As the popular saying goes: “Taste and color have no comrade!” Many people are proud of having built a huge multi-story mansion for themselves, and then complain about the hard work of maintaining it, about the need to climb stairs to the second or third floor. Of course, a two-story house looks larger and has a more practical design - with almost the same foundation and roof, you get 2 floors at once. Children are incredibly happy about several floors: the internal staircase is like in the movies, the specificity of the attic floors and much more attracts people when choosing the configuration of the building.

However, it is also worth thinking about real everyday things. The additional area of the house is not always used for practical purposes. At the same time, the cost of such a building increases significantly. Maintenance is difficult due to the number of floors in the building; more money is spent on heating and lighting all rooms. This is why many people choose one-story houses

for yourself and your family. They can be used both for permanent suburban and city living, and for country holidays with the whole family. Moreover, these one-story buildings have a number of significant advantages during construction and maintenance.

On this page we will tell you about all the advantages and disadvantages, features and specifics of one-story frame house projects.

A little history of one-story frame houses

This type of construction has a very rich history. Back in the 10th and 11th centuries, Europeans began to become acquainted with construction innovations such as the one-story frame house

. Its widespread use was due to the low cost of materials during construction, which led to a reduction in its cost in the end. At the same time, the speed of construction and available materials for insulation made them very popular among all segments of the population. After all, it could be insulated with the cheapest material: moss, sawdust, clay, straw, lime and manure, which did not change their attractive appearance.

In various countries, one-story frame houses could be recognized from afar by their distinctive external structure. For example, in the Czech Republic and Germany, crossed dark beams stand out perfectly against the light background of the wall - the so-called fachwerk. Different types of wood were used, making the finishing of the house with beams exquisite and unique, thanks to the natural color of the wood. Meeting art monuments on the streets of European cities. you can clearly verify the preserved strength and reliable construction, which once again confirms the strength of the frame structure.

Improvement of projects of one-story frame houses occurs in the USA and Canada in the post-war period of the last century. Companies sought high quality, savings, efficiency and comfortable living in such houses.

For Russia, the development of frame technology for the time being was not widely popularized due to the underdevelopment of the construction of individual housing and the banal shortage of high-quality building materials. The last century for our country was marked rather by the era of concrete panel housing; projects of one-story frame houses were simply not needed. Now, with the development of the market for modern building materials and the introduction of new technologies, the construction of frame houses in Russia has become widely popular.

Basic materials and tools used in the construction process

- Screw piles;

- Rockwool 1.5 cm for roof insulation;

- Boards 150x50 m;

- Antiseptic for treating all wooden coatings Senezh red ognebio;

- Rough nails 90 mm;

- Screw nails 50-60 mm;

- Sheathing paint;

- Metal tiles;

- Film for the facade and vapor barrier of the house;

- Windows and doors;

- Drywall;

- Workers from a construction company were hired to install the façade;

- OSB 18.3 mm (subfloor) and 9 mm (wall and roof cladding);

- Foam plastic for subfloor;

Features of various technologies for building one-story houses

Due to the least risk of injury, one-story houses are excellent for people who, due to age or health reasons, find it difficult to move, and families with children, because they do not have dangerous areas in the form of stairs or places where you can fall over the railings and endanger the health of a small child .

Projects of one-story frame houses

and construction in general depends on the purpose: permanent residence or seasonal option. Depending on this, the approximate budget for the event will be determined. In terms of cost, turnkey one-story frame houses are cheaper than their brick or block counterparts. In particular, insulation of this type of building is cheaper than the purchase of bricks, its transportation and the masonry work itself. After all, the construction of a brick building requires not only brick, but also other materials. However, in Russian conditions, brick does not retain heat sufficiently, so such buildings are additionally insulated, which significantly increases their cost compared to frame structures.

At the same time, one-story houses using different frame technologies may have different technical characteristics and design solutions. It is these differences that are the keys between several subtypes of construction technologies, which will be discussed further.

Frame wall cladding

External cladding was used with 9 mm OSB sheets, this is sufficient to provide the necessary rigidity. The bottom sheets were installed from the ground, and sometimes homemade sawhorses were used, and scaffolding was used to install the top sheets. The sheets were fastened using screw nails 50-60 mm long at a distance of 1.5 cm.

Tip: In order not to constantly count the required gap between the OSB sheets, you need to install two nails into the frame posts and place the sheet on top. Thus, a gap of the required size, 3 mm, is obtained.

After covering, we painted the edges to prevent them from swelling due to rain.

Tip: OSB sheets are an excellent wind barrier, but you should still be careful about minimal waterproofing to prevent the material from swelling.

The facade was wrapped with windproof film, and doors purchased in advance were installed.

Canadian houses

Canadian technology is based on the fact that the construction of a one-story house is carried out using special moisture-resistant slabs. Mineral wool is placed between them for insulation.

This allows this design not to allow moisture to pass through and not to let air out. In other words - a thermos. This approach allows the house to stay cool in the summer and warm in the winter.

However, this leads to minor difficulties. A one-story frame house built using Canadian technology must be equipped with a powerful ventilation system to prevent moisture from accumulating between the walls and the insulation. Constant circulation of indoor air should be maintained to ventilate the premises.

Also, a disadvantage of Canadian technology in particular and the use of OSB boards in general is the need for ideal drying of structural wood, otherwise the insufficient vapor permeability of such boards and sandwich panels in general can lead to the appearance of fungus, wood rot and degradation of the insulation. So the construction of Canadian houses in our Russian reality is possible only with reservations, at your own peril and risk.

Installation of frame walls

Tip: Wood for building walls should be chosen with no more than 15% humidity.

They assembled and raised the walls quite quickly. We decided to assemble the frame walls in a horizontal position on the prepared floor, since there is a possibility of encountering the problem of inaccurate calculations in the drawings.

The future walls of the house were assembled right on the floor. It is necessary to take into account that the slab must overlap the upper and lower frames by at least 5 cm, so the stand height should be selected from 2.6 meters.

When the installation of the walls is completed, it is recommended to check their level using a cord; this can be done as follows: pull the cord from one corner to the other. If there are still deviations, the walls must be pressed in from the side from which it is necessary to align. After final leveling of the walls, the jibs should be nailed.

Note: In order not to waste valuable time on leveling walls and filing posts of different lengths, you should carefully measure everything several times.

Glulam beams were used for the floors. They can withstand higher loads, which makes it possible to increase the pitch between the lags. Spacers were inserted between the floor joists.

Advantages and disadvantages of one-story frame house projects

At the moment, humanity has not come up with an even more advanced technology for building a residential building. But even with all the variety of advantages, the frame technology for constructing a one-story house also has its disadvantages. Even if we take the ratio of price and operating costs or price and quality, then frame technology is much better than its competitors. But still, to each their own.

Main advantages:

- Cheap construction. One-story frame houses are much more affordable than any other construction technology. This is why they are so common throughout the world;

- Short construction time;

- Relatively lower maintenance costs for such a house;

- The materials in the frame panels have low thermal conductivity, which will reduce heating costs in cold weather;

- Excellent sound insulation of rooms and the house as a whole;

- Communications can be laid inside the wall;

- This technology allows the use of a lightweight foundation due to its relatively low specific weight;

- High safety for nature and human health. The materials in the house materials do not emit harmful substances when exposed to high temperatures;

- An ideal microclimate is created in the premises thanks to wooden structures inside the frame base.

Flaws:

- The construction of the walls has a high “ringing” due to its small mass, which does not allow the house to reduce vibrations from sound;

- Competent construction of a frame house is associated with a carefully planned project. This technology is relatively complex in design and construction and requires specialists to have excellent knowledge and practical experience;

- In Russia, they are prejudiced against these designs. That is why very often on the Internet you can read shocking information about how a one-story frame house was blown away by the wind or the like.

Interior arrangement

Interior partitions are constructed in various ways:

- Installation of sheathing made of metal profiles and subsequent covering with plasterboard, plywood or OSB;

- Frame made of bars, finished with wooden boards, panels, lining.

- The thickness of the internal walls is less than the external ones, so the bars are chosen of the appropriate size, not forgetting the thickness of the sheathing material.

Instead of insulation, sound insulation is used; the use of moisture and vapor protection is not required.

Specificity of all projects of frame one-story houses

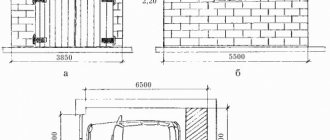

All one-story houses using frame technology have similar features. They have a fairly simple design. Often such buildings have a rectangular or square shape. It is very rare to find attached terraces and verandas in the designs of such houses. The presence of bay windows is almost completely eliminated. Due to this, such buildings have high reliability when subjected to heavy seismic loads or extreme weather conditions.

One-story frame houses for permanent residence

usually have the simplest layout. The entire common space is divided into rooms and an area for spending time together. The customer can choose the space for any needs, for example, the hostess can determine the dimensions for the kitchen herself. The bathroom is designed separately. In principle, all frame buildings are similar in design, their uniqueness lies in the methods of finishing and color design.

In conclusion, I would like to say about how to choose a project. On the websites of many construction companies you can find ready-made projects of one-story frame houses. Our company is no exception. On this page, everyone can choose a ready-made design and order the construction of a house they like on their site.

By calling our contact number you can order a consultation with our specialist and ask any questions about the provision of services. We are very happy for every client and look forward to feedback and suggestions to our email address.

Window installation

Windows, like doors, were installed after wrapping the façade of the house with film. No cutouts were made in advance for window and door openings. The following technology was used: the film must be carefully cut and the ends bent inside the opening, secured with a stapler. Next, insert the window block level and foam the seams. After the polyurethane foam has dried, carefully remove the excess. This eliminates the possibility of moisture getting between the opening and the window frame.