Rafters and sheathing are the roof frame, which bears the entire weight of the roofing pie, thermal insulation, and snow load, so they must have high load-bearing capacity and strength. The idea of using metal rafters to make the roof structure more rigid is not new, but previously it was used mainly for covering industrial or utility structures. Nowadays, rafter frames and metal profile sheathing are considered a real alternative to wooden roof elements if the length of the slope exceeds 10 meters.

Functions of rafters

The roof truss frame structure consists of many interconnected elements that form trusses. The pitch, the cross-sectional size between the rafters and other supports is determined by the calculation of the loads to which they are subjected during operation. The roof frame performs the following functions:

- Load distribution. Interconnected nodes, reinforced with corners, evenly distribute the weight of the roof, which can reach up to 500-600 kg, taking into account the snow load. The larger the cross-section of the rafters and the smaller the pitch between them, the greater the load-bearing capacity of the structure.

- Giving slope and shape. The rafters, located at an angle to the base of the roof, form an inclined plane of the slopes, so that snow and water do not accumulate on the roof surface.

- Forming a base for fixing the roofing material. The finishing coating of the roofing pie is attached to the roof frame. The sheathing acts as a basis for fixing the covering, distributing its weight evenly across the rafters.

Note! What all components, rafters and sheathing of the roof structure should be like is determined by engineering calculations. To determine the required load-bearing capacity of the frame, it is necessary to calculate the total load to which it will be subjected. To do this, add the weight of the roofing material, insulation, waterproofing, maximum snow load with the weight of the rafter system.

Internal structure

From the under-roof space, the roof is a rather complex load-bearing structure, having inclined, vertical and horizontal roof elements. For their manufacture, they mainly use well-dried wooden beams or boards, connecting them in a certain way. Instead of processed parts, natural poles of small diameter can be used.

The traditional gable roof is based on an isosceles triangle, the length of the base of which is greater than the length of each of the sides. The use of geometric laws makes it possible to obtain high-strength trusses that can easily cope with the load on the roof from roofing material, precipitation and wind.

Rafter system

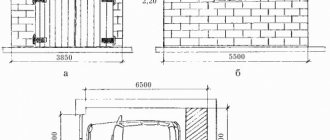

The main part of the roof is the rafters - long thick pillars, beams or boards knocked together in pairs, connected at their ends at a certain obtuse angle. Depending on the length of these parts, determined primarily by the dimensions of the building over which the roof is built, their minimum cross-section is determined. It is convenient to use a table for this:

Please note that the cross-section of the rafters or boards depends on the distance at which they are spaced from each other. An increase in the installation step of the pillars leads to an increase in the load on each leg, which requires an increase in its cross-sectional size.

The supporting ends of the rafter beams must rest securely on the walls of the pre-built box. There is also a certain complexity of installation here. Excessive load on the walls can lead to their destruction, so it is necessary to carry out preliminary calculations of this parameter and compensate for them.

Tightening, rack and struts

A simple way to reduce the pressure of the supporting ends of the rafters is to install a special tie between them - a tie, which is a long beam, post or boards nailed together, to which the lower parts of the beveled parts are attached. This option is possible only in one case - in the manufacture of an unused under-roof space - an attic.

Strengthening the triangle of rafter posts and tie beams is achieved by installing internal vertical and inclined parts. The short insert connecting the junction point of the rafters and the horizontal part of the truss is called a post. Small-diameter posts or cuttings of boards resting on inclined boards are called struts.

Types of rafter systems

The most common material from which the sheathing and rafters of the roof frame are made is wood. However, if the weight of the roofing material is large enough and the length of the slope is more than 6 meters, then the structure turns out to be too massive. Builders have to reduce the pitch between the rafter legs and increase their cross-section, which is why the roof assemblies acquire a lot of weight, increasing the load on the foundation. You can relieve load-bearing walls and the base of the building by using stronger, but lighter metal rafters. Based on the type of material used, the following types of rafter systems are distinguished:

- Wooden. Rafters and lathing made of wood are used for the construction of roofs, the length of the slope of which does not exceed 7-10 meters. The frame elements are fastened to each other using self-tapping screws, nails or movable metal elements. The step between the legs is usually within 50-80 cm.

- Metal. Metal roofing frames are made from steel metal profiles with a zinc coating, which is not afraid of moisture. Rafters and sheathing made of this material are light and durable, so the step between them can be increased to 1.5-2 meters. The metal profile is fastened using welding or fasteners. Metal roof components are used for slope lengths of 10 meters or more.

- Combined. A rafter frame that combines metal and wood components is called combined. The combination of support elements made of wood and galvanized steel makes it possible to create a cheaper structure with high load-bearing capacity by increasing the pitch between the rafters.

Please note that metal and wooden frame elements cannot be connected to each other without a lining of waterproofing material or treatment with an antiseptic drug. Since metal has high thermal conductivity, its proximity to wood leads to the formation of condensation and rotting of the rafters.

General structure

The roof structure is complex and can be represented by several mandatory elements. These include:

- rafters (rafter legs);

- racks;

- struts - long horizontal pillars;

- puffs;

- sheathing and counter-lattice;

- roofing material of one type or another;

- stingrays;

- ridge and valleys;

- gutters for collecting moisture - drainage systems and others.

Each part is important in the overall ensemble and performs specific functions. To better imagine the structure of the roof, let’s get acquainted with each of its parts in more detail.

Users often search for:

Fastening methods

Metal rafters are assembled into triangular, trapezoidal or arched trusses. Internal stiffeners are attached to the frame beams, which form corners that significantly increase the load-bearing capacity of the frame. This system allows you to make the pitch between the rafters larger, taking into account the support capabilities of each truss. Fastening the metal elements of the roof frame is performed using one of the following methods:

- Fastening by welding. If you weld the parts of the rafter system using a welding machine, you can get a rigid structure with high strength and load-bearing capacity. If you correctly calculate the roof, you can lighten the frame and reduce the load on the foundation of the structure. The disadvantage of this method is that only a professional can perform welding using special equipment.

- Fastening with bolts. Fixing the rafters with fasteners allows for a less rigid fastening. This method of assembling a rafter frame based on a metal profile is used in private housing construction, where the length of the slopes does not exceed 10 meters. Eliminating welding allows for faster roof installation.

Experienced craftsmen rely on the fact that metal sheathing and rafters can withstand more weight than wooden ones, so you can increase the step between them and reduce the thickness of the cross-section of the elements. Moreover, construction stores sell ready-made trusses, fastened by welding, suitable for covering buildings of standard width.

Correct installation of the power plate

Scheme for fastening a Mauerlat that does not transfer thrust to the wall.

It is worth recalling that the Mauerlat is the main supporting structure not only of the future frame, but also of the entire roof as a whole. It is this element of construction that takes on all roofing loads with its own hands, evenly distributing such loads onto the load-bearing walls of the house.

This allows you to increase the service life of the entire building, because in the absence of such timber, the roof load will destroy the walls in certain places. It is safe to say that the Mauerlat is the main supporting element of all known rafter systems.

This support element is not required only in the construction of wooden houses, in which the final row of logs or beams is used as a mauerlat. The described supporting element must be mounted flush with the inside of the load-bearing walls, which will simplify interior finishing work.

From the outside, the Mauerlat must be covered with brickwork or a strip of metal, which will protect the lumber from environmental influences. The top row of brick or block masonry requires a high-quality concrete blind area, which is covered with several dense layers of roofing felt or bitumen mortar.

Scheme of fastening the Mauerlat, which receives and transmits thrust to the walls.

Roofing material is needed so that all the moisture present in the walls stops in front of the support beam, which may suffer from excess moisture, as evidenced by its design. The simplest and most reliable way of attaching a support beam to the walls of a house can be considered the use of unique metal studs, which will connect the mauerlat and load-bearing walls.

Holes of the required diameter are drilled in the masonry, into which prepared metal pins made of simple steel reinforcement are lowered. By attaching the prepared support beam to such studs, you can mark the places for drilling holes.

The length of the studs should be such that after installing the Mauerlat, the reinforcement protrudes beyond the beam by at least 1.5 centimeters. At the ends of the reinforcement it is necessary to make threads, which will be required for the final fastening of the support beam with your own hands using extremely wide washers and nuts. This process of attaching the support beam can be simplified and done using a simple welding machine, which is used to weld a metal rod or washer to the rods.

Advantages

Metal rafter frames are used for the construction of roofs of any shape, any slope with a slope of 1-2 degrees. The materials from which rafters and sheathing are made are steel angles, round and rectangular pipes, and brands. In order to correctly select the thickness of the frame elements and choose the pitch between them, a calculation of the roof structure is performed, taking into account the permanent and temporary loads that are transferred to the rafter beams during operation. The advantages of a rafter system made from this material are:

- Fire safety. Unlike wooden ones, metal frame beams are not flammable, which increases the fire safety of the building.

- Easy to maintain. The zinc galvanic coating used to cover the steel corners protects the roof frame from corrosion throughout its entire service life. They, unlike wooden ones, do not require annual treatment with an antiseptic.

- Zero waste. Although metal structures are quite expensive, it is considered cost-effective, since fastening is carried out by welding, and there is practically no waste left.

- Long service life. If you correctly calculate the loads, then a metal roofing frame will last more than 100 years, which exceeds the service life of even the most stable roofing coverings.

Professional roofers believe that it is advisable to use welded metal structures for the manufacture of roof rafter frames with a slope length of 10-12 meters. In this case, the main task is to correctly calculate the loads, and then determine the step between the legs in accordance with the climatic characteristics and properties of the roofing material.

Rules for installing the Mauerlat

It is necessary to understand that the Mauerlat is the main supporting structure for both the roof frame itself and the entire roofing system. It is the Mauerlat that will fully accept external loads on the roof and distribute them evenly between the load-bearing walls of the building.

This makes it possible to significantly extend the operational period of the entire structure, because in the absence of such timber, roofing loads will destroy the walls in certain areas. We can confidently say that the Mauerlat is a key supporting component of any rafter structure.

There is no need to arrange a mauerlat when logs and wooden beams are used as rafters, the outermost row of which performs these functions.

- The described supporting component of the rafter system is mounted at the level of the walls on the inside. This makes it possible to significantly simplify further finishing work inside the building.

- From the outside, the supporting element is covered with a metal strip and brickwork. This makes it possible to protect lumber from the adverse effects of the natural environment.

- The top row of building blocks or brickwork requires the construction of a high-quality concrete blind area, which is subsequently covered with dense roofing material in several layers or a bitumen mixture. Roofing material will prevent moisture absorbed by the walls of the building from entering the wooden support beam.

- The most reliable and simplest option is to attach the Mauerlat to the load-bearing walls of the building using specialized metal pins. Holes of a specified diameter are made in the building block or brickwork, then metal fastening pins are lowered into them (they are made from ordinary metal reinforcement). Next, a support beam is placed on the inserted studs, and the points of the holes that also need to be made in the beam are marked. The length of the stud is taken such that the reinforcing bar, after installing the Mauerlat, protrudes beyond the timber by at least 1.5 cm.

- It is necessary to make threads at the ends of the reinforcing bars for final fixation of the support with nuts and washers.

Flaws

Despite the obvious advantages, metal rafter systems are not the most popular design solution in private housing construction. Even a large step between the rafters and sparse lathing with the high cost of metal cannot make the structure cheaper than a wooden one. The disadvantages of metal rafters are:

- High thermal conductivity. Metal has a high thermal conductivity coefficient, so the rafters and roof sheathing form cold bridges. From the point of view of energy efficiency, a frame made of metal profiles is not the best solution.

- Problematic transportation and installation. When choosing a metal rafter system, take into account that transporting, lifting and fastening long and heavy elements is more difficult than standard-length lumber rafters.

- Difficult to install. To lift the trusses to a height and fix them, special equipment is used, the rental or purchase of which is expensive.

- Deformation under high temperature. Although metal is considered a non-combustible material, during a fire it is greatly deformed, which usually leads to the collapse of the roof.

To determine whether it makes sense to use more expensive rafter elements made of metal profiles, you need to calculate the roof frame. If the length of the slope exceeds 10 meters and the load is more than 450-600 kg, then installing a metal frame is economically feasible.

Materials, tools for making a frame

Before you start building a roof frame, you need to select high-quality consumables. To arrange the rafter system, wooden beams and edged boards are used. It is recommended to use building materials made from coniferous trees, since it contains natural resin that acts as an antiseptic that prevents wood from rotting. The wooden beams for making the frame should have a cross-section of 15x15 cm, the parameters of the edged board should be 5x15 cm.

It is also necessary to remember that the rafter structure includes more than just rafters - purlins and racks are also installed under them, including the attic floor, sheathing, and counter-lattice. If the attic space will be used as a warehouse, and there are no plans to turn it into a living space in the future, then 5x15 cm boards are sufficient to cover the attic. But if the attic is to be built, then you need to use timber with a section of 15x15 cm.

For the manufacture of sheathing and counter-lattice, timber with a cross-section of 4x4 cm is perfect. This building material can withstand the load of any roofing structure.

Necessary construction tools

- Staples, brackets necessary for attaching rafters to the support beam.

- Special metal studs for reliable fixation of the mauerlat (support beam).

- Additional fasteners - galvanized nails, studs, self-tapping screws.

- Yardstick.

- Plumb line (building level).

- Saw on wood.

- Axe.

- Plane.

- Electric drill.

- Hammer.

Application of metal rafters

Metal is a heavy and quite expensive material. But at the same time, it has high strength and can be given almost any shape.

In some cases, when constructing a roof frame, it is much more convenient to use metal elements instead of traditional wooden ones.

A metal rafter system is used in the following cases:

- To manufacture the rafter system, a long beam (more than 10 meters) is required;

- To give the roof additional rigidity.

The metal rafter system is mainly used in the construction of industrial buildings, such as train stations, supermarkets, swimming pools, warehouses, etc. In private construction, metal roof rafters are used quite rarely, since these elements are expensive. In addition, their transportation and installation is quite difficult.

Metal rafters are used in cases where the length of the roof slope exceeds 10 meters. In such cases, it is appropriate to use purlins, ridge supports and Mauerlat made of metal. The Mauerlat beam is replaced with a powerful channel. Metal rafters are attached to it using welded corners.

Metal frame made of profile pipe

An excellent type of frame for roofs in use, where drainage is properly arranged and there is sufficient air circulation under the structure. With this type of frame, profile pipes 3x40x40 and 3x30x50 are used. A wide pipe is laid on the crawl, then pipes used as lags are installed perpendicular to it. They are placed horizontally in increments of 35-40 cm. As elements providing support and regulation, sections of profile pipe are used, which are welded to the upper and lower pipes. All structural elements must be painted with protective enamel to prevent the formation of rust. Stainless or plastic clamps for installing WPC decking are attached to logs from a profile pipe using stainless or galvanized self-tapping screws with a drill.

With proper installation of such a base, the flooring has excellent rigidity and reliability. When walking on boards on such a foundation, you get the feeling that you are walking on a concrete surface. We believe that this type of frame is perfect for commercial buildings (restaurants, shopping centers, etc.), where the flooring will be subject to significant pedestrian loads.

- Decent rigidity and reliability

- Low cost of work and materials

- Susceptibility to corrosion

Advantages and disadvantages

Light steel frame technology is an advanced technology for the use of metal elements. Elements of metal trusses are made from paired lightweight galvanized profiles.

Metal structures have the following advantages:

- Fire safety. The rafter system does not contain elements made of combustible materials. This eliminates the possibility of the building catching fire from the roof.

- There is no need to perform annual treatment of the structure with fire retardants and antiseptics.

- Long service life. Manufacturers provide a hundred-year guarantee. This design is not exposed to mold, mildew and rot. Metal protection from corrosion is ensured by applying a zinc coating.

- There is absolutely no waste during the work. This is due to the high accuracy of metal design parameters. Installation of such a structure can be carried out all year round.

- Environmental friendliness. The structures consist of environmentally friendly materials that are easy to recycle. It is important to note that the design parts do not need to be treated with chemicals that have a negative effect on the human body.

Metal rafters will be a good option for multi-story buildings. They are also used as a base for ceramic tiles, since this material places a significant load on the rafter system.

Processing lumber with additional compounds

As mentioned above, any lumber must be protected from moisture, insects and fire. To do this, it is worth using solutions such as an antiseptic and an antipyretic. The second composition allows you to increase the protective qualities of wood, which are associated with resistance to high temperatures. Antiseptics can protect wood from moisture, rot and harmful insects.

All lumber is processed before installation, which allows the entire surface of the board or beam to be processed. This is how you can count on increasing the service life of the wooden load-bearing frame of the roof of the house.

Combined rafter systems

When constructing roofs, combined rafter systems are often used. They use not only wood, but also metal elements.

This method has certain nuances that should be taken into account. Wooden and metal elements should not come into contact, since with a sharp change in temperature, condensation forms on the metal parts, which causes rotting of the wooden parts.

This can be avoided if you pre-treat the wooden elements with moisture-resistant compounds and antiseptics. You can also isolate wood from metal using roofing felt.

Some subtleties of independent design

A gable roof can be designed by a non-professional; there is nothing complicated about its design, but several additional roof parameters should be taken into account:

- roofing material significantly increases the weight of the roof. Lightweight and durable material (roofing tiles) is quite expensive. Heavy and durable tiles are also not cheap; their weight must be taken into account when calculating the rafter system;

- all lumber must be treated with a fire-resistant compound and anti-bug and rot agents;

- if the timber is laid on a brick or other similar material, there must be waterproofing between it and the wall;

- a very important part of the rafter system is the fastenings between the parts; they can be made using different techniques (bolts, mortise or other methods), but must always be made with the utmost quality;

- If you plan to equip an attic in the attic space, pay attention to the windows at the stage of drawing up the project. With a certain effort, you can avoid complicating the rafter system;

- if the attic is planned to be cold, then pay attention to ventilation; the roof should be ventilated in any weather.

Designing and installing a gable roof is entirely within the capabilities of a non-professional. But if you have such an opportunity, entrust the calculation of the main parameters to a specialist, this will help you avoid costly mistakes.

Types of metal trusses

Classification of metal trusses by belts:

- with parallel belt. This option has many similar parts, the same length of the belt and lattice rods, a small number of joints, and complete unification of the design. All this makes the process of installing metal trusses quite easy. Rafter trusses of this type can be used under soft roofing.

- trapezoidal ( single slope). It is characterized by the design of nodes of increased rigidity, as well as the absence of long rods in the middle part of the truss. This design is quite economical.

- truss of polygonal design . This option is quite complex and is usually used in the construction of buildings with a large span and weight. Using this type of trusses allows you to save a large amount of steel. It is not advisable to use such a design for small buildings, since the savings will be small.

- triangular truss design . The advantages of this type include ease of manufacture, as well as the possibility of use for roofs with a large slope angle. It should be noted that most support units have a complex structure. A significant amount of material is required to make the long bars in the central part of the truss.

Furniture for a small hallway

The ideal solution would be a small multifunctional mirrored wardrobe. Be sure to think through its internal architecture in advance in order to make the most of even shallow furniture. Corner hallways are also not a bad option.

For shoes, it is better to purchase a small shoe rack that can simultaneously serve as a table or chair.

Interesting shelving and space zoning

Provide spacious shelves on top for winter clothes and things you don’t use.

It is better to opt for light-colored furniture, but it is still better to make the lower level a little darker, so the dirt will be less noticeable. Strive for compact and multifunctional solutions; huge cabinets and upper mezzanines are immediately sent to landfill.

What to consider when calculating metal structures

To perform calculations of metal trusses, certain knowledge is required. Usually calculations are performed using special computer programs. Calculations must be accurate, since the strength and reliability of the structure will depend on this. The following factors must be taken into account:

- Constant loads on the structure (weight of the roofing and rafter system);

- Additional loads (wind, snow, weight of people on the roof);

- Periodically occurring loads (hurricane, seismic).

Slope - the flat, sloping side of a roof

As a rule, when paying attention to the roof of a building, the first thing that appears to the gaze of an outside observer is called the roof. Their main function is to collect precipitation and protect the house from the wind. In this regard, the angle of inclination of the plane relative to the horizon is of great importance. If its amount is small, the snow will not completely melt during thaws, which will lead to a significant increase in the load. With a large angle of inclination, the wind load on the roof will be high.

Depending on the presence of roof slopes, there are:

The number of slopes may vary. In many outbuildings, especially those located at the boundaries of the site, they prefer to make pitched roofs that have a slope in one direction. This type of roofing is easy to manufacture and easy to maintain. Some residential buildings are also equipped with similar roofs.

Thermal insulation of metal roof trusses

It is important to note that condensation is dangerous not only for the rafter frame, but also for the thermal insulation material. Most insulation materials lose their useful properties when wet. For this reason, it should be laid above or below metal rafters.

When laying thermal insulation material under the rafters, all other elements of the roofing pie must be located above the insulation layer. This is done in order to prevent the appearance of cold bridges.

When constructing a metal roof frame, it is necessary to contact roofers who have similar experience.

Creating a gash

Fixing beams without cutting is used for sliding connections. The corner for attaching the rafters to the mauerlat allows you to securely fasten the beams. The fixation method does not allow the roof structure to withstand significant loads, so it is used to cover a hipped roof with small spans.

You can get a reliable support unit using a cut or a blocking tooth. The insert is made in the rafter leg at a quarter of the thickness of the product. In practice, several options for the device are used:

- Rigid fastening - works to compress the inner side of the support beam.

- A movable fastening is obtained when a tooth is formed on the outer side of the beam (to prevent the rafters from slipping out of the Mauerlat, they are additionally secured with brackets or corners).

- Instead of sawing, a persistent beam can be used, which is nailed to the beam.

conclusions

- Metal rafters are used mainly in the construction of industrial and public buildings.

- Metal structures are very durable. They are able to withstand enormous loads.

- Combined type truss structures are often used. They include metal and wooden elements.

- The main elements of metal trusses are the lattice, the lower and upper chords.

- The strength and reliability of the structure being built directly depends on the accuracy of the calculations. The choice of type of metal systems is influenced by the roof slope.

Main structural elements

The main elements of metal trusses are:

- lower, upper belts - form a contour;

- a lattice assembled on the basis of braces and racks.

The elements are connected at nodes directly adjacent to each other. The grating rods are fastened to the belts by welding or using shaped elements.

In addition to rafters, there are also sub-rafters. They serve as supports for load-bearing structures and floors in cases where the distance between columns is greater than the pitch of the beams or the columns have unequal pitch.

Metal rafters: advantages and disadvantages

The entire mass of the roof and additional snow loads are taken by the rafters with sheathing. Therefore, it is important that the structure has a high load-bearing capacity and is durable. Usually wooden materials are used for this, but if the slope is more than 10 meters, it is more advisable to use metal. In the past, steel rafters were installed only on industrial buildings, but now the situation has begun to change. We invite you to find out where metal rafter systems are used, what types there are, as well as the advantages and disadvantages of the products.

Scope of application of metal rafters

As a material, metal frightens builders with its high cost and heavy weight. It is very difficult to install such a roof manually. However, it has high strength and flexibility, which allows you to make a roof of any shape.

Typically, metal rafter systems are used in the following cases:

- when you need to make a slope that is too long and the wooden beam will bend under its own weight;

- create a rigid, complex-shaped structure.

As a rule, metal roof truss systems are used in commercial construction: warehouses, shops, swimming pools, and so on. The rafter system is rare in private construction, since the material itself is expensive. In addition, it is difficult to transport long steel beams to a site within the city.

In construction, rafters made of metal purlins, special supports for the ridge and Mauerlat beams made of channel are used. The fastening of the slopes occurs through the corners secured by welding.

Types of metal systems

Although the article discusses metal rafter systems, they can be divided according to the materials used. There are two varieties:

In the first version, the frame is made of galvanized steel profiles, so the products are not afraid of moisture. Thanks to the increased strength of both the rafters and the sheathing, the pitch can be increased to two meters. The parts are attached to each other either by welding or special fasteners. The maximum length of a metal rafter leg is 30 meters. The service life of such structures is much higher than wooden ones.

What is good about a roof frame made from a profile pipe?

There are many options available for roof installation. Why should you choose a profile pipe? Firstly, it is streamlined, which practically minimizes wind pressure. This material is easy to paint and does not retain moisture. Thanks to this, profile pipes are resistant to corrosion. However, it is worth considering that the entire structure must be sealed from the ends to prevent moisture from getting inside.

Roof made of profile pipe

Despite the fact that visually they seem bulky, they are hollow inside, which means they are light. This reduces the load on the foundation.

When manufacturing pipes, they are processed using specialized machine equipment, due to which they have different cross-sectional shapes. It can be round, rectangular or square.

The profile pipe is made of steel, its diameter can range from 6 to 12 mm.

To understand how to make a roof from a profile pipe, you need to study its design.

One of the key factors determining the resistance of the roof frame to loads is the pitch of the rafters - the distance between adjacent rafter legs located on the same slope. The more accurately the rafter pitch is calculated, the more durable and reliable the roof structure. In addition, you should select the correct cross-section of rafter legs and other structural elements. Errors in calculations can lead to the fact that during operation the roof is deformed under the influence of external loads

.

The rafter leg must be strong and rigid in bending. Its length and cross-sectional size correlate with each other: the longer the rafter, the larger its cross-section should be. The length of the rafter leg is determined based on the angle of inclination of the slope and the height of the ridge. When calculating the gap between the rafters, you should also take into account the angle of the roof - the steeper the slopes, the greater the pitch of the rafters can be

. But if the rafter legs are long, the distance between them should be reduced.

The gap between the legs is on average 80-100 cm, with a rafter pitch of 60 cm being considered an acceptable minimum, and a reasonable maximum being 150 cm. To determine the optimal number of rafter legs on a slope, the following steps are performed

:

- the length of the wall on which the rafters will rest is measured;

- the resulting value is divided by the most suitable step;

- One should be added to the result and the resulting value should be rounded up.

This algorithm allows you to calculate the required number of rafters for one slope, and to find out at what interval they will be installed, the length of the wall should be divided by the resulting value. The result will be equal to the center-to-center distance between the rafter legs, which is the pitch of the rafters.

It should be noted that the general methodology does not take into account such nuances as the choice of insulation. By adjusting the pitch of the rafters to the width of the heat-insulating roll or slab material, you can simplify the installation of the roofing system and reduce construction costs. The size of the gap between the rafters can be adjusted to certain limits - you should not increase the calculated pitch of the rafters when constructing a rafter system for heavy roofing materials.

The rafter system for metal roofing, on the contrary, does not require special reinforcement. This material for external roof covering is characterized by fairly high strength with relatively low weight. Sheets of metal tiles are mounted on a sparse sheathing of bars or boards, which is attached to rafters located in increments of 60 to 95 cm. These are average values for rafter legs made from a standard board with a cross-section of 50×150 mm, with a length of up to 4.5 meters.

If you plan to use a heat insulator with a thickness of more than 150 mm, it is recommended to make rafter legs from boards with a cross-section of 50×200 mm, so that you do not have to increase the width of the rafters with slats from the attic side.

Features of installing a frame under metal tiles

In general, the rafter system and sheathing for metal tiles are calculated and installed according to standard rules. A fundamental feature can be considered the need to fasten the upper support of the rafter leg on top of the ridge girder, and not in the side of the ridge beam. In this case, in the upper part of the roof, in the ridge, there remains free space necessary for normal air circulation in the roofing pie. If you do not ensure proper air circulation in the system, condensation will form inside the roofing pie, causing corrosion of the metal tiles

.

To make the air exchange of the insulated roof more intense, it is recommended to drill holes with a diameter of about 10 mm near the upper edge of the rafter legs.

The construction of a roof frame made of metal tiles may require the use of elements to strengthen the rafter system. The elements that impart rigidity to the structure usually mean tie rods and crossbars - horizontal jumpers between the rafters in a hanging-type system. The tie is located at the base of the rafter legs, the crossbar is closer to the ridge. Reinforcement of layered rafter legs is carried out by installing horizontal purlins on racks - this provides an additional point of support. Additional elements include fillies - special boards that allow you to increase the size of the rafters in length to form an overhang for a metal tile roof.

When installing a wooden rafter system, it is important to take care to protect the wood from damage by rot and fire. Antiseptic impregnation will prevent the biological destruction of wood materials, and the fire retardant composition will reduce the risk of fire and the rate of fire spread. To treat rafter structures after assembling the frame (or individual elements before its installation), complex fire-bioprotective impregnation or separate specialized compounds can be used.

The treatment is carried out in two passes with a break for the first layer to completely dry. The composition is applied with a roller or soft brush.

Installation of a metal roof frame

The frame of a metal-tiled roof of a private house is most often built from wood - this material is easily adjusted to size and installed without the use of specialized equipment. However, the installation of a supporting structure for metal tiles in some cases can be made of a metal profile. In particular, during construction

:

- garages;

- hangars;

- pavilions;

- gazebos;

- outbuildings.

Metal profile rafters for metal tiles have a number of advantages

:

- withstand high loads;

- allow the installation of long beams (more than 10 meters) without additional supports;

- the design does not propagate combustion;

- the frame is durable (with proper installation and protection against corrosion);

- metal profiles make it possible to produce a reliable roofing structure of a non-standard configuration.

The disadvantages of an all-metal roof include the high thermal conductivity of the material - the frame acts as a cold bridge

. That is why a metal roof is most suitable for non-residential buildings that do not require heating. In addition, the use of metal profiles significantly increases the cost of construction.

The high strength of the metal profile and its bending rigidity makes it possible to span large spans without installing supporting structures. This simplifies the installation of the roof.

If metal rafters are to be used, the entire roof frame must be metal. A channel is used as a Mauerlat, to which the lower ends of the rafters are subsequently welded. The frame is made according to the project independently, or ordered at production. In the second case, the accuracy of geometric dimensions and the quality of welding are higher, but the finished structure will have to be installed on the walls of the building using lifting mechanisms. Installation of a frame from individual elements makes it possible to adjust them on site.

Particular attention should be paid to protecting metal structures from corrosion and preventing the formation of condensation.

Water vapor on the metal condenses when exposed to warm and cold air simultaneously. To prevent corrosion, welds should be made correctly: there should be no slag particles left in them

. The metal profile frame and, first of all, the joints of the elements are treated with a special primer, on top of which two or three layers of ordinary paint are applied. It is recommended to use paints and varnishes that prevent rusting.

The use of lightweight profiles for the construction of modern buildings

At the moment, new technologies are being used in construction, which are aimed at the construction of light truss structures in residential buildings.

These include galvanized cold-formed profiles, its advantages are:

- resistance to destruction processes, including rotting and damage from insects;

- high fire safety;

- does not require constant antiseptic treatment;

- such a metal roof frame is constructed, regardless of the time of year;

- compliance of purchased parts with the specified dimensions, which reduces the amount of waste;

- ease of installation - the work is performed with a drill and screwdriver;

- the collapsible design kit allows it to be transported without expensive lifting equipment.

Thanks to similar metal trusses. significantly different from profile metal elements with a metal thickness of less than 2.5 mm, developers can save on the purchase of material.

The lightweight design does not increase the load on load-bearing walls and foundations, which also reduces the construction budget. Any craftsman with basic skills in such installation can assemble a gable roof frame. The work will not be particularly difficult also because all drawings of parts and their markings are thoroughly checked in production.

Along with the listed advantages, lightweight rafter structures still have a drawback - they act as a conductor of cold, which means they are difficult to insulate. Also, condensation often appears on them, which has a destructive effect on the roofing cake. Based on this, it is still better to build residential buildings from wood.

Installation of a metal frame, watch the video: