Which roof is better for a garage, single-pitch or gable? How to build a roof correctly, and what should you pay more attention to during construction? The choice of roofing material and its characteristics are not unimportant. Concepts such as the angle of inclination, for example, are calculated using the formula. In addition, there are restrictions on the angle of the roof. In addition, its minimum value is different for each type of roofing material. If you decide to do it yourself, then you need to know all this, and also familiarize yourself with all the rules and features of roof construction.

Requirements for roofing material for a garage

Most car owners, when studying the issue of garage roofing, put forward the following requirements for the material:

- reliable protection from precipitation, i.e. the roof should not leak and must withstand the snow load characteristic of the region;

- thermal insulation. The material should at least slightly prevent heat from escaping from the room;

- safety. The roof should not be vulnerable to thieves;

- aesthetics. If the garage is located next to the house, then it should look attractive. It is advisable that the house, garage and other buildings on the site be covered with the same material - then the area will look holistic and stylish;

- efficiency. Well, who among us doesn’t want to save money! Of course, between two materials with similar performance characteristics, everyone will choose the one that costs less, and do it right.

Fortunately, a lot of materials meet these requirements. They can be divided into two types:

- soft . These are all rolled materials, including roofing felt, rubemast, linokrom, bikrost, uniflex, as well as other membrane materials and fiberglass-based coatings. Used to organize almost flat roofs. The materials are distinguished by their low price and good waterproofing performance, but there are also disadvantages. These are fragility, fire hazard and strong heating in the summer heat;

- hard. A good option for gable roofs. The properties are very different. This group includes profile sheets (corrugated sheets, metal tiles), slate, ondulin, concrete slabs.

How to make a rafter system

An integral element of any pitched roof is the rafter system, which provides support for the roof structure and evenly distributes all the loads present in it along the walls of the garage. To equip the rafter frame, it is best to use beams made of coniferous wood, having previously treated them with antiseptics and fire retardants.

There are two main types of rafter systems:

- Hanging . This type has two support points - at the top the rafters rest on the ridge girder, and at the bottom they are attached to the mauerlat. Hanging rafters are excellent for arranging a gable roof over a single garage of a small area - in such a building there are usually no internal load-bearing walls, so it will not be possible to install additional support. When using hanging rafters, there is no bursting load, which makes it possible to reduce the number of parts in the frame. To increase rigidity, additional elements are used - tightening, struts, etc.

- Layered . A distinctive feature of this type of rafter frame is the presence of a vertical post, which rests on a load-bearing wall located inside the building. This design allows you to distribute the load over a larger number of supports, reducing the degree of impact on individual elements of the building - that is, this is an excellent answer to the question of how to make a better garage roof. In layered rafters there is both a bending load and an expansion load. This type of rafter frame is suitable for spans up to 28 meters wide, but they are much more difficult to design and install.

Before making rafters for the garage, you need to carefully calculate them. During the calculation process, it is necessary to take into account the self-weight of the frame - it also affects the foundation of the garage. That is why proper selection of beams for rafters is important - their thickness and number should not be too large.

Type of roof structure

The choice of material for a garage roof depends on many factors . It is worth considering your budget, requirements for the appearance of the coating, as well as installation features. If you are planning to carry out roofing work yourself, then it is better to choose a material that is easy to install. It is also worth considering the load on the rafter system, foundation, and walls. Adjustments should be made for the climate in the region, incl. wind strength and direction, frequency and intensity of snowfalls, amount of rain. The maintainability of the coating is also important. But, first of all, it is worth taking into account the type of roofing structure:

- a pitched roof with a slight slope is the simplest and most inexpensive roofing option and is relatively easy to repair. Rolled materials (roofing felt) as well as sheet materials (metal profiles, galvanized) are excellent for such roofs. When the angle of inclination is less than 15 degrees, do not use slate and ondulin, which can crack if they cannot withstand the snow load;

- a gable roof can be arranged in almost any way. An exception will be rolled materials, which are difficult to fuse at an angle of inclination of more than 15 degrees. However, they are used as waterproofing. The optimal choice would be slate, ondulin, metal tiles and corrugated sheets. The latter will be a win-win option for areas with harsh winters, because the longitudinal ribs provide high resistance to snow loads. Do not forget that the roof, like the walls of the garage, must be insulated. This measure will reduce heating costs and prevent the formation of condensation, which can subsequently drip onto the car;

- Three- and four-pitched roofs are used extremely rarely, but they look original; all the same materials are suitable for them as for gable roofs. When purchasing, it is worth taking the material with a reserve, since there will be more waste when roofing a roof of a more complex structure. The most economical in this case will be metal tiles;

- A mansard-type roof has a slope angle of 45 degrees or more and a broken structure. An attic is a great way to complement a garage with a workshop, a recreation room or even a bathhouse, but you will have to be even more careful when choosing roofing material. Slate and thick sheet metal are not suitable, as they create an increased load on the rafters, so it is better to choose ondulin, metal tiles or corrugated sheets.

Now, armed with basic information, you can move on to analyzing the options for covering the garage roof.

Design

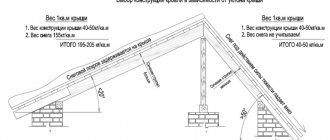

The first step in building a gable roof for a garage with your own hands is to create a project that reflects the main design parameters. To begin work, you need to determine three main characteristics: the height of the ridge, the slope of the slopes and the type of roofing. Calculations when creating a project are performed taking into account the loads placed on the frame elements. The total weight of the roof is calculated to determine how deep the foundation is required. To sketch a working diagram, you need to correctly make the following calculations:

- Based on the selected slope of the slopes, the height of the roof ridge is calculated. For this, geometric formulas are used, since the front projection of a gable roof is a triangle. The distance from the base of the roof to the ridge is calculated as the height of the isosceles triangle formed by the slopes and the base of the roof according to the formula: h= 0.5*b/tg(α/2), where b is the width of the garage, α is the slope of the roof. In most cases, to organize attic storage and maintain a slope of 20-30 degrees, a ridge height of 1.5 m is sufficient.

Important! The choice of suitable roofing material depends on the angle of inclination of the slopes. A slope of 20-30 degrees, which most experienced roofers recommend for a garage roof, allows you to use soft tiles, corrugated sheets, slate or rolled materials as a covering. But metal tiles, popular for DIY construction, require a slope slope of 35 degrees or more.

No. 1. Ruberoid

The cheapest way to organize a garage roof. Roofing felt is produced on the basis of roofing cardboard, which is impregnated with bitumen and protected with asbestos coating, which increases resistance to moisture, sunlight and mechanical loads.

Advantages of the material:

- cheapness;

- high degree of waterproofing;

- good for protecting hard-to-reach places;

- in the presence of special polymer additives, resistance to sunlight and temperature changes increases (these are the weak points of roofing material).

Main disadvantages :

- low durability. Within a few years after installation, there will be a lot of cracks on the roofing felt, so leaks are possible, and there is no need to talk about reliable protection of the garage;

- sensitivity to high temperatures (roofing material softens greatly) and low temperatures (becomes brittle);

- fire hazard.

In new types of roofing felt with modifying additives, some disadvantages were significantly reduced, which is why the material is consistently in demand. Experts call roofing felt more likely an option for waterproofing than for roofing.

Ruberoid is excellent for single-pitch, almost flat (slope up to 5 degrees) roofs. On the concrete base of the roof, a screed is first performed, creating a slight slope for better precipitation. For the screed, formwork is formed from boards; it is better to pour concrete at once. After 3-4 days, you can remove the formwork, and when the concrete has set well (15-20 days), you can begin installing roofing felt . Briefly the process looks like this:

- the screed is cleared of debris (swept up);

- the screed is covered with bitumen mastic, which will improve waterproofing;

- proceed to the installation of roofing felt, which is laid in strips in a direction transverse to the angle of inclination, the base is lubricated with concrete mastic, the bottom layer of bitumen is heated with a gas burner. The overlap of the sheets is 10-15 cm, installation begins from the bottom of the roof. After this, the roofing material is mounted in a perpendicular direction, coating it with bitumen;

- You can lay roofing felt in three layers, then the first is done in the longitudinal direction to the slope of the roof, the second - in the transverse direction, the third - again in the longitudinal direction. The bottom layer can be made not with roofing, but with lining roofing material.

Self-propelling and bulk roofing felt are also on sale.

Video description

All about the types and characteristics of soft roofs in the video:

See also: Catalog of companies that specialize in roofing materials.

Liquid roof

So, we continue to understand the question of how to cover the garage. And we move on to an amazing roofing material called “liquid rubber”. Essentially, it is a mastic that is applied in liquid form to a flat roof, and it polymerizes in air. The coating turns out to be very durable, but elastic, that is, it resembles rubber, hence the name.

Liquid roofing is divided into two groups:

- bitumen;

- polymer-bitumen.

The first one will last 15 years, the second 25. Their application technology is the same - using a spray bottle. The first group includes mastic brands: “Elomast”, “Gekopren”, BLEM-20 and others. The second is “Polykrov” with different fillings, for example, butyl rubber mastic or chlorosulfonate polyethylene.

Application of liquid roofing Source uteplippu.ru

No. 2. Rubemast

This is an improved type of roofing felt . It is also based on thick construction cardboard (although fiberglass can also be used), which is impregnated with bitumen on both sides. There is much more of the latter than in roofing felt, which ensures higher ductility, waterproofing and resistance to cracks. Powder is used for additional protection. The bottom layer is a polymer film designed to be melted by a burner during installation.

Advantages:

- low price;

- relative ease of installation;

- excellent waterproofing properties;

- resistance to heat and precipitation;

- durability up to 15 years.

Minuses:

- cannot withstand even light loads. If a person weighing more than 50 kg walks on the coating, then the appearance of cracks is inevitable;

- the base must be level, otherwise cracks may occur during operation;

- under constant exposure to direct sunlight, microcracks appear after 1.5-2 years.

Installation can be carried out using bitumen mastic (as in the option described above for roofing felt) or using a gas burner. If the installation work is carried out correctly, then the problem of roof leaks in the garage will not affect you for a long time.

Flat roof

We recommend reading: How to properly waterproof a roof

You can carry out the work of constructing a flat roof yourself, but it would still be advisable to invite specialists. Firstly, if you plan to use factory slabs for flooring, then it is impossible to lift and install them without a crane and workers. Secondly, even if the concrete floor is poured with your own hands, you will need not only a large amount of concrete, but also specific tools and devices.

If a concrete slab is poured directly on the garage, then it is made absolutely horizontal. The necessary slope is created already during the laying of the thermal insulation layer. And if factory floor slabs are laid, then the slope is made immediately, for which, when erecting walls, one is made slightly higher - normally the slope should be at least 2 cm per 1 meter of the building.

No. 3. Linocrom

Linocrom is a modern rolled material with a fiberglass base, which is treated with bitumen and protected with powder and polymer film.

Advantages:

- ease of installation;

- resistance to temperature changes;

- low weight;

- maintainability. If any part of the coating is damaged, then it is enough to simply fuse new material onto the desired area;

- tensile strength - the material can withstand significant loads;

- durability up to 10 years.

Flaws:

- the top layer is poorly resistant to aggressive substances;

- the material is only suitable for low pitched roofs;

- installation with construction tape is not suitable - the seams in this case will be a weak point.

Installation of linochrome is carried out in dry, windless weather, having previously cleaned the roof surface. The bottom layer is heated with a blowtorch or torch, and rolls of material are laid overlapping.

Why gable?

This garage will have a gable roof

. It will be easier to answer this question if you just know all the benefits:

- Great convenience and ease of installation. Having good instructions, even someone who does not have much experience in roofing can handle the construction of such a structure.

- Availability of components. All necessary elements can be purchased or ordered specifically for your project.

- Possibility to choose the best slope angle. This ensures good removal of precipitation, which means a long service life of the coating and other materials.

- If no roof space is planned, a cold attic will reduce the need for additional heating and ventilation.

- Convenient placement of various components in the under-roof space.

- The advantage of organizing an attic space.

- Choice of any type of roofing.

- Installing additional windows or skylights.

- Possibility of an individual approach.

No. 4. Slate

Asbestos-cement wave slate is a coating that is well known to everyone and is widely used in the arrangement of garages. The material is based on Portland cement, asbestos and water, while asbestos plays the role of a reinforcement cage, providing the slate with the necessary strength. The typical color is grey, but slate can be painted if desired to enhance its aesthetic appeal and level of protection.

Advantages:

- relatively little heating in sunny weather (when compared with roofing felt or metal coatings);

- high strength - an adult can walk on the roof without breaking a sheet of slate, which is important if necessary to carry out repair work;

- fire resistance, no release of toxic substances during combustion;

- good sound insulation. When it rains heavily outside, the inside of the garage will be almost silent;

- corrosion resistance;

- low price;

- durability up to 25 years.

It would seem that the ideal roofing material for the garage has been found, but that was not the case. Among the disadvantages of slate it is worth noting:

- the carcinogenicity of asbestos, which is part of the slate, therefore it is better to take chrysolite cement sheets;

- the high weight and fragility of the material significantly complicate installation;

- low resistance to temperature changes;

- under the influence of high temperatures, although slate does not burn, it cracks with the formation of sparks.

And even despite these shortcomings and the abundance of other materials, slate remains almost the most popular material for garage roofing.

Sheets of slate are placed on the sheathing, placing one sheet on top of another with an overlap of 20 cm. For fastening, special nails with an enlarged head are used; they are not driven in tightly, but leave a gap of 2-3 mm to avoid the appearance of cracks on the slate. In order not to deform the slate, it is better to pre-drill holes in it for nails. However, it is almost impossible to completely avoid cracks during installation, so upon completion of installation, the cracks are covered with a solution prepared from cement, PVA glue, asbestos and water in a ratio of 2:1:3:1.

Rafter frame

The basis of each gable roof is a rafter frame, a set of elements that ensure the stability and stability of the roof structure. The garage roof is built on the basis of rafters made of coniferous wood impregnated with antiseptic and fire-resistant substances. Depending on the layout of the building, the weight and coverage area of the roofing material, 2 different types of rafter systems are used:

- Hanging. A characteristic feature of this type of rafters, which distinguishes them from layered ones, is that they have only two support points. The upper part of the rafters rests on the ridge girder, and the lower part is attached to the mauerlat. This option is used to cover garages for one car space, where there are no load-bearing walls inside that can be used as an additional point of support. Hanging rafters do not experience expansion loads, they only work on deflection, so there are fewer elements in such a system. To stabilize the frame, tie rods, crossbars, headstocks and struts are installed. Using hanging rafters, you can cover a garage up to 14 m wide with your own hands.

Note! When calculating the rafter system, the weight of its elements is taken into account, since it increases the load placed on the foundation. To avoid overloading, leading to deformation of the base of the building, a balance should be maintained between the thickness of the section and the number of rafters. The size of lumber is selected in accordance with tables that take into account the length of the rafters and the pitch between them.

The most crucial moment if you are building a roof with your own hands is the installation itself. To avoid mistakes, it is better to sketch out a schematic drawing that reflects all the dimensions of the frame elements, the distance between them, and the method of fastening. The work is performed in the following order:

- They are laid and secured on the upper belt of the walls, along which the slopes and Mauerlat will be located. This term refers to a thick beam with a square cross-section that evenly distributes the load transmitted from the rafters to the load-bearing wall. Waterproofing material is placed on the upper part of the wall and the Mauerlat is fixed using anchor bolts.

- The rafter pairs are installed, connecting at the top with a metal plate, and at the bottom with nails or self-tapping screws. First, install the outer legs, pull the lace between them, and then fix the rest, checking the location and angle between them using a building level.

Note! If the garage premises will be heated, thermal insulation of the slopes and roof gables is carried out. For this, non-flammable fiber insulation is used, for example, basalt wool or expanded polystyrene.

No. 5. Ondulin

Externally, ondulin resembles slate. It is also sold in the form of corrugated sheets, but they are produced on the basis of cellulose fibers, which are mixed with minerals, impregnated with bitumen, resins and special additives. From above (and sometimes both above and below) ondulin is painted in one of many shades. Due to impregnation with bitumen and other protective substances, the material receives solid resistance to external adverse influences, and painting allows you to obtain an aesthetic coating, and all this at a relatively low cost.

pros:

- moisture resistance. According to this indicator, ondulin outperforms almost all other roofing materials. Over time, cellulose fibers become even stronger when exposed to sunlight, providing an even higher level of moisture resistance;

- light weight. An ondulin sheet is 4 times lighter than a slate sheet with the same dimensions, therefore it is much easier to transport and install the material;

- corrosion resistance;

- sound insulation - the sound of raindrops on the roof will not block out all other sounds in the room;

- ease of processing. Using a hacksaw for wood, sheets are easy to cut, and thanks to the flexibility of the material, it can be given a complex shape, which will come in handy if the roof has a non-standard shape;

- low cost.

Minuses:

- fading due to sunlight;

- flammability. Already at a temperature of +2500C, ondulin begins to burn;

- an unpleasant odor may appear in the summer heat;

- brittleness at low temperatures;

- low strength is usually associated with a violation of installation technology. If you fasten each sheet with 20 nails and make the sheathing in increments of at least 0.6 m, then you will not have any problems. However, in the heat, when the bitumen impregnation softens, it is better not to walk on the roof.

The durability of the material is 15-20 years, subject to proper installation and operation.

Ondulin is attached to a crate made of wooden beams, and the beams must be strictly parallel to each other. It is most convenient to cut sheets of ondulin while still on the ground. Installation work is carried out at above-zero temperatures; ondulin sheets are attached to special hardware with wide caps.

No. 6. Corrugated sheet

Another popular option for arranging a garage roof. Corrugated sheeting is a sheet of cold-rolled steel with a protective coating of zinc, aluminum or polymer. By giving the sheet a profile, it is possible to increase its strength qualities and at the same time improve its appearance. The profile can be in the form of waves or trapezoids, its height varies from 8 mm to 7.5 cm; sheets with a wave height of 35 mm or more are suitable for roofing work.

The protective coating is most often made of polyester, which well protects the steel sheet from corrosion, heat and frost, and mechanical damage. Acrylic and PVC coatings are cheaper and perform relatively well in operation. A good level of protection is provided by pural (polyurethane with the addition of polyamide and other substances). Zinc coating is the cheapest and is applied during the repair and restoration of sheets. For garages near the sea, busy highways or industries, you can take a profiled sheet with an aluminum-zinc coating, and for garages located in the northern regions - with plastisol protection.

pros:

- low cost;

- relative ease of installation;

- durability up to 50 years;

- resistance to fires and temperature changes;

- high strength - the metal sheet will withstand a person walking on the roof;

- corrosion resistance due to the use of protective coatings;

- wide range of colors.

Minuses:

- the metal gets very hot in the sun, so in the summer the garage will be like a bathhouse;

- The corrugated sheet makes a lot of noise when raindrops fall.

Both of these disadvantages can be minimized if the roof is properly insulated.

Installation of the profiled sheet is carried out on a 60*40 cm sheathing; the timber is pre-treated with an antiseptic. The sheets are secured using special self-tapping screws with rubber linings. The sheets are laid on top of each other with a slight overlap, the width of one wave. The corrugated sheets are fastened together with special rivets in the color of steel, and the space between the sheets is filled with sealant. You cannot fasten profiled sheets with ordinary nails - they will come off in a strong gust of wind.

Hard roof repair

If not resin was used to cover your garage, but, for example, corrugated sheeting, then the nature of its repair will be different. In most cases, it will most likely be enough to replace the damaged sheets of covering. Although there are cases when a tree has fallen on the roof. In this case, the repair will be major, including the process of making sheathing for the flooring.

If it is necessary to carry out the repair partially, then first of all you dismantle the old sheet and apply a new one

It is very important that it matches the wave. It is also important to ensure that there is correct overlap.

The sheet is screwed with special self-tapping screws for corrugated sheets.

If the covering is made of metal tiles, then the process of repairing it is almost identical

The only thing that is important to control is the locks that connect the tiles

By following these recommendations, you will be able to carry out roof repairs. This will significantly reduce costs than having to build it all over again. And with all this, always remember that very often the coating needs partial repair, and this is a significant savings. But most importantly, you can do all the work yourself.

No. 7. Metal tiles

Metal tiles, just like corrugated sheets, are made from galvanized steel sheets, only they are given not just a wave profile, but imitate the profile of natural tiles. A phosphate layer (additional protection), a primer and a polymer-decorative coating are applied over the protective zinc layer. A protective transparent varnish is applied to the back side. The greater the thickness of the sheet, the stronger the coating: for roofing it is better to take material with a thickness of at least 0.5 mm. Performance properties strongly depend on the type of protective polymer coating. The coating made of pural and plastisol has proven itself best. Matte and glossy polyester are cheaper, but if the installation technique is followed, they can also provide reliable protection.

pros:

- light weight, which simplifies installation and reduces the load on the foundation and rafter system;

- resistance to low and high temperatures, high humidity due to the protective coating. It also ensures free drainage of precipitation from the roof surface;

- relative ease of installation;

- excellent decorative qualities, wide range of colors;

- the material does not support combustion;

- relatively low cost.

Minuses:

- loss of a significant part of the performance qualities when the protective coating is damaged;

- difficulties when arranging a roof of a non-standard shape, but garages are usually built with fairly simple roofs, so this cannot be considered a minus in our case;

- heating in the sun and noise during rain, but with proper sound insulation, this disadvantage can be easily eliminated.

Metal tiles can be used on roofs with a slope angle of more than 15 degrees, otherwise snow removal will be complicated due to the topography of the coating. The material is often used when the garage is located on the same site as the house, so that all buildings have the same type of roof.

Features of care and operation

It is necessary to carry out annual cleaning and thorough inspection of the roof . Constant monitoring will allow you to notice the threat in time and prevent subsequent destruction.

A roof made of corrugated sheets is functional and lasts a very long time thanks to a reliable polymer layer - it protects the roof covering from corrosion. Constant exposure to moisture and low temperature, UV radiation, and various contaminants cause the destruction of the polymer coating. For this reason, cleaning roofs is a necessary job to increase their lifespan. It is convenient to clean with a stream of water, directing it along the slope from top to bottom.

Snow does not often collect on the polymer coating, and the matte surface does not allow it to slide down. Roof cleaning is carried out using tools that cannot damage the material. A wooden scraper with a soft rubber pad is suitable for this.

Soft roofing is subject to the same impacts as other coverings. Timely preventive inspections will allow you to detect defects in the roofing carpet in time and quickly eliminate the shortcomings.

A roof covered with natural tiles requires almost no maintenance. Cleaning the covering from fallen snow is done with scrapers, a shovel and a soft broom, which will not damage or move the tiles. Seasonal inspection includes monitoring the strength of hooks and detecting leaks. Work is performed in soft shoes every 4 years.

The construction of a gable roof on a garage requires compliance with safety requirements, like any work at height, and it is necessary to adhere to electrical and fire safety rules. This is the only way the roof will serve you for a long time and without extra costs.