To summarize, it should be noted that buying an attachment for cutting sheet material is recommended for specialists who deal with roofing houses and other buildings using steel sheet material. If you plan to cover a shed or other outbuilding yourself, then using a drill attachment for cutting metal, you will be able to complete the work with high precision and accuracy.

Reviews from craftsmen: do you need a drill attachment for cutting metal?

Do craftsmen think that drill attachments are better than other tools? Not all those who have used the tool agree with this statement.

Pavel Cherepnin: “Drills with such accessories cut very slowly. Everyone is afraid of the Bulgarian. I recommend this particular tool. Ten years ago I covered the roof with metal tiles. Nothing has rusted!”

Dmitry Isakovich: “In stores there are special blades for circular saws. The speed of working with such equipment increases significantly. This kind of drill is only suitable for shape cutting.”

Khariton Morozov: “Japanese attachments like the cricket are the most productive. There, the cutting pin is cast from durable steel, and cuts quite decently.”

Dmitry Ivanov: “Only hacks use a grinder for cutting! Such attachments give a better quality cut. It takes longer, but the metal lasts as long as the manufacturer has measured for it.”

Advantages and disadvantages of use

The attachment can be easily placed on the chuck and removed after use. In addition, the user discovers other advantages of using the equipment, including:

- evenness of the cut;

- absence of burrs on the workpiece;

- work comfort;

- ease of use and installation;

- no need for additional adjustment;

- increase in productivity;

- compatibility of known attachments with an electric or pneumatic drill;

- ease of maintenance;

- possibility of cutting holes.

Attachments for cutting sheet metal, aluminum, and steel have only two drawbacks. The first is that you need to get used to them. Over time, even a beginner in the construction and repair business will master a simple device and learn how to work with it effectively.

The second disadvantage is the need to work with two hands. This complicates the work, for example, when installing a roof, if drill attachments are used specifically for cutting metal tiles.

If you carefully read the installation instructions for metal tiles, you will find a note stating that cutting them with a grinder is strictly prohibited. If the user does so, the product warranty will be void.

This is due to the fact that the top layer of the roof covering is protected on top by a polymer that is not resistant to high temperatures.

A working grinder inevitably heats up, so the polymer layer melts at the cut points, and then the zinc coating. Moreover, sparks flying in different directions will increase the area of damage. The result is disappointing - deformation of the thin sheet metal, the possibility of rust. Therefore, for sensitive materials it is better to look for a nozzle.

Metal crowns

In addition to the main attachments, there are other devices, for example, a metal crown. This is a special drill designed for making wide holes . Its use is due to the need to lay communications. The downside of a metal crown is its roughness: the edges of the hole made require additional processing. It is in such cases that the cutter comes into play.

A set of crowns can include both simple edges and diamond-coated ones. With their help you can drill through concrete floors and thick metal sheets.

What are nozzles for?

Various types of cutters cut metal using a die through repeated, repeated movements. As a result, durable metal can be processed. This is how we cut, make holes or grind a metal surface. Point impacts allow you to work carefully without disturbing the structure of the elements. In addition, the natural protective layer of the product is preserved.

Using nozzles, you can act on the following metals:

- two-millimeter aluminum plates;

- copper, brass, iron, zinc and steel elements;

- galvanized parts 1.5 mm thick;

- stainless steel 0.8 mm thick.

No need for extra sacrifices

The modern man has a lot of hand and power tools in his arsenal, which, at first glance, can do an excellent job of cutting anything. But when working with metal tiles, it is better to avoid unnecessary experiments. Let's take a closer look at some of the possible options.

What if you try to cut metal tiles using these tools:

- jigsaw? This tool is good for many things, but not for metal tiles - a jigsaw will tear it, and besides, it can break its saw;

- hand scissors for metal? You may get down to business right away, but after a while you will look for other options to cut metal. In fact, this is very difficult to do with hand tools;

- Bulgarian? Here it is, the most logical option that comes to mind. It cuts sheets with ease, however, there is a downside to the coin that needs to be described separately.