We will also consider problems and malfunctions that may arise during operation of the device, errors and methods for eliminating them. St. Petersburg Bumazhnaya st. Protherm Skat 12 kW Electric boiler The delivery package of the Protherm Skat boiler includes detailed instructions that not only describe the equipment settings, but also give recommendations for installation and commissioning of the unit. What is cheaper to heat? I installed 4 boilers!

Any malfunctions are indicated on the display by an error code.

F85 means the temperature drops to 3 degrees and water freezes.

Outdoor temperature sensor for Protherm SKAT boilers In the retail network, its cost varies around rubles to 38 euros.

Load regulator relay. So, on the front, front part of the boiler there is a digital display with control buttons and indications: The interface itself is very clear and it is very easy to understand the settings.

Author: admin In addition to homemade electric boilers, in my practice I also have to connect factory-made boilers, both domestic and imported, such as the Protherm boiler.

Electric boiler connection diagram. Connecting an electric boiler

Boiler malfunctions

Page 37

- Image

- Text

37

Boiler malfunctions

Code

Description of the malfunction

F.00

Open circuit NTC flow sensor

– a malfunction is indicated if the NTC sensor circuit is broken. Contact an authorized service center.

F.10

Short circuit NTC flow sensor

– a fault is indicated in the event of a short circuit of the NTC sensor. Contact an authorized service center.

F.13

Short circuit NTC boiler sensor

– a fault is indicated on the boiler display in the event of a short circuit in the boiler NTC sensor. Contact an authorized service center.

F.19

Outside temperature sensor short circuit

– a fault is indicated in the event of a short circuit in the outside temperature sensor; – the boiler continues to operate in normal heating mode (without equithermal regulation). Contact an authorized service center.

F.20

Boiler overheating

– a malfunction is indicated if the emergency thermostat is triggered as a result of boiler overheating. Contact an authorized service center.

F.22

Low coolant pressure in the heating system

– a malfunction is indicated if the water pressure in the heating system drops below 0.6 bar; – the message will be automatically deleted after the coolant pressure in the heating system increases above 0.6 bar as a result of recharging the heating system.

F.41

Stuck relay

– this message will appear if the boiler fails to “unstick” the relay. Contact an authorized service center.

F.55

Contactor or relay stuck

– if error F.55 appears on the display, disconnect the boiler from the power supply and call an authorized service center.

F.63

EEPROM memory error

– this message will appear if there are problems with the data in the EEPROM memory. Contact an authorized service center.

F.73

Short circuit (signal - GND) or open circuit of the sensor

pressure

– a message will appear in the event of a short circuit (signal - GND) or an open circuit of the pressure sensor. Contact an authorized service center.

Post navigation

But, given the fact that the average price per kilowatt in Russia is 4.5 rubles, the heating season lasts seven months, the amount will be substantial. The control panel is equipped with a function for storing parameters and adjusting the boiler power.

Liquid fuel. In this case, a gas double-circuit boiler is a more preferable option, since water heating for hot water supply and heating occurs in one device, and connecting additional devices is not required.

The cable cross-section, the power of circuit breakers and RCDs must be selected taking into account the power of the boiler and circulation pump. Operating instructions for Proterm electric boilers Using an electric Proterm heating boiler to heat rooms for various purposes is not so difficult, because the regulation and control system for an electric boiler is quite simple.

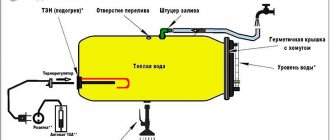

There are four heating elements in the heat exchanger with a power of 7 kW each. Automation allows the use of an electric boiler in conjunction with a load relay.

Code Description of fault F….

Page 38

- Image

- Text

38

Code

Description of the malfunction

F.74

Short circuit (signal - +5 V) pressure sensor

– this message will appear in the event of a short circuit (signal - +5 V) or an open circuit of the pressure sensor.

F.85

Boiler freezing

– this message will appear if the coolant temperature drops below 3°C – the message will be automatically deleted if the coolant temperature rises above 4°C

F.86

Water freezing in the boiler

– this message will appear if the water temperature in the boiler drops below 3°C; – the message will be automatically deleted after the water temperature in the boiler rises above 4°C

Advantages and disadvantages of Proterm Skat boilers

Most of these disadvantages and advantages are inherent in most boilers operating on electricity.

Pros of Protherm Skat boilers

- High efficiency

- Easy to install

- Unpretentious in maintenance

- Eco-friendly

- Doesn't require much space

- Silent operation

Disadvantages of Skat series boilers

- High cost of electricity

- Dependence on power outages

Sometimes electric boilers are credited with shortcomings that are no longer relevant or were obviously incorrect; let’s look at some of them:

The boiler power is not enough to heat a house larger than 300 m2

This statement is incorrect, due to the fact that Skat boilers can be connected in a cascade to increase the heated area, if there is a shortage of 28 kW.

Frequent replacement of the heating element

Due to the fact that the heating medium is heated using a heating element, many believe that such a heating element will not last long, but you need to take into account the quality of the heating element itself and do not forget that it is not water that circulates in the system, but a coolant.

Vailant group Slovakia, spol. s.r.o.Pplk. Plush,...

Page 40

- Image

- Text

Vailant group Slovakia, spol. s.r.o. Pplk. Plusta, 45 909 01 Skalica Slovak Republic

www.protherm-ru.ru

Your service:

With the right to change

Comments

Tell me what the tap icon with a drop means

Alexander 10/30/2020 13:58 GMT

The boiler does not heat, F does not blink. And 22 what to do

Vasily 01/24/2021 15:08 GMT

Tell me why, after turning off the boiler, the protection is triggered... and when you turn it on again, the error pops up F20 ??? And so almost constantly... until you press the button under the rubber band...

Mikhail 02/19/2021 18:54 GMT

Select → I found the instructions for my water heater here! #manualza

- Click →

In the instructions for the iron: - Do not iron clothes on the body.

Manualza!manualza.ru

Still not with us?

Electric boiler for home heating Protherm

March 08, 2012 News, Expert advice, Home electrical, Home electric heating

In addition to homemade electric boilers , in my practice I also have to connect factory-made boilers, both domestic and imported, such as the Protherm boiler .

This is the brand of electric boilers I want to tell you about.

The price category for such electric boilers is quite high, about 20 thousand rubles. depending on the power there are plus or minus several thousand.

the electric boiler Protherm Skat 14K impressed me in practice .

Boilers are made in Slovakia, in the city of Skalica.

It is made of very high quality and soundly, all parts are mounted very compactly and at the same time accessible for maintenance.

It is clear that manufacturers have puzzled over the internal structure of the electric boiler a lot.

All electrical wires and connections to them are also of very high quality, and almost all the internal contents of the electric boiler, from manufacturers of leading companies in the world, are at the highest level of quality.

To be honest, it’s nice to look at; a professional can immediately determine the high reliability of the operation of such a boiler, even from the component parts.

So, on the front, front part of the boiler there is a digital display with control buttons and indication:

The interface itself is very clear and it’s very easy to understand the settings.

How to connect a boiler to a boiler? Connection options and diagramsHow does the DHW function work in heating system boilers?

For example, you have one boiler in your heating system and you need to make sure that you also heat water with this boiler for hot water supply.

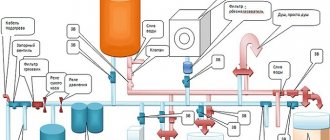

What methods are there for heating water through a boiler?

We will look at 5 schemes and tell you how each scheme works. Let's consider the advantages and disadvantages of each scheme.

Scheme of work No. 1.

Dull coolant intake from the boiler

Do not use a blunt water intake from the boiler!

This is a very uneconomical hot water system if the boiler temperature does not exceed 60 degrees.

Well, firstly, the boiler temperature can be set to 50 degrees. At this temperature, you will not be able to heat the water in the boiler above 48 degrees. Secondly, heating will take a very long time, since heat transfer drops significantly if the temperature of the water and coolant do not differ greatly. That is, to quickly warm up, you need to use a high temperature difference. 90-60=30 degrees. Because of this, indirect heating coil boilers use an increased coolant temperature.

There are indirect heating boilers, tank in tank.

This method uses a large heat exchanger area upon contact (coolant-DHW).

Such boilers have a much higher heating rate than a snake. This is achieved by increasing the contact area (coolant-DHW). And also due to the fact that the heat transfer limit is increased. Such a boiler increases the intake of more power due to the preservation of the coolant in the boiler, which has an inertial nature of maintaining temperature. Due to this, the very cooled coolant is immediately taken from the external tank. This process accelerates the extraction of thermal power to heat water. In this case, you can use the boiler, provided that the boiler temperature is 60 degrees or more. If the boiler temperature remains at 40-50 degrees, then you will have a low temperature in the boiler.

I would like to draw your attention to the accumulation of hot water. If you have heated water in the tank at 45 degrees, then you, for example, will have 10 minutes to wash with normal water in the shower. If your boiler temperature is 90 degrees, then you will be able to use the shower for more than 60 minutes. That is, by increasing the temperature, you increase the accumulation of hot water in the boiler with the same capacity. That is, the volume of hot water use will increase.

If you are not satisfied with the temperature change in the boiler, which changes over time and you have to reconfigure the mixer. Then there are special thermostatic valves for domestic hot water. They are called thermostatic mixing three-way valve.

This scheme allows you to always obtain a stable temperature at the outlet for DHW consumption

Work scheme No. 2.

Crutch method. We increase the boiler temperature.

According to this scheme, we simply set the boiler temperature, for example, 80 degrees, and the heating system will receive, for example, 60 degrees. By mixing through a three-way valve with cooled coolant backflow, the set temperature will be achieved.

I can't say how good this method is. On the one hand, they say that the boiler efficiency becomes higher if the coolant temperature is 60-80 degrees. This is due to the fact that at such temperatures chemical combustion is better and the gas burns better. That is, at low temperatures the gas does not burn out. That is, particles of combustible material do not completely release thermal energy. But for condensing boilers this efficiency rule does not work. There they specially lower the temperature of the coolant to 55-45 degrees.

On the other hand, high temperatures increase scale in heat exchangers and pipes, which in the future can lead to a decrease in power and failure of the boiler due to overheating. Also, build-up appears more often on steel pipes with high-temperature coolant. That is, steel pipes become overgrown.

What's wrong with this scheme?

It becomes bad compared to other DHW connection schemes. Well, for example, in some boilers there is weather-dependent regulation - equithermal mode. Also, when there is a need to turn off the boiler for heating and keep it running on DHW (automatically), it is problematic to do so. Because there are boilers with a function to turn off the heating using the room thermostat, but the DHW function remains working.

Work scheme No. 3.

Buy a ready-made double-circuit boiler and do not use a DHW boiler

Such a double-circuit boiler has an additional heat exchanger for domestic hot water inside the boiler. That is, the first-main heat exchanger is for transferring heat from the burning gas to the coolant.

Cold water passes through a plate heat exchanger under the pressure of the water supply system. There is a flow sensor on the DHW water supply pipe line. The flow sensor triggers a cascade of actions: Switches the three-way valve to redirect the flow towards the plate heat exchanger, and also increases the temperature of the coolant due to an increase in gas in the heater. That is, during DHW preparation, the heating circuit is switched off. And the movement of coolant through radiators and heated floors is turned off. During DHW, the coolant inside the boiler begins to circulate water through the DHW heat exchanger.

What does a double-circuit boiler with isolated circuits mean?

This is when the water supply circuit and the heating circuit do not interact in liquid. That is, liquids do not mix and liquids do not transmit pressure. Only temperature is transferred from one liquid to another liquid.

Water passing through a plate heat exchanger quickly heats up, usually to a maximum of 60 degrees. This temperature in some boilers is regulated only up to a threshold of 60 degrees. That is, the temperature cannot be raised above 60 degrees. This temperature is usually programmed and cannot be changed. Check with the manufacturer. Also in the passports are instructions for use.

Such a scheme with such a boiler is not suitable for high productivity. That is, it is problematic to service two or three appliances (sink, bath, shower). There's just not enough power. If you want to service several sanitary appliances (sink, bath, shower) you will have to install a storage tank. Making a storage tank for such a boiler is problematic. Next, we will consider schemes with hot water storage tanks.

Disadvantage of receiving hot water?

The hot water temperature will not be stable when the flow rate through the heat exchanger changes. There will be fluctuations in hot water temperatures. Practice has shown that with high flow rates, water may not heat up to the required 60 degrees. It happens that it doesn’t reach 45 degrees. Well, it depends on the power of the boiler and its response speed. Of course, in my practice I have come across boilers that respond well to heating water. The problem is that you have to wait for the water to become hotter due to the fact that the boiler takes a long time to think when it will switch to heating the water.

Also, such a boiler does not allow DHW recirculation.

What is DHW recirculation and how to calculate it?

Work scheme No. 4.

DHW accumulation through an indirect heating boiler.

Electrical diagram for connecting DHW to the boiler

The passport instructions must indicate the electrical diagram. Usually they indicate the letter marking and, having opened the boiler lid, you need to look for the letter marking for the DHW in the electrical board. In some passports in the electrical diagram they may be called DHW or boiler thermostat or something else. It rarely happens that they will draw a board to scale and show where the contacts are.

How can the electrical diagram of a boiler be indicated:

Sometimes there may be more than two contacts for DHW. Again this is done for greater functionality.

Also pay attention to whether there are contacts for pumps. There may be a contact for the pump to the DHW boiler.

Sometimes the boiler can use additional terminals for additional functions for your heating system. For example, you have a pump and it needs to be turned off when the boiler is turned off. That is, it is necessary to create a fully automatic system so that the client does not fool himself with additional operations. That is, if you turn off the boiler, then everything related to heating should turn off automatically.

Usually you need to take two conductors from the boiler and lead it to the thermostat on the boiler relay:

The boiler has two DHW conductors that can have a simple alternating voltage of 220 volts. But this should always be checked, perhaps there is a reduced voltage there. And you cannot run 220 volts independently from the sockets and connect them to the hot water supply line from the boiler. It is assumed that the DHW boiler contact comes to a dry contact to the boiler thermostat or to another short circuit contact. A boiler thermostat is an electrical relay that changes contact positions depending on the temperature of the water in the boiler.

Also, the boiler may have more than two conductors for DHW. For example, you may need a constant voltage of 220 Volts to power pumps, etc. The electrical circuit of the boiler may contain special conductors to control the three-way valve. This is again done for better functionality. If you turn off the boiler, then everything connected to the boiler should turn off along with the boiler.

An indirect heating boiler may have a larger circuit with all sorts of additional functions, for example, to illuminate lights indicating the operation of the boiler and much more.

But you need to understand the scheme in a simple way. And here's what you need to understand:

Almost all indirect heating boilers use a changeover contact and can be used as a dry contact. A switching mechanism that transfers contact from one conductor to another. Thus, we must connect the DHW function from the boiler to this contact. And the boiler will do the rest itself: Switch the three-way valve, which is built into the boiler. And it will add temperature to quickly heat the water in the boiler. Some sophisticated boilers may have timer protection when the boiler heats up in time beyond what is reasonable. In this case, the heating system may freeze. This may occur due to the failure of the boiler thermostat. Or due to the fact that the temperature on the thermostat is set higher than the boiler produces, and the boiler can never heat up to the set value.

But the schemes are different, and it happens that a pump needs to be installed on an indirect heating boiler. And the boiler does not have the ability to power the pump to the boiler. There is a connection diagram for this.

Contactor

– an electromagnetic relay that switches the contact due to another signal - a voltage of 220 Volts.

It may be possible to use the DHW contact to immediately give a command to the DHW and power the circulation pump. Check with the manufacturer or read the instructions for use. Also look for an electrical diagram for connecting the boiler to the boiler.

If you want help developing a connection diagram and selecting the necessary elements, you can ask for help. But I’ll say right away that it’s not free.

Order a service for developing an electrical and piping diagram

Scheme of work No. 5.

Accumulation of hot water through an indirect heating boiler in a single-circuit boiler

Many plumbers may be mistaken in the fact that if the boiler is single-circuit, then it does not have a DHW function.

However, single-circuit boilers with DHW function exist!

Moreover, some boilers will even prepare contacts for you to connect a three-way valve to redirect the coolant flow towards the indirect heating boiler. Connecting the pump to the boiler and much more!

This method is suitable for those who want to assemble a heating system themselves and come up with their own methods for an automatic system. That is, if the above schemes do not suit you, then you can take a single-circuit boiler with a DHW function and add any scheme convenient for you with three-way valves and pumps. For example:

The three-way valve is used only to redirect the coolant flow towards the indirect heating boiler.

Schemes can be different and if other schemes are not indicated, this does not mean that there are no other schemes!!! The electrical circuit of the electric drive for the three-way valve may be different. With priority to a constant voltage of 220 Volts and one control signal.

This circuit is shown with external electrical wiring. Boilers may have terminals designed to connect a three-way valve. You can also take 220 Volts from the boiler from the circuit for the pump and run it to the boiler thermostat and three-way valve. This will disable the entire DHW function when the boiler is not working. This is necessary for those who love automation or want to isolate the client from additional unnecessary processes of turning the system on and off. Let your clients live more peacefully. If the client turns off the boiler, then make sure that when the boiler is turned off, all systems and equipment are turned off.

There are, of course, many valves and many different signals for the operation of heating system circuits.

You have the opportunity to seek help in developing an electrical and piping diagram. The necessary material will also be selected for your system, including your boiler. There are ways to simulate other functions according to your operating logic: Apply for a development service: Order a service for developing an electrical and piping diagram

Conclusion on the most worthy scheme for using hot water supply

Schemes 4 and 5 are the highest priority schemes for the preparation of hot water from boiler equipment!

Advantages of schemes 4-5:

1. Fast heating of hot water. By increasing the boiler temperature. This happens automatically. That is, the system operates at one temperature, and when the DHW function is turned on, the temperature rises to 90 degrees.

2. Many expensive wall-mounted boilers use weather-dependent regulation. It is also called the equithermal mode of operation of the boiler. That is, the coolant temperature changes depending on the weather outside. Therefore, such a boiler combined with domestic hot water is the best solution. Because you are unlikely to be able to do such functionality with the DHW function with a boiler or circuit without DHW.

Disadvantage 4-5:

This is a heating shutdown when the hot water supply is running. But it's not so scary. Because some sophisticated boilers have protection against heating shutdowns caused by long warm-up of the hot water supply. The DHW function simply turns off after a certain time to turn on the heating of the house.

Subscribe to receive new articles. There is a form below, just enter your Name and E-mail and confirm your subscription. And you will receive useful articles.

| Like |

| Share |

| Comments (+) [ Read / Add ] |

A series of video tutorials on a private house

Part 1. Where to drill a well?

Part 2. Construction of a water well Part 3. Laying a pipeline from the well to the house Part 4. Automatic water supply Water supply Water

supply for a private house.

Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Water supply pumping station How to choose a pump for a well? Setting up a pressure switch Pressure switch electrical diagram Operating principle of a hydraulic accumulator Sewage slope of 1 meter SNIP Connecting a heated towel rail DHW recirculation diagram - the best solution! Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of radial distribution of a heating system Scheme with a heat pump and a solid fuel boiler - operating logic Three-way valve from Valtec + thermal head with remote sensor Why the heating radiator does not heat well in an apartment building How to connect a boiler to a boiler?

Options and connection diagrams DHW recirculation. Principle of operation and calculation You are not correctly calculating the hydraulic needle and collectors. Manual hydraulic calculation of heating. Calculation of a warm water floor and mixing units. Three-way valve with a servo drive for DHW. Calculation of DHW, BKN. We find the volume, power of the snake, warm-up time, etc. Water supply and heating designer

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servos and three-way valves work Three-way valve to redirect the movement of coolant

Heating

Calculation of the thermal power of heating radiators Radiator section Overgrowth and deposits in pipes worsen the performance of the water supply and heating system New pumps work differently... Calculation infiltration Calculation of temperature in an unheated room Calculation of a floor based on the ground Calculation of a heat accumulator Calculation of a heat accumulator for a solid fuel boiler Calculation of a heat accumulator for storing thermal energy Where to connect the expansion tank in the heating system?

Boiler resistance Tichelman loop pipe diameter How to choose the diameter of a pipe for heating Heat transfer of a pipe Gravity heating from a polypropylene pipe Why don’t they like single-pipe heating? How to love her? Smart selection of diameters in a heating system Balancing heating radiators - a step-by-step guide Top 5 problems in designing heating systems Heat regulators

Room thermostat - operating principle

Mixing unit

What is a mixing unit?

Types of mixing units for heating Characteristics and parameters of systems

Local hydraulic resistance.

What is KMS? Bandwidth Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, Du and PN? Plumbers and engineers must know these parameters! Hydraulic meanings, concepts and calculation of heating system circuits. Flow coefficient in a single-pipe heating system. Hydraulic paradox in a heating system. Riddle No. 4 Video

Heating Automatic temperature control Simple replenishment of the heating system Heat engineering.

Walling. Warm water floor Combimix pump mixing unit Why choose underfloor heating? Water heated floor VALTEC. Video seminar Pipe for heated floors - what to choose? Warm water floor - theory, advantages and disadvantages Laying warm water floor - theory and rules Warm floors in a wooden house. Dry heated floor. Warm water floor cake - theory and calculation News for plumbers and engineers Plumbers Are you still doing hack work? The first results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - wall orientation? Regulatory documents

Regulatory requirements for the design of boiler houses Abbreviations

Terms and definitions

Basement, basement, floor Boiler houses

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial contamination of water Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building ?

Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms classified according to their location? Personal experiences in hydraulics and heating engineering

Introduction and introduction.

Part 1 Hydraulic resistance of a thermostatic valve Hydraulic resistance of a filter flask Video course Calculation programs

Technotronic8 - Program for hydraulic and thermal calculations Auto-Snab 3D - Hydraulic calculation in three-dimensional space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Problems in hydraulic calculations

Pressure loss along a straight section of a pipe How does head loss affect flow?

Miscellaneous

Do-it-yourself water supply for a private house Autonomous water supply Scheme of autonomous water supply Scheme of automatic water supply Scheme of water supply for a private house

Privacy Policy

Reviews

- Andrey G. “I built a house, winter is just around the corner, I need something to heat it. I wandered around the Internet, read reviews, and decided to buy a boiler from the Slovak company Proterm. I chose the wall option based on the area of the house. The boiler with the beautiful name Cheetah model 23 MTV was the best choice. Well what can I say? It is controlled very simply with three buttons. The instructions are very clear and explain everything in detail. It makes a little noise, but it doesn't interfere with falling asleep. Very compact. Maintenance is very simple - just occasionally clean the dirt filter and wipe the dust from the boiler. It performs its functions without any problems. I didn't notice any shortcomings. I recommend".

- Vasily V. “I decided to change my old gas water heater. And since in severe frosts there is often not enough heat from the stove, I decided to install a modern gas boiler with the ability to heat water. The choice was determined only by price. I took an inexpensive Jaguar 11 JTV from Proterm. The boiler turned out to be surprisingly silent, with a beautiful design. In 2 years it has never broken down. There are no shortcomings."

- Vladimir U. “I have been working for 11 years in a service center servicing heating boilers, including gas ones. During this time, we had to install and repair all types of boilers from all companies that are sold in our stores. I can’t say anything bad about Proterm gas boilers. With proper installation and proper configuration, they work like a clock. But if the service specialists have neither the skills nor the experience, or the owners adjusted something on their own, then problems in the work and, as a result, bad reviews are inevitable.”

At what thickness of scale should boilers be cleaned?

Requirements for scale thickness in boilers are regulated by various governing documents.

Thus, there is RD 10-165-97 - Guidelines for the supervision of the water chemistry regime of steam and hot water boilers. P. 2.5. The document states: “For boilers with a steam capacity of less than 0.7 t/h, the period between cleanings should be such that the thickness of deposits on the most heat-stressed areas of the heating surfaces of the boiler does not exceed 0.5 mm by the time it is stopped for cleaning.”

The same figures are contained in PB 10-574-03 Rules for the design and safe operation of steam and hot water boilers.

Distinctive features

By installing a Proterm double-circuit gas boiler in your home, you will become the owner of a real home boiler room, which, in addition to standard functions, will provide your household with hot water.

Listed below are the main distinctive features of the Proterm line of gas boilers:

- efficiency, ease of operation;

- a large selection of models - by price, power, functionality, protection capabilities;

- the price-quality ratio is one of the best among manufacturers of similar equipment;

- high efficiency (more than 90%);

- Models with a built-in boiler are available.

Important! Proterm gas boilers are adapted for Russian conditions - they can function normally even with low gas or water pressure in the mains.

Gas boilers produced by Proterm will not disappoint you during operation and will meet your wildest expectations.

Connection and operation instructions

When installing and connecting equipment, you must use protective equipment and follow safety regulations

When choosing an installation location, pay attention to:

- For the dryness of a specific place and the room as a whole.

- Structures that could easily catch fire should be kept away.

- Devices must not be installed in such a way that they interfere with access to emergency exits.

- Large household electrical appliances cannot be located nearby. This is especially true for air conditioners.

- Installation is strictly prohibited where there is a possibility of water and other liquids getting into the boiler.

You must also follow the rules:

- To protect the boiler and users, grounding must be done.

- It is necessary to take into account the weight of the equipment and select appropriate fastenings when installing wall structures.

- When installing additional modules, you must strictly follow the attached instructions.

- When installing the wiring on the electrical panel, separate circuit breakers are installed to power the boiler.

- Heating pipes must be laid so that there are no distortions.

Introduction

- Image

- Text

4

You have become the owner of a direct-flow electric boiler designed for central heating systems, with the ability to regulate thermal comfort. We hope that the Skat electric boiler will serve you for a long time and reliably. When installing and servicing it, certain rules must be followed. Therefore, we ask you to carefully read the contents of this maintenance manual and, when working with the boiler, act in accordance with the recommendations and instructions contained in it. We believe that the SKAT electric boiler will help you create a pleasant atmosphere and optimal thermal comfort in your home.

Please pay attention to the following main points:

1.

The boiler, together with its associated equipment, must be installed and used in accordance with the design documentation, relevant laws and technical regulations in force, as well as the manufacturer's instructions.

2. The boiler should only be installed in

premises specially designed for this purpose.

3. Putting the boiler into operation after it

installations can only be carried out

a specialist from a specialized organization certified by Protherm.

4.

The boiler complies with the requirements of standards and regulatory documents in force in the Russian Federation, which is confirmed by the Certificate of Conformity issued by the authorized body, Permit for Use from the Federal Service for Environmental, Technological and Nuclear Supervision.

5.

In case of any malfunctions, contact only a specialized service organization - non-professional

Introduction

intervention may affect the equipment warranty.

6.

An employee of a service organization who puts the boiler into operation is obliged to familiarize the user with safety precautions when servicing equipment and controlling the operation of the boiler; operations that the user has the right to carry out independently and operations that only a qualified specialist from a service organization has the right to carry out. If the specified service organization is also the supplier of the boiler, it is obliged to ensure the safety of the original packaging of the boiler in case of its possible transportation.

7. Check integrity and completeness

supplies.

8. Make sure that the type supplied to you

boiler according to its input parameters (indicated on the nameplate), is suitable for operation in this region. By input parameters we mean: voltage of the electrical network.

9. In the case when you do not have a specific

Confidence in the correctness of your boiler maintenance actions, find and carefully study the relevant instructions and recommendations contained in this maintenance manual, and act exclusively in accordance with them.

10.

Do not remove or damage the markings or inscriptions on the boiler.

In case of possible transportation, keep the original packaging of the boiler intact until the boiler is put into operation.

11.

For repairs, use only original spare parts. It is prohibited to interfere with the internal structure of the boiler or make any changes to its design.

12.

In case of prolonged shutdown of the boiler, it is recommended to empty it and disconnect it from the electrical network. This recommendation is given taking into account the general

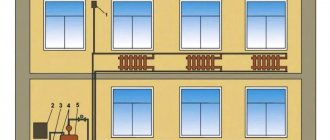

Installation of Proterm Skat boilers in a cascade

If a 28 kW boiler is not enough to heat the house, it is possible to install the Slopes in a cascade to increase the coverage of the heating area. When two boilers are connected in a cascade, the second boiler is controlled using a room thermostat, which is connected to the first boiler. This diagram will look like this:

Cascade connection of Proterm Skat boilers

The contacts of the room thermostat are connected to terminals 1 and 2 located on connector K8 of the main boiler, and terminals 9 and 10 of the main boiler are connected to terminals 1 and 2 of the slave boiler.

Only the Proterm Skat 28 kW and Proterm Skat 24 kW boilers can operate in cascade mode.

Heating scheme for a cottage with a solid fuel and electric boiler as a backup.

For many decades, most people in search of comfort consciously strove to big cities, now everything has changed - residents run as far as possible from multi-story anthills, choose secluded places with untouched nature and build houses far from civilization. A person approaches the arrangement of a country house more consciously than the renovation of a city apartment. The construction of a country residence is not only about choosing the color of wallpaper and laminate, but about creating life support systems from scratch: sewerage, heating, hot water systems. Already at the stage of designing a house, it is necessary to decide on the heating system: which boiler to install, where to lay the pipes, whether to connect heated floors, which radiators to choose, or simply limit yourself to convectors.

Criterias of choice

Boilers with cast iron parts last longer than steel ones.

When choosing heating equipment, several basic requirements are taken into account:

- Power is the main indicator of heating equipment. The manufacturer indicates the area for which its products are designed. When choosing a dual-circuit model, an additional 30-40% of power is provided.

- Fuel type – natural gas is the most convenient and economical heating option. If it is unavailable, electricity and solid fuel are considered.

- Purpose - the number of circuits depends on the requirements for the equipment - one is enough to heat the premises, and with two you can use hot water.

- Placement option - equipment can be wall or floor mounted. The choice depends on the available space in the room.

- Gas pressure - this parameter is important to ensure uninterrupted operation of the boiler.

- Heat exchanger material – cast iron elements last longer than steel parts.

- Type of ignition - piezo ignition is possible without electricity, but more gas is consumed. Electronic ignition is volatile.

When choosing equipment, the reputation of the manufacturer plays an important role. The Proterm company is one of the most respected and well-known companies producing thermal equipment.

Why does the pressure in the device increase?

A rise in pressure is an extremely dangerous situation, fraught with mechanical failure and even an explosion.

The liquid is incompressible; it fills the entire volume of the pipelines. If the pressure on the pressure gauge approaches 3 mbar and continues to rise, it’s time to take action.

One of the reasons is the failure of the expansion tank. When heated, the liquid expands and its volume increases by 4%.

A normally functioning expansion tank absorbs this excess interest, but if it is already full, the excess liquid simply has nowhere to go. This situation can be determined by the state of the relief valve - heating agents will constantly ooze out of it.

The main failure of the expansion tank is a rupture of the membrane. With it, water fills the tank completely, leaving no room to accommodate the expanded liquid. The solution would be to replace the membrane or the entire expansion tank.

Another possible reason is that the supply valve is not closed or has failed. Water continues to flow into the system, increasing the pressure.

It is necessary to check the condition of the tap and turn it off or replace it. You should check the condition of all shut-off valves and clean the strainer. There may also be problems with the boiler automation, which can only be resolved with the help of a specialist from the service center.

Model range of Protherm boilers - single-circuit and double-circuit

Gas equipment Proterm is produced by a European manufacturer in several modifications, which allows you to choose the model that is optimal in terms of functionality, as well as practical and most convenient to use.

Wall type

Wall-mounted gas equipment has undeniable advantages, including compact size, external aesthetics, excellent performance properties, the ability to adapt to operation with different energy carriers through a standard replacement of the nozzle, as well as cost-effectiveness.

- "Panther". Inexpensive model with two heat exchangers for space heating and water heating. A modern heating device with the ability to operate in a closed system. It has reliable protection against freezing, automatic shutdown of gas supply and control of pump operation.

Inexpensive heating device option in the Protherm line

- "Jaguar". A budget option for equipment that does not have a winter/summer mode. Double-circuit unit with a closed combustion chamber and control via handles.

A simple model with the minimum required set of functions

- "Cheetah". Double-circuit turbocharged boiler with a power of 11–23 kW and a closed combustion chamber. Even low-power models can heat 10–11 liters of water in one minute. A wall-mounted device in which the movement of the coolant is forced.

Turbocharged boiler with high efficiency

- "Tiger". It features a neat appearance, an informative LCD display and very simple controls. It is possible to program it for different operating modes or operate in automatic “comfort” mode. It is possible to automatically regulate the combustion process and is distinguished by a special ignition system.

Compact equipment with different operating modes

Main characteristics of the boiler

Floor type

Floor-standing single-circuit and double-circuit boilers have several advantages that make this type of equipment in demand among consumers. It is impossible to ignore high performance indicators, maximum thermal efficiency, economical fuel consumption, wide functionality and guaranteed durability.

- "Bear". A high-quality cast iron heat exchanger makes the unit durable and very reliable. The model has a “Winter-Summer” mode and convenient traction control. It has automatic regulation of the combustion process and is distinguished by a special ignition system.

The cast iron heat exchanger ensures long-term operation of the boiler

- "Buffalo". Easy to use and durable boiler with high efficiency, capable of operating on different types of fuel. A very powerful unit with a high degree of reliability.

Powerful equipment that can operate on different types of fuel

Main characteristics of the Bison model

Floor-standing boiler with a reliable heat exchanger

Main characteristics of the model

Stationary heating gas boiler

Main characteristics of the model Bear KLOM17

Classification by installation method

Floor-standing boilers require a separate room with ventilation and a window.

Based on design features, Proterm products are divided into 2 lines: wall-mounted and floor-mounted. Modifications differ not only in the installation method, but also in power, size, and installation requirements.

Wall mounted

Compact wall-mounted models are marked with the names of felines: Cheetah, Lynx, Panther, Tiger, Leopard. They are intended for installation in private houses and apartments. The equipment does not require a separate room. It can be placed in the bathroom or kitchen. Single-circuit and double-circuit models can be supplemented with a boiler. The units are equipped with an expansion tank and have an informative display.

Floor-standing

Installations for floor placement are characterized by high power and significant weight. They are made of steel or cast iron. The models have a wide power range - 12-150 kW. The series includes Bear, Bison and Wolf versions.

When installed, a separate foundation is poured under the boiler, so the equipment is recommended for private houses. The unit requires a lot of space; this criterion is taken into account when choosing a model.