The main purpose of fiber cement boards is cladding facades. Despite the fact that the material appeared on the domestic market relatively recently, it has already gained wide popularity due to its high performance characteristics, long service life, ease of installation and maintenance.

This review will examine the features of the technological process for the production of fiber cement panels, their technical characteristics, advantages and disadvantages, and will also pay special attention to installation technology. In addition, in the relevant sections of the article you can find useful information about leading manufacturers and reviews from customers who have assessed in practice the advantages and disadvantages of this facing material.

What are fiber cement panels

Fiber cement board is a durable and moisture-resistant composite material made from a cement-sand mixture, reinforcing cellulose fibers and special additives. In addition to cellulose, reinforcing fibers can be made from the following materials:

- Acrylic;

- Polypropylene;

- Basalt;

- Nylon;

- Polyamide;

- Polyester.

Reinforcement options are determined by the manufacturer depending on the purpose and specific operating conditions.

The dry mixture for the manufacture of fiber cement boards contains 80% cement, the remaining components account for 20%. This ratio ensures high strength and long service life of the material.

The decorative properties of the facade slab allow you to realize any design solutions. A wide range of colors and a large number of textures allow you to imitate:

- Brickwork;

- Broken brick;

- Natural stone;

- Ceramic tiles;

- Wooden panels, etc.

From exposure to ultraviolet radiation and atmospheric precipitation, the decorative layer is coated with a special protective composition, which not only prevents fading, but also ensures ease of cleaning of the panels. The back surface of the slab is treated with hydrophobic impregnation, which significantly reduces the moisture absorption of the material.

Application area

The scope of application of panels is incredibly wide. Typically, they are used for cladding:

- utility buildings;

- residential premises;

- production complexes;

- public structures;

- decorative structures;

- office buildings;

By the way, they are perfect for a bathhouse, or rather, for its cladding, say, made of foam blocks.

I would like to note that the material is often used as a heat-, noise- and moisture-proofing material. It is also used as a windproof and surface leveling material.

How are fiber cement facade panels made?

The technology for manufacturing fiber cement facing materials was developed in Japan. Currently, this material is produced in most European countries, and Russia is no exception.

Let us immediately note the fact that the production of high-quality fiber cement boards using a homemade method is impossible: special expensive equipment, large production areas, laboratories, warehouses, etc. are required.

The technological process for the production of facing material includes several stages:

- At the first stage, the cellulose included in the boards is separated into individual fibers, thoroughly cleaned and stored in a special container. After this, the purified fibers enter the hopper, where they are mixed with the other components.

- In a special drum, all the necessary ingredients (sand, cement, cellulose fibers, plasticizers and other additives) are thoroughly mixed. A strictly defined amount of water is added to the resulting dry mixture and kneaded until the required consistency and homogeneity of the mixture is obtained.

- The mixture obtained in this way is pressed in special forms, due to which excess moisture is eliminated, the structure of the material is compacted and the required texture is ensured.

- The next stage is the processing of the resulting semi-finished products in an autoclave chamber, where the final hardening of the panels occurs at a temperature of 170 - 1800C. In addition to high temperature, the sheets are processed with saturated steam under high pressure. It is the effect of saturated steam that ensures the formation of calcium hydrosilicate. The presence of this element in the structure of the slabs significantly increases their strength and durability.

- At the final stage of the technological process, hydrophobic, decorative and protective coatings are applied, which significantly reduce moisture absorption and increase resistance to weathering and temperature changes.

The fiber cement boards obtained in this way are either stored in special hangars or immediately sent to retail outlets or to the customer.

Konoshima – new generation products

Another leader in the Japanese market, which has been manufacturing fiber cement panels for almost 30 years, is Konoshima.

Each product of this brand is distinguished by the presence of a nanoceramic coating and is made of organic fiber, silicate materials and coal raw materials.

Konoshima nanoceramic coating allows you to protect the facade from weather, sun and dirt; it is presented in the form of an ultra-thin layer based on titanium oxide molecules, which are responsible for the self-cleaning of products. The coating is resistant to chemicals, anti-corrosion, and does not spoil the appearance of the products, as it is invisible.

The surface of Konoshima panels has a unique ability to repel moisture , as a result of which water forms a barely noticeable film on it, acting as a barrier between the product and dirt.

Konoshima products are a material suitable for finishing both the walls of a building and the basement part, which is most susceptible to changes in temperature and moisture, with a number of advantages.

The panels are made from materials without harmful substances, based on calcium silicate and additional additives to increase strength - glass and viscose.

Konoshima panels are produced using extrusion, followed by embossing and heating in an autoclave. The final stage is coloring the finished products.

The main advantages of Konoshima panels are:

- in the ability to resist various types of pollution due to the nanolayer;

- excellent sound insulation performance;

- high degree of thermal insulation;

- seismic stability;

- practicality;

- resistance to low temperatures;

- fire safety;

- environmental friendliness of konoshima products;

- not exposed to sunlight;

- wind resistance.

Konoshima panels are mounted on lathing to create ventilated facades. The frame can be made of either wood or metal with a pitch of 500 mm.

Technical characteristics of fiber cement panels

The main regulatory document regulating the main technical characteristics of fiber cement slabs is GOST 8747-88. All manufactured modifications must comply with the requirements of this document, which is clearly presented in Table 1.

| Options | Manufacturer | |||

| Rospan | LTM | Crospan | Latonite | |

| Water absorption no more, % | 10÷16 | 20 | 20 | 18 |

| Expansion from moisture no more, mm/m | 2 | 2 | 1.8 | 2 |

| Porosity, % | 25 | 23 | 23 | 22 |

| Frost resistance (cycles) | 50 | 100 | 150 | 150 |

| Specific gravity, kg/m3 | 1500 | 1650 | 1500 | 1650 |

| Flammability group | G1 | G1 | G1 | G1 |

| Modulus of elasticity along the fibers, N/mm² | 1200 | 1200 | 5.5 | 1400 |

| Modulus of elasticity across the fibers, N/mm² | 1400 | 1300 | 7.5 | 1500 |

| Bending strength, MPa | 18÷25 | 17÷26 | 24 | 16÷26 |

| Thermal conductivity coefficient W/m×ºС | 0.3 | 0.25 | 0.2 | 0.6 |

| Thickness, mm | 6, 8, 10 | 6, 8, 10 | 7, 8, 10, 14, 18 | 8, 9, 11, 16 |

| Width, mm | 306, 455 | 1195 | 1190, 1220 | 200 |

| Length, mm | 1200, 1590, 3000 and 3600 | 2500, 2780, 2800, 3050, 3100 | 1560, 2400 | 1800, 3000, 3600 |

| Weight kg/m² | 16÷18 | 6 mm - 15.7; 8 mm - 19.0; 10 mm - 22.6. | 8 mm - 10.5 | 8 mm - 10.5; 9 mm - 13.5; 11 mm - 18; 16 mm - 16÷19 |

| Availability of accessories | Corner elements. | No | Hanging systems for mounting panels. | Hanging systems for mounting panels |

As can be seen from the table, the main technical characteristics of various domestic manufacturers are very similar.

Pros and cons of using fiber cement boards

The widespread use of this finishing material in industrial and civil construction is due to a number of significant advantages:

- Using a composite slab as a cladding allows you to reliably protect the walls from atmospheric influences and amplitude temperature changes.

- Since installation is carried out mechanically (screws, rivets, etc.) and does not require the use of any mortars or mixtures, cladding the facade with fiber cement boards can be done at any time of the year.

- The use of fiber cement panels makes it possible to fully satisfy all fire safety requirements.

- The use of exclusively natural ingredients eliminates the occurrence of allergic reactions and other harmful effects on the human body.

- The high mechanical strength of the material and its inertness to aggressive chemical compounds ensure a long service life (the average service life of fiberboard is from 40 to 50 years) and long-term preservation of decorative properties.

- The antiseptic properties of the material prevent the active development of fungal colonies and other microflora.

- The optimal price-quality ratio makes fiber cement panels one of the most popular facing materials.

- The ability to imitate any natural material and a wide range of colors allow you to bring any architectural concept to life.

The above list of advantages of fiber cement cladding panels looks quite impressive, however, despite this, some disadvantages should be noted:

- Despite the relatively small specific gravity, it is almost impossible to install fiber cement boards alone.

- The material has a fairly high moisture absorption rate; in a humid climate it can reach 10%, but this does not affect the strength characteristics.

- To cut the panels you will need a circular saw or grinder, preferably with a diamond blade. It will not be possible to achieve acceptable cutting quality using a hacksaw.

Objectively assessing these disadvantages, we can say that they are unlikely to limit the scope of use of fiber cement cladding.

What types are there?

There is a wide choice of materials, but the most common home decoration is with fiber cement panels to resemble brick, stone and wood. Brick cladding looks ideal on any buildings: country cottages, houses, offices, shopping centers and so on. You can choose to imitate new or aged brick, it all depends on the design of the building. Stone-look panels will be an excellent solution in cases where it is not possible to use natural material. This finish looks very beautiful and solid. Boards that imitate wood are often used for finishing the facades of country houses.

Well-known manufacturers of fiber cement panels

Currently, cladding panels of both domestic and foreign production are widely represented on the building materials market. Among domestic manufacturers, the products in greatest demand are “ LTM” and “Latonit”

and

"Rospan".

Among foreign manufacturers, the most popular panels are

“NICHIHA”, “KMEW” and “Eternit”.

Kraspan

In addition to the production of fiber cement boards, the company produces elements of fastening systems. Full compliance of the standard sizes of subsystems and fiber panels significantly simplifies the façade cladding and allows for high-quality joining. Currently, two types of subsystems for installation of fiber cement cladding are produced:

- L -shaped systems

can significantly speed up the installation process through the use of adjustable mounting brackets.

- U -shaped subsystems

provide the necessary rigidity and reliability of fastening, and in addition, they allow you to correct defects in the load-bearing wall or partition using the axial displacement of the brackets - holders.

Thanks to the high-quality protective coating, Kraspan fiber cement panels withstand temperatures down to -500C, exposure to ultraviolet radiation and precipitation. The main technical characteristics of the panels can be found in Table 1.

The quality of the products produced by the company is evidenced by customer reviews, here are some of them.

Andrey, Chelyabinsk

When it came time to start cladding the facade of our country house, we decided to use Kraspan fiber cement boards for this. Several factors prompted us to make this decision: firstly, the strength and durability of such cladding, secondly, ease of installation, and thirdly, the affordable cost of the material. We decided to install the slabs ourselves so as not to waste any extra money. For cutting we used a grinder with a diamond blade. The work turned out to be not only feasible, but also quite interesting, and the result exceeded all expectations. For two years there were no unpleasant surprises; even on the sunny side, the brightness of the paint remained virtually unchanged.

Dima, Moscow region.

At the beginning of summer, I watched as my neighbor in the country was tidying up his house. I really liked the result, and I decided to decorate my house too. After asking my neighbor in detail about all the intricacies of installation and the cost of this pleasure, I decided to purchase Kraspan fiber cement facade panels and immediately start working before the vacation is over. No special tools were required for installation, and my brother and I did the job perfectly within a week. We were quite satisfied with the result.

LTM

TD LTM LLC began production of fiber cement facing materials in 2008. The use of modern high-tech equipment and highly qualified service personnel made it possible to achieve high quality products and reduce their cost.

Currently, TD LTM LLC produces 4 modifications of facing panels:

- Moisture resistant.

Such slabs are used for external and internal cladding of walls in rooms with high humidity: swimming pools, showers, saunas, etc. - Facade.

These modifications, due to their high strength and elasticity, can withstand significant mechanical stress, and the decorative acrylic layer provides wear resistance and immunity to ultraviolet radiation, precipitation and temperature changes. - Windproof.

Due to their average density, the specific weight of such slabs is significantly less than that of façade and moisture-resistant modifications, which makes them an optimal material for cladding multi-storey buildings and structures located in areas with high wind loads. - Fire resistant.

This fiber cement cladding has a low density and is used for finishing buildings with increased fire safety requirements.

Technical characteristics of façade fiber cement panels “LTM” can be found in Table 1.

Below are reviews from customers of TD LTM LLC products who have assessed the performance properties of the material in practice.

Nikolay, Smolensk

After reviewing the characteristics of fiber cement cladding on the Internet, we chose it. For cladding the utility block at the dacha, we bought “LTM” façade panels. The installation instructions did not look particularly complicated, so we decided to carry out the work ourselves. Everything went as well as possible, now our barn doesn’t look like a barn at all, everything turned out very neat and nice. As for operation, it is still difficult to draw conclusions, since only a year and a half has passed, but at this stage there are no complaints.

Vasily Petrovich, Kursk

I needed fiber cement panels for the interior lining of a small bathhouse. Sales consultants in the store recommended a moisture-resistant option from LTM, and a suitable color was found. Having extensive experience working with plasterboard systems, I considered it inappropriate to hire specialists and took up the matter myself. The installation process is not much different from installing drywall, except that cutting is more labor-intensive. It turned out very well and quickly, the whole job took three days.

Rospan

The group has been known in the building materials market for more than 20 years. During this time, the company's products have earned the most positive reviews from both professional builders and private developers. The use of the most modern equipment and the latest technologies has allowed the company to take a leading position in the domestic building materials market.

Fiber cement cladding panels "Rospan" are in high demand due to the following advantages:

- A three-layer protective coating completely eliminates the impact of ultraviolet radiation, precipitation and other undesirable influences on the decorative layer.

- The precision of imitation of natural materials allows you to implement any design projects.

- Rospan fiber cement facade panels can maintain their performance characteristics in the temperature range from -35 to +500C and air humidity up to 90%.

The main technical characteristics of fiber panels produced by the company can be found in Table 1.

Latonite

Having started its activities in 2013, LATO OJSC is now firmly established in the domestic market. The high quality and reasonable price of the products made them popular both among large construction companies and private developers.

The company's product range includes four main modifications of fiber cement boards:

Painted pressed panels. This modification is universal and can be used both for cladding facades and for interior work.

Unpainted pressed panels. The material is used primarily for cladding facades, as it has high mechanical strength, low thermal conductivity and resistance to atmospheric influences. The main disadvantage of such panels is the need for independent painting with special facade paints.

Unpressed and unpainted slabs. This variety is intended for interior work (wall cladding, partitions, etc.). After installation it requires additional finishing.

Fiber cement siding. Used for decorative cladding of facades. In terms of its mechanical and protective properties, it is practically no different from conventional façade panels; only the installation method differs.

A complete list of technical characteristics of Latonit fiber cement materials is presented in the table. Below are customer reviews about LATO OJSC products.

Vyacheslav, Novomoskovsk

Walking through my holiday village, I often noticed on houses lined with plastic siding traces of various mechanical influences: cracks, chips and even small holes. The sight is not pleasant, so I decided to clad my house not with plastic siding, but with its analogue made of fiber cement. As it turned out later, the technology for installing fiber cement siding “Latonit” is not much different from installing conventional siding, but the strength characteristics cannot be compared. Proof of this can be the fact that in two years I have not found any significant defects in my house, but houses lined with plastic receive new “wounds” almost every month.

Oleg, Novgorod

In the new apartment there was a need to erect several partitions. I have been decorating for over 15 years. During this time, I gained some experience. I decided to install the partitions from unpressed and unpainted fiber panels using a plasterboard subsystem made of galvanized profiles. I consider the result to be quite satisfactory, because you must admit that the strength of fiber cement and plasterboard cannot be compared.

Among foreign manufacturers, special mention should be made of “KMEW” and “Eternit”. Technical characteristics of products manufactured by these enterprises are given in Table 2.

| Options | "NICHIHA" (Japan) | "KMEW" (Japan) | "Eternit" (Belgium - Germany) |

| Moisture absorption, %, no more | 3 | 20 | 20 |

| Expansion from moisture, mm/m, no more | 1.55 | 1.75 | 1,5÷1,75 |

| Porosity, % | 22 | 23 | 23 |

| Frost resistance (cycles) | 150 | 150 | 150 |

| Specific gravity, kg/m3 | 1400 | 1300 | 1650 |

| Flammability class | G1 | G1 | G1 |

| Longitudinal modulus of elasticity, N/mm² | 1400 | 1300 | 5.5 |

| Transverse modulus of elasticity, N/mm² | 1500 | 1500 | 7.5 |

| Bending strength, MPa | 24 | 24 | 24 |

| Thermal conductivity coefficient W/m×ºС | 0.32 | 0.25 | 0.25 |

| Thickness, mm | 14, 16, 18, 21, 25, 35 | 14, 16, 18 | 8, 10, 12 |

| Width, mm | 455 and 910 | 455 | 190, 1250 |

| Length, mm | 1818 and 3030 | 3030 | 2550, 3100, 3600 |

| Weight, kg/m² | 14 mm - 16.5; 16 mm - 18.9. | 14 mm - 13÷15; 16 mm - 15÷16. | 8 mm - 14.9; 12 mm - 23.2. |

| Availability of fittings and additional elements | Metal and fiber cement corners. Start and finish bars. | Starting, corner, finishing and dividing strips. Corrective paint, castings and clamps. | Starting, corner, finishing and dividing strips. Corrective paint, castings and clamps.. |

NICHIHA

The production of NICHIHA fiber cement panels began in 1956. The products of this company became available to domestic consumers starting in 2012. The high quality of the panels, original design and long service life allowed the company to firmly establish itself in the premium segment of the building materials market.

Unlike most domestic ones, it offers its customers additional elements made of fiber cement, plastic or metal:

- Decorative trim for outer corner. The element allows you to hide possible installation inaccuracies and ensure the tightness of the cladding.

- Metal corner. With the help of such a corner, internal and external corners, as well as window and door openings, are decorated.

- Corner module made of fiber cement. It is installed together with the main panels on a specially mounted frame.

In addition to high strength, moisture resistance and resistance to various atmospheric conditions, NICHIHA fiber cement panels are distinguished by their authentic imitation of natural materials and a wide range of color options.

KMEW

Another Japanese company presenting premium fiber cement cladding boards on the domestic market. The use of high-strength cement grades with special additives and a three-layer protective and decorative coating ensure not only a long service life of the cladding, but can also give the house individuality and style.

In addition, KMEW panels are distinguished by their richness of textures, accurate imitation of natural materials, be it brickwork, wood or natural stone, and a variety of colors and shades.

Eternit

This German-Belgian company specializes not only in the production of EQUITONE facade fiber cement panels, but also Cedral siding. Both facing panels and Eternit siding can be classified as a premium class of finishing materials, which is justified by the high quality and variety of product designs.

The front side of the panels is painted with a special paint, which, in turn, is coated with a protective coating, the composition of which is not disclosed. The back side is treated with hydrophobic impregnation, which prevents moisture from entering.

Despite some superior quality, imported fiber cement boards are less in demand than their domestic counterparts. This is explained by three factors:

- The cost of products from foreign manufacturers is significantly higher than the cost of domestic analogues;

- Delivery of the modification selected from the catalog can take up to 2 months;

- The use of high-tech equipment at domestic enterprises minimizes the advantages of imported analogues, and the cost of domestic samples is noticeably lower.

Design

One can talk about the design of panels intended for arranging a ventilated façade for an eternity. Therefore, I’ll tell you a little about the facing material, which is in great demand.

Slabs with the following texture are in demand:

- under the tree;

- under brickwork;

- under masonry;

- under decorative plaster.

Popular panels are the following shades:

- fiery red;

- sunny yellow;

- soft peach;

- sky blue;

- noble chocolate;

- royal lilac;

- virgin white;

- soft cream;

- bright green;

- deep emerald;

- luxuriously golden.

I guess I'll stop here. The color palette is so rich that it would take several days to list all the tones.

By using so-called fiber cement siding, you can easily turn an ordinary and nondescript building into a real work of art.

Installation technology of fiber cement facade panels

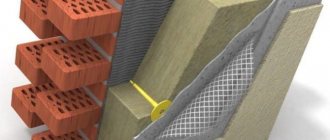

As has already been said many times, the installation of fiber cement boards is not particularly difficult, but it requires care and precision. In general, facade cladding includes the following sequential stages:

- Marking. At this stage, the condition of the walls is assessed, the horizontal and vertical levels of the walls are checked, and markings are made for the future supporting frame. The distance between two adjacent subsystem profiles should not exceed 600 mm.

- Installation of supporting brackets. Load-bearing brackets are attached to the wall using dowels. When installing them, one should take into account the design features of the subsystem and the thickness of the insulating mats.

- Laying a thermal insulation layer and waterproofing film. Mineral slabs are laid directly against the wall and secured with dowel umbrellas.

- Installation of a supporting frame made of metal profile. At this stage, special attention should be paid to the accuracy of installation of the supporting system, since the quality of installation of the fiber cement panels themselves will depend on this.

- Fastening of facing slabs. Depending on the thickness of the material, either self-tapping screws or special clamping clips can be used. In some cases, the use of blind rivets is permitted.

- Sealing seams. Upon completion of installation, non-standard joints should be treated with moisture-resistant sealant.

Important! When carrying out installation work, you should ensure the strength and stability of scaffolding, decking and platforms.

After carefully analyzing all of the above, we can draw the following conclusions:

- Using fiber cement panels for cladding a private house is one of the most economical options.

- The performance properties of the material ensure high strength of the cladding, resistance to various atmospheric conditions and the formation of fungal colonies, and compliance with all fire safety requirements.

- The ease of installation and availability of material allows you to carry out installation work yourself, which allows you to save significant money.

- Cladding with fiber cement panels gives the building an attractive appearance, emphasizing its individuality and style, and resistance to ultraviolet radiation allows you to preserve this impression for a long time.

Against the background of these advantages, the relatively large specific gravity, some difficulties with cutting and the need to work with a partner can be considered very conditional disadvantages.

Technological features of installation of fiberboards, step-by-step instructions

The installation stages begin with preparatory work, during which all the irregularities in the walls of the building are first identified. Then the facade is cleaned, the window casings are removed, and unnecessary parts attached to the walls are removed.

When the walls are cleaned, the following steps follow:

- Waterproofing (membrane film or polyethylene).

- Installation of fasteners for thermal insulation.

- Installation of thermal insulation. If the insulation is two-layer, then the seams overlap.

- Waterproofing (second layer).

- Installation of additional partitions that strengthen the structure near windows and doors.

The installation of the panels themselves begins from the foundation, that is, from the bottom of the wall. The tiles are drilled and screwed with self-tapping screws, and the recesses from the caps are treated with sealant.

Self-tapping screws should be painted over to avoid corrosion. The joints of the cladding and slopes are sealed or sealed with connecting strips. Both methods can be used together.