Reed roofing is an elegant solution for those who keep up with the times and want to create a unique landscape design on their plot of land. Modern technology for laying a reed roof allows you to increase the service life of the roof to 50-60 years. At the same time, reed roofing is quite affordable, the price, even taking into account installation and delivery of all materials to the site, is minimal. Moreover, all types of work and materials used are covered by a 50-year warranty.

Fact: Many people confuse the reed roof with the thatched roof, which was installed only on outbuildings or old village houses, and was preferred only by the poor. This thatched roof is less reliable and more flammable. We offer reed roofing, which decorates luxurious country houses, bathhouses and complements the landscape design with its originality. The main thing is that a reed roof is laid much more densely and will retain heat, quality and fire resistance for many years. If you want to make sure that a reed roof looks great, look at photos of completed projects on our website.

Raw materials for reed roofing

Roofs made from natural materials are durable and do not cause any problems during operation, but it should be understood that the service life of such a roof is, first of all, determined by the quality of the material.

High-quality raw materials guarantee that reed roofing will withstand the negative impact of environmental factors for many decades.

It will not rot or crumble, will not become covered with moss and will not leak if the quality of the raw materials for the natural roof does not raise any questions.

- Stems with a spongy core and uneven coloration in the form of spots are not allowed for use as roofing material.

- The best raw material is mature reed, about one year old, harvested in fresh water bodies, since salt water significantly worsens its characteristics and quality.

- The surface texture should not contain traces of fungi and mold.

- The optimal length of reed stems that will be used as roofing material is 1.5-2 meters, and in diameter - from 5 to 8 millimeters.

- Thin stems are more preferable because they are characterized by better flexibility, which allows for a truly high-quality reed roof installation.

Reviews

I was looking for a way to save on hydro, steam and thermal insulation when building a roof. I came across information that coverings such as straw, reeds and reeds completely eliminate this issue. An interesting solution, I didn’t even initially imagine that I would take a closer look at this option. I myself live in Petrozavodsk, I have never seen such roofs on anyone yet.

Michael

https://trostnik.su/gostbook.php

Vapor barrier is not needed, the reed does not rot (note that it remains in water even after the death of the plant). Since it does not rot, there is no place for microorganisms to live there. Fire impregnation is needed if there is a danger that the fire pit will fall on the roof; if not, then you can do without it. Insulation is also not needed - the thickness of the coating allows you to do without it.

hilyaki

https://www.forumhouse.ru/threads/94039/

I want to share my experience on how to make thatched roofs. The thickness of the coating layer is determined by the slope and length of the slopes. I had the following data: length six and a half meters and angle of inclination of forty degrees. The straw was laid twenty-three centimeters thick at the ridge and twenty-five centimeters thick at the base.

Victor S

https://trostnik.su/gostbook.php&page=4

A reed roof is a good thing... it is advisable to burn out or cut off the first reeds, and next year there will be even ones of the same size. And thick reeds are not suitable, only thin ones are 5-6 mm, and thick ones lie heavily and are suitable for walls.

Solly267

https://www.forumhouse.ru/threads/94039/

Information for those who are concerned about the flammability of thatch and thatch roofs. The solution is very simple: between the base and top layers of a thatched roof, a fire-resistant membrane is laid, which inhibits the spread of flame, and the roofing material itself is treated with fire retardants

Andrey Dmitriev

https://trostnik.su/gostbook.php&page=4

Good day to all! From my personal experience I can say that a reed roof is a reliable roof. It’s already “worth” itself 7 years in peace. He doesn’t ask to eat or drink, just yet) All the neighbors come and admire him. If anyone is interested, I can send you a photo. By the way, the reeds are from Russia and the roof slope in my house is -40 degrees. As they explained to me, the angle of the slope is important for a reed roof.

89267667546

https://www.forumhouse.ru/threads/19292/page-4

I tell many who ask me about reed roofs that the main criteria that determine its service life are the angle of inclination and orientation of the slopes. The Dutch, and these are the gurus in reed roofing, give the following dependence of the service life on the angle of inclination of the slopes: 25 ° - up to 15 years 30 ° - from 10 to 20 years 45 ° - from 25 to 45 years 50 ° - 45 years and more Let me remind you, that the service life is calculated from construction to major repairs. If you properly maintain your roof, the period of repair can be significantly extended.

eco-structure

https://www.forumhouse.ru/threads/19292/page-4

Advantages and disadvantages

As with other roofing materials, reed roofing has its advantages and disadvantages.

The advantages of this solution include:

- external beauty and identity,

- naturalness and environmental safety,

- the possibility of using complex structures in the construction of roofs,

- increased heat and noise insulation, which is ensured by the special structure of the stems (tubularity),

- good natural ventilation,

- resistance to critical temperature changes, strong gusts of wind,

- operation in conditions of high humidity is permissible.

A few disadvantages of reed roofs are easily eliminated:

- Fire safety issue. Most people consider roofs made from natural materials to be highly flammable due to their low fire resistance. In fact, this significant drawback is always eliminated through a special technology for laying reeds, special processing and installation of fire safety systems. The high density of the stems makes it difficult for air to reach the inner layers of the roof, and the use of fire retardants prevents the reeds from catching fire. The fire safety of a reed roof is also ensured by installing chimneys at a greater height and supplementing them with special spark arresters.

- The likelihood of damage to natural roofing by rodents and birds . Such damage to a reed roof occurs only in cases where the installation of the covering is carried out improperly (for example, there are protruding ends of the stems). When installed correctly, neither rodents nor birds can harm a natural roof.

About the advantages of reed covering

Such a roof is not afraid of temperature changes and high air humidity.

No fungus forms on the surface, the roof does not rot, because a natural plant naturally grows in a humid environment.

The reed roofing system has natural ventilation; no additional installation of thermal insulation materials is required.

The tubular structure of the reed stems contributes to reliable protection of the under-roof space from extraneous external noise. The service life for reed roofing is 50-60 years.

In addition to the aesthetic advantages, we also note the uniqueness of this coating and its sophistication.

After installation, the natural roof has a golden color, its intensity gradually increases. The facade of the house and the surrounding area are complemented by natural colors, which significantly improves the overall perception of the house.

Design

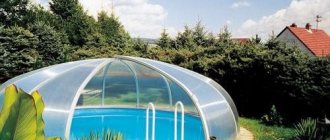

The types of reed roofs can be very different, so when developing a house project you don’t have to give up what you like best.

Of course, there are recommendations that need to be followed. For example, a flat roof will not last long, and it is better if the slope of the roof starts at 40 degrees.

A smaller slope is also acceptable, but, as a rule, in this case the customer must understand that the contractor’s guarantee will not apply to the durability of the coating.

Practice shows that with a slope angle of 50 degrees and above, you can count on the operation of such a coating for more than 45 years. If the slopes are made at 25-30 degrees, then the natural roof will please you for no longer than 20 years.

It is necessary to understand that a significant slope will help ensure rapid drainage of water from the roof, and the less time the moisture is in contact with the coating, the better.

If we talk about the types of reed roof structures, then they make single-pitch, gable, multi-gable, mansard, hip and hip roofs, which delight everyone around with their beauty and originality.

Basic properties of natural raw materials

This material contains many positive qualities:

- it is very easy to work with such material;

- not allergenic;

- resistant to rotting processes;

- protected from strong humidity;

- good sound insulation;

- high-quality waterproofing.

The main advantages and disadvantages of the material

The main reason for refusing to use reeds in construction was the laboriousness of harvesting the reeds themselves, preparing them and installing them on the rafter structure. Of course, it is much easier to install corrugated sheeting or special slate on the roof slopes. Many people think that in the summer season they will have to feel extreme heat and discomfort while being in a room with reed flooring, and in winter they will have to pay a high price for heating. If you try to save money on roofing, you may end up with an uncomfortable home.

In this case, the solution will be artificially created insulation, which will be installed under the roof or in the attic. It really protects the room from overheating and helps keep it warm inside during the winter. But when used, such thermal insulation can release substances that are dangerous to the residents of the house.

In recent years, when information has become available that many modern construction products have a negative effect on the human body, owners of private houses are purposefully beginning to use clean materials in structures again, including reeds in this group.

It must be admitted that the first steps to return reed coverings to use were taken by the owners of suburban areas, hotels and restaurants in order to attract more visitors. They began to create buildings in a certain style, into which reed walls and roofs fit well.

Inspired by this example, the majority of owners of private houses, who wanted to make their home not only environmentally friendly, but also give it a beautiful appearance, began to use this material for the roofing of buildings. That is why the demand for roofing material in the form of reeds began to increase significantly.

Reed has many properties, which include the following:

The most important quality of a reed roof will be its thermal insulation ability. So, even at very low temperatures in winter, reeds do not allow heat to escape through the roof. In summer, a thick layer of reeds protects the house from severe overheating, keeping the house cool inside. With this quality, you won’t have to resort to additional devices and materials for thermal insulation. Reed primarily grows in humid environments, which is why it is considered absolutely insensitive to water.

It will not rot or rot, which is very important; fungus, moss and any mold rarely settle in it. It can be noted that the material is highly resistant to negative external influences: ultraviolet radiation, temperature changes, precipitation and wind loads. The reed roof is laid with the creation of additional ventilation in the attic space in the under-roof space. This feature of the coating helps eliminate the need for additional hydro- and vapor barriers inside the house.

Reed layers, due to their hollow tubular structure, are considered good soundproofing materials

Such a roof will absorb all noise and will never resonate. This quality, together with the property of thermal insulation, allows the use of reed mats for wall cladding. A reed covering, unlike a metal one, is not considered a static voltage accumulator, so the risk of one-time lightning strikes can be completely eliminated. Long time of use. Such roofs do not require major repairs for 55-60 years; they do not need to be painted or cleaned. If minor repairs become necessary, the operation may include installing patches. In this case, bundles of new material are attached to the damaged area. At first, the newly installed layer may differ slightly from the entire coating in color, but over the course of the year, under the influence of weather factors, the color becomes more even.

It should also be noted that over time, the color of reed rays not only does not begin to fade, but also becomes deeper and more saturated.

Installation methods

The installation of reed roofing, depending on the personal preferences of the developer and taking into account the roof structure, can be done using one of several technologies.

- Dutch technology is the most common when installing reed roofs on residential buildings. It involves attaching reed sheaves to a solid base made of waterproof plywood, chipboard sheets, and fiberboard.

- Also, installation can be carried out using English, Danish, Polish, American technologies, the differences of which lie in the different sizes of reed stems used, the density of their laying, and the labor intensity of the process.

- Methods of fastening sheaves by stitching with wire, hemp rope, and constrictions have a long history and have proven themselves well.

Harvesting reeds

Considering the fact that reed is a coastal plant and it is difficult to get close to it in summer, harvesting is carried out in winter, using the surface of the ice. The reed stems are cut using any available method: with a scythe, sickle, knife, shovel or brush cutter. For roofing work, material with a height of 1.5 to 2.0 m and a diameter of 6.0 – 10.0 mm without the spikelet part, which is cut off, is suitable. Transporting reeds is not particularly difficult since its stems are strong and flexible enough to retain their original appearance.

At first glance, everything seems simple, however, if you consider that you will need a lot of reeds, you need to be prepared for a long and labor-intensive process. After the stems have been cut, they are piled into sheaves of such a size that they can be grasped. Typically this size is 600-650 mm. The sheaves are tied in several places with rope, wire or the stems themselves. For the convenience of tying sheaves, specially made wooden “goats” are used.

It should be noted that in some cases the spikelet part is not cut off, since there is a technology for laying it with it. Alternatively, knitting sheaves can be done in the spring, and then trim the flower part. When the required amount of reeds in sheaves has been collected, it will be possible to begin installing the reed roof. As practice shows, for 1.0 m² of roofing there are ten sheaves of a generally accepted size, that is, up to two meters long and 600 mm in diameter.

Operating rules

Any roof requires special maintenance activities.

- In the case where reeds were used as a covering, a year after the installation of the roof, if necessary, specialists correct it, compact it and comb it.

- To prevent other plants from growing on the roof, the covering is regularly cleaned of knots and leaves.

- Treatment of reed roofs with fire retardants is carried out at the request of homeowners.

- Replacing the topmost layer of coating every 10-15 years is not mandatory, but helps to significantly extend the life of a reed roof.

Peculiarities

How to choose roof rails for the kitchen: a fashionable and practical solution

This wonderful natural raw material for roofing does not require the use of special tools, much less equipment. The main thing in such work is the knowledge, practical skills and skill of a roofer who understands all the nuances of the work. If the structural elements are equipped according to all the rules and are ready to be covered with reeds, this material after installation will provide effective protection of the building from any weather. Architectural benefits are more pronounced on roofs that have a simple structure.

For configurations with complex transitions, angles and differences, laying exotic material will be much more difficult. The flexible properties of reeds allow you to cover surfaces of any complexity. The basis for such a roof is a rafter system with lathing, which is designed for a load of 35 kg/m².

Note! It is recommended to make the lathing from bars 4.0x6.0 cm or 5.0x5.0 cm with a distance of 0.3 m between each other. At the design stage, such structural elements of the roof should be provided as: ventilation and chimneys, windows, openings and other

At the design stage, such structural elements of the roof should be provided as: ventilation and chimneys, windows, openings and others.

Roof service life

How long a reed roof will last will depend on many factors:

- quality of raw materials,

- laying technology,

- roofer qualifications,

- environmental conditions,

- the complexity of the roof structure and the steepness of the slopes,

- correct service.

Gable roofs made of reeds with a slope above 35 degrees last the longest.

If all rules and recommendations are followed, the issue of replacing a reed roof may not arise for more than fifty years, or even longer.

A little about the properties

In addition to its extravagant appearance, reeds have truly unique qualities:

- it is characterized by incredible resistance to scorching sunlight, very low temperatures, strong gusty winds, and heavy precipitation;

- thanks to the presence of a flexible stem, you can create very complex architectural roofing structures;

- due to the fact that the stems are empty inside, and the dried leaves do not fit tightly together, air passes freely inside the roof, creating natural ventilation;

- the material has exceptional mold and fungal resistance;

- is distinguished by its durability.

Roof for a gazebo made of reeds

All kinds of small architectural forms are one of the methods for decorating adjacent areas, designing gardens and parks.

A gazebo with a reed roof is the element that best helps shape the overall perception of the landscape design of a certain limited area.

The roof for a gazebo made of reeds can have, in addition to the standard gable shape, a conical or hipped structure.

Most often, the installation of reed covering on a gazebo is carried out using open technology: the sheaves are laid on the sheathing in such a way that the inner surface, i.e., the back side of the roof, acts as a ceiling.

Thanks to this technique, the gazebo becomes a small architectural form that has its own individuality not only outside, but also inside.

Conditions of stay for prisoners in the Alger camp

Women had to sleep on three-tier bunks. Those who did not have enough seats sat on the wooden floor. Prisoners were forbidden to receive letters, parcels and other things from outside the prison. Visits were not allowed either.

The territory of "Alger" was fenced with three rows of barbed wire. Every day women were forced out to work. Moreover, only a few worked in their specialty. Agricultural and construction work were the main ones. Children, the sick and elderly women were sent to embroidery and sewing workshops.

Local residents fed the camp prisoners. Kurt is a cheese made according to a national recipe. It looked like stones. Therefore, the guards had no idea about the “delicacy” being planted.

Reed roof cost

- The cost of a roof made of reeds with a thickness of about 0.30 m is from 1,750 rubles/sq.m.

- Roofing reeds 200 mm. / bunch - 150.00 rub.

Reed consumption for roofing

There is often a question about the consumption of reeds when installing this type of roofing. The answer to this question cannot be clear.

First of all, the consumption will depend on the thickness of the roof itself. With a roof thickness of 30 cm, for example, the consumption will be 7 - 10 bunches per square meter, or otherwise 0.50 - 0.60 cubic meters / meter2

DIY reed roof: installation, relevance, disadvantages

Assessing the benefits of using natural materials for roofing, many people ask the question: “How can you make a reed roof with your own hands?”

Self-installation of reed roofing is possible on gazebos, outbuildings and other objects that are not intended for permanent residence.

If you are building real estate and plan to use it for permanent residence, then a do-it-yourself reed roof is not a very rational solution.

The guarantee of high quality, as in the case of any other roofing materials, is provided only by professionally performed work on installation of the coating, so it would be wrong to rely only on your own strength.

Disadvantages of installing a reed roof with your own hands

Lack of knowledge and experience, if you want to save on paying for roofing work, can lead to troubles in the future:

- leaking or poorly drying roofs, which allow not only moisture to pass through, but also heat or cold;

- insufficient density of reeds increases its flammability;

- the appearance of a reed roof made by yourself will not be neat;

- the service life will decrease several times, etc.

Since the price of roofing reeds is quite high, and this material today belongs to the elite category, you should not take risks and try to do the work yourself, which should be done by professionals.

Savings when installing a reed roof

It is possible to save a lot of money when installing a reed roof due to the absence of the need to purchase additional heat, hydro, sound insulation, various additional elements, etc., which are mandatory in cases of installing roofs made of other materials.

Considering this point, and also calculating the price of a year of operation of a reed roof, you can see that in fact it is truly practical and one of the most inexpensive.

Properties of reeds as a finishing material

First, let's define what exactly we mean by the word “reed”.

Difficulties of terminology

The fact is that there are three very similar types of lake and water plants: reeds, cattails and reeds.

Lake reed looks like small inflorescences on a thin long stem

Cattail is a stem with long sharp leaves-ribbons, topped with an inflorescence-cone.

Reed is very easy to confuse with reeds, but its inflorescences are more spiky and larger. I discovered that most of my friends do not even know the difference between reeds, reeds and cattails - although in appearance they are quite different. The funny thing is that all these varieties can be used for roofing - wherever they grow. For example, cattail predominates in Central Asia, and reed predominates in southern countries. In terms of performance, they are almost identical. But for some reason people call all such roofs reed roofs. Let's follow this example, especially since in Russia roofs are often made from reeds.

Unique qualities of reeds

For many millennia, people have used reeds as roofing material. And not only in cases where there was nothing else in the area where the house was built. This material was valued everywhere because of its unique qualities, low cost and durability. This is confirmed by thousands of documents - for example, a drawing of a “Cossack hut” from Vadim Shcherbakovsky’s book “Ukrainian Folk Mystery. Ornamentation of the Ukrainian house”, published in Rome in 1980.

The drawing of the “Cossack hut” from the book by Vadim Shcherbakovsky proves the long history of the use of reeds

In Central Asia, reeds were used not only for roofs; sometimes they were added to clay instead of straw to make building bricks and plaster. Such clay was called “adobe”, and houses made from such bricks were called adobe.

Reed roofs and adobe shopping arcades can be seen in many Central Asian markets in the mid-19th century

The tradition of covering the roof with reeds and using it for other purposes in Central Asia has been preserved to this day. At the market, private owners from riverine villages sell reed boards of various thicknesses - for roofs and fences. In my Tashkent house, the beds and plantings were fenced off from dogs by low reed fences. In the first few years they are very beautiful - golden and glossy, then they darken, but still create an inexpressibly beautiful color. And on the plot with the house where I grew up, we had outbuildings covered with reeds - apples and grapes were stored there all winter, because dampness and mold would never develop in a room covered with reeds.

Many of the sheds of my childhood were covered with homemade reed roofs

Reed is used not only as a roofing material and an additive to clay for adobe. Mats are also made from reeds for wall cladding for sound and heat insulation.

Houses are sometimes lined with reeds for thermal insulation.

In the modern technogenic world, people have become increasingly striving for a clean environment, so reeds have returned to construction after a long break. And now many Russian companies are engaged in the preparation of sheaves for reed roofs, specifically growing a special variety of this natural material.

Photo

| Country cottage with reed roof |

| House with reed roof in the suburbs |

| Reed roofing on a cozy country house |

| A reed roof looks impressive on a large cottage |

| Roofing reeds on the roof of the main building and garage |

| Rural house with a roof covered with reeds |

| Ecological roofing using reeds as a covering |

| Brick house with a roof made of natural reeds |

| Submit your application | Request a call | Ask a Question |

Laying technology

Laying reeds on the roof begins with the installation of sheathing. Sheathing slats, made of timber 40x60 or 50x50 mm thick, are laid across the rafters in increments of 300 mm. After this, you can proceed to directly laying the plant material. The installation process is as follows:

- Screws are screwed into the sheathing or nails are driven into which the galvanized wire or hemp rope necessary to hold the cattail sheaves will be attached.

- Laying begins from the lower edge of the roof overhang; the lower tier of cattails should extend 50 cm beyond the edge of the roof overhang.

- The first tier of plant material is fixed from a stepladder, scaffolding or high ladder, and subsequent installation is carried out by moving the lathing, which must support the weight of a person.

- Cattail sheaves are fixed tightly to each other on a wire until a uniform layer is obtained that will not allow moisture to pass through.

- After laying the sheaves on the slopes, they proceed to the design of the ridge. To do this, shorter stems are used, which are laid along the ridge connection and then pressed with a ridge profile.

- After the installation process is completed, the sheaves are tapped and leveled so that the roof acquires a beautiful, aesthetic appearance.

Remember that it is more effective to treat the finished roof with a fire retardant compound, rather than the raw materials. When treated with a fire retardant, the composition penetrates to a depth of 5 cm. During operation, the substance protecting against fire is washed off by rain, so the treatment should be repeated after 3-5 years to prevent fire due to a lightning strike or a spark from a heating device.

Reed laying scheme

Laying

Leveling the reeds