Photo: stroymaster-base.ru Wood is still the most popular and versatile building material for all occasions. Wooden fences are stylish and beautiful, practical and durable, and also absolutely environmentally friendly. They will fit into any site: it doesn’t matter what the house is made of or what kind of landscape design you have. Classic is a classic! You can work with wood in completely different ways, so we share photos and ideas.

Fence construction diagram

Regardless of the chosen material and type of structure, the entire construction process consists of the following points:

- Assessment of site parameters and soil preparation.

- Construction of a trench for support pillars.

- Pouring support structures.

- Installation of main sections.

Each stage is mandatory and, with the right approach, allows you to make a fence for a long service life.

Price

The cost of erecting a fence depends on many factors. Here are some of them:

- Foundation dimensions. The amount of mortar that will be used for construction depends on this parameter. Accordingly, the heavier the fence, the more massive the foundation must be laid.

- Fence size.

- Material for construction.

- Installation. You can save a lot on installing a fence if you decide to build it yourself, without the help of specialists.

In order to find out how much it will cost to make a fence, you need to determine its exact dimensions and choose the material for construction.

Assessment of site parameters

First of all, the owner of a summer cottage and the builder should assess the nature of the soil:

- Strength level.

- Presence of groundwater and karst voids.

- Presence of old foundations.

The site must be prepared for construction: cleared of debris, removed fragments and large boulders, leveled all holes and uneven areas.

Wattle

These are shields made of rods woven together like baskets. This design is not particularly durable and is rather decorative. Pros: almost free source material and ease of repair.

Construction of a trench for support pillars

For supporting structures, it is necessary to prepare holes of appropriate depth (depending on the selected material and type of fencing). The walls of the pit should be leveled and compacted well. A sand cushion and broken crushed stone are laid on the bottom, and then the first support is installed.

Advantages and disadvantages

The main advantages of building a wooden fence:

- ease of erecting a fence - no special tools or construction experience are required;

- low cost;

- inexpensive repairs;

- does not require constant maintenance during operation, it is only necessary to periodically inspect the structure for damage;

- looks attractive;

- ease of construction;

- ease of updating the hedge.

Board blinds

The main advantage is, naturally, low cost. Unlike metal or brick, a wooden fence is much cheaper. At the same time, wood is much easier to process. From a practicality point of view, the ease of repair is pleasing.

Since to partially replace a damaged element you do not need to completely remove the fence, this greatly simplifies the process.

Combination of brick and wood

Despite all the advantages, board fences also have disadvantages:

- relatively short service life, about 10–15 years (this directly depends on how often the fence is maintained);

- Wood needs more frequent attention compared to other building materials. This includes dyeing, cleaning, treatment with disinfectants;

- poor protection from uninvited guests and intruders;

- easily subject to deformation under mechanical loads;

- increased fire hazard.

Facing stone and boards

Naturally, all this must be taken into account during the construction and operation of the fence. But in this case there are more advantages than disadvantages. That's why wooden fences are so popular.

Inside view

Installation of supporting structures

The support is secured in a vertical position using wooden posts or stops. The presence of a deviation angle from the axis is checked using a building level.

To fill a trench, cement mortar is mixed and poured into the pit. The mixture is allowed to harden, periodically wetting the surface of the solution with water.

It is recommended to use reinforced iron bundles and scraps of old pipes as supports. Load-bearing structures are placed along the boundaries of the site, at regular intervals.

How to buy quality raw materials

When choosing, pay attention to the following points:

- The material must be wrapped in transparent polyethylene or other packaging. It's not worth taking in a beautiful but dark wrapper. Otherwise, there is a high risk of buying a low-quality product.

- Knotted wood with chips is not suitable. It has a limited service life.

- If drops of water are visible under the polyethylene, then the material is damp. It is not advisable to take one like this, because when it dries, it will begin to deform.

- The color should be natural, without stains on the surface.

- The smell is woody and fresh. If you feel damp, this is a sign that the boards are beginning to rot.

- Larch is considered the most durable species. but it costs a lot, less strong ones are pine, spruce, but they are cheaper. For decorative hedges, it is better to take birch, beech, and ash.

- Planed boards have a smooth surface without roughness.

- Look at the rooms where materials were stored. It should be dry and warm there.

- Take boards from the same batch so that they do not differ in surface color.

Clearly calculate the consumption of raw materials, buy with a 10% margin. Carefully evaluate the type, storage conditions and quality of packaging.

Installation of main sections

After securing the foundation and supporting structures, the installation of fence sections begins. The installation method in this case depends on the selected material.

The last two points in the work are appropriate in the case of constructing a mesh fence, profile fencing or wood picket fence.

For poured cement fence and brickwork, a different technique is used.

Note!

Shed for a summer residence: TOP-130 photos of modern options for a shed for a summer residence. Types of sheds, their sizes and shapes, choice of materials for building a shed for a summer residence

- Closed gazebos: advantages and disadvantages of closed gazebos. Choosing the location, size and shape of the gazebo. Necessary materials and tools (TOP 100 photos)

Chicken coop for a summer residence: TOP-110 photos of building options. Varieties of chicken coops, DIY instructions for beginners

Support structures are made according to a similar principle, but a brick block or a strong pillar of concrete and decorative stone is built on top of the metal frame.

Use of ornamental plants

In addition to various materials, shrubs and trees can be used to create fences. The height, density and protective functions of hedges depend on the parameters of the selected plants. They can be decorative, no more than 50 cm high, or functional, consisting of 2-3 meter trees.

Beautiful, but not always practical

VIDEO: Beautiful fences for your home

Fences for private houses

Beautiful fence options

Features of working materials

In modern building materials stores you can find the most popular materials for arranging fencing in the country:

- Metal grid.

- Profiled sheeting.

- Wooden beams.

- Concrete blocks.

- Brickwork.

- Decorative rods for weaving.

Each of the presented options differs in construction technology, financial investments, and operating features. In these master classes we make a relatively cheap fence with our own hands.

Ladder or Christmas tree

On such a fence, the boards are not positioned horizontally or vertically, but at an angle and overlapping. Each subsequent board partially overlaps the previous one, which creates absolute opacity and at the same time does not interfere with air movement.

Mesh fence

The simplest option and economically accessible to every dacha owner. Step-by-step instructions that will help you learn how to make a chain-link fence with your own hands:

- The first three stages of construction work are carried out in accordance with the given plan.

- After preparing the supporting structures, the mesh is unfolded and tensioned.

- There are two main methods of fastening a mesh structure: continuous, when fastenings are made on each post.

- The second method is sectional, where mesh sections are placed in rigid frames and then attached to supports.

For fastening, pre-welded hooks and screws are used.

Note!

Pergola - the use and benefits of a pergola on the site. Types and shapes of structures, internal filling and decoration of pergolas (photos of new designs)

Do-it-yourself barbecue - step-by-step instructions on how to build a barbecue at home (photos and videos)

- Brick barbecue: advantages and disadvantages of the material. How to create a brick barbecue with your own hands. 120 photos + instructions

The main stages of fence construction

The actual construction itself includes three stages, which have already been mentioned above: installation of support pillars, fastening of transverse joists and cladding of the frame.

Each of them contains a certain range of work. In general, the workflow involves the following actions:

- Wooden or metal pegs are hammered into the markings. Twine is stretched between them;

- Pre-dug holes 0.8 meters deep. At the bottom of each of them there is a sand bed 10-15 centimeters thick. Next, the profile pipe is installed and secured. The pit is filled with crushed stone to a height of twenty-five centimeters. Carry out thorough compaction. The supports are fixed and filled with concrete;

- Transverse joists are being installed. Fastening is done using metal corners (35x35). There are two corners for each support;

- They make either continuous cladding of the frame, or with alternating boards. The top can be either a straight line or with protrusions of the supports above the skin by 10-15 centimeters;

- Since the material is wood, it is necessary to treat it with fire-prevention agents;

For painting, it is best to purchase special paint compositions recommended for such surfaces and designed for any atmospheric influence (sun, rain, wind).

Painting is considered an economical option. Dark colors are always more popular. After all, this is an outdoor structure and is not immune to dust and dirt, and accordingly, light colors create the risk of having to repaint it again.

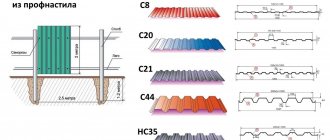

Corrugated fencing

A very popular way of arranging high-quality fencing today. We make a fence from corrugated board with our own hands, according to the following instructions:

- After installing the support pillars, crossbars are welded to install sheets of material.

- Profile sheets are screwed over the transverse supports.

Screws and large bolts are used as fastening elements.

Materials and tools

- Picket fence - any wooden elements are suitable: edged boards, planed boards, slabs and, of course, lining. Any wood is used - both soft and hard, and all species - both deciduous and coniferous. The choice depends on preferences and financial capabilities.

- Wooden blocks for transverse elements, section 50*50 mm.

- Support posts can be either metal or wood.

- Saw (chainsaw), ax and shovel.

- Nails or screws.

- Paint or drying oil, primer.

Clapboard fence

Wire fence

Quite a decorative fencing option for a summer cottage or private house. Elegant decor and original appearance are the main advantages of this method.

Step-by-step instructions for beginning craftsmen describe in detail how to make a wicker fence with your own hands:

- Willow twigs are most often used as the main material. They have a fairly flexible structure that allows you to simulate the shape and size of a decorative fence.

- Support structures are installed according to a similar principle, but with a reduction in the distance between adjacent pillars.

- The most voluminous willow rods must be dug into the ground in a vertical position, placing them between metal posts.

- They begin to knit the rows of the fence, retreating 15 cm from the ground level. This step will save the fence and material from rotting and damage by pests.

- The technique of knitting vines is in a checkerboard pattern. Metal wire should also be passed at regular weaving intervals to enhance the strength of the fence.

Such a fence is decorated at the request of the master.

Wooden picket fence

A traditional type of fence in which vertical boards (slats) are attached to horizontal slats mounted on dug posts. The planks can be placed at different distances: tighter or looser. To save time, it is worth purchasing a ready-made picket fence. If you decide to make it yourself, then try to maintain the same proportions. You can install the planks according to the principle of a classic wooden fence.

Wooden elements must be well dried. To protect the fence from adverse natural factors, do not forget to varnish the parts.

Advantages of a wooden picket fence: high mechanical strength, parts can be given any height and shape, and the distance between the planks can be adjusted.

Disadvantages: may become askew over time.

Wooden fence

The principle of installing a fence does not differ much from the classical method. The arrangement of supporting structures and crossbars is carried out in the specified order.

Note!

Gazebo with barbecue - TOP-140 photo examples, pros and cons of gazebos with barbecue. The best options for gazebos with barbecue in a summer cottage

DIY tandoor: 100 photos of the best options. Construction instructions at home

Wooden gazebos: advantages and disadvantages of wooden gazebos. Easy to install, environmentally friendly and practical. A selection of examples (photo + video)

The main difference is that the wooden planks are positioned strictly vertically and with gaps between adjacent elements.

This type of fencing is decorative, has a rich appearance, and also stylishly emphasizes the overall interior of a garden or summer cottage.

Carrying out any model of a fence on a summer cottage requires a creative approach from the master, the presence of certain construction skills and the ability to follow step-by-step instructions.

And advice from experienced craftsmen and photos of original fences made by yourself will help you decide on the technique for carrying out the work.

Simple option

- Places for pits are marked along the perimeter of the site. The distance between the support pillars should not exceed 3 m, otherwise the structure will acquire high windage and may be damaged by a strong gust of wind.

- Support posts are installed in pits. Filling with concrete rather than backfilling with soil is recommended.

- Wooden beams are attached to the posts with self-tapping screws. The minimum distance from the ground is 30 cm.

- Pickets are fixed to the crossbars on the outside of the fence (from the street). If regular lining without grooves is used, the slats are attached at a certain distance from each other, depending on personal preferences. If a European profile with grooves is used, then the lamellas can be joined in the same way as is done when covering the surface. In this way you can make a solid fence.

- The fence is treated with a primer and painted after drying. It is recommended not to skip this stage of work, since painting creates a protective film on the surface of the lamellas and helps to increase the service life of the product.

The photo shows a clapboard fence.

Photo of a fence made by yourself

Lattice

This is the most elegant type of wooden fence. The slats intersecting each other are located horizontally and vertically, or at 45 degrees to the ground. A lattice made of slats of different widths or with different spaces between them looks unconventional. Climbing plants spreading across the trellis look very decorative.

To extend its service life, any type of wooden fence needs a topcoat.