When arranging the roofs of private houses, garages, outbuildings and other structures, slate is often used.

This is a reliable and versatile material, characterized by ease of installation and unpretentiousness to operating conditions.

In order for the roof to last longer and not require premature repairs, it is necessary to pay due attention to the choice of material, correctly perform calculations and installation work.

We’ll talk more about arranging a pitched slate roof in the article.

Advantages and disadvantages of the design

This material has many advantages that make it in demand and popular:

- Affordable price .

Slate is one of the most inexpensive materials used in the construction of roofing structures. Its average market price starts from 150 rubles per square meter. For comparison: corrugated roofing with a thickness of 0.65 mm will cost approximately 200-220 rubles per m2. To install a roof made of soft slate (for example, ondulin) you will need almost 2-2.5 times more money, its price is from 350 rubles. Good quality metal tiles are sold at approximately the same price.

Long service life .

There are thousands of cases where slate roofing on buildings built more than 50-70 years ago (back in Soviet times) remains in perfect condition to this day. This coating easily withstands changes in humidity and temperature, does not deteriorate due to frequent rains and snowfalls, and is not destroyed by ultraviolet radiation.- Non-flammability. In the event of a fire, slate does not ignite and therefore does not contribute to the spread of fire.

It can only crack or become covered with soot. But it should be taken into account that the wooden sheathing and rafter system are susceptible to fire - when these structural elements burn, the roof simply collapses, which leads to the destruction of the slate sheets themselves. To avoid such situations, wooden elements should be treated with special fire-resistant compounds.

However, the material has some disadvantages, which in certain conditions are important:

- Fragility. Slate sheets are not designed for heavy loads, especially impact loads. Walking on such a roof, careless handling of the sheets during their installation, as well as the accidental fall of heavy dry branches from trees - this can lead to the material becoming covered with cracks, or large pieces starting to break off from it. Therefore, slate should not be used for roofing buildings next to which tall old trees grow.

- Heavy weight . One square meter of slate, depending on its thickness, can weigh about 7-10 kilograms. Such a coating places a significant load not only on the roof frame, but also on the load-bearing walls and foundation of the building. Therefore, heavy slate, especially 7 mm, is not recommended for use in buildings built on relatively weak soils and without a reinforced foundation.

A little history

Translated from German, the word Schiefer means “slate” - a layered rock that has been used in construction since ancient times as roofing. Therefore, the sometimes used definition of “slate slate” is redundant. For us, slate is, first of all, a roofing material made from an asbestos-cement mixture in the form of corrugated sheets with standard dimensions. Flat sheets are also produced, but they are not used in their original form on roofs, but for household needs, sheds and fences they are in demand, although in recent years, with the advent of corrugated sheets and cellular polycarbonate, they have also lost their position. From the article about popular facade materials you can find out how to decorate a house so that the walls match the roof.

Thanks to the properties inherent in the raw material base, slate is resistant to temperature fluctuations, absorbs sound, is not subject to combustion, the effects of acids and aggressive chemicals, and has a long service life.

But the raw materials also “rewarded” it with weaknesses - asbestos dust is carcinogenic and causes lung diseases, the natural gray color is dull and monotonous, over time the coating can be “mastered” by various microorganisms, and mold and mildew can hardly be considered decor.

As for claims regarding the tightness of slate roofing, in most cases it is not the material as such that is to blame, but unscrupulous businessmen hiding behind dubious specifications instead of GOST, and violations of technology during installation. High-quality, correctly installed slate serves for decades without requiring intervention from the owners, and insufficient external attractiveness is successfully “treated” by purchasing colored slate (painting it yourself) and original installation.

Responsible manufacturers solve the issue of carcinogenicity by replacing dangerous asbestos with chrysotile, which is considered neutral - the product characteristics are similar, and chrysotile cement slate wins in terms of environmental friendliness. However, in fairness, it can be noted that slate lying on the roof does not cause significant harm, but the dust released when working with sheets can adversely affect health if protective equipment is not used.

Types and basic requirements for roofing material

Roofing coverings of this type are divided into several main categories depending on the composition and manufacturing technology. Let's look at the most popular types of slate:

Asbestos

Cement, asbestos and water are used to make this material . The proportions of these components are typically 85, 10 and 5 percent, respectively. Asbestos-cement slate sheets are cheaper and therefore are one of the most popular roofing coverings.

Non-asbestos

This material has a flexible and plastic structure. Unlike asbestos, it withstands shock loads much better and has a higher resistance to cracks.

One of the important features of the material is a wider range of colors, which allows it to be used for the implementation of unusual design projects. Non-asbestos materials include soft (European) or bitumen slate. The most common representative is ondulin.

Metal

Iron slate is made from painted steel sheets . In terms of its characteristics, it is practically no different from corrugated roofing sheets; in fact, these coatings are identical. The only difference is the wavy shape of the metal slate.

There are a number of specific requirements for such a roof. Firstly, the material must be highly resistant to thermal influences. This criterion is fully met by asbestos and metal slate, partially soft (can smolder and melt under the influence of open fire).

Secondly, the coating must have a smooth surface, otherwise the self-cleaning properties of the roof will deteriorate: snow, dust, leaves, etc. will accumulate on it.

The characteristics of slate materials are also regulated by the requirements of GOST 303040-95 and GOST 18124-95 .

The height of the wave and the distance between the upper/lower points of two adjacent crests are standardized and correspond to two ratings: 40-150 and 54-200 mm. The thickness of the sheets can range from 5.8 to 7.5 mm.

Owner reviews about colored slate

Unfortunately, some reviews about colored slate are negative.

Vitaly Golikov, 32 years old, Moscow: “Colored slate has a beautiful appearance, and such a roofing material is unusual. But as for me, this is a normal option for arranging a roof in a country house, but definitely not for a residential building. But why? Everything is very simple - this material looks tasteless and cheap. I had the opportunity to work not just with asbestos-cement material, but also with colored ones. It seems to me that there is no difference between the materials, other than the shade. Technical parameters and quality are similar in the two cases. In the case of colored materials, the issue of aesthetics can be considered. The only thing is that in this case with colored material we can talk about aesthetics. It turns out that if you can choose any shade that would fit the overall design.

I also noticed that during operation, under the influence of direct rays of the sun, the slate begins to fade and also lose its shade, which is very frustrating. This is exactly the moment that pushes me away from purchasing colored slate. As for me, it is better to buy the simplest slate, even if it is not so beautiful, but after a while the shade will remain the same and there will be no terrible fading spots on the surface.”

Sergey Milin, 39 years old, Tver: “During the construction process of a country house, the need arose to buy inexpensive roofing materials, and the choice in this case will be in favor of colored slate, which is included in the middle price category. The choice of material with a suitable shade, the technical parameters are very high, and I was disappointed by the fact that the slate is fragile, which is why cracks appeared on several sheets during installation work. Due to the large sheets, roofing installation will not take much time, but the disadvantage in this case is the huge weight, as a result of which it is important to have several people, because lifting slate is extremely difficult. During operation, I began to notice that when exposed to direct rays of the sun it could become much lighter. It is possible that the material will last about 50 years, but during this time its appearance will not be very good.”

Pie structure

Since slate has a wavy shape, moist air can penetrate into the space between the ridges in the lower parts of the roof (the upper parts are sealed with special metal ridges). To minimize the negative impact of moisture on the wooden elements of the roof frame, it is necessary to use a multi-layer roofing cake.

Its structure consists of several elements , which must be arranged in the specified order (from bottom to top):

- inner lining;

- ventilation gap;

- vapor barrier;

- insulation;

- waterproofing;

- counter-lattice;

- sheathing;

- slate covering.

Inexperienced builders often confuse the location of vapor and waterproofing, mistakenly believing that these materials perform identical functions. This leads to a noticeable reduction in the service life of the roof, since the vapor barrier layer is designed only to retain water vapor, and not rain or melt water in its liquid form.

The insulation, in turn, must be reliably protected from moist air penetrating from the premises of the house, as well as from precipitation, which can penetrate under the slate from the outside if it is accidentally damaged or improperly fastened.

Therefore, the thermal insulation material must be located between the vapor and waterproofing . Otherwise, it will quickly lose its properties.

The sheathing should not be attached close to the waterproofing layer. There should be ventilation gaps below and above it. Otherwise, condensation will accumulate.

Slate painting

Carrying out this operation will increase the service life and decorative qualities of your roof. An acrylic film will delay the destruction of slate for several decades. But the choice of paint must be approached very responsibly. It is better to use compounds from trusted manufacturers that are resistant to solar radiation and temperature changes.

It is recommended to paint slate with acrylic paint Source regstroy.com

The use of water-dispersion paint has a very important advantage: the mixture seals all microcracks on the surface of the material. In winter, roofing slate coated with this composition becomes more slippery, which helps remove snow and moisture.

Alkyd paints make the surface more elastic, and this prevents the appearance of defects. This type of coating also protects the roof from fading.

Special matte paint for slate Source tr.decorexpro.com

Minimum tilt angle

The slope of the roof is one of the key parameters on which its reliability, safety and service life depend. Depending on the type of slate and the weather and climatic conditions in the region, this indicator can vary within a wide range.

For asbestos slate, the optimal angle of inclination of a pitched roof is within 20-25 degrees . At lower values, snow masses will accumulate on it, and their spontaneous removal from the roof will be difficult due to the rough surface of the material.

If the slope is too great, the slate sheets may fall off the fastenings under their own weight, since the surface density of the material often reaches 8-10 kg per square meter.

Soft slate should be installed at an angle of 30-35 degrees , since ondulin has a higher coefficient of friction than asbestos cement. Accordingly, to prevent snow from accumulating on the roof, it should have a steeper slope.

If the building is covered with metal slate, you can reduce the angle to 5-8 degrees - to the same value as for corrugated roofing sheeting, which has a similar structure of the working surface. This material is smoother than asbestos or soft, so snow masses slide off the roof surface even with a relatively small slope.

What should be the minimum angle of inclination of a pitched roof, read here.

Preparing for slate installation

First you need to measure the area of the future slate roof in order to calculate the required volume of material. This process will allow you to roughly estimate the upcoming costs of constructing the structure. In order to take measurements, you can use the building design, or hire a professional.

After purchasing roofing material, you need to check if there are any defects on it. Damaged sheets should be replaced.

Slate sheets need to be checked for defects Source krovlyakryshi.ru

See also: Catalog of companies that specialize in roof design and repair.

Also, during the preparation process, mounting holes are drilled, and the material itself is cut to length.

You definitely need to pay attention to the fact that if you are going to cover the roof with slate, you will need reinforced sheathing. In order to create it, it is better to hire specialists, because the service life of the structure, as well as your comfort, depends on the quality of the support.

Reinforced roof sheathing Source stroyvolga.ru

Construction of the rafter system and sheathing

Slate sheets are relatively heavy, so the strength and load-bearing capacity of the frame is of key importance. In order for the structure to withstand such a load, which further increases in winter, it is necessary to equip a reliable and durable frame.

For rafter legs, it is recommended to use a wooden beam measuring at least 60x150 mm, the optimal option is 100x150 mm. Wood moisture content should not exceed 15%.

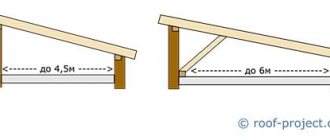

The spacing between adjacent rafters is chosen so that each sheet of slate rests on at least two longitudinal supports. The standard value is 1 meter .

Fixation of rafter legs can be done with or without cutting:

- When fastening without a cut, the projection of the cornice is usually ensured by the rafter itself. To ensure a tight fit of the rafters to the mauerlat, support bars are used; fastening is done on both sides through special metal corners with holes for self-tapping screws.

- Fixing with a notch requires cutting the rafters so that they fit snugly against the mauerlat. For the installation of eaves overhangs, fillies are more often used, which are attached to the rafters with an overlap of at least 1 m. Increased reliability of the assembled frame is ensured by rigid fastening using corners.

The sheathing is made from boards. The spacing of the transverse elements of the sheathing should be approximately 2 times smaller than in the rafter system - about 40-50 cm. The sheathing elements can be fixed in different ways. The traditional option is nails or long screws.

How roofing work is done when using slate

The slate sheets are attached from the bottom to the top vertically. The point of this is that the upper wave overlaps the lower one. In this case, one sheet must overlap the other by at least 10 cm. To ensure that all sheets protrude at the same distance, a tape or rope is stretched along the edge.

There are two ways to lay sheets. The choice depends on the roof slopes. If the vertical slope is narrow and the horizontal slope is wide, then offset laying is used. This option is notable in that it does not involve cutting the sheets at the joints. The sheet is attached to the sheathing one wave to the side. Each subsequent sheet is fixed on the previous one, overlapping one wave. In this case, laying is done in horizontal rows.

Correct installation of slate on the roof Source proroofer.ru

In the case where the vertical slope is narrow and the horizontal slope is wide, an installation with cut corners is used. In this case, the corners of the diagonal sheets are removed, and the joint is made with a small gap. This method allows you to avoid the appearance of cracks and defects in the roofing.

Installation of slate with cut corners Source www.remontyes.ru

How to install hydro- and vapor barrier?

To ensure effective protection of the roof and under-roof space from precipitation and condensation, you need to use high-quality hydro- and vapor barrier materials .

For waterproofing, roofing felt, polyethylene or polyvinyl chloride (PVC) film is most often used. Adjacent rolls are overlapped by 15-20 centimeters.

The joints must be glued with a special adhesive or construction tape. The film itself is attached between the rafters and the counter-lattice using a stapler or thin galvanized nails.

In a similar way, a vapor barrier coating is laid at the bottom of the roofing pie. For vapor barrier you can use both polyethylene and polypropylene products . They can have a flat or membrane structure.

Thermal insulation, if provided for by the project, should be located between the vapor and waterproofing layers. The thermal insulation layer creates a more comfortable environment in the premises, or in the under-roof (attic) space, if it is provided for by the roofing design.

Life time

The number of freezing/thawing cycles that the material must withstand is about 25-30. Since there are 2-3 cycles per year, or even more, the service life will be about 7-9 years. Not a very impressive figure. But it can be easily increased. All you need to do for this is to paint the slate. This can be done either before installation, or by painting an already installed roof. If you have a spray gun, it is more convenient to paint a large surface; if you work with a brush, it is easier to do it on the ground.

The service life of a slate roof will be longer if it is painted.

There are mainly two types of paint used for painting:

- Acrylic water-dispersed. They create a water-repellent film on the surface and fill the slightest cracks. As a result, both water and snow melt away faster. The disadvantage of these paints is that they fade quite quickly.

- Alkyd paints. They retain color for a long time, create a smoother surface, since they are thicker compared to other compositions.

Choose those properties that are more important for your case. Painting increases the service life of a slate roof by 1.5-2 times. In addition, the look is completely different, more stylish and modern. The disadvantages include the need to update the paint layer: you will have to paint it every 3-5 years.

Construction stages

Before starting construction work, you need to prepare the necessary materials and tools. In addition to the slate itself, you will need the following:

timber for the rafter system, sheathing and counter-lattice;- construction tape, glue and sealant;

- steam, heat and waterproofing roll materials;

- slate nails, self-tapping screws or special screws;

- fastening elements for a wooden frame (nails, screws or bolts);

- laser or water level;

- roulette;

- drill or screwdriver;

- hammer;

- grinder or hacksaw.

The selection of fasteners for installing slate sheets is carried out taking into account the material from which the roofing is made.

Slate roof structural elements are installed one at a time. It is most convenient to carry out roof insulation after installation of the roof covering:

- Rafter system . It is built from wooden beams, the thickness of which is selected individually, taking into account the slope of the roof, its size and other factors. Rafters can be installed using different types of fastenings: nails, bolted connections, etc. Bolts provide more reliable fixation, but their installation requires additional time for drilling holes. The rafter frame is attached to the mauerlat.

- Waterproofing. Moisture-proof coatings significantly increase the service life of wooden frame elements, protecting them from changes in temperature and humidity.

For this purpose, roll waterproofing is used. The waterproofing strips are fastened with a construction stapler along the roof, starting from the bottom. The strips are laid with an overlap of 10-15 cm. In the lower part (at the end of the eaves overhang), the waterproofing is glued to the drip, which serves to drain moisture that has fallen on the membrane into the gutters. - Counter-lattice. On top of the rafters, the waterproofing is fixed with counter battens. They will prevent the roofing material from tightly adhering to the waterproofing, which will contribute to a better level of roof ventilation and removal of moisture that forms on insulated roofs, while at the same time they act as a pressing element, which is necessary for waterproofing.

- Lathing. A sparse sheathing is laid under the slate with a step of 1-2 m between the boards.

- Slate. The sheets are laid with an overlap of at least 10 cm. If the overlap is too small, moisture will penetrate under the top sheets.

- Thermal insulation. The insulation is laid between the rafters, pressing it against the waterproofing and shifting each subsequent layer to the side relative to the previous one, so that cold bridges do not arise. The insulation is cut 2 - 3 cm wider than the width of the rafter span (the material should fit tightly, but not bend over).

- Vapor barrier. Rolls of vapor barrier material are placed on top of the heat insulator.

A conventional vapor barrier film is secured with staples using a construction stapler. The first strip of vapor barrier is attached at the ridge, and the subsequent strips are closer to the eaves, with an overlap, and are fixed in the same way as a waterproofing film, only carefully stretched, because There should be no sagging. The glued areas are reinforced with a pressure strip. It is very important to ensure a tight connection to surfaces. In areas adjacent to complex surfaces (chimneys, walls), glue must be used. The staples from the stapler are glued with tape. - Counter-lattice. It is mounted along the rafters and is made from smaller timber (section 50 mm). These bars will provide a longitudinal ventilation gap. It is possible to have a roofing pie with one ventilation gap, the top one, and the vapor barrier is always adjacent to the insulation.

- Inner lining . This part of the roofing structure is fixed with nails or fixed with long screws on the lower sides of the rafters.

Correct fitting and professional installation of slate - in the video:

Conclusion

It is quite possible to turn a tired, but one of the most durable and reliable materials into an exclusive coating with the help of cutting, painting and original styling. And in order to minimize the threat to health during work, you should not neglect protective equipment.

You can find out how to decorate the facade with flat slate in the topic “Frame thatched house”. About slate roofing, natural or from the same slate, see the article “Roofing like dragon scales.” About the roof of an unusual shape with an increased usable area - in the material “Sudeikin’s Roof...”. The video on making shingles shows another traditional roofing material.

Subscribe to our Telegram channel Exclusive posts every week

How to lay different types of slate?

How to lay asbestos sheets: most often they are fixed with special nails, which contain metal washers and shock-absorbing rubber rings.

The use of nails not intended for slate roofing is strictly prohibited. If you use unsuitable fasteners, the edges of the holes may crumble, causing them to gradually enlarge and allow precipitation to pass into the roofing pie.

To prevent the fragile material from crumbling when driving slate nails, holes should be made in advance at the fastening points using an electric drill with a thin drill of the appropriate diameter.

How to correctly lay sheets of asbestos slate: it is recommended to lay them staggered (in a checkerboard pattern). This means that the sheets in the top rows should be offset to the left or right relative to the bottom ones by about half their width. This should not be confused with overlapping, in which sheets are overlapped lengthwise.

Metal and soft slate are secured with self-tapping screws or screws with rubber washers , using a special power tool (this work is inconvenient and difficult to do with hand tools). Unlike asbestos, staggered laying is not necessary. They can be mounted without lateral displacement, since the metal sheets fit more tightly to each other.

Asbestos slate

There are three types of slate covering: metal, Euro-standard and asbestos. Metal is made of thin galvanized steel coated with a protective layer of polymer. The composition of Euro slate includes cellulose and basalt fibers, fiberglass, and jute. The last type is the most popular. The material is characterized by very high rigidity, because asbestos fibers are stronger than even steel. They are connected by cement. Asbestos threads are evenly distributed over the sheet, which creates a good reinforcing mesh. This helps to increase the impact strength and strength of the coating.

Asbestos slate is highly durable Source rmnt.mirtesen.ru

There are different types of corrugated asbestos slate:

- VU is a wavy slate with a reinforced profile. This material is used for roofing work in the construction of industrial buildings.

- VO - slate with a regular profile, having a rectangular shape. Not only the sheets themselves can be made from it, but also other roofing elements, for example, a slate roof ridge.

- UV is a wavy unified slate. It has a good wave width and sheet size. All this allows you to significantly reduce the number of joints.

Typical mistakes of novice builders, useful recommendations

Laying a slate roof, especially asbestos, is a very painstaking job, since such material is easily damaged by careless actions.

Inexperienced builders often make mistakes, due to which a significant amount of building material is damaged, unnecessary costs arise and the quality of installation work decreases.

A fairly common mistake is driving nails into the lower parts of the waves . This is incorrect, because with such fixation the material can crack, even if you drive the nail half a millimeter deeper than necessary. The attachment points should be located at the top of the ridges.

The second mistake is installing fasteners in the middle of the sheets. This also leads to cracks and rainwater penetration under the roof. The slate must be fixed in places where there is a side overlap, along the contours of the sheets. Each nail must be driven simultaneously through two sheets.

The third, one of the most serious mistakes, is the incorrect sequence of laying slate sheets. They must be installed in the direction from the eaves to the highest point of the roof, from bottom to top. Otherwise, the overlap will be incorrect.

The upper parts of the sheets, which are located lower on the slope of the roof, must necessarily be under the lower parts of the upper sheets, and not vice versa. Otherwise, water will flow under the joints.

Slate tiles - a classic of the genre, but side view

Current manufacturers adhere to either GOST 30340-95 or technical specifications, so sheets with different dimensions and thickness can be found on sale. In private construction, a standard 8-wave slate with a length of 175 cm and a width of 130 cm is usually used. Today, natural tiles, their imitations made of metal and composite, as well as soft roofing materials are at the peak of popularity, and the familiar slate wave has remained out of the topic.

If your financial capabilities do not allow you to take aim at the leaders in demand, but you want a roof that is not only durable and strong, but also beautiful, there is a way to both save money and show off - lay slate under the tiles.

To achieve the desired effect, the sheet is cut crosswise into two or three parts - short tiled waves are obtained that look more attractive than the standard layout. Portal users who have chosen traditional roofing material, but in an original design, prefer the first method - a sheet in half. So the look is transformed, and there is less fuss with cutting and fastening, as well as seams with gaps.

unkasFORUMHOUSE Member

The fact that you cut it into three parts, and not into two, will not add much to the beauty, but there is more fuss and the sheathing needs to be done more often than for ordinary sheets. And if you cut it in half, the lathing will even be simpler - you don’t need to make the middle board thicker.

By the way, some manufacturers offer already cut slate. If you find a similar supplier at a reasonable price (in Moscow this is quite easy), then there will be no need for cutting.

Stage 8. Installation of the ridge aerator

When installing the roof ribs, the row tiles are cut so that there is a 0.5 cm wide slot between the coverings of adjacent slopes. Please note that the “dragon tooth” cutting shape does not require laying ridge-eaves tiles on the roof ribs, because it can be cut from ordinary tiles. Roof aerators are installed on the ridge.

Roof aerators are then covered with ridge-eaves tiles. Please note that the ridge-eaves tiles are attached to 45 mm galvanized roofing nails with a wide head.

Replacing asbestos-cement slate with flexible tiles takes very little time. The technology for dismantling the old covering and installing a new roofing system is quite simple and does not require special preparation for renovation from slate to flexible tiles.

Stage 7. Installation of flexible tiles

Each shingle is nailed to the base with a regular hammer or using a pneumatic nail gun. A special tool allows you to increase the installation speed several times. If the roof slope does not exceed 45%, then the tiles are nailed with 5 nails, but if it is more, nails are required. Let us remind you that flexible tiles can be mounted on roof slopes from 12 to 90 degrees.

The illustration shows the installation of two-layer flexible tiles TECHNONICOL SHINGLAS Jazz Castile series, the warranty period of which is 50 years. This tile is produced in the form of “Dragon Tooth” cutting with a shingle size of 100x33.5 cm. The material is unpretentious in installation, because there is no need to remove adhesive films from each shingle, and the starting line uses ordinary shingles rather than ridge tiles. However, it must be remembered that for this form of cutting, the nail must secure the overlap of the two components of the tile.

The arrangement of nails depends on the series and shape of the tiles (refer to the manufacturer’s instructions), but what remains unchanged is that special galvanized roofing nails with a wide head must be used to install the material. If the roof is installed with regular nails, poorly nailed shingles can fly off during strong winds. Correctly installed roofing ensures that the roof will withstand wind gusts of up to 180 km/h.

Slate roofing maintenance and repair

You need to check the condition of the roof twice a year: before the start of the rainy season - in early autumn and after its end - in late spring.

It is necessary to clear away debris, plants and moss. It is mosses that need to be combated most actively: they secrete an acid-containing liquid that quickly destroys slate.

Over time, cracks appear on the roof

Sometimes the sheets crack or small holes form on them. They can be sealed with putty. You can prepare it yourself. You will need:

- 1 part of cement grade M-300;

- 3 parts asbestos fibers;

- PVA glue;

- water.

First, asbestos and cement are mixed dry. In a separate container, dilute PVA with water in a ratio of 1*1.

The area to be repaired is cleaned of dirt, washed with water, and then allowed to dry. Then coat with PVA diluted in water. After drying, an aqueous solution of PVA is gradually added to the mixture of cement and asbestos until a paste-like consistency is obtained.

This mass covers up the damage. The layer must be at least 2 mm. After the putty has dried, the repair area is painted over. It is better to work with PVA on a cloudy day - on a heated roof everything sets instantly, and you won’t have time to properly level it.

There are two more methods for sealing cracks. Using molten tar and using a fused roof. There are no questions about efficiency. If everything is done correctly, there will be no leaks. There are questions about the appearance: on a light gray roof, the black patches are very visible. Unless you glue a piece of slate on top, covering the size of the patch. In general, see the video for two more ways to repair slate.

Features of lathing installation

It is important not to forget about the potential danger of deformation of thick timber in conditions of high humidity. If you use a thinner element, it may not support the weight of the roof structure. The optimal timber thickness is considered to be 50-75 mm.

It is recommended to use edged boards without bark, since harmful insects that destroy the wood may grow under it during operation. All wooden elements of the sheathing should be treated with an antiseptic and fire retardant. There are situations when some time passes between the construction of the sheathing and the laying of the slate. In this case, it is advisable to strengthen the fastening of the roofing felt with several additional brackets to protect it from gusts of wind.

Calculation of the amount of slate for the roof

When choosing a slate profile from which the roof will be made, it is worth considering that the more waves a product sheet has, the more economical the roof will be. This means that adjacent sheets will overlap less, hence more sheet area will be beneficial.

NOTE!

It should be remembered that when calculating the amount of slate required, you need to take into account the angle of the roof.

Let's consider two options.

- The tilt angle is less than 15 degrees. In this case, the overlap of the slate during laying should be in two waves, and the length of overlap of the lower sheets with the upper ones should be at least 200 mm.

- The angle is greater than 15 degrees. The overlap of adjacent sheets can be in one wave, the amount of overlap is 160 mm.

Roof overlap

Accordingly, in the first case, if the roof is flat, more material will be needed. In addition, at small slope angles, snow may accumulate on the roof in winter, which will lead to significant loads on the roof structure.

IMPORTANT!

To calculate the number of slate sheets , as well as the calculation of rafters and sheathing, we recommend using our online calculator.

So, to calculate the amount of slate required for roofing, you need:

- Divide the total length of the roof slope along the canopy by the width of the sheet of material and add 10 percent to the result (18 percent for flat roofs) to take into account the vertical overlap of the sheets.

- Measure the distance between the eaves and the canopy , add to it the length of the overhang of the covering above the canopy, divide the result by the length of the slate sheet and add 13 percent (20 percent for flat roofs) for the horizontal overlap of the sheets.

- We multiply both results and add 10 percent “in reserve” so as not to run to the shops if a couple of sheets are missing.