Many people are interested in how to make a cold smoked smokehouse with your own hands, because everyone loves to enjoy delicious smoked meats from time to time, because these products have a unique taste and aroma.

Previously, smoking was used to extend the shelf life of meat and fish, due to the property of smoke to prevent food spoilage.

Now, meat and fish, smelling pleasantly and smoky, have become a real delicacy and appear in our homes, both on holidays and ordinary days, and are also indispensable in the country.

If you are the happy owner of a summer house or a private home, then you can buy a smokehouse or make a homemade smokehouse for hot or cold smoking with your own hands (from a refrigerator, barrel or brick) to enjoy tasty and aromatic products as often as possible.

Do-it-yourself cold smoked smokehouse video, photos and varieties

A characteristic of a homemade smoking device is its low cost. You can build it from a variety of materials - old barrels, steel sheets, pieces of brick: all of this will make a useful device.

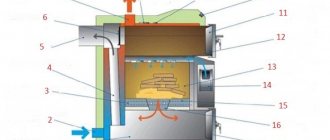

Diagram of a simple smokehouse device

Helpful information! Since fat is released from various products during smoking, a special tray is placed behind the grate. In this case, there should be gaps between the container and the walls. It is also worth placing a damp cloth above the firebox, through which combustion products will escape, but pollutants will not penetrate.

How to assemble a stainless steel smokehouse

A similar do-it-yourself cold-smoked smokehouse is often made from stainless steel. The insides of such equipment resemble a box with gratings that are installed on welded corners. This is a portable option that looks like a suitcase. For the camping structure, sawdust and small firewood are used.

You can build the entire structure or only some elements from stainless steel

Brick construction

A brick smokehouse is a stationary option. To build it, you must first select a suitable location on the site. Before work, a drawing of the product is made with markings of all sizes. Be sure to consider the placement of the smoke source. In some cases, a potbelly stove is used for firewood. In this case, the oven is connected to the smokehouse chamber using a pipe.

The brick structure is solid

Model from a gas cylinder

You can build a good cold-smoked smokehouse with your own hands from an unnecessary and empty cylinder. Videos, photos and drawings of individual projects will allow you to choose an option for your site. If you have an old gas cylinder, you can do a useful thing by following these points:

- You need to drain the remaining gasoline from the cylinder;

- remove the tap and pour water into the hole. Only after this can the container be sawed;

- You will need a large door to load products. At first, the cuts are not made completely so that the door does not boil;

- clean the places for the hinges that need to be welded to the door and the main part of the cylinder;

- a strip is cut off at the bottom, and then the bottom;

- the firebox must be made of iron sheets. The firebox is welded to the cylinder.

Product using an empty gas cylinder

Before carrying out the first smoking, you need to ignite the structure with firewood.

Helpful information! Remember that gasoline residues and its vapor pose a great danger.

Recommendations and drawings with dimensions

When planning to build a smokehouse with your own hands, you need to wisely choose a place for it in your local area. Such rules are relevant for dimensional modifications that cannot be moved to another area or, if necessary, removed to the basement. When choosing a site, remember that:

- during operation, the smokehouse emits a lot of smoke, and it should not penetrate into living spaces;

- the components in the smoke harm not only people, but also vegetation.

Expert opinion

Valery Garmash

Chef of the Grill House restaurant, griller

The best place to install a smokehouse is a leeward area. It will not allow smoke to enter the garden or the house itself (yours or a neighbor's).

Finished smoked meats can be stored in the basement or cellar. It is important to keep the area cool and dry. And before you start “testing” procedures, test your home smokehouse (without using products).

This is necessary so that the smoking chamber is saturated with the natural smell of smoldering coals. The products will turn out much tastier and more aromatic.

How to do cold smoking at home: smokehouse design

The drawings of a homemade cold smoked smokehouse will help you build the correct installation. You can install the unit yourself if you know its design features and operating principle.

Construction from a refrigerator

The principle of such smoking is that the product is blown with smoke, which has a temperature of no more than 30 degrees. The smoke is cooled in a pipe that connects the combustion chamber with the smokehouse container. Products in this design can be smoked for a couple of days.

Smoking equipment consists of the following components:

- partitions;

- covers connected by tongues;

- chimney;

- a chamber consisting of a barrel-shaped reservoir;

- knees;

- chimney structure.

The product includes two cameras. The first burns wood, and the other stores meat and other products. In the installation, the distance between the tanks must be longer than in a hot smoking device, since the smoke must cool down. There is another pipe in the combustion chamber that removes excess smoke.

A do-it-yourself cold-smoked smokehouse is a universal piece of equipment. Videos and photos of individual models allow you to see their device. You can smoke not only meat products or fish, but also some vegetables and fruits.

Functional structure made of wood

Helpful information! The best option for a private home is a brick device. Before work, you need to calculate the chimney line.

Important points during production

To properly build a smokehouse yourself, you just need to carefully study the design drawings.

You can smoke products using hot and cold smoking. You can smoke various types of meat, lard, fish, vegetables and even cheese.

Video:

Hot and cold smoked smokehouses are very similar. They consist of a hearth, an area for prepared foods, a tray for accumulating fat, and hooks for future delicacies.

The structural structure of the smokehouse ensures the movement of smoke, resulting in smoking. The longer the chimney, the colder the smoke will be.

The difference between hot and cold smoked smokehouses lies precisely in the length of the chimney.

The hot smoking process occurs at temperatures from 80° to 150° (for fish) and 35-50° (for meat), so the products are cooked very quickly.

Usually after a few hours you can get a smoked delicacy. These products will have a rich taste and smell.

The temperature of cold smoking, unlike hot smoking, usually does not exceed 40°, so smoking lasts several days.

After cold smoking, products retain their density and texture and are stored for a long time.

Smoking occurs due to the smoldering of wood chips, which produces a lot of smoke.

It is very important that the wood does not ignite or become charred, since in this case carcinogens will begin to be released from the sawdust and, as a result of smoking, we will get harmful charred products.

To prevent this from happening, you need to create a reliable design. The chamber lid must be tightly sealed so that air does not enter the chamber and the wood chips do not ignite.

After repeated combustion, the metal of the chamber may bend, so it is better to press the lid on top with something heavy, for example, a piece of brick.

It is also important to choose the right firewood for the fireplace.

If there are too many wood chips and sawdust in the composition, then smoke smoke will form very slowly due to lack of air. And components that are too large can catch fire, which also should not be allowed.

Therefore, approximately half should be firewood, the rest should be wood chips and shavings for smoking. This composition will provide the right amount of heat.

You cannot use pine sawdust, as this will prevent the production of smoked meats. Tasteless products are obtained when smoking over aspen wood.

The best choice is cuttings and chips from various fruit trees - apple, cherry, apricot, sea buckthorn, which you will probably find at your dacha.

Bird cherry, birch and alder firewood will add a delicious aroma to the product, but you should get rid of the bark, as it can impart bitterness.

How to make a cold smoked smokehouse with your own hands: stages of work

There are a large number of methods on how to make a cold smoked smokehouse. We propose the following method. The structure looks like a building on supports. On the front part there is a door through which food is served. Below is a door where a container for collecting fat is installed.

For installation you will need a steel sheet 1 mm thick, lining, lath and timber.

Table 1. Creating a cold-smoked smokehouse with your own hands

| Image | Stages of work |

| We construct a frame from timber, which should be equal to the dimensions of the smoking chamber. | |

| Using lining we cover the floor, walls and roof of the frame structure. In this case, you need to fit the boards tightly. Just in case, reinforce the walls with spacer strips. | |

| A hole is cut at the bottom where the smoke will pass through. It should be equal to the cross-section of the chimney elbow. And make a hole in the roof to allow smoke to escape. The strips where the hooks will be hung are also fixed there. | |

| A door is made using boards and then hung on hinges. The door is located under the roof of the structure. | |

| A hole is made at the bottom where a reservoir will be mounted to accumulate fat released from food. Corners are attached inside the chamber, with the help of which the tray will move. | |

| A tray is formed from steel, to which a door with a handle is welded. | |

| You can use a stove, like a potbelly stove, as a firebox. If there is no suitable equipment, then you can make a base from a pipe or cylinder. The legs need to be welded to the body. The stove should be located below the smoking chamber. A pipe is welded to the back of the stove, and a pipe adapter is placed in the hole. A door is cut out for the firebox, which should have a hole in it to create better draft. | |

| A corner adapter is attached to the hole in the smoking chamber. | |

| The smokehouse tank and the firebox are combined using pipes. Remember that the chimney must be made with a certain slope. This bevel will increase the draft in the smoking container. After assembly, the device must be checked. For smoking, it is better to use wood made from raw wood. You can use wet wood chips for DIY smoking. | |

| This is what will happen in the end |

Helpful information! If smoking is done correctly, the products will have excellent shelf life and excellent taste. Such products do not have harmful properties, especially when made at home.

Useful tips

We provide you with recommendations that will help you when smoking:

- do not forget to monitor the temperature inside the chamber;

- do smoking in dry weather, it is important that there is no precipitation;

- do not open the camera door too often, as this will delay the process;

- for a better aroma you can add juniper, cherry or grapes;

- To ensure a pleasant taste of the product, take care of uniform heating and fumigation of the product;

- do not use coniferous trees, as they will spoil the taste of the products.

Read also: What types of propane cylinders are there?

A homemade smokehouse can be easily constructed from scrap materials

If the process of building a smokehouse is too complicated for you, you can purchase a ready-made option. At the same time, pay attention to the material of the product. It should not contain harmful impurities. The thickness of the structure matters. If the material is too thin, the product will quickly rust. Special sensors will allow you to regulate temperature conditions.

Individual items can be purchased in the store

Now you know what a cold smoked smokehouse is. If you follow simple recommendations, you can make a high-quality homemade unit without much hassle and extra financial costs.

What kind of wood is needed for smoking?

Any type of wood is suitable for fuel, but juniper and alder wood chips are considered the best for creating aromatic smoke. They also use oak, beech, hazel, ash, maple, apple and pear branches, and even birch.

Each type of wood gives the product its own special aroma. A mixture of different breeds is also used.

Before splitting wood, it is better to remove the bark from it (this is especially true for birch). The bark contains resin, which is undesirable for smoking.

For this reason, coniferous wood is not used. The wood is chopped into pieces up to 3 cm (sometimes sawdust is also used) and slightly moistened, then laid out in an even layer on the bottom of the smokehouse.

For a bucket-sized smokehouse, one large handful of wood chips is enough.

Video: DIY cold smoked smokehouse

Save time: selected articles delivered to your inbox every week

Reading time: 6 minutes No time?

Grocery stores offer a wide range of smoked meats, but buyers do not know what quality they are and what additives they contain. But every person wants to eat only fresh and natural products. So how to get out of the situation? Easy, all you need is a DIY cold smoked smoker. Videos, photos and detailed instructions for implementing this project can be found in this article.

Read in the article

The essence of the cold smoking machine

The basis of smoking dishes is the use of cold smoke treatment, which comes from smoldering wood. Regardless of what you smoke, meat, poultry, fish, vegetables or fruits, the cooking process is always the same. The box in which the smoking procedure takes place can be of almost any shape. The body materials are also different: metal, wood, polyethylene and other non-toxic materials that do not allow air to pass through.

Cold smoking can be compared to canning, because the smoke that settles on the food during cooking has a temperature of 20-25 degrees, the time for complete readiness takes about 1-2 days (sometimes up to 6 days). During this time, all the water leaves the smoked meats, which allows such products to be stored for more than two weeks.

Note! The ideal time of year to use a cold smoked smokehouse is winter. At low air temperatures, the development of bacteria in the middle of the products practically does not occur, which negates the spoilage of the dish during the smoking process.

How does the smoke formation process for cold smoking occur?

The production of cold smoke is practically no different from the type of coolant. The principle is always the same, but the designs for producing haze are different.

- If the smokehouse runs on wood, then you need to build an iron box for the fire or simply dig a hole and line it with stone. A chimney pipe is attached to the side, which leads into the box of the smokehouse itself. The length of the pipe should be about two or more meters so that the smoke coming from the fire has time to cool to 25 degrees before reaching the food.

Smoke generation from a fire

- In the case of using gas or electricity, the iron box for the heat exchanger is made with two horizontal levels. Heat is released at the bottom, which heats the top sheet, on which wood chips or shavings are poured. The wood smolders and produces smoke, which goes into the smokehouse. Smoke formation occurs regardless of how you make a cold smoked smokehouse.

Connection to a gas stove

The gas smokehouse does not require any connection to the stove; you just need to place the structure on the stove and turn on the gas. The device can operate on any gas. Wood chips are laid out at the bottom . If you use a water seal, you need to pour water into a special tank.

Important! Smoking devices come in completely different sizes, so before going to the store you need to measure the dimensions of the gas stove ! Ceramic stoves are not suitable for use in smokehouses.

Installing a gas smokehouse, its correct and safe use is a simple process; it is only important to know the exact dimensions of the gas stove and the room in which you plan to place the device.

The sizes of gas smokehouses vary from 450x300x270 mm (the smallest models, ideal for a small family) to 610x310x300 mm (the largest devices).

A separate issue is the correct choice of wood chips.

The best option is fruit chips , which give the dish a special taste and aroma.

Attention! Under no circumstances should you use chips of coniferous or birch - the bitterness contained in the resins will make the smoked products bitter and harsh.

Types of cold smoking devices

Depending on the place of use, volumes of processed products, type of heat source and other circumstances, smokehouses have different modifications.

Materials for smokehouse body

- Stainless steel. It is mainly used in factory models for home use. Less often, for homemade structures. In homemade versions, steel is used when assembling structures for hot smoking, since they are in direct contact with fire.

Heat sources

- Wood stove. This method is used to smoke in dachas, on the territory of a private house, and in personal plots. Firewood can be used to organize the operation of a smokehouse of any size.

Smoking fire

- Gas-burner. A more expensive option, but it has its advantages. Possibility of adjusting the flame and autonomous operation that does not require intervention (supplying firewood).

- Electric heating. Used in smokehouses for enclosed spaces. Basically, smoke generation using electricity is used in factory models, because building an electric smokehouse with your own hands without working with an electrician is quite dangerous.

Electric smokehouse

Smokehouse locations

- On the street. This is the main place for such structures. Due to the fact that the process of burning wood produces smoke and a smell that is absorbed into everything around it, smokehouses are located away from living quarters, children's playgrounds on the territory of a private house and away from public streets. Often the smokehouse body is placed on a hill so that the smell evaporates faster without spreading to the sides.

Street version of the design. Barbecue and smokehouse

- In enclosed spaces. Either you have an apartment, but really want to cook smoked meats, or you own a private smokehouse at a factory level. If in the first option you can use only electric units, then the second allows you to use any type of fuel, because it is not difficult to organize smoke removal in an industrial building.

Industrial smokehouse

Important! Whatever variation of smokehouse is present in your location, always follow safety precautions during installation and operation. A box of sand or a fire extinguisher located next to the installation will never be superfluous.

Advantages and disadvantages

Smokehouses made from wood have both positive and negative sides.

The advantages of such designs are much greater:

- availability of material;

- ease of processing of the material - a wooden structure can have any shape, size and even decorative finish;

- ease of repair - damaged fragments of a wooden smokehouse are easy to replace;

- the possibility of internal insulation of the smokehouse - you can use materials that do not emit harmful substances when heated;

- environmental friendliness;

- ergonomics.

Due to the ease of working with wood, smokehouses can be manufactured in various designs. If desired, you can make a design that fits perfectly into the landscape design.

A wooden smokehouse also has some disadvantages. They are associated with the characteristics of the material used. The disadvantages of wood smokehouses are as follows:

- Risk of fire - the tree can ignite, and the fire can spread to other structures, trees, dry grass. It is fair to say that fire occurs when the smokehouse is not used correctly.

- Sensitivity to changes in temperature and humidity. This drawback can be overcome by treating the smokehouse externally, but even without this technique the structure will last quite a long time.

Cold smoking at home. Smokehouse design

Regardless of the shape and dimensions of the box, the design features and necessary devices do not differ.

Design Features

A DIY home smokehouse should have sealed walls that do not emit harmful substances when heated. There must be a chimney in the roof of the structure to remove excess smoke. Access to the inside must be organized so that you can easily work with products (the door must cover the entire front part of the structure). The presence of a tray at the bottom of the smokehouse will make it easier to clean up the liquid that drains from the products, and the presence of all kinds of hooks, cross rods and mesh trays will ensure a rational arrangement of future smoked meats.

Smokehouse from the inside

Preparing products before cold smoking

Before you start smoking, you need to do some preparatory work. For vegetables and fruits, preparation involves washing and removing seeds and pits. For foods such as meat, poultry and fish, the preparation process is a little more complicated.

- Smoked meats. The main preparation consists of salting the workpiece. But depending on the fat content in a particular piece of meat, the salt concentration should differ. If you are preparing balyk, it is better to use wet salting (130 grams of salt per liter of water. Bring the concentrate to a boil, remove the noise and allow to cool). The reason why balyki are salted in this way is that meat without layers of fat dries out greatly during dry salting, and the wet version prevents the soft tissues from splitting and the product remains juicy when smoked. If you want to smoke balyk or lard, then dry salting is suitable, because salt cannot penetrate completely into the fat.

In both methods, the salted product must lie for two to 6 days, after which it is placed in clean water to soak for 1-3 days. Next, the meat is hung in a room with a temperature of 2-4 degrees, covered with gauze to prevent insects and left to dry for a period of 1 to 3 weeks. That's it, the product is completely ready for smoking.

Read also: Ultrasonic inspection of pipeline welds

Salted lard

- Preparing the bird. The carcass must be plucked, tarred, gutted and started salting. Prepare the brine by adding 100 grams of salt, two tablespoons of vinegar and spices to 1 liter of water. Submerge the bird in brine for three days. After brining, you need to dry the carcass with a towel and hang it for drying in a cool place for 3-4 days. After these procedures, you can start smoking.

Chicken carcass in brine

- Smoked fish. Fish must be handled with care; its gastronomic quality depends on the thoroughness of preparation. If you have freshly caught river fish, then you need to gut it, peel it and rub it generously with salt. The fish is kept in the salt crust for about three days (the time increases if the fish has been frozen). After salting, you need to hang the carcasses, covered with gauze, in a cool place and dry for one week (large specimens are split open with skewers in the belly area). Now the fish is ready for the cold smoking process.

Salted fish carcass

Note! The components of the brine or salt rub are selected depending on the taste preferences of the cook and can consist of a huge variety of spices and herbs, because you have the right to determine for yourself what to cook in the cold smoked smokehouse you created with your own hands.

Features of a home smokehouse

It’s not difficult to create a smokehouse with your own hands, although a lot depends on its type and dimensions. The simplest mobile mini smokehouses can be built literally in a matter of minutes and prepare a variety of dishes, unique in aroma and taste, which cannot be obtained even in megamarkets.

Smoking is a type of heat treatment; after prolonged fumigation, products acquire characteristic taste qualities.

The smoking method of processing has many advantages :

- smoke effectively destroys pathogenic microflora, making dishes not only healthy, but also safe for health;

- smoked meats retain important microelements to a greater extent, which are destroyed under the influence of too high temperatures;

- The shelf life of smoked products is much longer, because the smoke “preserves” them.

Did you know that the type of firewood used affects the taste of the finished smoked dish? After all, each type of wood burns differently and has an individual flavor. For example:

Alder. Ideal for the production of plant products and any meat.

Willow. It is better to take it for specific meat dishes (venison, wild boar, elk, bear meat). It is also suitable for smoking fish caught in swampy areas.

Oak. Suitable for cooking red meat, beef or pork.

Cherry. It is advisable to use this wood for smoking berries, nuts and vegetables.

When talking about how to create a smokehouse with your own hands, it is necessary to explain the methods of smoking. Namely, about different temperature conditions during cooking. They depend on the distance to the source of fire of the products. The most original and aromatic smoked products are obtained by cold smoking (it is carried out at +25⁰С - +45⁰С). The cold smoking procedure is lengthy and can take several days.

For the cold smoking method, products are prepared and processed in advance. And if stored for too long, the finished dishes may dry out a little, but without losing their declared qualities.

If you need to cook smoked meats very quickly, the ideal method would be hot smoking at a temperature of +50⁰С-+100⁰С. The readiness of the products is noted after 3-4 hours. But they must be consumed quickly, otherwise they may spoil during long-term storage.

Choosing wood chips for cold smoking

The raw material for the formation of the necessary smoke is wood shavings or wood chips. The main thing is that the material is not too fine in structure and does not have excessive dryness. Otherwise, the wood will burn intensely and give the food a burning taste. The optimal moisture level of wood chips is considered to be 65-70 percent; such a structure will create ideal conditions for creating smoke.

Types of wood suitable for smoking

Not all types of wood are suitable for smoked meats, because some species emit a specific odor and negatively affect the products. Ideal: cherry, sweet cherry, apricot, pear, apple, aspen, beech, alder, oak and ash. Coniferous species should not be used; they emit a large amount of resin.

Some manufacturers are engaged in the production of ready-made wood chips for smoking, but the main disadvantage is that the composition of the final raw material is unknown to the consumer. Unscrupulous manufacturers may add chemical elements to improve smoke production. To avoid unpleasant moments, you need to make wood chips yourself.

Store-bought wood chips

Making wood chips for cold smoking with your own hands

Wood should be collected from trimmings of fruit or deciduous trees that have not been pre-treated with chemicals. After collecting the branches, you need to completely remove the bark, and then chop the tree. To process it into shavings or chips, they use a special tool, like an electric planer, but you can also use an ax (it takes a lot of time). It is also necessary to take into account that the moisture content of the rock is always different, so it must be adjusted manually. If there is a lot of moisture, then it is necessary to dry the wood, and if there is little, then moisten it. The main thing is to remember that wood chips prepared for smoking yourself are environmentally friendly raw materials.

Features of connection and operation

There is no need to connect the device to a gas stove. The smokehouse is used and installed as follows:

- Wood chips are poured into the lower part of the device, where a special container is located. It should be lightly moistened with water beforehand, as wood chips that are too dry will quickly burn out. You should also not put wet wood - because of this, the smoke will be too acrid, and the process of cooking smoked meats will be delayed.

- A tray is installed inside the device into which the fat will drain, and covered with foil. It is not necessary to do this, but if you do not use foil, you will subsequently have to wash the baking sheet for a long time to remove the accumulated frozen fat.

- Prepared (salted, pickled and, if necessary, cut into pieces) products are placed on the grid or hooks: fish, lard, meat, chicken, sausages, sausages.

- A special container is filled with water to create a water seal for the smoke.

- Close the smokehouse lid, place the apparatus on the stove, and turn on the gas.

- Place the hose on the fitting located on the top cover and lead its end into the hood above the stove.

The smoke produced under the influence of high temperature envelops the products and gradually fills them with a characteristic smoked taste and aroma. As a source of smoke, shavings and branches of trees such as aspen, beech, oak, alder, and ash are used. Wood from fruit trees is also suitable, but it is better to avoid coniferous trees - they impart bitterness to the finished products and contribute to the appearance of black acrid smoke.

When cooking fish in a gas smokehouse, it should be taken into account that its meat has a delicate structure, so during the cooking process it can fall apart and become soft. To avoid this, you need to tie the carcass with twine or wrap it in a special film.

DIY cold smoked smokehouse. Video, photo instructions

The idea of making your own smokehouse has a lot of advantages. The main advantage is the unlimited possibilities in choosing dimensions, location and method of smoke generation. The device can be made for both outdoor and indoor use.

How to make a cold smoked smokehouse with your own hands

The process of constructing the structure will be outlined using the example of a stationary smokehouse in the courtyard of a private house.

Homemade cold smoked smokehouse with your own hands. Drawing

- You need to plan a place on the site for the future smokehouse. You will need approximately 1 meter wide and 4 meters long.

- Using a shovel, you need to dig a trench half a meter deep, 0.3 meters wide and the entire length of the planned area. At the beginning and end of the trench, you need to organize two pits with dimensions of 0.5x0.5x0.5 meters. The side on which the fire pit will be located should be lower in level than the opposite side, at least 20 centimeters. This is due to the fact that at this angle it will be easier for the smoke to reach the smokehouse itself.

Trench for the structure Now, the fire pit needs to be lined with fire bricks. The stone walls must be 10 centimeters above the ground so that the lid for the combustion chamber tightly covers the top. In the wall on the side of the smokehouse you need to make a hole for the pipe, the upper edge of which should be at a level of 5 cm from the top of the soil.

Fire Pit Time to put the chimney in the trench. The pipe can be used either asbestos or metal. The chimney should fit a couple of centimeters into the pit for the fire, and on the smokehouse side the pipe should have a 90-degree elbow in order to fit into the bottom of the structure in a horizontal position.

Photo of the chimney gasket. Now it’s time for the installation box itself. What shape and what materials it will be from is up to you to decide. Take the prepared box and place it over the smoke pipe so that it is in the center of the bottom. The legs of the structure must be securely fastened to the ground.

The smokehouse body is in place

Now you can hang hooks, place baking sheets and lay out products for smoking. Light the fire and expect delicious delicacies.

conclusions

A homemade cold-smoked smokehouse with your own hands (video + photo) will definitely expand your gastronomic horizons and help surprise your guests with delicious dishes of juicy chicken or gorgeous carp. Do not deny yourself pleasure and smoke for your health.

Given the high prices and dubious quality of industrially produced smoked meats, many are thinking about preparing their own sausages, hams and hams. To implement this idea, you will need a home cold smoked smokehouse.

Basic smokehouse structure

There are two main types of devices: made of wood or metal. Wooden ones are built using standard technology for small buildings with one amendment: it is necessary to use ONLY deciduous wood without a pronounced odor. Oak, walnut, and maple are considered optimal. Boards made of pear, elm, and beech are also suitable.

The simplest device for a homemade cold smoked smokehouse includes:

- smoke generator - a place where the fire is lit and from where the smoke enters the container with food;

- smoke channel - a pipe or hermetically sealed box through which smoke flows from the smoke generator into the chamber with a temperature loss of up to 20...25 degrees Celsius;

- smoking chamber - a hermetically sealed container in which smoked products are located.

To obtain the required temperature of smoke in the smokehouse, it is important to maintain the experience-tested dimensions of the device: at least 1.5 m from the smoke generator to the chamber, at least 1.5 m from the bottom point of the chamber to its ceiling (products are suspended at different levels, depending on the required temperature smoking and sizes).

A do-it-yourself cold smoked smokehouse can be made from:

- bricks or concrete blocks. In the firebox, the brick must be fire-resistant; you can use natural stone with appropriate properties (granite, basalt);

- metal - a pipe is mainly made from it, sometimes a smoking chamber;

- wood (hardwood) - only for the smoking chamber.

Required tools and materials

To make a smokehouse from wood, you should choose non-resinous species. It could be:

As a material for a wooden smokehouse, you can use plywood (minimum thickness 8 mm), planed boards, bars, lining, block house. The selected material should be treated with a special antiseptic.

For the manufacture of a wooden smokehouse, materials that consist of several layers and are impregnated with an adhesive composition are not suitable. The selected wood should also have a minimum of knots.

In addition to the selected wood, other materials and tools will be needed to make a smokehouse:

- wood hacksaw;

- hammer and nails or screwdriver and screws;

- screwdriver;

- door hinges;

- chimney pipe;

- thermometer;

- metal tray for collecting fat;

- gratings for products or fittings for their production;

- hooks for hanging products;

- metal corners or wooden blocks as guides for the pallet and gratings;

- roofing material – the roof can be covered with slate or profile;

- bricks or blocks for the firebox and smokehouse base;

- cement, sand, crushed stone for the foundation;

- for sealing joints - tow, moisture-resistant sealant.

Design in detail

When planning cold smoking at home, it is important to understand in detail the design of the smokehouse.

Below is a version of the drawings of a cold smoked smokehouse with your own hands (without specifying materials, the design is suitable for both wooden and metal chambers).

In this version of the device, the smoking channel is made as a box rather than a pipe. For it, you can use boards with mandatory sealing, metal sheets or bricks.

Read also: Large stapler how to change staples

Stage-by-stage execution of work

- Preparing the base. The soil is selected to a depth of 60...80 mm. The dimensions of the recess must be at least 50x50 cm, the dimensions depend on the required performance of the smoke generator. For a chamber with a volume of 100...150 liters, a firebox of 60x60x80 cm is sufficient; for larger volumes, the dimensions are calculated individually. A place is also prepared for laying the smoke channel and smoking chamber: a strip of soil is selected that is 20...30% wider than the planned cross-section of the channel and a rectangle (circle) with dimensions that is 20...30% larger than the dimensions of the chamber. A cushion of crushed stone with a fraction of 20...40 mm, a thickness of 5...7 cm, is placed on top of a compacted sand cushion with a thickness of 2..3 cm. For weak soils and high groundwater, you can additionally “spill” the cushion with a weak cement mortar using the technology described in the feature article .

- Pouring the base of the firebox with reinforced concrete (optional). If the smoke duct is made of a pipe, it must be laid before pouring concrete.

- Laying the firebox with refractory bricks (if you plan to use firewood) or installing a homemade or industrial smoke generator.

- Smoke duct installation. If a pipe is used, it is fixed with bricks, blocks or concrete screed. In addition to maintaining the desired position, this measure allows you to speed up the cooling of the smoke. When laying a channel with bricks or boards, mandatory sealing with natural sealants is required.

- Installation of the smoking chamber. This part of the structure must be sealed, have a chimney and a door for placing products and removing them. Additionally, shelves or hangers are arranged in one or several tiers; a tray is mounted below to drain fat from smoked meats. For convenience, you can attach a canopy to the chamber where firewood will be stored in the future.

- Installation of a lid over the firebox.

When placing a tray in the lower part of the smoking chamber, it is important not to completely block the smoke exit from the smoke channel and at the same time make the walls of the chamber as dense as possible and non-conductive of heat.

The diagram of a cold smoked smokehouse from a barrel or a refrigerator with your own hands differs only in the design of the smoking chamber - the remaining parts retain their purpose and dimensions.

The principles of assembling such a device are discussed in the video clip.

The presence of lattice shelves in the refrigerator, on which you can place products for smoking, is convenient; the plastic trim inside is questionable. The best option for a refrigerator for home smoking is the old ZIL type, with metal walls inside. You can line the inside of the body with wooden planks.

The construction of a barrel smokehouse is even simpler - a metal or wooden barrel with a door or a removable lid cut into the side surface is used as a chamber for processing products. Shelves and tiers of suspensions are made in the same way as for a wooden or brick chamber.

The barrel can be positioned vertically or horizontally.

Smokehouse in the form of a house with a pitched roof

Stationary and portable smokehouse

If the smokehouse will be used regularly throughout the year, it is advisable to choose a permanent, capital-type structure. As a base for the house, you can use supports made of brick, pipes or timber. It is advisable to choose materials that are resistant to natural factors. The supports themselves are left as is, sheathed or used as the basis for a small cabinet. The box can be used to store smoking equipment, firewood, and various small items needed in the household.

If a portable model is chosen, it should be made compact, lightweight and collapsible with grooves, hinges and locks. To make the hut look good, the pitched roof is made solid, and the exhaust pipe is attached to the back or side. This will not affect the quality of the drying process. The flooring itself is made of thick boards with grooves that fit tightly together. As a decorative element, you can cover the roof with copper tiles. It weighs a little and looks appropriate.

Schemes, drawings and dimensions

The dimensions of the firebox and chamber are selected based on the volume of food that is planned to be dried at the same time. If the owners expect to smoke fish, meat and vegetables occasionally, at picnics or before entertaining guests, a small box with a volume of 30-50 liters is sufficient. It should be borne in mind that the food will not be prepared in a few hours.

To prepare large batches of pickles, you need to build chambers with a volume of 100 liters or more. To create the required quantity and concentration of smoke, a lot of firewood will be required, which means effort, time and money.

The owner can easily design a smokehouse and make a drawing on his own; there is nothing complicated here, the calculations are simple, errors are acceptable. To save time, you can use ready-made projects, which, after implementation, have proven themselves well in practice.

Necessary materials

The list of materials for construction is small:

- pipes for chimneys with a diameter of 100 mm;

- planed boards 20-30 mm thick;

- beam 40-50 mm;

- accessories - handles, hinges, thermometer;

- self-tapping screws;

- roofing;

- metal grill;

- wire for hooks;

- pallet of their iron.

To make the smoking chamber, you should use wood that does not contain resins:

- cedar;

- oak;

- alder;

- Linden;

- birch;

- aspen.

Waterproof plywood is suitable as an alternative.

When buying boards, you need to pay attention that they do not have knots. Over time, they shrink and fall out. You should categorically avoid chipboards. When heated, they release harmful substances and soon delaminate.

Tools for building a smokehouse

The master will need the following tools:

- hacksaw;

- jigsaw;

- drill;

- screwdriver;

- level;

- roulette;

- square;

- pencil.

It is mandatory to use protective glasses and gloves.

Homemade smoke generator for cold smoked smokehouse

The abundance of options for industrial smoke generators, with and without compressors, does not stop the imagination of craftsmen who invent new devices for producing smoke.

There are two main types of smoke generator for a DIY cold-smoked smokehouse: using wood chips or “liquid smoke.” In the first case, a metal or brick (made of refractory brick) chamber is used, in which a fire is lit at the bottom, just above the level of the fire there is an opening for air intake (blower). The device requires additional air injection through a flexible hose and pipe directed into the smoke channel. Air flow can be ensured using any pump of suitable power.

The design of such a smoke generator is presented in more detail in the drawing.

An interesting option with a dosed supply of wood chips into the combustion zone and gradual removal of ash was proposed by K. Nedosekov.

The electrical circuit provides for a different device: it requires heating the liquid to a given temperature and there is no open combustion.

To move smoke from the generator into the smoking chamber, a forced-air fan mounted in the smoke duct is used.

More traditional (and efficient) industrial smoke generators are designed with a smoke filter and temperature control.

A homemade adaptation of such a generator with an ordinary glass jar as a filter is shown in the photo below.

Chimney design features

When building smokehouses with your own hands, an extremely important step is making the chimney. Let us remind you that it is better not to use brick for its arrangement - its porous walls will actively absorb substances released during combustion and, over time, the products will absorb unpleasant odors.

The best material for a chimney is metal.

But remember that a metal chimney will have to be regularly cleaned to remove soot and soot. There is also the option of arranging a chimney directly in the ground - the soil cools the smoke well naturally (which is especially important for cold smoking) and actively absorbs condensate, and the microorganisms contained in the soil clean the smoke from carcinogens.

An earth chimney is made like this:

- A suitable site with a slope is found (you can do it yourself by adding a layer of earth).

- The combustion chamber of the smoking apparatus is located directly under the slope.

- A ditch is dug on an earthen slope - it will become the future earthen chimney.

- The ditch is covered on top with metal plates. An additional layer of earth is placed on top of them to ensure good thermal insulation. The earthen chimney is brought to the chamber of the smoking unit.

Alternative smokehouse options

In addition to the independent device, there are a number of combined smoking devices.

In this version, a compact mobile smokehouse is combined with a barbecue, and the process of smoking and cooking food on coals can be carried out simultaneously.

Here, in addition to a wood-burning stove with smoke escaping into the smoking chamber, there is a tandoor.

And here is a full-fledged complex for preparing almost any food - from porridge and soups stewed in a Russian oven to kebabs and smoked sausage.

Additional accessories

The cold smoking process takes - depending on the preparation of the products and the size of the pieces - from 8 hours to 7...12 days. In this case, it is necessary to constantly maintain a uniform smoke temperature and, accordingly, control the burning of wood chips or the operation of the smoke generator. For this, thermostats are used. They are mounted on the facade of the smoking chamber so that the metal pin that senses the temperature is located inside a hermetically sealed space.

In industrial products, the thermometer, as a rule, is already built into the lid or wall; in home-made products, you have to install it yourself.

Preparing products for smoking

Since cold smoking is carried out at a low smoke temperature (20...30 degrees Celsius), no heat treatment of the product occurs. Therefore, to prevent the development of harmful microorganisms, it is recommended:

- cut up products or package them in portions that are as close in size and weight as possible;

- use raw materials with a high fat content - salmon fish, lard, brisket, fatty pork and poultry, sausages with lard;

- pre-soak the cut products in salt and/or cook (stew, fry);

- After initial processing, dry the pulp in a drying chamber or in the open air (a smoking room without smoke supply, but with constant forced ventilation, can be used as a drying chamber).

Below is a standard diagram for industrial smoking of fish.

For home conditions, you don’t have to adhere to the technological process so strictly; just follow the basic conditions:

- the prepared product is rubbed or sprinkled with salt at the rate of 15...40 g per kilogram of raw materials (the amount depends on the smoking technology, the type of product and the required shelf life) and is kept in its own juice for at least 5 days. For frozen raw materials, the salting period increases by 20...100%. It is possible to add saltpeter (25 g/1 kg of salt);

- in recipes with a high salt content, soaking is required for 1...4 days; for low-salt options, rinsing is sufficient;

- drying (drying) in a well-ventilated area with a temperature of 18...20 degrees Celsius until the juice flow stops completely.

When smoking, it is important to consider the type of wood from which the wood chips are made.

Features of preparing different products

- Lard for smoking is chosen to be tender, with a thin skin or without skin. The salt is first scraped off from the salted food and washed in lukewarm water.

- Poultry and rabbit are smoked by cutting the carcass along the spine. Preliminary salting is carried out in a marinade with the addition of spices according to the recipe.

- Small game (waterfowl, upland) can be smoked only if the integrity of the skin is preserved and proper plucking (flaying) is done. Keeping the product “ready” in a cool, dry room after smoking for 8…12 days helps to bring it to readiness. In this case, the game is stored for up to six months.

- It is advisable to tie large pieces of lard, meat, fish, sausage with twine before smoking; fish are smoked with spacers in the belly.