There are several ways to figure out how suitable foam materials are for an attic space. For example, use reviews about attic insulation with polystyrene foam. It’s even better if you manage to take part at least once in the process of laying insulation in a residential attic or any other room similar in structure and size to an attic. Once done with your own hands, insulating an attic with penoplex is worth ten reviews, although, from a practical point of view, you can find a lot of rational ideas in them.

Disadvantages of polyurethane foam, reviews

Reviews and practice of application most often provide the most objective assessment of insulation. Usually, users are primarily interested in the shortcomings of materials in order to find out what awaits in the future and whether money will be wasted. Each material has its own characteristics, which can also be considered disadvantages; polyurethane foam is no exception.

Which insulation to prefer

Choosing insulation often becomes an overwhelming task for the consumer. There are too many technical nuances that are not obvious at first glance. The heat insulator is specified in the project, but it is difficult to solve the problem on your own.

Every insulation product has disadvantages, which the developer is not aware of or has a false idea due to advertising. For example, the durability of materials, about which very contradictory data are given in different sources, cannot be considered an advantage for many materials.

The eternal question of what to give preference to is best solved by acquiring ready-made reviews, operating experience... Or acting according to the approved documentation...

What is polyurethane foam?

Polyurethane foam is synthesized directly on the construction site by mixing complex components using special equipment. Therefore, insulation services with this material are provided only by organizations with special equipment. Independent use of polyurethane foam is impossible.

As a result of the constant slight expansion of the foamed substance and its hardening, a material with a porous structure is formed, 90 - 95% of the volume consisting of voids in the cells. But the characteristics are unique - the highest degree of thermal insulation among artificial materials. At the same time, the price is moderate. Specific costs for very large volumes are low, i.e. over large areas the material also becomes advantageous.

Individual disadvantage

But the creation of polyurethane foam occurs every time without standards, “like an uncle twisting a pen.” This also entails its big drawback - the characteristics will completely depend on the desire of the creator, his conscientiousness, the quality of the equipment, the quality of the components...

The most important parameter is achieving the design specific gravity - kg/m3. Strength characteristics, thermal insulation coefficient, vapor permeability will depend on this... But the creators want to fill the volume and spend as few components as possible….

Therefore, one of the most important indicators of this material is simply consumer reviews of a particular organization involved in spraying. To avoid negative consequences, independent technical control at the construction site is also important.

Afraid of the sun

The effect of ultraviolet radiation on most synthesized plastics is negative. Irradiation destroys chemical bonds and the structure of the material. Users comment on the shortcoming - “the material turns yellow and shrinks.”

When coating external surfaces, it is not recommended to keep polyurethane foam in the sun without protection. In any case, manufacturers may not focus on this. But reviews of polyurethane foam speak precisely to the need to protect it from radiation.

Can be used under protective putty or paint. True, external use is questionable due to another disadvantage of the material...

No flat surface

A typical area of application for polyurethane foam is in cavities covered by hinged panels. Or in places that do not need aesthetic evaluation. Why panels that are hung on the sheathing?

Because it is not profitable and difficult to apply a plaster and paint layer on top of the material. A too uneven surface is created. Spraying is done individually, as the master can. And the thickness of the layer is determined by the average result, while in some places it can be +- 2 cm.

Vapor barrier - advantage or disadvantage?

Reviews about polyurethane foam say one thing - it is better not to use it on vapor-transparent materials from the outside. The insulation will block the escape of moisture from wood, from aerated concrete, from expanded clay concrete... It is better to use the material strictly in accordance with the design, where the structures are specially designed, for example, vapor barrier membranes are provided.

Doing it on your own can literally lead to disastrous results for the wall (structure) - water will flow from it. Thus, the property of the material to poorly allow water vapor to pass through itself will turn into a major disadvantage if used ineptly...

Destroys and binds

Expansion during the formation of the structure can also be considered as a disadvantage of this heat insulator. Using these criteria, users usually make reviews about polyurethane foam - for example, “this foam brought down half of my wall, I didn’t expect...”

Indeed, in closed cavities the material can cause trouble - it will rupture the shells. For example, when pumping without rules into the cavity of a three-layer wall behind a brick wall, there is a risk of squeezing out the cladding, collapsing...

On the other hand, the material is designed in prefabricated structures on lathing, in panel houses. Here it not only fills the internal cavity of the panels, creates a heat-insulating shell, but also fastens the outer cladding itself, creating a monolith….

What is the downside in case of fire?

The material does not support combustion, but at a high enough temperature it begins to decompose, smolder, and ignite. At the same time, releasing substances that are not at all useful. It is not recommended to use it from the inside in an open form for fire reasons; it is better to cover the polyurethane foam on top with a fire-resistant shell.

Typically, an application in which fireproof walls made of mineral materials, or panels made of gypsum fiber or cement fiber, are located inside the living space.

What reviews say about the durability of polyurethane foam

One of the most important qualities of materials used inside permanent structures, such as walls, is durability. It’s good if the wall can be easily disassembled and the insulation material can be replaced, as for example in a ventilated façade system with hanging panels on the outside. But if the material is bonded to a supporting frame, as polyurethane foam does, and covered with heavy finishing in wet processes, then its low durability is the main drawback.

Alternative to foam

The main competitor of polystyrene foam is basalt wool. Some of its varieties have a thermal conductivity coefficient as low as foam plastic - from 0.032 W/m*C.

We have already talked about the disadvantages of basalt wool, it’s time to mention the advantages: this material does not burn and does not emit harmful gases when heated. But there is one thing. Phenol-formaldehyde resin is used to glue the fibers in basalt wool.

If the material is produced according to all the rules and using modern equipment, this substance does not pose a danger.

But if stone wool was made in some artisanal workshop, it will most likely become a source of toxic fumes.

In addition, the “left” cotton wool produces more dangerous dust.

Today, ecowool is becoming more and more popular. This extremely cheap heat insulator consists of finely chopped paper impregnated with fire retardants and antiseptics.

When dry, Ecowool is a bulk material - it can be laid in wall cavities and under floor coverings.

But if this material is slightly moistened (special equipment is used for application), it becomes sticky and can stick to vertical surfaces, and even to the ceiling. Such materials are called sprayed. They are able to penetrate hard-to-reach areas and form a seamless coating. Ecowool's thermal conductivity is extremely low - about 0.032 W/m*C.

Like polystyrene foam, it is a flammable material, although fire retardant additives give it some resistance to fire. But its smoke is not so poisonous. Antiseptic and fire retardant additives used in the production of Ecowool are considered moderately toxic.

Ecowool insulation

Among foam plastics there are also sprayed materials. This is, for example, polyurethane foam, better known as polyurethane foam. Its characteristics are similar to expanded polystyrene, but it is much more expensive, so it is mainly used to fill small cracks and cavities.

When applying polyurethane foam over a large area, you need to wear a protective suit with a hood, since it is almost impossible to remove it from clothing or hair (hair has to be shaved off).

Most of the heat in the house escapes through the roof, so if you want to save on fuel, be sure to insulate it. How to insulate the roof of a private house - an overview of traditional and innovative insulation materials.

Heat loss in a corner apartment is much higher than in a regular one. Read tips on insulating a corner apartment from the inside and saving on heating.

Why is thermal insulation necessary?

If you neglect thermal insulation and limit yourself only to heating the attic, then the following situation may arise:

- In winter, warm air will quickly leave the room, which will entail significant financial costs.

- When warm air comes into contact with the roof, the snow on it will melt and form ice and icicles, which can lead to damage to the roofing.

- In cold weather, condensation will form on the inner surface of the roof, leading to rotting of the elements of the rafter system.

- In the summer, the room will heat up intensely to such an extent that living in it may simply become impossible.

Insulating an attic from the inside is a more difficult task than insulating ordinary rooms:

- The need to apply insulation not only to vertical surfaces, but also to roofs that have a negative angle of inclination.

- There is a high probability of moisture from the roof getting onto the insulation and getting it wet.

- Possibility of carrying out work only in the warm season.

All these problems are eliminated by insulating the attic space with polyurethane foam.

Applying insulation to the roof from the inside

2.3 Spraying technology

Insulating an attic with polyurethane foam probably has only one significant drawback: using such insulation with your own hands is impossible for most people. The reason is the high cost of special equipment - the installation with which polyurethane foam is applied to the surface.

The simplest compact model costs approximately $2000-2500 (the same cost for insulating the blind area around the house), so purchasing it for treating one building is unprofitable. In addition, the operation of such an installation requires some experience, and the correct preparation of the insulation itself is also not a task for an inexperienced person.

Let's consider the sequence of work stages:

- The attic room is completely emptied of contents. Insulated surfaces are completely cleaned of finishing materials, thermal insulation, dirt, dust, mold. If possible, detected leaks, cracks, holes in the roof must be repaired. Logs are installed on the insulated surface. Polyurethane foam is prepared on site. Between the logs The composition is sprayed. After the first layer has completely hardened, the next ones are applied if necessary. After applying the required number of layers along the joists, the facing material is installed and further finishing is carried out.

As you can see, in addition to the insulation, the thermal insulation layer does not contain a waterproofing layer - it is simply not necessary, due to its resistance to moisture. This reduces both time, effort and money for work.

What is polyurethane foam

Polyurethane foam (abbreviated as PPU) was created in Germany in the late thirties of the last century for the needs of the aviation and military industries. Later it began to be used for thermal insulation of freezers and refrigerators, and by the seventies of the twentieth century it began to be used for insulation of residential buildings.

Polyurethane foam is a plastic permeated with millions of tiny air bubbles. The insulation consists of two components, which are mixed directly at the insulation site in a special apparatus.

The components are supplied in separate containers attached to a special spraying apparatus. When the mixture is sprayed and interacts with carbon dioxide contained in the air, a light foam is formed that adheres well to any surface. After some time, the foam hardens, and the insulated surface is covered with a continuous layer of durable material - polyurethane foam.

In this way, an insulating layer is created that protects the premises from energy loss.

Polyurethane foam layer

About the features of polyurethane foam

Among all the properties of polyurethane, the following characteristics are important for good insulation:

- Low thermal conductivity - no more than 0.03 W/(m*K) due to the large number of closed air cells (up to 85%);

- Low weight of the insulating layer – 30-70 kg/cub.m.;

- Completely waterproof for closed cell material;

- Fire safety level G-2;

- High adhesion to any surfaces;

- Possibility of creating an insulating layer of any thickness directly during the work process;

- Good sound insulation;

- Fast hardening time - about 1 hour;

- Resistant to water, the material does not rot or deteriorate;

- No treatment required for insects and rodents, they cannot live in this material;

- Long service life - up to 40-50 years.

The thickness of different materials providing the same degree of insulation (mm)

The disadvantages of polyurethane foam include:

- Susceptibility to ultraviolet radiation. Exposed material in direct sunlight quickly deteriorates;

- Carrying insulation is carried out only when using special equipment.

Polyurethane foam is applied to surfaces in liquid form. Once applied and reacted with carbon dioxide in the air, it foams and hardens quickly.

Due to the formation of many air bubbles inside the material, its structure becomes very porous, which ensures high consumer qualities.

Important! The use of closed-cell polyurethane foam for attic insulation makes it possible to abandon hydro- and vapor barrier.

Application area

Liquid two-component polyurethane foam serves as an excellent insulation material for any structural elements of frame, brick, block and panel buildings, since its low weight does not create serious mechanical loads on house structures, including lightweight ones.

Good adhesion of polyurethane foam with all building materials allows you to spray insulation on vertical and inclined surfaces: facades, roofing, walls inside the house, ceiling. Excellent thermal insulation properties coupled with fairly high moisture resistance make this type of insulation attractive for thermal insulation of country houses, attics, balconies, floors (along joists). Low level of moisture absorption - foundation.

Attention: the use of the material under compressive loads reduces the thermal insulation effect to zero, and therefore polyurethane foam is not sprayed under the screed and “wet facade”.

Polyurethane foam insulation is also used in other industries. It is used to insulate freezers and is sprayed onto pipes of heating systems. Recently, in industrial construction they have begun to use ready-made sheet material for sandwich panels, when liquid polyurethane foam is poured into molds at the factory.

Insulation technology

Surface preparation

In the attic, it is necessary to protect all objects that could be touched and damaged by spray polyurethane foam. Window glass, window sills and slopes are covered with plastic film, which must be securely secured with tape. When insulation gets on any surface, it sticks tightly to it and it will be very difficult to clean off random drops and splashes. So, it is better to spend time on preventing such cases.

If there were any coatings (for example, old paint) at the place where the insulation was applied, it is better to remove them. Otherwise, it may subsequently move away from the surface, and the insulation will come off with it.

Then you should inspect the wooden cladding elements, repair damaged parts, and replace worn ones. After applying polyurethane foam, they will be inside the insulation and it will be impossible to get to them.

The material must be applied to a dry and clean surface, so it is recommended to completely remove all debris and dust.

All surfaces must be thoroughly cleaned

Necessary materials and equipment

To apply insulation you will need:

- Two containers for polyurethane foam components;

- Mixing apparatus;

- Compressor;

- Connecting hoses;

- Spray gun;

- Respirator or mask for breathing protection;

- Gloves, overalls, shoes.

Apparatus for applying insulation

Application process

An important feature of insulation with polyurethane foam is that it cannot be carried out without special equipment. Purchasing it to carry out work in only one house is unprofitable due to its high cost, so it is necessary to either rent it or turn to the services of professionals.

Where does the heat go?

Before insulating the attic, it is important to determine where the heated air goes, and why is it so difficult to maintain the optimal temperature?

Walls, ceilings, floors, windows and doors – through all these elements of the room’s structure there is a fairly active exchange of air with the outside space. And if the first floor of the house is fully insulated, leisure time in the attic will be more comfortable. But to make the atmosphere as pleasant as possible, you need to pay attention to the entire room.

Heat escapes through cracks in doors and windows, walls and roofs. Cladding with insulation, steam and wind insulation materials will allow you to maintain a comfortable temperature for relaxation and active pastime, and save on heating system resources. Next, we will talk about the nuances of insulating the attic roof, walls, floors and ceilings, recommend materials and demonstrate some expert advice, which will allow you to make the room warmer on your own.

Important nuances when insulating with polyurethane foam

When working, the following factors must be taken into account:

- The proportion of water and polyurethane foam when mixed should be 1:1. Failure to comply with this rule leads to a sharp deterioration in the properties of the applied insulation.

- The quality of the mixture is controlled by its color - darkening indicates a violation of the proportions of mixing the components.

- For central Russia, the attic needs to be insulated with a layer of polyurethane foam of at least 150 mm.

- The air temperature during operation should not be lower than +10 o C.

- Application of insulation is allowed only at an average level of humidity. Exceeding this parameter can lead to the appearance of large bubbles in the thickness of the material or to its detachment from the surface.

- When working, it is necessary to ensure good ventilation of the attic.

When working with a spray gun, you must follow the basic rules:

- The material is sprayed from bottom to top, at a distance of 50-60 cm from the surface to be insulated.

- The layer being created must immediately have the same thickness; going back after a few minutes is strictly not recommended - applying a new layer can deposit the old one.

- Polyurethane foam is not toxic, and if it gets on exposed skin, it can be removed with a rag soaked in solvent.

After the last layer has dried, it is recommended to protect it with paint.

Advantages and disadvantages of technology

Using spray polyurethane foam to insulate attic spaces has the following advantages:

- The material is applied seamlessly, which eliminates the formation of cold bridges in the insulation.

- Spraying is allowed on surfaces of any shape and in the most inaccessible places. No complex protrusions and depressions will interfere with the creation of proper insulation.

- The thin layer of insulation created due to the high thermal insulation properties of the material leaves more space for living in the attic.

- Quick application of insulation compared to sheet materials.

- The created layer adheres tightly to the surface and is not subject to slipping or destruction.

- There is no need to use hydro- and vapor barrier layers.

The disadvantages of polyurethane foam include:

- Vulnerability to ultraviolet radiation. This drawback can easily be eliminated by applying a protective layer of paint.

- Despite good fire resistance (flammability class G-2), the material begins to smolder when exposed to high temperatures. It must be protected from contact with objects that can heat up to high temperatures.

- Quite a high cost of the material.

Floor insulation with polyurethane foam

Video about insulation with polyurethane foam

There is no ideal insulation material that does not have disadvantages. But polyurethane foam has so many advantages that it can be safely recommended for insulating attic spaces in private homes.

Roofing pie composition

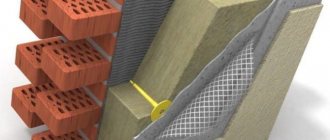

One of the options for multilayer thermal insulation with polystyrene foam is shown in the diagram below.

The use of thin sheets significantly complicates the process; this option turns out to be much more effective. Using three to four layers of expanded polystyrene, laid without using glue, has its advantages:

- Significantly more effective sound insulation;

- There is no risk of destruction of the attic insulation even with severe watering of the material;

- Complete absence of cold bridges.

In the diagram shown, the vapor barrier is laid on a wooden sheathing with a wind barrier and a ventilation gap.

Next come three layers of insulation, a vapor barrier and a final layer covering the ends of the rafters.

Advantages of attic insulation with polyurethane foam

Owners of private houses with basement insulation from the inside can supplement the useful space of their home not only with a spacious basement. If desired, they can also equip an attic - a room under the roof (essentially the same attic, only landscaped).

Insulated attic from the inside

If various workshops are usually located in the basement, then the attic often serves as another bedroom. However, in order for it to be fully used as a living space during the cold season, it is necessary to take care of insulation. And the best solution to solve this issue is PPU - or sprayed polyurethane foam.

Waterproofing

The purpose of waterproofing the outside of the insulation is to prevent moisture from entering the insulation in the event of a roof leak. For this purpose, it is better to use special membranes with vapor-proof properties. Such membranes are more expensive than conventional waterproofing, but in fact they will repeatedly justify the costs.

By the way, closed-cell polyurethane foam lacks the ability to absorb and retain moisture, which makes it an excellent solution for attic insulation. Adhering tightly to the attic ceiling material, polyurethane foam does not leave gaps or voids into which moisture could enter.

So, let's summarize. Proper attic insulation is based, figuratively speaking, on “three pillars”:

- thermal insulationwaterproofingvapor barriers

Sprayed polyurethane foam solves all three problems simultaneously, which makes it so far the most practical material for insulating an attic roof.

We will help you select and calculate the amount of material, taking into account the area and type of your attic, and give recommendations for use. We will calculate the cost of services for thermal insulation of the attic roof and walls using our specialists.

Expert's answer to the question: “What are the characteristics of polyurethane foam?”

- fill all spaces of a room with a complex configuration;

- obtain a hard coating of surfaces without seams, voids, or cold bridges;

- normalize temperature, humidity, sound insulation;

- make the roofing system stronger.

PUF is environmentally friendly, suitable for covering surfaces made of various materials, does not allow moisture to pass through and does not support combustion. There is no need for fastenings before coating; the thickness of the layer is adjusted during the spraying process.

When choosing insulation for the attic, it is necessary to take into account the disadvantages of polyurethane foam. It does not tolerate ultraviolet radiation at all, so interior finishing is required. When exposed to fire, it can smolder. To carry out insulation work, special equipment is required, which increases the overall cost of insulation.

Selection of materials

When choosing insulation to protect against cold air, you must be guided by its basic properties. It is important that the materials have the following characteristics:

- low thermal conductivity; fire safety; light weight; environmental friendliness; the ability to “breathe”.

There are various materials and products on the market for insulating attic walls, ceiling and floor cladding. One of the most popular and relatively inexpensive insulation materials is mineral wool. This fibrous material is characterized by frost resistance, it is not susceptible to biological influences, fungus and mold, and is resistant to fire.

Insulating the attic with polystyrene foam is an opportunity to protect the room from heat or cold for a long time with a technologically advanced and environmentally friendly material. It is not susceptible to insects, fungus, mold and other microorganisms that destroy the fiber texture. Working with extruded polystyrene foam is simple and not labor-intensive.

For insulation, you can also use cellulose material - ecowool.

This fiber is environmentally safe. It has similar characteristics to polystyrene: fire safety, low thermal conductivity, lightness. The material also has excellent sound insulation properties. But its use requires the use of special equipment.

The answer to the question: “Is it possible to insulate the attic with polyurethane foam?”

There are no walls in the attic, so thermal insulation can be considered zero. If this room is simply heated, the heat will rise, heating the roof and contributing to the formation of ice in the winter. Attic insulation should cover all cracks and prevent the formation of excess moisture . Thermal insulation of the attic room with polyurethane foam ensures all this one hundred percent .

Insulating the top floor of a house with polyurethane foam by applying it to the ceiling is an almost ideal option if the attic space is not planned to be used as a living space. It is enough to spray polyurethane foam in several layers to save up to 30% of heat.

Vapor barrier

The fact is that the insulation has low thermal conductivity, while actively absorbing moisture and “breathing”. If there is no vapor barrier, warm indoor air passes through the insulation and condenses in the area of contact with the roofing pie. Condensation in the form of water droplets penetrates the insulation - hence dampness, mold, and the loss of the insulator’s ability to retain heat.

If you use mineral wool for insulation, aluminum foil or already foil insulation will help solve the problem of vapor barrier in the attic.

How to do everything in practice?

There are 3 types of this insulation, with three levels of rigidity. This must be taken into account when choosing technology, which can be classical or complex . When using the first, a material of the same hardness is taken and one or several layers are applied. If the second technology is chosen, then first a layer of high-hardness polyurethane foam (3-5 cm) is applied, then a softer layer (5-8 cm).

If the attic was uninhabited before treatment, before starting work it is necessary to empty it of unnecessary things and clean all surfaces of the remnants of the old coating and dust.

The next step is preparing workwear, tools and material . You will need 2 containers (for liquid insulation and water), a sprayer, a pump with a compressor, hoses, thick clothing, a respirator, goggles, and a tool for cutting off excess frozen material.

The PU foam components should be mixed according to the instructions and mixed thoroughly to maintain the positive characteristics. Attic insulation using polyurethane foam is the application of liquid material between the rafters and on the floor, filling all the cracks and hard-to-reach places. If necessary, application of 2 or more layers is allowed.

Upon completion of the work, the roof and floor form a single whole with the insulation. In winter the attic will be warm, in summer it will be cool. If you cover polyurethane foam with finishing material, it can last up to 30 years.