Features of the correct calculation of gates made of corrugated sheets

The gate or gate in the fence also plays the role of a leading violin. The gate is mainly intended for the passage of people, and through the gate both people and cars are allowed to pass through at the same time.

In addition, a beautiful gate will easily decorate the entire appearance of your home. The most modern and popular are gates and fences made of corrugated sheets, as in the photos presented.

Briefly about the main thing

Forged gates are evidence of the artistic taste of the owners and the impeccably elegant appearance of the entrance area. The combination of forging and corrugated sheet allows you to save your budget while maintaining an attractive appearance and performance characteristics.

Forged elements increase the strength and reliability of the structure. They can be produced by cold or hot forging. The decor is prepared separately, welded into a composition, painted, covered with patina, and mounted on a frame or canvas. The cost of the finished product depends on the dimensions and design features of the gate, as well as the complexity of the forged patterns.

Ratings 0

Advantages of corrugated sheets

Corrugated sheet or profiled sheet is a composite material with a heterogeneous structure. Externally, it is a galvanized steel sheet coated with polymer.

The main feature of profiled products is their protective polymer layers, varying in quantity. A sheet of metal, galvanized on both sides, is one of the simplest, three-layer models.

If galvanized with 10 layers, the products are considered to be of the highest quality. And the service life of the profiled sheet directly depends on the type and quality of the coating. To make a gate from corrugated sheets with your own hands, first of all, you need to find out what material you will have to deal with.

Based on service life, there are three main types of sheet coating:

- galvanized (service life up to 5 years);

- aluminum-galvanized (service life up to 10 years);

- polymer (from 10 to 20 years of service).

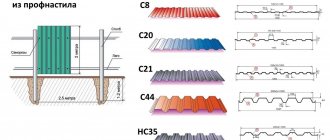

By type, profiled sheets are divided into:

- wall (with small waves of profiles: 8, 10, 15, 20, 21 mm);

- roofing (with medium waves: 20, 21, 35, 45, 57, 60, 75, 80, 90, 100 mm);

- carriers (with wave heights of 75, 80, 90, 100 mm).

The most popular are wall profile sheets.

How to choose a profiled sheet

For the manufacture of gates, wall corrugated sheeting marked “C” is used. It differs from roofing and other options in the height of the waves. The size of the stiffeners is indicated by a number. The higher it is, the stronger the sheet itself and its ability to withstand loads.

The most convenient corrugated sheet for installing gates is marked C-18, C-20, C-21. It can be used in the harshest conditions. When choosing the type of material, you need to take into account the terrain and climatic features. Metal sheets consist of several layers, each of which performs its own function. The steel base can have the following coating:

- From zinc;

- Aluzinc;

- Polyester;

- Plastisol or pural.

Types of gate designs

When choosing gate designs, it is necessary to take into account the ease of their operation, the reliability of protection, and the optimal dimensions for the passage of trucks and cars.

There are two types of gate designs: swing gates made of corrugated sheets, single-leaf or double-leaf, single-sided or double-sided, with or without a wicket) and sliding gates (suspended, rail, cantilever and telescopic).

Color variety

According to the method of applying the paint layer, sheets are divided into those painted on one side only, painted on both sides in the same shade, and multi-colored on both sides. The color scheme used is regulated by regulatory documents, among which the following standards are the most common:

- European (RAL);

- Finnish (RR);

- English (HPS);

- Swedish (PRELA).

For the construction of a fence, the most acceptable is corrugated sheeting that has double-sided painting. When choosing a suitable color, pay attention to its compliance with the overall design of the site and the house. Most often, preference is given to a green tint. It fits well into almost any landscape design and looks great against the backdrop of natural green spaces.

Brown, blue, and gray tones are also in demand. They are compatible with most building materials used for fences and building facades. It is not advisable to choose red and yellow colors. The worst solution would be to use unpainted galvanized corrugated sheet. It is not only unattractive in appearance, but also less durable and practical.

Making gates from corrugated sheets with your own hands (step by step)

Making swing gates is difficult, but possible. Even if you are a master with a capital letter, you cannot cope with this matter alone. An assistant with experience in gate manufacturing is simply necessary, because you have to overcome several stages:

- determine the location of the gate;

- make a drawing;

- calculate the need for necessary materials

- prepare the base;

- install racks;

- build a frame and fix it on supports;

- perform sheathing with corrugated sheets.

Right choice

Metal profile sizes used for fencing cladding

Corrugated sheets usually differ in thickness, height of steel ribs and strength. There are types of profile steel sheets intended for wall cladding, which have a fairly small thickness and a relatively small rib size. It is this wall corrugated sheeting that should be used for cladding gates with your own hands, since it is a reliable and durable option.

However, it is permissible to use thicker sheets of corrugated sheets, as well as sheets with a high wave. This choice will significantly increase the safety factor of the material, but will also affect the weight, respectively. Such heavy and massive sheets are rarely used for gate cladding, since it is impractical. They are most often used in the construction of garages and hangars, as well as when covering the roofs of buildings.

To get a neat cut and sheets adjusted exactly to the required dimensions, it is better to immediately specify the dimensions when ordering from the factory. This will simplify the work when installing the material on the gate, ensuring beauty and correct dimensions.

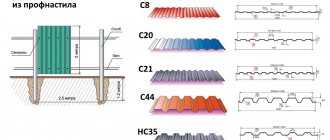

Gate location and dimensions

First, you need to decide what kind of gate you want: garage or front. Then select their height based on the height of the fence of the site. Ideal option: the gate and fence are at the same level in height from 2 to 2.5 m.

When installing a gate, set the passage width from 1.00 to 1.2 m. When choosing the width of the gate, you should focus on the following factors: proximity to the roadway, turning angle upon entry, fire hazard. The optimal width is 4.00 m.

Required tools and materials

When installing gates from corrugated sheets, you will need ordinary construction tools that you probably still have after building your house: shovels, crowbars, a concrete mixer, buckets, an old basin, a drill, self-tapping screws, etc.

The materials you will need are: paint, sand, cement, crushed stone, locking devices for gates, hinges of sufficient power, pipes of different diameters for the frame and support posts, corrugated sheets.

Gate installation process (do it yourself)

In more detail, the process of installing gates from corrugated sheets is as follows:

We begin installation of supports by preparing the area (clearing and marking). We outline the location for installing the racks. We fix the level with a thread and proceed to the main work.

We make a depth of 1.5 meters. We fill the bottom with crushed stone and tamp it; if necessary, add crushed stone and tamp again. Then we insert the pre-prepared support (primed and painted) into the recess, secure it with bricks and cobblestones, and fill it with concrete mixture (the ratio of cement, sand, crushed stone is 1:3:6, respectively). To ensure that the mixture sets well, let it dry for about 7 days, periodically sprinkling it with water to avoid cracks.

Before starting this stage, it is necessary to measure the width of the wicket and gate again to avoid discrepancies in dimensions or making necessary adjustments. Next, using a grinder, we cut blanks of a certain size from the profile pipe (angle). We clean their surfaces.

On a flat plane, using welding, we connect the workpieces in the shape of a frame. We check the evenness of the structure (this is important!). If the geometry is correct, we proceed to welding the seams. We strengthen the frame with stiffening ribs.

We fix the sashes to the hinges of the supports. The number of hinges is determined depending on the severity of the sashes. We install the doors on the support between the posts and secure the top with a rope. We mark the location of the hinges and lightly weld them to the sashes and supports. We check the functionality of the valves. If no comments are found, we finally weld the hinges.

After fixing the gate, we proceed to installing fittings (handles, bolts, latches) using welding. We install locking devices, automation, alarms and video surveillance systems.

To paint the frame, you need to prepare its base (clean the metal surface and seams with sandpaper, degrease, prime) so that the paint adheres well to the metal. Then paint with a roller and let dry for about 12 hours.

Lastly, the structure is sheathed with corrugated sheets on top of the frame. We cut off the excess and check the level for evenness. We secure the corrugated sheets carefully with self-tapping screws. The gate is ready.

But, if you doubt your abilities, and you are not embarrassed by the price of gates made of corrugated sheets with installation offered by specialized organizations, then feel free to contact the professionals.