Folding tables are often found in everyday life. They have found application inside buildings and on land. Conventional factory products perform only a direct set of functions. Modern materials and construction techniques include decorative aspects. Mass-produced brands produce beautiful transforming models with a book-like structure, a complex motor mechanism and high-quality coating. It can be difficult to achieve the same parameters on your own. But individual attempts usually end in the creation of exclusive furniture, unlike anything from mass production. Options for assembling and decorating a folding table with your own hands include classic as well as original design solutions in a modern manner. Calculations, accumulated experience and step-by-step instructions will help you achieve an exact match.

DIY folding table: drawings, photos

Homemade wooden folding picnic table, two manufacturing options with drawings, diagrams and photos.

Folding furniture is very convenient and practical, it takes up little space and does not clutter up the space in the room. We continue the series of homemade projects and in previous articles we have already looked at how to make a small folding table with your own hands, now we will make a convenient folding table for a picnic in the country or in nature.

Here are two options for making a folding table, the first option is more convenient to transport when folded, but with a more complex folding mechanism, it is a little more difficult to make.

Types of folding tables

Folding tables can have different designs and be made from different materials. They also differ in their shape and the way the legs are attached. It all depends on their purpose.

Small tables are perfect for small spaces, hiking and outdoor recreation. The smaller and simpler their design, the more likely it is to build it yourself.

The advantage of such furniture is high mobility and compactness. It does not take up much space and can be folded and placed in any corner at any time without taking up much space.

Tabletops can have different geometric shapes. As for the materials from which they can be made, the best option is tables made of metal or wood. Combining them is also permissible. It can take shape in completely different ways: it all depends on the imagination of the master.

There are tables in which only the legs fold out. And there are completely dismountable ones, the parts of which are attached using threaded connections.

There are also more complex designs, for example, a table that, after being assembled into a transport state, resembles a suitcase.

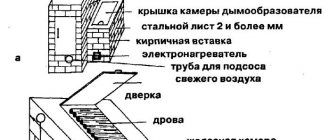

Drawings of a folding picnic table.

The table consists of two tabletops measuring 550 x 300 mm, which, when unfolding the table, turn into one continuous surface measuring 600 x 550 mm. As a tabletop, you can use furniture board, chipboard, thick plywood or wide boards.

For the table you need to make four legs measuring 690 x 45 x 20 mm. To stabilize the table, we cut the legs at one end at an angle of 45 degrees, and round them at the other end for a movable connection with the foot supports.

We drill holes in the legs for bolt fastenings according to the drawings.

The tabletops are attached to the foot supports with self-tapping screws or another convenient method; you will need 4 supports measuring 500 x 45 x 20 mm. We attach two supports to each tabletop.

The supports are connected with bolts and nuts to the table legs.

We attach crossbars to the legs in the lower part with self-tapping screws; you will need two crossbars, bars measuring 450 x 45 x 20 mm.

Homemade folding picnic table.

The design of the table should be easy to unfold, the table should be stable and not wobble.

Now let’s consider the second option with a simpler mechanism; its production will take less time.

Simple folding table diagram (2 option).

In this option, one tabletop is used, which is attached to two supports, in turn, the supports are bolted to two pairs of legs, the second pair of legs, when unfolded, simply rests against the limiter under the tabletop.

Homemade folding table.

Assembly order

First you need to drill holes in the paired legs, placing them evenly along their length. There will be two pairs of them. Then the first pair is fastened with transverse supports using self-tapping screws. You should get a kind of rectangle, only the bottom block, which acts as a footrest, should be slightly higher from the edge of the legs.

The second pair is attached in such a way that the structure fits tightly into the first rectangle. That is, one pair should be smaller in width (the outer edges of the smaller one should coincide with the inner edges of the larger structure).

After this, they are evenly connected and secured using a movable bolt connection. The finished design of the legs resembles a “goat” for sawing wood in appearance. Moreover, the axial bolts should not be too tight so that the legs can rotate along the axis.

Next, along the long edges of the tabletop, supports are attached to which the legs will be joined. The distance between them should correspond to the width of one of the pair of legs. They are also fastened using a movable bolt connection.

- Furniture in the hallway: keeping the living space comfortable

Advantages of custom-made wardrobes

Buying a sofa

There is no need to attach the second pair - this will ensure the necessary functionality of the table. After everything is ready, the wood must be sanded and varnished. In the same way you can make a folding table on the balcony.

This folding table in its design resembles the well-known ironing board and folds according to the same principle.

After looking at photos of folding tables made by yourself, you can come up with your own design, combining their operating principle.

DIY folding table: various purposes and various designs

Making things with your own hands is a very exciting activity. And doing things that are also useful is doubly exciting. Making a folding table falls into the category of such activities. In every home, situations may arise when you really need to add a little more work space to the main table, when there is a need to organize a feast in the garden, outdoors. And for fishermen who sit for hours on the shore of a reservoir, a table will also not hurt. And after use, you can quickly fold it and hide it until next time. This is what a folding table is for.

Types of folding tables

There are a great many design options for folding tables. Before you begin the creation process, you need to clearly formulate what the table is for. When used indoors, it will be larger and heavier; for outdoor activities, you need a small and light one. It is only necessary to provide protection against squeezing the soil under the legs.

The degree of complexity of the work is determined by the choice of folding method and the design of the mechanism that implements this method. Any table consists of a tabletop and legs.

Benefits received

Due to their compactness, folding tables are quite common. They provide a number of benefits:

- have an excellent appearance;

- made from environmentally friendly material;

- can have a multifunctional design;

- have low cost;

- able to harmoniously fit into any interior of the room;

- They are distinguished by their compactness and the variety of design solutions used.

A folding table can be seen in rich and poor homes, in office and technical premises, and in special-purpose vehicles.

This is an amazing design that helps improve human comfort and reduce costs.

Check it out here too!

DIY furniture made of wood: the best photos of solid wood furniture! The process of making wooden furniture: drawings, diagrams, furniture assemblyHow to make book shelves with your own hands: drawings and step-by-step photos. Wall shelves, floor standing, portable, Montessori book shelf

We make a kitchen countertop with our own hands: design, methods of application, design options and decor ideas (135 photos and videos)

By making such a product, a person gets a lot of pleasure. He enjoys the work process and enjoys the fruits of his labor. At the same time, it saves the family budget!

Leg design

The design of the legs also depends on which method of folding the table is chosen. If the legs are unscrewed, then they can be either round or rectangular in cross-section. For indoor use, they can be made more elegant - round in cross-section and slightly conical in length. The small base rests on a hard floor. If the table is intended to be installed on the ground, the leg at the bottom should be more substantial. A rectangular block with a cross section of 40×40 mm² is suitable for it. If the legs are not wooden, but metal, then a round plate with a diameter of 50 mm can be attached to the base so that the table does not fall into the ground.

If the design of the folding legs is planned on hinges or hinges, then there are other options. But first you need to decide what to make this system from - wood or metal. A beautiful option is obtained by combining materials - a wooden tabletop and metal legs.

Related article:

Furniture made from pallets : what is it, advantages and disadvantages; step-by-step production of a coffee table, armchair, sofa, bench, rack; decor features with photos - read in the publication.

Small kitchens and unusual folding tables

Arranging furniture over an area of 4 meters or a little more is a common situation. Then you can use options for folding tables that do not clog up the free space.

Usually we mean models attached to one of the surfaces with loops. A folding leg or stops are created to support the product when unfolded. These countertops come in different sizes and are attached to the walls with long or short sides.

When choosing specific dimensions and features, you must rely on the following factors:

- Layout.

- Furniture arrangement.

- Number of people for whom seating is required.

It is better to decide on the sizes on the spot, and then place an individual order.

The main thing is not to forget the importance of ensuring free access from different sides.

Some companies produce round transformable tables with metal mechanisms. They are quite expensive, but they will last as long as possible due to their characteristics.

Recent developments include block tables. Their main feature is the presence of compartments of different sizes inside. It resembles puzzles that perform not only decorative, but also practical functions. Such folding tables easily fit on the balcony.

Folding tables can be called universal solutions for any environment. They will be relevant not only in a suburban area, but also for an ordinary apartment.

The operating conditions can be any; now even wood and plastic can be easily protected from harmful influences. You just need to choose compounds that successfully resist the effects of certain factors.

DIY folding table

You can easily make a good wooden folding table for your garden. It can be used in the house, in the summer kitchen, and in the garden.

Materials and tools

For the tabletop, it is best to use two sheets of chipboard measuring approximately 650x300 mm, 20 mm thick. Approximately - since the size is not critical and is selected according to need and the availability of material. You will also need 15 boards 550 mm long, 50 mm wide, 20 mm thick. You also need self-tapping screws 45 mm long, about 10 M6 bolts with nuts and washers.

Drawing

In this case, a drawing is not required, everything is visible in the photographs.

Step-by-step execution

The manufacturing technology of wooden folding tables is practically independent of their design. It can be considered the same. This is the preparation of the material - sawing, planing, sanding, and if desired, painting. Then comes the production of parts and their hinge connection. The last operation is to assemble the entire structure.

Sawing boards PHOTO: youtube.com

The nuances of making small folding tables

These tables will differ from the country tables only in size.

DIY folding tourist table

The tourist carries everything on his back. He also needs a small and light table. A tabletop measuring approximately 500×350 mm should be made of plywood 3-6 mm thick. Legs made of aluminum tubes. To avoid bending the tubes yourself, you can use folding benches with a cloth seat for this purpose. If desired, their height can be increased by extending the tubes. You should not make the height more than half a meter. Repeat the design of the hinges in the appropriate size as described in the “Picnic Table”.

DIY folding table for fishing

A table for a fisherman can be completely similar to a tourist one. The tabletop should be covered with hard, easy-to-clean plastic. After all, you will probably have to clean fish on it.

How to make a folding table with your own hands?

A table is an integral attribute of every home, allowing you to create comfortable living conditions. But many residential apartments cannot place a full-fledged structure inside, since this piece of furniture takes up a lot of space. Transformable tables, which can be disassembled or converted into another product if necessary, will help correct the situation. Before you make a folding table with your own hands, it is important to choose the optimal design and functionality of such a design. This will allow you to optimally fit it into the interior, making it as useful and in demand as possible.

Design options

Despite the fact that almost all models of transformers use the same scheme, almost all home-made workers try to design a folding bench in their own way, to make its design more individual and attractive.

Features and benefits of a folding table

A folding table is a structure that consists of several independent elements. All elements of the system are connected to each other with special fasteners, which allows, if necessary, to disassemble it into separate parts. A classic representative is a table in which the tabletop slides apart and another part is inserted into the freed-up space.

Tables of this type have several positive aspects:

- Functionality. The table can change its dimensions, which allows them to be increased if necessary (arrival of guests, etc.). At the same time, such a system is very easy to supplement with drawers, which will be used as additional storage space.

- Small dimensions. The design is completely disassembled, which allows you to keep it in the pantry or on the balcony. The dimensions of the table itself are compact and practical.

- Originality. Almost all tables that are made by hand have no analogues on the market and differ in many details.

- Practicality. The table can be installed both in the kitchen and in the living room, transforming its size. This approach also allows you to save quite a lot of space, which is important for small apartments.

- Reliability. The service life of the structure can be very long if you follow the manufacturing drawings and use high-quality fittings.

Peculiarities

Outdoor furniture

There are the best types of materials for outdoor furniture that can last a long time and not lose their beautiful appearance from rain or hot summer.

Below is information about the most common materials.

Tree

Wood is the most popular material

Tree

In most cases, craftsmen prefer to make tables intended for open spaces from wood. This material is easy to process, environmentally friendly and durable. It also has a pleasant texture and a special aroma.

The disadvantages of the material include:

- high cost

- instability to moisture, temperature changes (the legs of a wooden table begin to rot when immersed in the ground)

- the need for regular treatment with antiseptics and paints and varnishes

Options made from planks are more durable and reliable. They are well ventilated and withstand bad weather.

Wood species that are most suitable for making outdoor furniture:

- pine

- ash

- beech

- oak

- larch

- Linden

- alder

Linden and alder also have a high tolerance to physical stress.

Vine

Beauty and lightness

Vine

Only very patient people can make a table from wicker. But patience will be rewarded. Such furniture is distinguished by its beauty, lightness, environmental friendliness, and ease of use. It does not require special care. Wiping the furniture with a damp cloth will prevent it from cracking. With proper weaving, the table will be strong and durable.

Disadvantages of the material:

- intolerance to high humidity (in rainy weather, it is better to put wicker furniture in a shelter)

- susceptible to drying out, which will be facilitated by prolonged exposure to sunlight

Types of vines that are most suitable for weaving:

- broom

- willow

- raspberries

- hazel

- bird cherry

- rattan

- vine

According to the advice of experts, bird cherry twigs are better suited for novice craftsmen. They are as flexible as possible.

Metal

Strength and Durability

Metal

The strongest and most durable material is metal (these qualities do not apply to recycled materials). Metal products have sophistication and grace.

Of course, it will not be possible to make forged furniture yourself without having the appropriate experience. But a simpler design, which uses standard sheets and a metal profile, is quite feasible for a non-specialist. The product will also be durable and sustainable. It will not be afraid of cold, heat, or wind. Metal furniture can be used in open spaces all year round.

Disadvantages of metal:

- susceptibility to corrosion (special treatment required to prevent)

- In hot weather it gets very hot, in cold weather it cools down

- high price

- heavy weight

Aluminum is the lightest material, but it is not as strong as steel or cast iron.

Materials

The quality of transforming tables depends largely on the material from which they are made. Today, to design such systems they use:

- Chipboard. The plate is durable and low in price, so it is very often used in the manufacture of such furniture. To give the table an attractive design, you can make it from laminated chipboard.

- Fiberboard. This material is in many ways similar to the previous type of product. The plate is perfectly processed and is practically harmless to humans.

- Tree. Solid wood tables are the most durable and expensive. The material is easy to work with and also has a unique texture that can be matched to any style of home.

- Plywood. This product is not used as a main product. Auxiliary elements are made from it (shelves, back walls, drawers, etc.).

- Metal. This material is one of the strongest and most durable. It is used to construct parts that are subject to significant loads (metal legs, etc.). Very often, profile pipes of different sections and shapes are used here.

It should be noted that today many parts for tables can also be made from polypropylene pipe, glass and other similar materials.

Wood or plastic?

The choice of materials for a homemade table is determined by their availability and appearance

Particular attention is paid to the tabletop. It can be made from the following materials:

- tree.

The most spectacular, but also expensive, option is solid wood. Such tables have a rich appearance, but the overall design is heavy. A cheaper option is shields assembled from boards. They can be tightly fitted to each other, imitating a monolith, or they can be laid with a gap - a lightweight country table; - wood-shaving and wood-fiber materials. Chipboard, MDF, and plywood are widely used. They are technologically advanced, but have a reduced service life;

- plastic. Plastic sheets can be selected in different colors. Their advantage is low cost, light weight;

- glass. Glass countertops have become fashionable and are in demand for modern interior styles. The main disadvantage is the complexity of manufacturing.

In addition to the tabletop, the table must stand securely on legs. For their manufacture, wooden beams are most often used.

Tip: you can also use a metal profile for them; in particular, an aluminum flat pipe, corner or U-shaped profile looks modern.

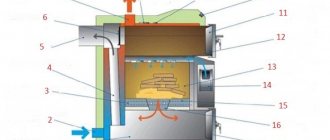

How to make a folding transforming table yourself?

Transforming tables come in several types, as they are used to solve various problems. The algorithm for creating such structures consists of several sequential actions:

- Initially, you need to decide on the type of product. Today, tables-beds or tables-sofas are very popular. The next step is to create drawings with all structural elements. The best option would be to use ready-made plans.

- At this stage, the selection of materials and accessories is carried out. There are several types of transformer mechanisms. They differ in the method of fastening and the parameters of spatial movement. For example, a bench-table should have not only sliding, but also lifting mechanisms.

- When all the materials have been collected, we begin to manufacture the structural elements of the table (tabletop, legs, and so on). Here it is important to carefully adjust all dimensions so that the future system can move without effort or failure.

- The procedure ends with assembling the table. They all start with small elements that are not transformed minimally. After this, they move on to larger systems, where they already install rotary-sliding mechanisms. At the same time, careful measurements are taken before fixing each element.

The process of constructing transforming tables can be either easy or complex. It all depends on your imagination and desire. Sometimes you can simply attach wheels to a transformer to change its purpose and functionality.

What materials are used for country tables: pros and cons

In the process of making tables for summer cottages, the following is used:

- plastic elements that are connected with rivets, screws or glued with epoxy-based materials;

- steel sheets and profile trim; welding, bolts or rivets are used for assembly;

- wooden or plywood blanks, which are fastened with pins, wood glue or screws.

Lightweight plastic

Plastic tables are assembled from factory blanks processed in accordance with the required dimensions. The advantages of the material include resistance to rotting and precipitation.

But one should take into account the increased fragility of plastic at low temperatures (from +5°C) and flammability. Sheet plastic is rarely used for making homemade tables.

Plastic set for a summer house - table and chairs.

Iron sheets

The metal structure is assembled from steel angles connected by bolts or resistance welding. A tabletop made of sheet reinforced with profile scraps is mounted on top.

The table is heavy and durable. To prevent the product from sinking into the ground, support plates are welded to the legs. When installing the product outdoors, it is necessary to protect the surface with soil and impact-resistant enamel, otherwise traces of corrosion will appear on the metal.

Iron country table.

Wood

The most widespread are wooden tables made of solid wood, plywood sheets or chipboard. The material has a beautiful appearance, is easy to process and has a low specific gravity.

To reduce the rate of decay, wood is impregnated with compounds containing antibacterial additives. There are solutions that reduce the flammability of the material.

Wood table.

Manufacturing a rotary-folding model

Rotary and folding tables are systems in which the tabletop can be moved to the side parallel to the floor. This design is much more complex than a regular folding model. It uses special hinges and mechanisms that provide this functionality.

The algorithm for constructing such a structure can be divided into several successive stages:

- First of all, you need to carry out careful calculations of the table-book. It is advisable to use ready-made drawings on which all the main dimensions are indicated.

- After this, a material is selected that can withstand many rotation cycles. The best options would be metal and natural wood.

- When everything is ready, the frame and tabletops for the table are made. The upper part must be completely covered by one element. The second tabletop will be hidden under the table. After careful measurements, the lid is screwed to the frame using special transforming mechanisms. It is important to control the location of all structural elements.

Please note that the second cover can be attached to the first element, forming a kind of book. A table like this with a folding tabletop is much more convenient and practical.

Preparation of the drawing

You can freely find ready-made drawings for making an extendable table yourself. When choosing them, you should pay attention to:

- design features;

- suitable materials;

- recommendations presented.

Otherwise, the quality of the table will suffer. When adapting to your own size, you should take into account the height and build of household members, and the number of seats. If necessary, these parameters are increased or decreased.

The standard width of the additional element is 50 cm. When unfolded, the length of the table reaches 230–280 cm. When assembled, the dimensions are reduced to 120–180 cm. The height of the product is usually 70 cm.

To perform detailing, you must specify the parameters of each element. For example, to make a folding table from laminated chipboard you will need:

- Tabletop parts (2 pcs.) – 45 x 70 cm.

- Removable element – 40 x 70 cm.

- Sidewalls of boxes (4 pcs.) – 42 x 12 cm.

- End parts (2 pcs.) – 60 x 12 cm.

If desired, the circuit can be completed independently. To do this, you need to draw a circle on whatman paper using a compass or by tracing any round object. Thus, the table parameters will meet the user requirements.

Homemade folding wooden table against the wall

Wall-mounted tables are one of the most optimal solutions for small kitchens. These designs do not take up much space, which makes them very functional. The construction of such a structure involves performing the following operations:

- Initially, you need to select the material for the countertop. Many today use chipboard sheets for this, but wood is best, as it is durable and beautiful. The shield can be knocked down or glued together from several polished boards. After this, you need to determine the height of the table. Based on these values, 2 support legs are made. Theoretically, they can be adjusted to the height after fixing the cover to the wall.

- At the very end, the tabletop is screwed to the wall. For this purpose, special rotary mechanisms are used. Please note that the product should not fit closely to the support, as it will not be possible to close it. When the canvas is screwed, you should take care of the fixation system in a vertical position. The process ends with installing the legs. They are attached to two corners using rotating systems.

Design solutions

There are different sizes and designs of handmade folding tables. They depend on the application and the wide variety of designs. As an example, you can specify:

- traditional kitchen table with insert;

- a table attached to a cabinet or wall;

- work table with folding design;

- portable folding picnic table.

There are a large number of options for such products. They can be seen in the interiors of rich and poor people. Each of these examples has its own advantages and disadvantages.

Functionality of folding furniture

There is a wide variety of folding tables - typical options are visible in the photo. Often the finished product is purchased in specialized stores; it is not difficult to make a table yourself.

In small rooms, furniture is often used that allows you to rationalize free space - it is folded out if a large work surface is required, and removed in other cases: student desks, tables in the kitchen, hall, garage, workshop, etc.

It is convenient to use portable table models: they are light, compact, and moderately durable. They are made from different materials, each of which has its own strengths and weaknesses.

Wood must be protected from exposure to water and mold, but it is affordable and well processed, steel is heavy but durable, aluminum is easily damaged, but is light.

It should be taken into account that for outdoor use protection from moisture is required. Metal structures should not rust, the materials used must be moisture resistant - an aluminum frame and a plastic tabletop are often found as the optimal combination. Plywood, wood, fiberboard are suitable for indoor spaces.

If you need to fit a folding table into a travel backpack, the requirements are higher: minimum weight with maximum functionality.

During operation, it is important not to overload the tables - they are usually not designed for the weight of an adult, so it is unacceptable to use them as a stand for large items.

Materials used

Depending on the scope of application of the product, appropriate materials are selected for the manufacture of a folding table. It can be:

- wooden beams and boards;

- metallic profile;

- plywood, laminate, chipboard.

Depending on the selected material, its components are selected. The tools used are a jigsaw, a screwdriver, a plane, measuring instruments, etc.

Dimensions

Most folding structures are small in size when folded. Standard options are designed for four people. The width of such a table is in the range of 80-85 cm, the length is no more than 100-120 cm, and the comfortable height is 75 cm. A small folding table, even when unfolded, has smaller dimensions than the standard.

Folding dining tables, most often installed in living rooms, have standard or close to standard dimensions when folded. Long when unfolded and compact when folded, the table is an indispensable piece of furniture.

There is a relationship between capacity and tabletop size. A table with a size of 90*150 cm can comfortably accommodate from 4 to 6 people. For 8-10 people the surface size should be 110*200, and to accommodate 12 people you will need a large table with dimensions 110*320.

A compact and low coffee table, thanks to the transformation of the table top, can accommodate from 4 to 6 people, depending on the model, and thanks to the lifting of the table top, it provides a high level of comfort.

Folding tables, which have mini sizes, are portable tourist models. Their length is in the range of 40-45 cm, and their width does not exceed 25-30 cm.

Table attached to cabinet

Having chosen the design and diagram of how to make a folding table attached to the cabinet, we will begin to manufacture it.

The workflow looks like this:

- A slab of chipboard of the required size is cut out or a shield is made from natural wood.

- Using a bracket, one side of the working surface is attached to the cabinet wall at the required height.

- On the other side, legs are installed, which must be made in accordance with the design features. They can be folded or secured using threaded connections. These elements can be made from metal profiles or wooden blocks.

- The working surface is covered with film or paint material.

This design allows you to quickly unfold the table for use if necessary. After which the table is folded, and the area is freed up for use for other purposes.

Required Tools

You will need a lot of fasteners. Including self-tapping screws 20x4 and 16x3 mm, M4 screws, furniture locks, telescopic guides of approximately 500 mm and aluminum corners 50x50 mm. The legs may require 4 thick metal tubes - 710 mm in diameter. For installation work, hot melt adhesive is used, applied to the edges of PVC, plastic or wood boards. During work, protect your hands with household gloves. Among the auxiliary devices you will also need a marker, a long ruler, a thick pencil, a tape measure and a building level. A heat gun and a hair dryer will ensure the reliability of the glue connection. Chipboard sheets are cut with clamps. For cutting, you may also need a small-tooth file, a jigsaw, a circular saw and a router. A screwdriver is used to work with hardware. The holes are made with a drill using 4.2 mm drill bits.

Portable table

Special instructions have been developed on how to make a portable folding table with your own hands. It looks like this:

Check it out here too!

- a sketch of the future product is sketched, taking into account its compliance with the specified parameters;

- a drawing with exact dimensions is made;

- material is selected according to your taste;

- according to the drawing, blanks are made, namely a working surface made of natural wood or chipboard and legs made of wooden blocks or metal profiles;

- With the help of components, these blanks are assembled into a single structure.

This creates a portable table with a folding structure. Its legs can be screwed into brackets or secured using special stops.

Step-by-step work algorithm

Regardless of whether the master is going to make a table from timber, boards or solid wood, oval or square, with 4 or 2 legs, the algorithm will be similar. The first stage is cutting all the necessary parts. Since the drawing with the dimensions of each element is already ready, you can begin making a wooden table with your own hands. If the legs are planned to be metal, the best option would be a steel or aluminum pipe of a suitable cross-section. But the easiest way is to make table legs from timber with your own hands. For this purpose, you will need a block with a cross-section of at least 5 × 5 cm. It is even easier to find ready-made balusters.

The second element is the tabletop. When talking about how to make a wooden table with your own hands, we can mention different shapes and types of tabletops. The easiest way is to make it rectangular or square. They use boards, timber, solid wood, even tree cuts, glass, and other decorative materials. The main thing is to cut them to one size and fasten them together - most often, special glue and wooden dowels are used for this.

At this stage, it is important to remember the strict sequence of actions:

- manufacturing, fitting of all elements;

- sanding;

- opening with soil;

- grinding.

At the second stage we assemble the table. To do everything correctly yourself, you need to adhere to a certain scheme:

- The legs are fastened in pairs with transverse boards, using screws and glue;

- fix pairs of legs to long crossbars;

- Use screws to connect the frame and tabletop.

The last stage is finishing. The DIY wooden dining table is almost ready. All that remains is to give it a beautiful appearance. You immediately need to hide all fastening points using a special putty for wood. It is applied so that the composition completely covers the recesses, leveling the surface. Then everything is sanded and brought to perfect smoothness using a grinder.

Next is the application of paints and varnishes. Those who know how wooden tables are made will name many types of coverings. This is a colorless or tinted varnish (acrylic, solvent-soluble), paint, oils, waxes. Stain does not lose popularity, after processing which the surface is covered with a transparent varnish. It is better to apply coatings to the tabletop with a brush.

Cutting parts

Fitting elements

Making a countertop

Making legs

Installing the feet

Assembling a single structure

Painting parts

Ready table