In modern life, accompanied by technological progress, it is difficult to imagine plots from old novels, where in late autumn, during a cold, pouring rain, you cannot even hide in the house due to a leaking roof... Was this once a common situation? But on the other hand, how could it be otherwise, if previously the roof was susceptible to hydrolysis using parchment and low-quality roofing felt.

Nowadays, in the construction market, one’s eyes are wide open from various proposals to strengthen the technical condition of one’s home. Modern types of materials are presented in a wide range of varieties, which makes it difficult to settle on any option without the help of a specialist, making the right choice. In order not to waste money in vain by purchasing high-quality, but unsuitable material for you, we will take a closer look at roof hydrolysis.

In the Russian Federation, in private houses, the process of roof hydrolysis is accompanied by the use of waterproofing films or membranes; Rolled materials and special liquids are more suitable for industrial construction.

Naturally, each option has both a number of advantages and disadvantages. Let's start to figure it out.

How to choose the right waterproofing material specifically for the roof?

The difference between waterproofing materials for roof protection and materials for underground waterproofing:

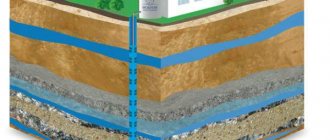

Although roof and underground waterproofing are similar, there are important differences between them that should be taken into account by designers, architects and contractors performing the work. Both have some similar functional requirements, but also completely different ones. For optimal performance, it is important to understand the different loads and stresses that underground waterproofing systems are subjected to compared to roof systems.

The operating conditions for waterproofing underground and on the roof have several differences. As a result, the physical properties that are important for underground protection are not necessarily the same as those that are required for roofing.

Some of these differences are summarized below.

Open list of main differences

- Availability for repair and replacement. Unlike roof insulation, it is impractical and expensive to excavate around foundation walls or dig slabs below grade to replace or repair flashing. Roofs are generally easier to access and easier to repair if problems arise.

- Constant contact with water and its pressure. Depending on the amount and level of water in the ground, the waterproofing system may be in constant contact with groundwater and wet soil. Roof systems, if properly constructed with sufficient slope to drains, are usually only exposed to water for a short time. In addition, the hydrostatic pressure to which they are subjected is much less than that of systems that are located underground. Even a heavy and poorly drained roof with 2 inches (50 mm) of surface water is subject to only approximately 0.07 psi (0.5 kPa).

- The waterproofing barrier must withstand exposure to chemicals in the soil. The chemical attack to which underground insulation is exposed differs from that to which the roof structure is exposed. The soil often contains acids, alkalis, salts and many other pollutants that cause the destruction of waterproofing materials. Unlike roof insulation, the selected underground waterproofing system must be able to withstand exposure to these chemicals for its expected service life.

- The waterproofing barrier must withstand abuse during construction. Unlike the roof surface, waterproofing coatings for foundations and walls typically need to be protected from mechanical damage until the excavation is completed (for example, gravel, debris, and other sharp materials may be dumped during backfilling).

- Waterproofing foundations and walls, unlike roofs, must be able to withstand certain dynamics. Concrete walls and foundations can settle and dry out. The roof structure may experience thermal movement and load deflection. The waterproofing coating must be able to bridge small cracks and, to some extent, resist rupture from thermal expansion and contraction. It should be noted that the volume of traffic below level zero is significantly less than during roof construction. For this reason, properties such as elongation and tear resistance are very important for roofing.

- Exposure to sunlight, precipitation and wind erosion. Roof waterproofing must be resistant to ultraviolet rays, otherwise over time it will crack and lose its properties.

It is vital that designers, architects and contractors understand the differences and similarities between different waterproofing materials so they can choose the right materials and get the job done once and for all.

Diffusion waterproofing

The most expensive and modern materials for arranging waterproofing are diffusion membranes, which, preventing the passage of moisture into the roofing “pie”, release it to the outside.

There are several types of diffusion waterproofing materials:

- Pseudo-diffusion . Being the cheapest option for diffusion membranes, such materials are characterized by low vapor permeability, which indicates their low efficiency. It is best to use this type of membrane in unheated roofs.

- Membranes with normal vapor permeability . A good and balanced material that can be successfully used for arranging residential premises under the roof. For non-residential attics it is better not to use such membranes - dust clogs the pores and the waterproofing loses its properties. There is also a limitation on weather conditions - diffusion membranes cannot work at temperatures below -25 degrees, since moisture in the pores freezes and violates the integrity of the waterproofing layer.

- Superdiffusion membranes . This material, consisting of three layers, is suitable for any operating conditions - superdiffusion membranes are not afraid of dust, temperature changes and other negative factors. The main problem is the high cost, so you need to choose such a material with full confidence in its necessity.

Prices for construction and installation of roof waterproofing

Below is a table describing the prices for installing various types of waterproofing protection. The prices indicated are preliminary and may change depending on the complexity of the object and its other parameters. To obtain an accurate calculation of the price for installation and waterproofing work, it is recommended to contact our estimate department by phone or by sending a request to our email address -

If necessary, our field engineers can go to your site, take the necessary measurements and give the necessary advice on all possible options for protecting your home or building from water.

| Name of works | Unit _ | Price in Rubles |

| Waterproofing works | ||

| Work on installation of built-up waterproofing in 1 layer horizon | m2 | from 360 |

| Installation of built-up waterproofing in 1 vertical layer | m2 | from 480 |

| Installation of PVC membrane horizon | m2 | from 580 |

| Vertical PVC membrane installation work | m2 | from 600 |

| Work on the installation of a pole weaver | m2 | from 900 |

| Work on installation of bitumen mastic | m2 | from 200 |

| Work on the installation of liquid rubber | m2 | from 300 |

| Work on the installation of polymer-cement waterproofing | m2 | from 600 |

| Work on installing polyurethane protection | m2 | from 600 |

| Applying primer or primer | m2 | from 100 |

| Installation of ebb tides | m.pog | from 400 |

| Installation of drip pipes | m.pog | from 200 |

| Installation of drain funnels | PC | from 1900 |

| Roofing | ||

| Installation of gutters | m.pog | from 400 |

| Installation of thermal insulation | m2 | from 150 |

| Slope screed device | m2 | from 600 |

| Installation of fillets during the transition from horizontal to vertical | m.pog | from 100 |

Roof waterproofing cost calculator

Click to open the calculator and calculate the cost of work

Calculation of the cost of waterproofing a roof, terrace or balcony

Waterproofing horizontal roofs

A horizontal roof is considered to be a building whose inclination angle is no more than 5%. If this is your option, then for waterproofing it is better to work with bulk, coating, spraying and weld-on materials.

Welded waterproofing

This type of work is carried out with an overlap followed by melting using a burner. This is a budget option for waterproofing, but they need to be bothered, since the work is carried out with sealant and open fire.

Not so long ago, roofing felt with glassine was actively used for insulation. However, they will not solve the problem for a long period of time, and are highly flammable. That is why they were replaced by roll material. It is provided in two forms:

- polymeric;

- bituminous.

In addition to them, euroroofing material is often used, which includes: bitumen, polymer materials, synthetic rubbers. This type of coating is enhanced with an additional layer of mineral chips.

Spray waterproofing

The use of coating, pouring and spraying materials creates a single membrane. This type of work is possible using special tools. Consumers also actively work with powder insulation, which contains synthetic resins, cement, plasticizers and hardeners. They are on sale only in powder form. It must be mixed immediately before use. Thus, the mixture will seep into the joints and will reliably protect the roof from leaks. The only drawback is that after a few years the top layer of the protective coating will begin to wash out and lose its ability to reject excess moisture.

Coating waterproofing

Bituminous materials are used for a number of advantages: they are reliable, ductile, durable, yet soft and resistant to a wide range of temperatures and changeable weather conditions. Such materials form a multi-ball block, the base of which consists of either fiberglass or polyester fabric.

There are two types of bituminous materials. The former are suitable for climates with seasonal changes in temperature and precipitation, while the latter are suitable for climates with predominantly high temperatures.

Bitumen also serves as a raw material for special insulating mastics. To do this, polymers and mineral accumulators are mixed with liquid bitumen. Such mastics can be hot or cold. You can use the second option in your work yourself. In addition, bitumen cannot be used to cover metal tiles.

Mounted waterproofing

For insulation work on arranging a horizontal roof, you can use a tape type of insulation. For example, if you want to make a green roof. For this purpose, a film, liquid rubber or polymer membrane is used.

Nuances depending on the type of roof

Whatever roof you have, choose materials from reliable manufacturers

For flat and pitched roofs with a slight slope, the following waterproofing methods are optimal:

- pasting;

- coating with subsequent laying of facing material;

- welded

Gable and complex roofs are most often sheathed with corrugated sheets, ondulin and metal tiles. To lay these materials, a sheathing is required to provide a ventilation gap. Waterproofing films are laid under it.

Work order:

- removal of old roofing;

- surface cleaning;

- installation of sheathing, in the cells of which insulation is placed;

- laying film waterproofing with an overlap of 10-12 cm and fixing with staples using a construction stapler;

- installation of counter-lattice;

- laying facing roofing material.

Roof tiles

There are several types of roofing material where this term is present:

- Bituminous shingles. Waterproofing is provided at the level of installation technology from the manufacturer. This is a lining carpet that also serves as an additional fixing element. The bitumen contained in shingles and carpet bakes together when the roof heats up from the sun.

- Composite tiles. This is a kind of metal tile with a small sheet size. The differences lie in the composition of the protective and decorative layer. As with any metal roof, waterproofing must be installed underneath it.

- Ceramic and cement-sand tiles. They differ from each other in composition, shape, manufacturing technology. But despite this, installation proceeds according to general principles. And the manufacturers of these types of roofing, when describing the installation technology, also stipulate the presence of waterproofing.

Video description

About the choice of diffusion membranes, see the following video:

Below is a list of some of the main brands of roof waterproofing under corrugated sheets, which can be purchased on the domestic market:

- Vapor and waterproofing for cold roofs. Izospan D (two-layer, unreinforced) – from 1,500 rubles. per roll 70 m2. Izospan DM (three-layer, reinforced, with anti-condensation surface) – from 3,000 rubles. per roll. Ondutis RS (reinforced)—from RUB 2,190. per roll 75 m2. Yutafol H 110 Standard – from 2470 rub. per roll 75 m2. Yutakon (four layers, reinforced, with anti-condensation surface) – from 4,500 rubles. for 75 m2.

- waterproofing . Izospan A – from 1500 rub. for 70 m2. Ondutis A 120 (with double self-adhesive tape) – from 2070 rub. for 75 m2. Yutafol D 96 – from 1560 rub. for 75 m2. Yutafol D 110 – from 2470 rub. for 75 m2.

- Superdiffusion membranes . Izospan AM – from 2070 rub. for 70 m2. Izospan AS – from 2900 rub. for 70 m2. Izospan AQ proff – from 3890 rub. for 70 m2. Ondutis Smart SA115 (with self-adhesive tape) – from RUB 3,100. for 75 m2. Yutavek 85 – from 3050 rub. for 75 m2. Yutavek 115 – from 4000 rub. for 75 m2. Yutavek 135 – from 5000 rub. for 75 m2.

Stekloizol

This type of roof waterproofing is made using a unique technology. A binder containing bitumen is applied to the base on both sides.

The outer side of the material is covered with coarse-grained topping. This creates a protective layer. The material has the following advantages:

- High moisture evaporation;

- UV resistance;

- Resistance to environmental influences;

- Resistance to mechanical damage.

It should be noted that this material can be laid at low ambient temperatures. Stekloizol will not lose its elasticity. The basis of this waterproofing material is fiberglass or frame fiberglass.

Rules for installing hydrobarrier film

When working with waterproofing, it is important to remember several installation rules:

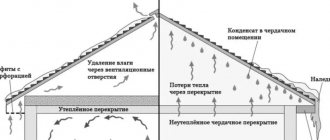

- if not a diffuse membrane, but another type of film is used as a hydrobarrier, then there must be a gap between it and the insulation. It must also be observed between the film and any flooring;

- the film is always mounted with a slight sag;

Installation of reinforced film on the roof

- logs should be laid in increments of no more than 1.2 m if waterproofing is being installed;

- There should be no blind unventilated areas due to the installation of a hydraulic barrier in the roof pie;

- a corrosion-resistant fastening element is used to secure the material;

- The waterproofing film is laid on pipes and other structural elements of the roof with an overlap of about 10 cm.

Waterproofing membrane for metal tiles

Is it possible to use roofing felt?

Sometimes roofing felt and its analogues are used as waterproofing for pitched roofs. But these materials are intended for waterproofing flat roofs over a continuous floor.

The technological map of the TechnoNikol company for the installation of bitumen roll materials indicates that the roofing material is attached to the base using mastics or by fusing.

Mechanical fasteners at large roof slope angles are used as additional “point” fixation to prevent bitumen waterproofing from slipping in hot weather. And this limits the scope of use of roofing felt on pitched roofs.

On those roofs where the slope angles are large and the technology for laying the roof is continuous, lathing is not needed, it is not economically profitable to install it, even though roofing felt is cheaper than waterproofing films. But only mechanical fastening along a row sheathing does not provide sufficient reliability of fixation due to the low tensile strength of roofing material.

Choosing a waterproofing manufacturer

The choice of waterproofing for the roof is very important, because its durability and reliability directly depend on it. In addition to characteristics and cost, when choosing, you should also pay attention to the manufacturer - a good reputation is not acquired without reason.

When choosing a certain type of waterproofing, you should first look at the products of the following companies:

- Roll waterproofing . Euroroofing material produced by . has the best characteristics. The products include the best European fiberglass and high-quality Ukrainian polyester. When choosing a regular roofing felt, preference should be given to materials made in Samara.

- Coating waterproofing . The most popular and most effective mastics are products of the brands “Elastopaz”, “Inopaz” and “Master Ruf”. The best option is polyurethane mastic of the Inopaz N20 brand, which provides the most reliable waterproofing at its relatively low cost.

- Film and membrane waterproofing . Waterproofing films with the best characteristics are produced by Takofol and TechnoNIKOL. The products of these companies do their job perfectly at an affordable price. Good pseudo-diffusion membranes are produced by Svitapfol-D and Elvitek. When choosing high-quality and expensive super-diffusion waterproofing, it is best to give preference to products from TechnoNIKOL and Tyvek.

What is a roofing membrane

Membrane roofs have good diffusion properties. They are assembled from several hermetically joined panels. It can be laid directly on the thermal insulation. It is most effective on straight sections without the presence of different types of roof structures.

The most common types of membrane materials

Polymer membranes

- EPDM. It is based on synthetic rubber. And it receives additional strength thanks to the fiberglass included in its composition. Mounted using glue or vulcanization.

- PVC. Plasticized polyvinyl chloride, due to the presence of glass fiber in its composition, has acquired excellent strength. However, with prolonged use under the influence of ultraviolet radiation, it can crack and become unusable.

- TPO. Made from thermoplastic olifins. Thanks to the reinforcement with a special mesh and fiberglass, they have good strength and wear resistance.

Using coating waterproofing

Application of liquid mastics is also carried out using our own technology. To apply mastics, brushes, rollers or a sprayer are used - the choice is made individually, and each tool allows you to make high-quality waterproofing.

The manual method of applying a layer of waterproofing is not difficult. First, the prepared composition is poured over the roof, and then leveled and spread in an even layer. In order for roofing waterproofing to be reliable, it is necessary to apply several layers of material.

The mechanized method is even simpler - a special mastic is simply sprayed onto the desired areas of the roof. For horizontal surfaces, in this case, a single waterproofing layer will be sufficient, but vertical sections will have to be covered 2-3 times.