In regions with a pronounced seasonal climate, reliable, economical insulation of buildings under construction for any purpose is always relevant. One of the universal insulation materials, with a 30% share in the global production of thermal insulation materials, is penoizol. Foaming cavities and walls with foam insulation and applying it to other surfaces allows us to qualitatively solve the problem of insulation with the parallel organization of reliable sound insulation of structural elements. Available, safe, inexpensive penoizol is equally effective for insulating old houses or new suburban buildings.

Penoizol - universal insulation for the whole house

Penoizol: what kind of material is it?

The correct name for the material in question is urea foam. “Penoizol” is the name of a trade brand, which, due to its popularity, has become a household name for all compounds in this group. Among builders and developers, insulation is defined as poured or liquid foam. Different manufacturers have their own name for penoizol. But let's skip the linguistic details and focus on the main issues.

In essence, liquid modified foam is a pre-foamed and then frozen mass of a cellular structure based on urea resins.

Meet Urea Foam

To prepare it you need the following components:

- urea-formaldehyde synthetic resin;

- foaming agent;

- specially prepared water;

- orthophosphoric acid.

All components in a certain proportional ratio are placed in a foam generator, where pressure is created. The output is a white foamy mass with a jelly structure. This composition quickly fills all kinds of cavities, voids, and layers. The simple technology for producing penoizol, the availability of inexpensive components, the possibility of producing insulation directly at the work site, reduces the cost of insulation, and allows work to be completed much faster than using other thermal insulation.

For your information! The applied modified foam hardens in 10 minutes. In 4 hours the composition hardens throughout the entire volume, after 72 hours it acquires final strength.

Price

One of the main advantages of the presented insulation is its price. Penoizol costs about 600 rubles/m³. At the same time, the quality of thermal insulation is not inferior to the popular insulation materials existing on the market today.

If we compare penoizol with mineral wool, a product with similar thermal conductivity will cost the consumer 1.5 times more. Moreover, the price of this insulation is 900-1000 rubles/m³.

The price of penoizol is 1.5 times lower than the cost of polystyrene foam. Material with similar thermal conductivity costs 950-1000 rubles/m³. The cost of extruded polystyrene foam is 6.6 times higher than that of penoplex. It is about 4 thousand rubles/m³ (taking into account the thermal conductivity coefficient).

Also, in terms of cost, urea foam is more profitable than basalt slabs, staple fiber and expanded clay. For this reason, many private property owners prefer this type of material.

Pros and cons of using it

Thermal foam that hardens after pouring has the following advantages:

- High thermal insulation ability.

- Elastic penoizol does not lose its original shape after prolonged dynamic loads.

- Temperature fluctuations do not affect the properties of penoizol.

- Due to its liquid operating state, the foamed heat insulator qualitatively fills any voids and has good adhesion to all building materials.

- Versatility. Possibility of filling volumetric cavities, application to various surfaces.

- Vapor permeability allows the insulated structure to “breathe” and remove absorbed moisture. This property is very important when choosing penoizol for insulating wooden buildings.

- The insulation applied as a continuous layer has no joints or cold bridges. Before applying it, the working surface does not require leveling.

- Low cost.

- High speed of work with the composition.

- Environmentally friendly, safe for health (after crystallization).

Now about the weaknesses of penoizol:

- You cannot work at temperatures below +5°C.

- Elasticity and resilience do not interfere with effortlessly tearing or piercing penoizol, violating the tightness of the thermal insulation.

- The high cost of the necessary equipment and its dependence on the availability of power supply limit the ability to carry out the work independently.

- Due to possible water absorption, there are limitations when insulating some surfaces (for example, foundations).

- Penoizol is subject to volumetric shrinkage of up to 5%. If the application technology is violated or the proportional ratio of the ingredients is not observed, the shrinkage of the material can increase significantly.

Result of abnormal shrinkage of modified foam

Liquid foam foam Penomassa

TIS Channel Plant LLC

“Foam mass” is a liquid foam plastic that, with ordinary manual mixing in a bottle, after pouring the mixed liquid into a cavity or mold, increases in size by 10-12 times and acquires unique physical and mechanical properties. There are many types of foam plastics, this is ordinary foaming polystyrene foam in slabs and granules, extruded slab foam, but Penomassa is a special foam, it is liquid, which during the polymerization process increases 10-12 times and takes on the necessary shape with unique foam characteristics that are not inferior to conventional foams and even surpass them in many respects. The resulting material “Foam mass” has an orange color, high mechanical strength (withstands compressive strength loads of up to 33 tons per 1 sq.m.), low water absorption (almost does not absorb moisture), low thermal conductivity coefficient (lower than that of conventional granular PSB foam and approximately identical compared to extruded foam, such as penoplex, technoplex), greater adhesion (stickiness) to many materials, a high buoyancy index (does not sink), and most importantly, it can take any shape and completely fill all voids. Liquid foam "Penomassa » is produced according to Technical Specifications TU 2254-007-86901126-2015 in the city of Yekaterinburg on - intended for filling voids, cavities, thermal insulation, noise insulation, thermal insulation of building structures, making beehives, making sculptures, for filling voids in floating devices, construction joints structures, insulation of equipment and pipelines. The process of obtaining “Foam Mass” is very simple. One set of “Foam mass” contains two containers, one of which contains “foam”, and the other contains “mass”. To successfully use “Foam Mass”, both bottles must be preheated to a temperature of +20 - +25ºС. After that, you need to open the bottle with “FOAM” and pour it into the bottle with “MASS”, close the bottle with “MASS” with a lid and shake the resulting substance vigorously in the bottle for 20-25 seconds. Then open the bottle with the resulting composition and pour it into the cavity or mold to be filled. After you pour the material into the cavity to be filled, after 20 seconds the “Foam Mass” will begin to increase in size by 10-12 times and fill all available cavities. “Foam mass” hardens within 2-3 minutes after pouring. Foam mass has a closed-porous structure, which prevents the penetration of moisture and steam through the material.

Original link: https://www.youtube.com/watch?v=5bzfHiL5cx0

Specifications

After studying the performance properties and technical qualities, it can be argued that these characteristics make penoizol a high-quality insulation material in the domestic construction market. Here are the main characteristics of penoizol:

- The thermal conductivity of the frozen mass in the range of 0.028-0.047 W/(m•°C) indicates high thermal efficiency.

- Penoizol absorbs up to 50-65% of extraneous noise.

- The fireproof composition does not burn; when exposed to high temperatures, it evaporates without releasing toxic substances.

- Chemical neutrality.

- Biological resistance to pathogenic microorganisms.

- The density of the light composition falls within the range of 5-70 kg/m³.

- Penoizol is usually used as a liquid composition. But there are other forms of release - sheets of a certain size made from crushed, fine chips.

- Water absorption capacity is up to 10-20% by weight per day.

- Operating temperature -50°С – +120°С.

- The service life declared by the manufacturers is up to 30-50 years.

Consumption rates per 1m2

When planning a construction budget, you need to accurately determine the amount of material. To determine the amount of liquid insulation that will be required to insulate the entire building, you need to know the consumption rates of penoizol per square meter.

According to manufacturers, the consumption of liquid foam per 1 m2 varies between 1-1.3 liters.

To calculate the required amount of material, you need to multiply the length and width of the wall by the consumption rates stated by the manufacturer.

For example: 7*3.2*1.3=29.12 l. In this case, the final amount of thermal insulation must be taken with a small margin, taking into account unforeseen situations.

Is penoizol harmful to health?

When the foam substance polymerizes, a small amount of formaldehyde is released. But its concentration is so low and its presence is so fleeting that formaldehyde is safe for specialists performing work in protective clothing. Many paint and varnish products are much more dangerous in terms of harmful emissions. The safety of already hardened penoizol is confirmed by relevant certificates received by manufacturers after professional testing.

Advice! Do not try to save money on cheap compounds from unknown manufacturers that do not have certificates of conformity and product safety.

Recommendations, installation

In order to reduce the costs associated with the thermal insulation of a structure, you can not purchase ready-made equipment, but install it yourself at home.

Such a device must have:

- gas-liquid unit;

- hoses for supplying reagents and foam;

- plastic containers;

- compressor;

- taps.

Installers advise working with penoizol according to this scheme:

- assembling the installation in accordance with the instructions;

- mixing all the necessary components in a barrel;

- preparing the surface to be treated by dismantling old facing materials (the base does not need leveling: a layer of liquid foam can hide all bumps, protrusions and other flaws);

- installation of metal or wooden sheathing (wooden structures must be treated with antiseptic compounds);

- installation of logs from wooden beams;

- applying a uniform layer of penoizol or foaming voids;

- cutting off excess material with a construction knife after it has hardened;

- installation of reinforcing mesh after polymerization of insulation;

- facing works.

In order to install a heat insulator efficiently, it is best to contact certified installation organizations.

Craftsmen are able to quickly insulate any structure and provide a guarantee for the work done.

Insulating a house with foam insulation

With the help of penoizol, frame and capital structures are insulated with equal quality, and any gaps and cavities are filled without any remaining voids. Insulation work can be carried out outside and inside the building.

Internal insulation of a wooden building

External insulation is a priority, its advantageous features:

- Creating additional protection for wall material.

- The internal usable area of the housing is not reduced.

- The dew point moves to the outer surface of the base.

Important! When using the external method, penoizol is protected with a vapor barrier laid in such a way that condensate vapor is discharged towards the street. During interior work, vapors must pass through a layer of vapor barrier, insulation, and then out.

In addition to capital structures, foam insulation can be used to insulate floors, interfloor ceilings, attics, attics, and roofs. The work can always be divided into the following stages:

- choice of insulation method;

- preparation of surfaces and equipment;

- mixing components;

- pouring or applying penoizol;

- keeping the composition until completely cured;

- trimming excess.

Independent reviews from construction forums

To understand the real effectiveness of insulation, you should not unconditionally trust the words of sellers and manufacturers. It will be much more effective to turn to the reviews of real people who have already used the subject of our conversation for insulation. Let us immediately note that opinions on the properties of liquid thermal insulation are divided.

Not bad, but there was a small nuance. Alexander (www.forumhouse.ru)

Penoizol is an excellent alternative to any type of modern insulation. The price is quite reasonable, the mice will not be stolen, the declared characteristics are at a high level. However, during practical use, a small drawback emerged: when insulating wooden walls, unfilled areas remained.

Recommended by friends. The house has a comfortable microclimate. Ildar (mastergrad.com)

We decided to insulate the walls with foam insulation about 5 years ago: the outer wall is made of block and brick. 6-7 centimeters left between the masonry . Glass wool and mineral wool did not give the expected result: the wall began to mold, the rooms were quite cool.

Friends recommended penoizol. As the crew worked, one could hear and see the insulation filling the space between the walls, emerging from the cracks. Now the house maintains a comfortable microclimate at any time of the year.

No complaints, but problems arose during the filling process. Mikhail (forumnov.com)

It is clear that seamless insulation has undeniable advantages. There are no complaints about the quality of insulation, however, for the operation of the equipment, a connection to a 380 V . I did not have such an opportunity, which caused some difficulties during the pouring process.

I really don't like the toxic smell. Konstantin (forum.vashdom.ru)

After pouring, penoizol noticeably decreased in volume, which already reduces the quality of thermal insulation. In addition, the material has an unpleasant and clearly toxic odor. They said that the composition includes formaldehyde, the use of which has long been abandoned in European countries. I recently insulated the house, so I can’t say anything about the properties of the material, however, doubts about the correctness of the choice are already tormenting me.

The price of the work is steep. Eduard (www.forumhouse.ru)

Personally, I am satisfied that penoizol will not be chewed by mice, the insulation accurately fills any gaps, and provides reliable heat and sound insulation. I didn't like the fragility of the material and its susceptibility to deformation. And the overall price of the work is a bit steep.

Where to start finishing

If during the work the foam composition is poured into the layer between the elements of a well or three-layer masonry, prepare holes in the material of the outer layer to supply insulation through them. This applies to already completed buildings. When insulating structures during their construction, drilling is not required.

It is necessary to clean the base from dust, prepare a frame or sheathing, between the elements of which liquid material will foam.

At the preparatory stage, it is important to choose high-quality working material. When purchasing the composition, a demonstration sample of the prepared penoizol should be dazzling white, not literally settle before our eyes after leaving the supply hose, after 12-15 minutes. must withstand pressure by hand and quickly restore its shape; large or heterogeneous pores should not form in the volume of high-quality insulation.

How to assemble a working installation

Buying a spraying installation for building a house is irrational. It’s much cheaper to rent it or assemble it yourself if you have:

- Gas-liquid installation;

- Compressor;

- Transport platform for containers.

The installation and the compressor are connected in series. The solution is poured into the container, the machine is started, and insulation layers are applied layer by layer, row by row, to walls, ceilings/floors or into molds.

If you have no experience in insulation with sprayed materials, you should seek help from professionals or test your strength on a separate area, for example, on an unnecessary board

It is important that the spray is uniform, without spitting. If necessary, adjust the solution supply power

Necessary equipment

Complex and expensive specialized equipment is necessary when using penoizol in liquid form. Sheet and granular materials are handled with a minimum set of simple tools. The sheets are installed similarly to other insulation materials (expanded polystyrene, penoplex and others), and the filling of air voids with granules is carried out by backfilling and blowing.

The installation for producing and applying liquid foam has containers for each component of the future mixture. When you turn on the device, the ingredients are mixed in a separate chamber. There, thanks to air supplied under a certain pressure, foaming of the resulting composition occurs. Foam is supplied through the sleeves to fill insulated openings or apply to the required surfaces. The equipment set includes a compressor and containers with reagents.

Compressor for preparing working foam

Since liquid penoizol must be prepared immediately before use, a set of equipment must be delivered and located at the work site. At small sites, low-cost gas-liquid installations are used, and for large-scale works, pneumohydraulic ones are used.

Kinds

There are several types of penoizol for various types of work. The most popular of them are the following:

- Liquid penoizol - this type is most often used in the construction industry, since among specialists it is considered the most convenient. It is manufactured immediately at the construction site using special equipment. It can also be purchased in special cylinders if there is no need for extensive work. This type is suitable for filling gaps when renovation work is being carried out in buildings.

- Leaf variety. To obtain such material, liquid foam is poured into special molds. Then the mass hardens and is cut into layers of a certain length. After this, the material must be dried and cleaned. Some companies also offer customers special foil foam insulation. It will not be possible to use glue, since such sheets must be installed using dowels. A cladding must be installed on the surface.

- Chit. This type of penoizol is obtained by crushing a finished solid sheet of material. Its size should not exceed 15 mm.

Tools

When filling internal gaps and cavities, you will need a hammer drill (to form foam filling points) and a knife to remove dried excess insulation.

When insulating surfaces, a frame can be constructed; usually, subsequent protection of the insulation with vapor barrier films and a layer of facing material is required. In these cases, the list of tools is supplemented by a drill, screwdriver, hammer, level, and stapler. Due to the specifics of the work and differences in objects, the list may be adjusted upward and vice versa.

Flaws

The main disadvantages are different: penoizol is not suitable for all structures; it should act only as a middle layer and be reliably protected from external factors.

Penoizol gives significant shrinkage (1-3% of volume). Since penoizol can only be installed at a certain temperature, this may cause a delay in construction work, which is also a disadvantage.

Please note: penoizol can only be installed at an air temperature of 6 degrees or more.

Despite the fact that pouring insulation does not take much time, this work must only be performed by a specialist, otherwise the material may lose its properties.

Penoizol must be insulated. In addition, it is often necessary to additionally insulate the material in the structure, which leads to unnecessary costs.

If this has not been done, the insulation may release formaldehyde gas, which causes an allergic reaction in people.

It is the poor quality of work and material that causes negative reviews.

Be careful: before purchasing, you should make sure that the manufacturer is reliable and has quality certificates; beware of counterfeits.

This article is about the features of equipment for the production of penoizol.

Read the article about making penoizol with your own hands here.

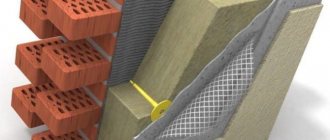

Interwall thermal insulation with foam insulation

Using this technology, thermal insulation measures are carried out in panel, brick and frame buildings.

Pouring the composition between the supporting structure and the brick cladding during the construction phase

The interwall air gap can be filled in two ways:

- During construction work. Penoizol is used to fill the open technological cavity between the masonry layers being built. The composition is served on top. In this case, the result of the work is of higher quality, the pouring process is easier to control, and no additional preparation is needed that would damage the integrity of the masonry.

- In an already used house. At the joints of bricks or building blocks used, technological holes are drilled into which the tip of the supply hose must freely pass. They are arranged in a checkerboard pattern. A sleeve is mounted into the hole in the bottom row, then the supply of penoizol under pressure begins. When foam appears from the hole at the next level, stop the supply and move the hose to the next hole in the same row. The procedure is performed sequentially with the remaining top rows. All technological holes are sealed.

Interwall thermal insulation of the facade of a residential building

The presented video material will help you understand and remember the sequence of work:

Where to use spray insulation

- Roofing and attic structures

- Insulation of floors

- Insulation of wall surfaces

Objects can be classified as follows:

- Industrial buildings

- Outbuildings

- Refrigeration equipment

- Pipeline communications

- Vessels for technological purposes

Important to consider! Although spray-on insulation is considered environmentally friendly, thoughtful precautions must be taken when installing insulation in residential buildings. At the moment of application of the material, a polymerization reaction occurs, accompanied by a high degree of toxicity. And only after final hardening the risk of poisoning disappears completely.

And only after final hardening the risk of poisoning disappears completely.

And only after final hardening the risk of poisoning disappears completely.

As for the type of materials that can be used for insulation, there are no restrictions in this regard.

DIY spray insulation

In any case, for self-insulation with polyurethane foam you will need a balloon installation and the components necessary for this procedure, namely:

- Polyol, which must be mixed in a container with freon

- Isocyanate, also combined with Freon 134

Both cylinders must be inflated until the pressure in them reaches at least 8 atmospheres.

Next, spraying is carried out on the treated and prepared surface - just press the spray gun and direct a stream of insulation to the desired area.

Attention! When working independently with sprayed insulation, it is imperative to use personal protective equipment!

Sprayed insulation in cylinders

Sprayed insulation in cylinders is more practical, as it has been professionally prepared at the factory, including optimal pressure conditions.

Price for sprayed insulation

In the long term, the cost of insulation with sprayed insulation pays off by reducing energy costs.

Sprayed polyurethane insulation Polynor

Thus, this type of thermal insulators is a priority in the choice of material for a number of technological indicators and for reasons of practical and budgetary value.

Video about sprayed insulation

The process of insulating the roof of a house with sprayed insulation.

Video about sprayed polyurethane insulation Polynor. Instructions for working with this material.

https://youtube.com/watch?v=CWFeIrEClmM

Thermal insulation of the façade with foam insulation and cladding with cladding slabs

With this method, the process of filling the air cavity with foam insulation is preceded by more labor-intensive preparation and installation of the restrictive lining. Frame elements (galvanized metal profiles) are vertically attached to the façade wall. Facing panels made of plastic or metal are attached to them (the choice is up to the owners). After installation, a three-layer structure is obtained - a base, an air layer, and an outer cladding. Its insulation is carried out using inter-wall thermal insulation technology. After filling the filler holes, the facade is decorated.

A simplified version of facade insulation using a membrane:

After studying the characteristics of the thermal insulation material and the rules for working with it, it can be argued that choosing penoizol is a profitable, reasonable decision. Having assessed the quality of the house insulation, many developers will add liquid foam to the list of top thermal insulators.

Price

One of the advantages of this material is not only that it is considered environmentally friendly, but also the low price of penoizol . Moreover, if you compare its main advantages over other types of thermal insulation (resistance to mechanical damage, protection from rodents and insects, moisture resistance), then the prices will seem more than profitable.

In this case, pouring occurs immediately at the construction site. This allows you to reduce most of the costs of storing material. If we talk about average prices, then 1 cubic meter of solution costs about 1,900 rubles.

If a solution of higher density is used, the price will be from 2200 rubles. In some cases, the calculation is carried out depending on the area. In this case, the price is about 200 rubles per 1 sq. m. meter.

Floor insulation with foam insulation

Roof treatment

You can insulate the roof of your house before or after installing the roof.

Features of pouring insulation depend on the type of roof. If the roof is made of slate or metal tiles, then the empty space under them must be filled. If there is an attic in the house, it is necessary to insulate its floor with a thick layer of penoizol. Before pouring insulation, it is necessary to carry out preparatory work, which consists of several stages:

- The surface on which the insulation will be poured is covered with a film membrane (instead of film, you can take corrugated board or plywood). For vapor barrier, it is necessary to leave an extra 15 cm, which will overlap the wall.

- The spread film is secured with staples at a distance of 20-30 cm from each other.

- After fastening with staples, special slats are stuffed onto the film to avoid sagging.

- Insulation (penoizol) is applied on top of the film.

- Wait 15 minutes so that the material becomes viscous, but does not have time to harden completely, level the surface. Leave for another 4 hours until the material has cooled completely.

- After this, further work on the roof can be carried out.

Foaming walls

The walls are insulated from the outside and a protective façade is then installed. For this:

Several holes are drilled in the wall and penoizol is poured into the voids using a pouring hose.

- After this, a metal profile is installed, which will serve as a suspended structure for pouring penoizol. The distance between the wall and the metal sheet should be at least 5-10 cm.

- Prepared penoizol is poured into the space between the walls.

- After pouring the insulation, you need to wait 4 hours, and then carry out further work - trimming the foam insulation released through the through holes, painting the walls, leveling the layers.

Review of manufacturers

) owns the trademark of urea foam or penoizol, it has all the rights to use the new generation polymer. In Russia, some companies produce the base for liquid foam: these are CJSC Metadynea, OJSC Togliattiazot, OJSC Acron.

Penoizol is also produced abroad, where it is produced under different names:

- in the UK it is called flotofoam;

- in Germany it is known as animotherm;

- Insulspray is produced in Canada;

- Mofotherm is being created in the Czech Republic.

Despite the different names, it is still the same universal penoizol, which is rightly classified as a high-quality building material. Domestic and foreign consumers talk about it as one of the best heat insulators. “Material of the Future” allows you to carry out reconstruction or basic work with high quality and at an adequate price.

Physical basis

Prepared penoizol

Penoizol is a urea resin reduced to a foam state, used in construction for room insulation and sound insulation. It is made by mixing urea resin, hardener and foamed water and then drying them.

Developed in the 30s of the 20th century, penoizol has firmly established itself in the ranking of the most popular and universal insulation materials. Its production in all countries of the world accounts for about 30% of all produced types of insulation.