Smoked lard, fish or meat are delicacies beloved by many. Excellent aromatic smoked meats, prepared without chemical additives, will always be on the table if you set up a cold smoked smokehouse with your own hands in your garden or summer cottage. A suitable design option can be selected in this article.

Dear readers, we also recommend reading excellent articles on our website on how to make a cellar with your own hands - detailed instructions with drawings and photos. And also in the DIY foundation section, you will find varieties for any of your buildings.

Cold smoking process: features

The preservative properties of smoke have been known for a long time, but today this is not the most important thing that attracts people in smoked products. An appetizing smell and unique taste - this is what is achieved when smoking meat, fish products, cheese and even fruits. During the process of cold smoking, the semi-finished product is saturated with aromatic substances that are released during the combustion of wood raw materials. The best are sawdust from fruit trees - apple, pear, plum, apricot. Of the wild ones, alder and oak give an excellent smell.

Cold smoking involves prolonged exposure to smoke at a temperature of 30-50°C for several days. In this mode, the products are evenly saturated with aromatic substances and finally ripened.

What kind of firewood can you use?

Firewood from different types of trees

Not all firewood can be used. Firewood from the following trees is best suited:

- plum;

- cherry (without bark);

- pear;

- Apple tree;

- dogwood;

- apricot.

If you need to give smoked meats a tart taste, then the following are suitable:

- elm;

- oak;

- nut;

- beech.

For smoking fish caught in heavily polluted waters, it is recommended to use the following wood:

- willow;

- broom;

- willow.

If there is no firewood from fruit trees or if the smokehouse is made in camping conditions, the following trees can be used:

- Linden;

- poplar;

- alder;

- aspen.

Coniferous trees and those affected by fungus are unsuitable for smoking. In addition, since the pores of the fungus are easily carried by the wind, all trees located within a radius of 50 m around the infected tree automatically become unusable.

Stationary smokehouse: how to make, device

If the area and topography of the site allow, you can build a stationary cold smoked smokehouse. The design consists of a smoking chamber connected to the firebox through a chimney. The area should have a slight slope to ensure natural smoke draft.

Camera

The chamber is made of wood or metal, equipped with a tight-fitting door and a pipe for removing smoke. You can build a smokehouse out of clay bricks, installing the structure on a solid foundation.

The chamber is placed in such a way that there is a height difference between it and the firebox. Due to the pressure difference, a natural draft is created, causing the smoke to move upward.

Firebox

The firebox is made of masonry heat-resistant materials or metal. For periodic cleaning, it is equipped with an ash pan with a door. The smoke supply is regulated by a damper. As a rule, when igniting it is kept closed so as not to spoil the product with the first caustic combustion products.

Chimney design

The purpose of this important design element is to precipitate tars and other carcinogenic substances contained in smoke, as well as to reduce the smoking temperature. The longer the chimney, the more efficiently the flue gases are burned and purified from combustion products.

The design consists of a pipe 2 or more meters long. It is made of metal, and more often a tunnel is simply dug into the ground. Soot and condensation settle on soil particles, and soil bacteria do an excellent job of removing carcinogenic waste.

Important. Unlike metal surfaces, soil does not need to be cleaned. The smoke, passing through the channel, maintains the optimal temperature for smoking.

A natural slope is selected on the site, a chamber is installed at the top, and a firebox is organized below. A groove is dug for the chimney, covered with sheets of metal and covered with earth. The cold smoked smokehouse with your own hands is ready, you can carry out tests.

Chimney in the ground

Homemade smoke generator for smokehouse

If it is not possible to place a full-fledged firebox and a long smoke channel on the site, a smoke generator will be useful to produce smoke. This compact device does not require much space, and the structure can be made from available materials - an old fire extinguisher, a tin can, a piece of large-diameter pipe. You will also need thinner pipes for the chimney, a compressor (can be an aquarium compressor), a fitting, and a container for collecting condensate.

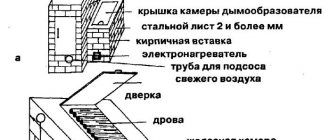

The simplest smoke generator consists of the following elements:

- the housing where woodchips smolder without air access;

- chimney;

- cooling system.

At the bottom of the container there is a grate for wood chips, the space under it is used to accumulate ash. The air required for combustion is accessed through the lower opening with a damper.

Smoke generator device

Important. If you make the grate removable and equip the bottom of the smoke generator with a lid, it will be easier to clean the surfaces from ash and soot.

The device is connected to the chimney via a pipe. To regulate the supply of smoke, an ejector is provided in the form of a movable tube inserted into the pipe.

The sawdust is placed in a container and ignited through the bottom valve. The smoke, passing through the tube, is partially cleaned and fed into the smoking chamber. The movement of gases is activated by a compressor.

Video - DIY cold smoked smoke generator

Smokehouse from the refrigerator: step-by-step instructions

An old household cooler that you have long wanted to get rid of can get a “second life” and benefit the owner. This is an almost ready-made smoking chamber, which already has shelves for food and a tightly closing door.

Setting up a cold smoked smokehouse from a refrigerator will not be difficult for the home craftsman. You will need:

- 2 steel pipes - one for the chimney, the other for smoke removal;

- firebox or smoke generator;

- bricks or blocks for the foundation;

- refrigerator, better than the Soviet model with metal inner lining.

Newer generation refrigerators can also be used. It is recommended to remove the plastic insides, leaving only the metal. You will need hooks and racks to hang or display food. Old accessories will come in handy in Soviet coolers.

Stages of making a smokehouse from a refrigerator:

- Prepare the unit - drain the freon, remove the plastic casing, secure the devices for hanging hooks and installing grilles.

- To collect draining fat, make a metal tray with legs.

- Cut a hole in the bottom of the refrigerator for the chimney. It should be inserted as tightly as possible.

- Make an outlet hole for the chimney in the upper part of the chamber.

- On a level area, lay a foundation of bricks or blocks or secure a strong stand.

- Install the refrigerator on a pedestal to create the required height difference.

- Connect the smokehouse using a pipe to the firebox or smoke generator.

- Conduct a test run.

To regulate the supply of smoke and the intensity of draft, the chimney is equipped with dampers or valves. In a similar way, you can build a cold smoked smokehouse from a barrel, steel box or large diameter pipe.

Smokehouse from a gas cylinder: step-by-step instructions

Surely the thrifty owner will have an old gas cylinder for oxygen, carbon dioxide or propane in his bins. Having the skills to work with metal, you can build an economical version of a cold smoked smokehouse from a gas cylinder.

Universal design from gas cylinders

You will need 2 gas cylinders - one larger, the other smaller, steel pipes with a diameter of 80-100 mm, handles for lids, grates, maybe from a barbecue. To work you need a tool: a welding machine, a device for cutting metal. A place for the smokehouse is first equipped and the supporting frame is welded.

Oxygen or carbon dioxide containers are not dangerous. It is enough to bleed off the remaining gas. The propane cylinder needs to be prepared: after emptying the explosive substance, unscrew the valve and fill it with water. If the metal flask is old, the valve can be carefully cut off with a hacksaw. To avoid sparks, water the cut area with water.

The procedure for carrying out work on the manufacture of a smokehouse:

- Fill the containers with water and let stand for 1-2 days. Drain the solution

- Cut holes for the chimney at the ends of 2 cylinders.

- In a container intended for burning sawdust, cut a hole for the damper (of any shape). Cut a hole in the smoking cylinder for the exhaust pipe.

- Make several cuts in the body for the lid, weld the hinges and then cut it off to the end. Install handles.

- Make the lid of the second cylinder in the same way.

- Weld the connecting and exhaust pipe. Install dampers.

- Secure the supports for the grates inside the smoking chamber.

- Equip the smokehouse with a thermometer and paint the structure any color you wish.

Making a smokehouse from gas cylinders

This smokehouse is universal. With some modifications it can be used as a barbecue or grill.

Advantages and disadvantages

Smokehouses made from wood have both positive and negative sides.

The advantages of such designs are much greater:

- availability of material;

- ease of processing of the material - a wooden structure can have any shape, size and even decorative finish;

- ease of repair - damaged fragments of a wooden smokehouse are easy to replace;

- the possibility of internal insulation of the smokehouse - you can use materials that do not emit harmful substances when heated;

- environmental friendliness;

- ergonomics.

Due to the ease of working with wood, smokehouses can be manufactured in various designs. If desired, you can make a design that fits perfectly into the landscape design.

A wooden smokehouse also has some disadvantages. They are associated with the characteristics of the material used. The disadvantages of wood smokehouses are as follows:

- Risk of fire - the tree can ignite, and the fire can spread to other structures, trees, dry grass. It is fair to say that fire occurs when the smokehouse is not used correctly.

- Sensitivity to changes in temperature and humidity. This drawback can be overcome by treating the smokehouse externally, but even without this technique the structure will last quite a long time.

Brick smokehouse

A cold smoked smokehouse made of brick is a strong, reliable structure, the construction of which requires the skills of a mason. You can build a universal option for hot smoking or grilling food.

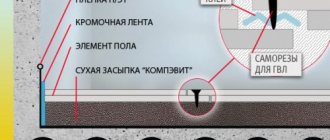

Before construction begins, a location on the site is selected and the foundation is prepared. A special feature of a brick smokehouse is the internal chimney. Smoke from smoldering wood chips enters the channels and shafts, cools and fills the smoking chamber. For masonry, only fire-resistant materials are used.

The drawing of a cold smoked smokehouse made of brick gives a visual representation of how fire can be used for 2 types of product processing at once - a smoking chamber at the bottom, a brazier at the top.

Materials and tools you will need:

- refractory brick, clay, water;

- doors, dampers, grates and hooks for food, grate, lid;

- shovel, bucket, spatula, building level, string.

The masonry is carried out in order. The seams are tightly filled with mortar and rubbed to ensure airtightness. A chimney is formed inside the structure so that natural draft stimulates the movement of heated gases in a certain direction.

Brick smokehouse laying

At the top of the firebox there is a metal tray for heating sawdust. The speed of smoke passage and temperature are regulated by dampers fixed in the gaps of the channels. Around the ash pit, a thermal insulation zone is arranged in the masonry, into which small river pebbles are poured.

Important. The structure can be decorated with various materials - facing tiles, brick, plaster. Such a smokehouse will become a decoration and “highlight” of the site.

Varieties

The most common are 2 options for smokehouses with their own design features:

- Vertical (shaft). The easiest to manufacture, taking up little space. The smokehouse looks like a kind of cone; products are located on its top. The disadvantages include inconvenient adjustment of the smoke volume.

- Horizontal (tunnel) . More difficult to produce, requiring a suitable site, preferably on a slope.

Tips for use

A cold smoked smokehouse at home is convenient and practical. But when using the device you must follow the safety rules:

- avoid contact with flammable materials;

- do not touch hot surfaces with an unprotected hand;

- do not install the structure on an unstable base;

- do not allow water to get into the electrical wiring and the smoke generator compressor;

- do not use sawdust with traces of paint, varnish, or impregnation;

- do not leave small children unattended around;

- do not install the smokehouse near a residential building to prevent smoke;

- control the temperature to prevent overheating;

- Do not process products that have expired.

Smokehouse at a safe distance from home

The chimney and chamber must be periodically cleaned of carbon deposits, and the grates and hooks must be washed with detergents. When the smokehouse is not working, it is advisable to leave it slightly open for ventilation.

Important. Before consumption, finished smoked meats are kept in a draft for 1-2 days to remove any remaining smoke.

Food preparation

Lard, game, fish or meat are prepared in a certain way before smoking, since the products are processed with smoke at low temperatures. Smoking has preservative properties and extends shelf life, but this does not happen immediately, but gradually. To prevent the delicacy from spoiling during a long process, pre-salting is required.

Salting fish before smoking

Cut the lard into pieces 7-15 cm, soak in a marinade of water, salt and spices. The brine must be concentrated so that the raw egg floats. Keep in the refrigerator. After 3-5 days, remove the lard, dry it and put it in a smokehouse for further processing for 1-2 days at a temperature of 30°C.

The fish must first be gutted and washed. Place in a bowl, sprinkle generously with salt. After 2-3 days, remove, rinse thoroughly in running water and soak for 1-2 days. Then the fish should be allowed to air well in a draft until it is semi-moist. The time depends on the size and structure of the pulp. Smoke for 2 days at a temperature of 30-40°C.

Meat is salted dry, wet or a combination. Keep in the refrigerator under pressure from 5-7 days to 2-3 weeks. Then the semi-finished product is dried for about 5 days in a draft and sent to smoke for 2-3 days.

Review of the most popular models

The best option is to do something in between, for example, build a smoking container yourself, but buy a generator.

Merkel

Here it is quite justified to remember about. German quality and assembly guarantees the longevity of the device. Moreover, the manufacturer offers an extended factory warranty.

Smoke generator "Merkel": delivery set

The budget model will cost about 3.5 thousand rubles.

"Bradley-Smoker"

And if you are planning a large party or are engaged in individual production of smoked meats on a small scale, then you can pay attention to the Canadian one.

Eclectic smoke cabinet with automatic smoke supply "Bradley-Smoker"

The electric smokehouses of this company are fully automated. A person just needs to set the necessary parameters, and the system will do the rest itself: from choosing the smoke generation option to the temperature, and will give a signal after the task is completed.

Preparing firewood

The taste and smell of the final product largely depends on the composition of the wood chips. A variety of ready-made raw materials for smoking are sold in stores, but you can prepare firewood yourself.

If work is being done in the garden to form crowns and trim fruit trees, there is no need to rush to throw away branches and twigs. After drying well, they are crushed and used for their intended purpose. Smoked meats acquire a particularly appetizing aroma from apple tree shavings.

The wood chips must be dry and clean

Grapevines are often used for smoking and cooking barbecue in the Caucasus. The smoke from the smoldering vine gives the delicacy a delicate fruity taste and golden color. In summer cottages and garden plots in the more northern zone, this heat-loving crop is also quite common. With annual pruning, a lot of unnecessary branches remain, which can be dried, crushed and used in a mixture with sawdust.

To add spicy notes, sprigs of juniper, rowan, and acacia are added to the wood chips. They not only enrich the product with a bright aroma, but also additionally have a bactericidal effect.

Important. Do not use wood chips from coniferous trees. It imparts bitterness to the smoke due to its high resin content.