It’s hard to imagine a holiday in the countryside without eating in the fresh air. This means that appropriate furniture must be placed in the yard - tables, chairs. You can buy them in a store or make them yourself. The second option allows you to save money and make real furniture masterpieces. But the master naturally has a question about what is best to assemble the table from with his own hands.

Each of the existing materials has its own advantages and disadvantages, so before making a choice, you need to decide whether you plan to permanently place the table on the street, or whether it will be periodically removed from the room.

Affordable, lightweight plastic

This lightweight, inexpensive material is great for cases where furniture is not often taken outside. Plastic is not suitable for constant outdoor use, because its structure is destroyed under the influence of direct sunlight. Although if you place the furniture in the gazebo, this problem is solved.

The main operational advantage of a plastic table is its extreme lightness. Even a woman or teenager can move such furniture. If the design is also collapsible, then it is easy to store. The disadvantages of plastic are a short service life, rapid loss of aesthetics (for example, white material quickly turns yellow when used outdoors).

A table made with your own hands from plastic can be easily damaged by dropping a knife or any heavy object on it. If it is not individual elements that are assembled from plastic, but the entire structure, then the product may be unstable. This table will easily tip over, so it should only be placed on a solid, level base.

How to make a metal table with a wooden top

One of the interesting and durable options for garden furniture. For self-production you will need:

- metal profile pipe or high-quality rolled metal of sufficient cross-section;

- primer for working with metal surfaces;

- paint on metal surfaces and brushes;

- chalk or light marker;

- flat surface for stencil;

- wooden tabletop;

- bars and adhesive to secure the table top.

The tool can be represented by a welding machine, grinder, metal saw, hammer, screwdriver, self-tapping screws and bolts. The metal is first cleaned of rust and dirt using a steel brush, after which a frame is created in accordance with the stencil.

Welding must be done carefully to avoid the formation of welding build-up. The entire structure is cleaned with a wire brush, after which it is primed and painted. After the paint has completely dried, the tabletop is fixed, which also needs to be treated with special antiseptics, and then varnished or painted.

Reliable, aesthetic wood

Making an outdoor table out of wood with your own hands is the option preferred by most craftsmen, because a structure made from this material fits most organically into the country landscape. In addition, wood is easy to process, environmentally friendly, and durable. It has a pleasant texture and a special aroma.

But wood has a number of disadvantages. Thus, it is more expensive than plastic and lacks resistance to moisture and temperature changes. It is not recommended to place wooden furniture on sand or grass, because the legs will sink into the ground and rot. A table made of this material needs regular treatment with antiseptics and paints and varnishes.

To make a durable, reliable table with your own hands, it is recommended to give preference to a model made from slats. This design will be well ventilated and withstand bad weather. The types of wood most suitable for making outdoor furniture are pine, ash, beech, oak, larch, as well as linden and alder. The last two types have another important advantage - they are able to withstand high physical stress.

DIY kitchen countertop made from tiles

Another option that is optimal for a summer kitchen is a concrete base lined with porcelain stoneware or tiled non-corrugated tiles.

Advice. If you want to use a chipboard board as a base for the tile, it must be covered over the entire area with moisture-proof impregnation or mastic in several layers.

The tiles are laid in the usual way. For the base of chipboard, acrylic or polyester glue is suitable, for a concrete slab - cement. When the adhesive has dried, the seams are grouted with waterproof grout.

It can be seen that there are many options for countertop materials for a summer kitchen. All you have to do is choose which one you like best.

The material was prepared by the website E-stoun.ru.

Colorful, airy vine

Making a wicker table with your own hands is a task that only a person with great patience can cope with. However, his efforts will be rewarded, because wicker furniture has a number of advantages. It is very beautiful, lightweight, environmentally friendly, easy to use, and does not require special care (just wipe it with a damp sponge to prevent cracking). If the weaving is done correctly, the table will be strong and durable.

But the vine also has disadvantages. Thus, it does not tolerate high humidity well, so furniture made from it cannot be left outside in the rain. Drying out also damages the products, so prolonged exposure to sunlight should be avoided.

The most suitable types of vines for weaving are broom, willow, raspberry, hazel, bird cherry, rattan, and grapevine. Experts recommend that beginning craftsmen use bird cherry because its rods are characterized by maximum plasticity.

What tools are needed

To work you will need:

- hacksaw,

- circular saw or jigsaw;

- drill;

- screwdriver;

- hammer (if you decide to use nails).

Many species of wood are suitable for a garden or kitchen table.

This list includes only the most necessary tools, but to make the work more comfortable and the finished product to look aesthetically pleasing, it is advisable to buy or rent a rotary miter box, an eccentric sander and a milling machine.

The rotating miter box makes it possible to make cuts at exactly the right angle. An eccentric sander will allow you to prepare parts simply, quickly and efficiently: you will sand the boards in an hour, instead of doing it all day by hand with sandpaper. For high-quality processing of the ends, a belt sander is useful, and a milling machine allows you to select wood for the required grooves and process the edges.

If you do not plan to do furniture work permanently or are just starting to practice.

Sleek, durable metal

Metal is often used in the production of outdoor furniture because products made from it can last for decades (but only if high-quality metal is used and not recycled materials). Modern forging technologies give wide scope for imagination. A forged table will look especially impressive in a courtyard with ornate metal gates, wickets, fences, and gazebos. Such products seem exquisite, weightless, elegant.

But you can make a simpler design with your own hands using standard sheets of metal and a profile. Aesthetically, such furniture is inferior to forged furniture, but it has the main advantages of outdoor metal products, namely durability and stability. Metal furniture is not afraid of cold, heat, wind, it can be used outdoors all year round.

Metal also has certain disadvantages. In particular, it is susceptible to corrosion and therefore requires special treatment to prevent rust. It can get very hot in hot weather and cool in cold weather, which creates some discomfort when using it. Metal has significant weight and is one of the most expensive materials for furniture production. Aluminum has the most affordable price, but it is inferior to steel and cast iron in strength.

DIY stone countertop for the kitchen

Using natural stone is the most expensive, but also practical option. Such a working surface will last about 100 years. Marble, granite and other countertops made of rocks and minerals are often purchased to order, but if you wish, you can make it yourself by purchasing only a board of the required dimensions.

Important. Rarely do any summer kitchens have a sink, so there’s one less hole in the countertop! The exception is warm regions where there are no cold winters and the danger of pipes freezing.

The tabletop can be made whole by cutting out holes for the sink and hob in it with a grinder and a stone disc, or it can be made up of small modules, gluing them together at the ends with polyester mastic.

Advice. To prevent the stone from overheating when sawing and dust from flying around, it is recommended to water the cutting area with water. In this case, the grinder must have a waterproof disc.

Solid, stylish stone

You can also make a table with your own hands from stone - granite, marble, sandstone, onyx or composite stone. This material is characterized by a long service life, pleasant appearance, ease of maintenance, and environmental friendliness. A stone table is perfect for outdoor use.

But such a piece of furniture will be quite expensive, even if it is made by hand. Another disadvantage of stone products is their very heavy weight. Some types of stone are sensitive to chemicals and, due to their porosity, can absorb moisture. So, for example, a stain may remain on marble from wine spilled on it.

A popular solution is to use several materials when making a table. For example, the legs and base can be forged, and the tabletop can be wooden. But in this case, you need to take into account the characteristics of each of the materials used and provide the product with appropriate care.

The combination of concrete and wood gives the impression of something “inedible” only at first glance. In fact, this trick is now widely used in the manufacture of not only outdoor furniture, but also home furniture.

As for outdoor furniture, as well as garden furniture, the use of concrete on flat horizontal surfaces reliably protects the wood from the adverse effects of precipitation.

Such furniture is easy to clean, it does not look trivial, and lasts a very long time, without requiring any special care or repairs. However, the consumer is usually attracted not so much by the practical characteristics of such pieces of furniture as by the usual contrasting combination of materials.

In a burst of fresh and new ideas, you can try to make something similar yourself. A table or bench is perfect for training flights.

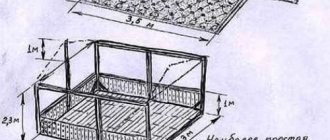

The author of this master class invites us to make a small wooden table with a concrete top for the terrace with our own hands. To work you will need:

Materials:

1. natural pine block with a cross-section of 50 x 50 mm for making the table frame: – 4 pieces x 50 x 50 x 390 mm – parts of the legs; – 8 pcs x 50 x 50 x 525 mm – horizontal frame parts; – 4 pcs x 50 x 50 x 525 mm – parts of the lower tier-shelf; – 2 pcs x 50 x 50 x 525 mm – transverse parts of the tabletop frame. 2. glue for woodworking; 3. silicone glue for fixing concrete tiles to the frame or tile adhesive; 4. four concrete tiles according to the size of the countertop; 5. furniture screws or wood screws; 6. a product for the protective and decorative treatment of wood, such as furniture varnish or decorative oil.

Tools:

– a miter saw, a jigsaw or a hand saw for cutting bars; - electric drill; – screwdriver; – grinder; – construction tape and square; – paint brushes; – soft, lint-free fabric.

Step one: choosing materials

Lumber. Decide on the type of wood you plan to use for your outdoor table. Choose traditional pine or dense hardwoods such as oak, maple, acacia or ash.