One of the most affordable and versatile materials used in construction today is profiled sheets or corrugated sheets. It is widely used in the construction of outbuildings, fences, wall cladding and roofing work. Corrugated roofing: an excellent solution for the roof of a house. Due to the lightness and simplicity of installation, even a non-professional can cover corrugated sheets. Let's try to figure it out how to cover a roof with corrugated sheets. Video and photo examples of roofing work will help you understand this.

Roofing material for the roof: types of coating (read more) Corrugated roofing: an excellent solution for the roof of a house.

What is a profiled sheet and how to cover a roof with it

Thanks to the development of advanced technologies, new materials have appeared in construction with high performance characteristics and an affordable price. High-tech building materials include corrugated sheets - galvanized corrugated metal sheets of various sizes with or without polymer coating.

Sheets of corrugated sheets of various colors and with different corrugation heights.

On the outside, the profiled sheet consists of the following layers:

- galvanized sheet - the basis of the corrugated sheet;

- anti-corrosion coating;

- polymer coating;

- protective mounting film.

On the inside, the sheet can also be protected with an anti-corrosion layer and protective varnish.

Roofing corrugated sheeting: purpose, features, pros and cons

Roofing profiled steel sheet is designed to cover single-pitched and gable roofs of any size.

Its main feature is the alternating longitudinal protrusions and depressions stretching along the entire sheet. They serve as stiffeners, greatly increasing the strength of the coating compared to the original sheet metal.

Advantages:

- high bending strength;

- resistance to snow and wind loads;

- durability;

- affordable price;

- ease of installation.

Flaws:

- dull, industrial appearance;

- high noise, the profile acts as a resonator.

Typically, corrugated sheeting is used for roofing industrial and warehouse buildings. But it also works well as a budget roofing material for a private home.

Advantages of using profiled sheets in construction

Thanks to its high protective characteristics and aesthetic qualities, corrugated sheets are simply irreplaceable when arranging a roof. The convenience of using this material also lies in the fact that wall cladding, installation of fences and roofing with corrugated sheets can be done with your own hands. Numerous specialized websites have video and photo instructions on how to cover a roof with corrugated sheet metal.

High strength, anti-corrosion properties and rigidity, combined with a variety of sizes and low weight, have ensured the popularity of corrugated sheets in the construction of various types of premises.

Even a non-professional can install profiled sheets.

The main advantages of using profiled sheets include the following:

- durability;

- resistance to corrosion;

- rigidity;

- light weight;

- versatility;

- ease of self-installation;

- availability of component materials;

- ease of transportation and storage;

- low price;

- wide choice of sizes;

- high aesthetics of the coating.

A roof made of corrugated sheets is not subject to corrosion.

The use of profiled sheets speeds up the time and overall costs of DIY construction.

A small number of joints ensures the reliability and tightness of the structure, and the low weight allows even beginners to attach the corrugated sheet.

Manufacturing technologies

In the manufacture of sheets, various protective coating compositions are used.

Rolled products with aluminum-silicon coating

A layer of aluminum and silicon compound is applied to the sheet. This coating has increased strength and chemical resistance and is a leader in service life and quality.

Thin sheets with aluminum zinc coating

The corrugated sheet is coated with an alloy of zinc and aluminum. The alloy has high elasticity and does not reduce its thickness during deformations associated with profile processing.

Aluminized thin sheets

Used for the most critical and high-quality structures. It has a high price.

Zinc-coated thin sheets

This is a traditional way to protect ferrous metal from corrosion.

Its advantage is the low cost of materials and technology.

The disadvantage is the following: when rolling complex profiles from such a sheet, the coating on the bends becomes thinner. At this point, the leaf protection is reduced.

How to cover a roof with corrugated sheets with your own hands

After profiled sheets entered the construction markets, roofing work using this material became much faster and easier. A large amount of information, photos and videos on how to cover a roof with corrugated sheets with your own hands will allow you to learn how to attach a roof from corrugated sheets yourself.

Like many repairs, covering the roof with corrugated sheets is best done by two people. It is first necessary to clarify the dimensions of the area that needs to be covered with corrugated sheets, make sure that the slopes are rectangular in shape and check their flatness using a level. Then decide on the color, shape, thickness and brand of corrugated sheet, as well as select the necessary tools and components.

Sheet thickness

What thickness of corrugated sheeting is best for the roof?

Manufacturers offer the consumer sheets from 0.37 to 1.2 mm. For the roof of a residential building, it is optimal to use thicknesses in the range from 0.45 to 0.55 mm. The thicker the material, the more expensive it will be and the final cost will be comparable to the price of metal tiles, for example, which, nevertheless, has superior characteristics, all other things being equal.

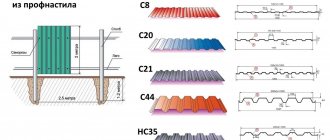

Types of corrugated sheets: selection and marking of corrugated sheets

The variety of types, shapes and wide range of sizes of corrugated sheets for the roof make it possible to find the right material for any roof.

Profiled sheet with capillary groove.

Corrugated sheets differ in the height of the corrugation, the presence of a capillary groove and the variety of colors of the polymer coating. The corrugated shape of corrugated sheets can be trapezoidal or sinusoidal; rounded and rectangular sheets are less common.

A capillary groove is necessary to remove moisture from the roof when overlapping corrugated sheets, and the polymer coating provides a protective and aesthetic function. Thanks to the variety of colors, you can install a roof of any color with your own hands, giving a special personality to your home.

Note! All data about the profiled sheet is reflected in its marking. For the roof, corrugated sheeting is used, marked with the letter H - load-bearing, and the subsequent series of numbers means a number of characteristics.

Marking of corrugated sheets: H - for roofing (installation of permanent formwork, as interfloor ceilings), C - for wall fences and partitions, NS - for roofing and wall fences.

For example, corrugated sheeting is marked N-60-0.7-840, which means:

- corrugated roofing;

- corrugation height 60 mm;

- metal thickness of the corrugated sheet is 0.7 mm;

- installation width of the sheet is 840 mm.

The choice of profiled sheet is made depending on the purpose of the premises under construction and the climatic conditions of the area. Unheated rooms, sheds, hangars and other ancillary buildings can be covered with inexpensive galvanized corrugated sheets without a polymer coating. Residential buildings, where the roof slope is more than 10°, need to be covered with polymer-coated corrugated sheets, thick metal and high corrugation.

To attach profiled sheets, use self-tapping screws that match the color of the roof.

Note! When choosing a profiled sheet, pay attention to its appearance. The surface of the material must be smooth, without cracks or scratches, with an intact protective film.

An important parameter when choosing a grade of corrugated sheet is the angle of the slope. The greater the slope angle, the larger the roof surface, the higher the windage, but the lower the snow load, since snow easily rolls off the sloping roof. To avoid deformations, the roof of a slight slope must be covered with a thicker corrugated sheet.

Scheme for laying thermal and waterproofing for a corrugated roof.

Types of coating

The steel from which the corrugated sheet is made is susceptible to corrosion in the open air. To prevent it and extend the life of the decking, manufacturers use various protective coatings.

Galvanized

Hot-dip galvanizing is carried out at a metallurgical plant during the rolling of a flat sheet. A thin layer of zinc protects the surface from rust. This is the most inexpensive, but also the least reliable protection.

With additional protective coating

A primer, acrylic paint and a polymer protective coating of several layers are applied over the galvanization. Under such protection, the sheet can serve for many years. It increases the cost by 30-60%.

Color options

The following color options are used:

One-sided

The corrugated sheet is painted only from the outside. The back is only primed. This allows you to save up to 20% of the price. This option is applicable in residential buildings and buildings with normal humidity.

Double sided

The sheet is painted on both sides. This type of corrugated sheet is used in factories, swimming pools and other buildings with high humidity.

Corrugated roofing: necessary tools and materials

Before covering the roof with corrugated sheets with your own hands, you need to decide on the tool and purchase the appropriate materials.

Metal shears: manual, electric, tools overview (read more)

To install a corrugated roof yourself, you must have the following:

- cordless screwdriver;

- construction stapler;

- electric scissors and hacksaw;

- building level;

- roulette;

- markers of different colors;

Tools for installing corrugated sheets: 1 - screwdriver, 2 - hammer, 3 - rubber hammer, 4 - metal brush, 5 - tape measure, 6 - strip, 7 - marker, 8 - water level, 9 - metal scissors, 10 - pliers .

- gun with sealant;

- drill with a set of drills;

- self-tapping screws with a sealing washer;

- ridge for connecting sheets;

- metal brush to remove chips;

- wind bar against rainwater;

- snow guards for the roof made of corrugated sheets.

Composition of metal profiled sheet.

The value of the height coefficient for calculating the wind load

Buildings covered with corrugated sheets are subject to permanent and temporary loads. In the first case it is:

- own weight of roofing material;

- weight of the rafter system of auxiliary elements.

Temporary factors include:

- payloads, including all elements of the building, furnishings, people and animals;

- snow;

- wind.

The wind load is calculated taking into account the height of the location above the ground surface. Designers use the following formula as a tool.

Wр = 0.7 × W × k × C

Explanation of symbols:

- W – the value is determined from the maps in the appendix to the regulatory documentation, denotes the force created by the pressure of air masses;

- K is the coefficient of dependence of pressure on height above the level of the top point of the ground;

- C is the aerodynamic coefficient, which takes into account the direction of air flow onto the roof slope.

| Height above ground level | Regional location of the area | ||

| ① | ② | ③ | |

| up to 5 m | 0,75 | 0,5 | 0,4 |

| 6-10 m | 1,25 | 0,65 | 0,4 |

| 11-20 m | 1,25 | 0,85 | 0,55 |

| 21-40 m | 1,5 | 1,1 | 0,8 |

Explanation of values:

① - forest-steppe, tundra, desert, uncluttered spaces on the shores of reservoirs, seas, lakes:

② - area with buildings no higher than 10 m, populated areas, forest;

③ - urban area built up with houses over 25 m high.

One of the applications of SNiP is the calculated wind load taking into account the regions of Russia.

| Construction area | I | II | III | IV | V | VI | VII |

| Design wind load, Wp, kPa (kg/m²) | 0,32 (32) | 0,42 (42) | 0,53 (53) | 0,67 (67) | 0,84 (84) | 1,02 (102) | 1,19 (119) |

Stages of work and material calculation

The main stages of do-it-yourself roofing work using profiled sheets are:

- roof design;

- installation of sheathing;

- determining the size and quantity of corrugated sheets;

- identification of components and additional elements;

- installation of corrugated sheets on the roof;

- installation of wind bars, ridge and snow retainers.

Before covering the roof with corrugated sheets, you need to decide on the project. This can be done using specialized construction programs or you can make the calculation yourself. If you have to cover a complex roof with many slopes at different angles, it is best to use ready-made programs or turn to architects. With a simple design, the question of how to cover a roof with corrugated sheets without a special program can be solved by ordinary mathematical calculations.

Roof prepared for laying corrugated sheets.

The basic formula for calculating the number of profiled sheets to cover a simple roof is as follows:

N = D / L ,

Where N is the number of profiled sheets for laying a horizontal row, D is the length of the roof slope, L is the useful (installation) width of the sheet. In the final calculation, parameter N is rounded up.

Note! When talking about the dimensions of corrugated sheets for a roof, it is necessary to keep in mind that the calculations take into account not the total, but the working, i.e., useful width of the sheet. In this case, the overlap of the material is equal to the difference between the total and useful width of the sheet.

For a simple roof, the number of required profiled sheets can be calculated independently.

The size of the horizontal overlap depends on the angle of the slope and is determined using a special table:

| Slope angle | Up to 15 degrees | 15 - 30 degrees | More than 30 degrees |

| overlap | 20 cm or more | From 15 to 20 cm | 10 - 15 cm |

The vertical overlap depends on the brand of corrugated sheeting chosen and it must be covered with overlapping waves.

The grade of corrugated sheeting also plays a significant role in determining the size of the overhang: the greater the height of the corrugation, the longer the overhang should be. If the overhang is short, water may leak under the roof.

After determining the number of horizontal profiled sheets, you need to calculate how many such rows are needed to cover the roof. This value is calculated based on the length of the roof slope, eaves overhang, roofing sheet, size of overlaps, and also taking into account additional elements.

Installation of sheathing under corrugated sheets.

Green shades

Green colors of corrugated roofing sheets are the second most common among all shades of profiled sheets. Mainly three tones from the palette are used:

- RAL 6005 (Moss Green). The most common shade from this group, which is used in 70–80% of cases. A dark green tone that looks original on the roof, but not too bright.

- RAL 6002 (Leaf Green). Medium brightness saturated green color. Fences are mainly made from RAL 6002 sheets. A profiled sheet of this shade is rarely laid on the roof, since its brightness makes it difficult to combine with other materials.

- RAL 6026 (Green Opal). A very rare corrugated sheet for roofing - the color RAL 6026 looks blue and, because of this “borderline”, is difficult to use. Typically, industrial and commercial buildings are lined with this sheet, and fences are also built from it.

Since RAL 6005 is the green shade most often chosen for residential roofs, let’s talk in more detail about its compatibility with other materials.

Previous NextExamples of corrugated sheets for green roofs - photos of houses lined with wood and siding

Green Moss profiled sheet is a metal profile that is mainly used to cover log houses and houses made of timber or lined with wood. Corrugated sheet RAL 6005 also looks good on the roofs of houses with red brick trim. Simply put, Moss Green corrugated sheets are combined with brown-red shades. But it is rarely used in combination with light brick, gas block and plaster - in this case, there is a high risk that the roof will look like a colored foreign spot in the appearance of the house.

Choose a green metal profile for the roof if you like such shades and have a house made of wood or red brick.

Top ↑

How to attach a corrugated sheet to the roof: installation features

Before you start attaching corrugated sheets with your own hands, it is advisable to watch the relevant training videos and photographic materials. Roofing the roof with corrugated sheets should begin after installing the end boards, from the bottom row, taking into account the size of the overhangs. You subsequently need to attach the end strip of the corrugated sheet (wind corner) to the upper end board. Then use self-tapping screws to install the cornice strip.

Scheme of roof preparation for laying corrugated sheets.

Note! The installation of the eaves strip should be below the waterproofing carpet. Then the resulting condensate will fall into the catchment area or onto the blind area.

There are two ways to cover the roof with corrugated sheeting yourself: cover the previous sheet with the next one, or place it underneath. The corrugated sheets must be secured to the sheathing using self-tapping screws with an EPDM gasket to protect them from moisture. The number of screws is calculated based on the formula: 5-7 pcs. per 1 sq.m of roof. To fasten the profiled sheets, screws are screwed into the upper wave of the profile in increments of 0.5 cm.

On a note! To avoid deformation of the gasket, try to tighten the screws carefully and without additional force.

It is important to screw the screws into the corrugated sheets correctly.

Profiled sheets can be fastened using a four-block or three-block method. In the first option, the installation sequence is as follows:

- The first sheet of the first row.

- Second sheet of the second row.

- Second sheet of the first row.

- Second sheet of the second row.

In the second option, you need to fasten the sheets according to the scheme:

- Two sheets of the first row.

- One sheet of the second.

Corrugated roofing - practical advice on choosing

- appearance of the profiled sheet . This is the easiest way to determine which roofing sheeting is better. Of course, one that does not have defects, chips, peeling or paint sagging, “stretch marks”, etc.;

- clear geometry of the dimensions of the roofing corrugated sheet . The manufacturer is obliged to provide the opportunity to measure each profiled sheet in thickness, length and width. Deviations greater than the minimum acceptable (according to GOST 24045-2010) are a sign of a violation of the manufacturing technology. Even knowing how to properly attach corrugated sheets to the roof, it will not be possible to efficiently install obviously defective sheets (substandard);

- geometry of the overlapping wave . The first wave of the top sheet should very accurately cover the last wave of the bottom sheet. In this case, the likelihood of water getting under the sheet will be minimized;

- edge quality . Chopping (cutting) corrugated sheets in the factory is carried out with a special device - a guillotine. This cut is very accurate and smooth (without nicks or paint sagging). This is an indicator that the sheet will not begin to rust from the edge;

- strength of roofing corrugated sheets . When demonstrating the color scheme, the seller will most likely show you a selection of round swatches. This shape was not chosen by chance; a round sample is more difficult to bend than a square one. Therefore, the sheet appears durable.

In practice, you can check the strength of a corrugated sheet in a simple way by applying a little force: with slight bending, the corrugated sheet will easily return to its previous shape, but with strong pressure, the bend will remain.

- Availability of specifications and layout of corrugated sheets . This does not apply to the choice of corrugated sheet directly, but it is mandatory when purchasing material for the entire roof. After all, you need to not only know how to choose corrugated sheeting for the roof, but in what order the purchased sheets should be placed, especially in the case of a roof with a complex configuration;

- packaging of corrugated sheets . Its presence is important only at the stage of storage and transportation. It must be removed before installation. After prolonged exposure to ultraviolet radiation on the protective film on the corrugated sheet, it cannot be removed and significantly spoils the appearance of the roof;

- guarantees and certificates for professional sheets . Allows you to judge the reliability and responsibility of the supplier.

Installation of additional elements: snow guards

After installing the corrugated sheeting, it is necessary to install those additional elements that were not attached during the roofing: ridge, ebbs, corner strips, snow retainers, etc.

Additional elements for roofs made of corrugated sheets.

Considering our climatic conditions with harsh and snowy winters, snow retainers are an important element of the roof. Due to the high heat capacity of the profiled sheet, the lower layer of snow becomes flooded and there is a danger of an avalanche.

Installing snow guards with your own hands allows you to evenly distribute the load on the roof, ensuring safety and increasing thermal insulation due to snow cover. Snow retainers also protect the protective layer of the corrugated sheet from damage by solid particles contained in the snow.

Snow guards will protect you from snow falling off the roof in winter.

On a note! Considering the cost of snow guards, you can mount them not over the entire surface of the roof, but in the most important places: above the paths and entrances to the building.

Snow guards have different sizes and designs, the choice of which is determined by the average height of the snow cover in the area, as well as the characteristics of the roof. It should be remembered that installing snow guards does not exempt you from regularly clearing the roof of snow.

Based on the information received and the video materials presented, you can easily and quickly create a beautiful roof for your own home yourself.

Color of corrugated roofing

Color does not affect the technical parameters of corrugated sheets. However, when choosing corrugated sheeting, you should take into account the color scheme of other buildings on the site, facade decoration and other factors, so that the roof of the house does not stand out from the overall design concept. The colors of the corrugated sheets correspond to the RAL palette (from the Finnish manufacturer Ruukki - the RR palette), which simplifies color selection.

Roofing corrugated sheets - colors, color map with names according to the RAL table

Note. When choosing a color, you need to take into account that any coating is susceptible to ultraviolet radiation (fading in the sun). Therefore, if it is necessary to replace one sheet, it is possible that the shades will not match. The more time passes from the installation of corrugated roofing, the more it will manifest itself.

Marking - meaning of letters

- Profiled sheeting “N” (load-bearing). Profile height of 35 millimeters or more. With its help, reliable roofs, canopies, ceilings, including suspended ones, blind formwork, overlapping and other load-bearing structures are installed. To produce corrugated sheets with this marking, steel up to 0.9 millimeters thick is used. The corrugation of this profile has an increased height, sometimes exceeding 100 millimeters. Such high-profile sheets are more often used in the construction of commercial and industrial buildings. In private construction, corrugated sheeting with a much lower wave height is usually in demand. Some types of “N” grade corrugated sheets have special ribs that increase the rigidity of the roof, as well as additional longitudinal recesses through which excess moisture drains from the roof without entering the space under the roof.

- Corrugated sheeting “C” (wall). The height of this profile is up to 44 millimeters. It is intended mainly for covering walls, erecting vertical partitions, fences, fences. For this corrugated sheet, cold-rolled steel up to 0.6 millimeters thick is used. This brand of corrugated sheet has a very low load-bearing capacity, which in most cases does not allow its use as a roofing covering. An exception (with many reservations) is when the height of this profile is at least 17 millimeters, and it is mounted on a reliable rafter system with durable and as frequent lathing as possible.

- Profiled sheeting "NS" (universal). This load-bearing wall profile with a height of 44 millimeters is for universal use in all areas - installation of fences, gates, load-bearing structures, roofing and walls. All its characteristics and indicators are average: the height of the profile, the thickness of the metal used, as well as strength and cost for the consumer. This is why NS profiled sheeting is used very often in individual construction. Because it is convenient to purchase and deliver to the site a large batch of corrugated sheets of one parka, one size and often one color, and then in a short time cover the roof of the house, the walls of the garage with it and install a new reliable fence.

Manufacturers

Consumers and experts in 2021 highlight the following best manufacturers of corrugated sheets:

- GRAND LINE (Russia). The company is rapidly developing a distribution network throughout Russia. Offers corrugated sheeting of all main types. The main coating is plastisol.

- Neva Steel. The company pays special attention to the quality of raw materials. High-quality rolled steel ArcelorMittal, Corus, Zalzgitter, Ruukki is used.

- Pokroff plant. Finnish technology is used in the production of profiled sheets. The steel is supplied by Severstal. The main coating is polyester.

- Ural Roofing Materials Plant (UZKM). The products are distinguished by ideal geometry and dimensional accuracy. For coating, purol, polyester, and plastisol are used. Original models with a velvety effect are offered.

- MetalProfile. The plant is considered the largest manufacturer of corrugated sheets in the Russian Federation. PURETAN, PURMAN and other branded polymers are used for coating. A wide range of products is offered.

Important! When purchasing corrugated sheets, it is important to pay attention to the manufacturer. Only trusted companies can guarantee quality and durability.

Disadvantages of corrugated sheets and ways to minimize them

Despite the solid list of positive qualities, corrugated roofing sheeting also has disadvantages that are revealed during operation. Understanding the weaknesses of the material makes it possible to reduce their influence at the roof installation stage. The disadvantages of the profiled sheet include the following features:

- Low sound insulation . The insignificant thickness of the metal sheet leads to the appearance of a drum effect - amplification of sound during rain. Some people like to fall asleep to the sound of falling drops, while others slowly begin to get annoyed by the monotonous noise. In order not to experience discomfort during every, even slight rain (and in some areas there is a lot of them), they use a proven method - reinforcing the roofing pie with an additional layer of sound insulation. The role of the insulating layer is most often performed by mineral wool with a parallel insulation effect.