What kind of bathhouse it should be depends mainly on the stove in it. According to tradition, a Russian bathhouse should have a brick stove, which replaced the more ancient stone one. And many owners of baths under construction or built a long time ago are trying to install one of these - after all, this is a thing that has been tested for centuries. But how to assess the scale of the effort, time and finances associated with the construction of a brick stove for a bathhouse? We want to help you - read and decide whether you can handle it yourself or still look for a professional, or is it easier to abandon this idea in favor of a brick-lined metal stove, which, if handled skillfully, can produce the same conditions as a brick one ?

Advantages and disadvantages of homemade sauna stoves

Most often, a metal or brick stove is chosen for a bathhouse, and in order to make the right choice, their advantages and disadvantages are taken into account.

Among the “advantages” of metal sauna stoves, it is worth highlighting the following:

- quick heating of the steam room (stone or brick gives off less heat than metal: a couple of hours after the start of kindling, and sometimes even earlier, you can go steam);

- compact design (this allows you to get more space in the main bath room);

- durability (subject to high-quality assembly, the stove will last from five to fifteen years);

- ease of use (compact metal stoves can be transported from one place to another);

- ease of manufacture (unlike, for example, the brick version);

- profitability (materials for the production of baths are inexpensive).

The advantages of a brick kiln include:

- soft steam, which is typical for spacious brick ovens;

- long-term preservation of steam and heat;

Soft steam from a brick stove Source wikimedia.org

- ease of use (there is no need to take fire protection measures before operating such a stove);

- aesthetic appeal (a brick stove looks very presentable, unlike its metal counterparts);

- ease of construction.

A simple stove for a sauna Source neoenerg.ru

However, for both types of homemade sauna stoves, the following negative points must be taken into account:

| Metal | Brick |

| Rapid cooling, which forces you to regularly add solid fuel | Heavy weight |

| The stove walls heat up too much, which reduces fire safety | Lack of mobility (all brick stoves are stationary) |

| In most cases, only suitable for small bath spaces | It is necessary to build a foundation for the furnace |

| Limited number of forms and modifications | The need to allocate a fairly large space in the bathhouse for installing a brick stove |

| Possibility of deformation from strong heat | Need to spend more money on buying building materials |

| Too dry air | Even one mistake in the brickwork can make the stove of poor quality (it will not hold high temperatures well) |

| Emission of infrared radiation | Low preparation speed for steaming (all preparatory work can be completed within an hour, and then it will take up to five to six hours for kindling). |

| Uneven distribution of heated air | — |

| The chimney needs to be cleaned constantly | — |

The chimney of a metal stove needs to be constantly cleaned Source kamin.lutsk.ua

Price

Another criterion that concerns future stove owners is its cost.

The cheapest option is a steel stove. Not only does it cost a little, but it also does not require additional steps on the part of the installer. They can be located on the floors of the first floor, which makes such stoves very cheap. However, in bathhouses the iron stove is often lined with bricks. This is done to increase its heat capacity. Such heating devices can retain heat longer than their “naked” counterparts. Thanks to the uniform distribution of thermal energy, the stoves will not be very aggressive to careless touches, but even a stove lined with brickwork is not recommended to be touched.

The average price is a cast iron stove; a high-quality model is several times more expensive than the steel version. Such structures require additional arrangement of the site to evenly distribute the load over the base.

Stone stoves for the home will cost the largest amount. This is due to the skill of the stove maker. It has been very difficult to find real professionals in their field lately; they are usually called on the advice of friends. Only when working with a trusted person can you hope for his conscientious work.

Features, types of metal and brick stoves

Simple in shape, metal sauna stoves may differ slightly in design. The classic, easiest to make option is the potbelly stove. Essentially it is a metal box with a door and a pipe. However, this form is considered uneconomical: fuel consumption is high and heat transfer is low. The thickness of the metal for a modern, more economical type of sauna stove should not be too large, the optimal one is 4-5 mm.

Some owners make a combined stove for their bathhouse, the core of which consists of metal sheets, and the outside of the structure is lined with bricks. Thus, they achieve a reduction in fire hazard and an improvement in the uniformity of heating of the surrounding air. The basis for installing such a furnace can be a concrete slab lined with ceramic tiles, refractory bricks or a metal sheet.

Among the small variety of types of metal sauna stoves, three main types stand out: closed, open and combined stoves. The first type is distinguished by a completely closed combustion zone and small size. Open stoves contain in their design places for laying out heating stones that do not close.

Closed oven Source tildacdn.com

Typically, the firebox of a homemade iron stove for a bath is placed in the waiting room, and the part with heating stones is located directly in the steam room. To properly operate an open stove, it is necessary to ensure maximum contact of stones with the outer surface of the firebox.

As for combination stoves, they have the additional ability to heat the air in the room. This can be done by equipping the structure with a network of pipes, which are attached to the stove through a pipe and are then brought out so that they cover the entire perimeter of the bathhouse complex. When the fuel in the stove burns, the energy generated heats the air, after which it begins to circulate through the pipe system. In this case, the supply of heated air is carried out by moving a special grille in the form of a valve.

Brick stoves themselves are safer than metal stoves, and also more convenient. The reason lies in the gradual and uniform heating of the air surrounding the stove. The location for the construction of such a stove must be chosen carefully. The heating element should be located near the wall of the room, but no closer than twenty centimeters from it.

Brick oven Source wmpics.pics

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Work on insulating flammable materials

A modern bathhouse is most often built of wood, and sometimes even a brick bathhouse has wooden partitions. Therefore, the partition opening where the heating device is located must be insulated.

This opening, as well as the section of the wall near the opening, is sheathed on both sides with asbestos cardboard and a sheet of metal 4 mm thick is placed on top of it. In this case, the distances from the stove body to the walls and partitions must be maintained: 32 cm to unprotected ones and 26 cm to protected ones.

Places where insulation is required

How metal sauna stoves are made

To make a homemade metal sauna stove, you will need:

- five- to eight-millimeter steel sheet (several pieces will be needed, and the size and quantity will depend on the dimensions of the firebox of the stove being manufactured);

- water tap;

- ruler or tape measure;

- Bulgarian;

- a thin metal pipe with a thickness of 5 mm to 10 mm and a length of about two meters;

- grate;

- metal scissors;

- hinges and latches (depend on the number and shape of stove doors);

- four metal squares with a side length of 10 mm, or doors for three functional compartments of the stove: for the firebox, heater and blower;

- welding machine.

First of all, the firebox is made. To do this, nine square pieces of metal measuring 50 × 50 cm are measured on a metal sheet and a box is welded from them. There should be another one inside (a separating plate), while the upper part of the firebox is needed to burn fuel, and the lower part is needed to collect ash and ash. In each of these parts, holes for the doors are cut so that they are located on top of each other. After attaching the doors, proceed to the next stage.

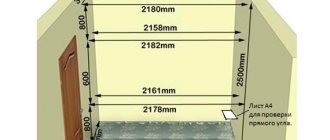

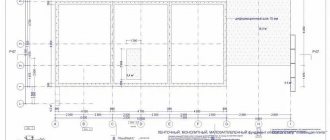

One of the options for a stove for a bath (drawing) Source vbanepar.ru

Next, two pieces are cut from a two-meter pipe: one for the firebox (90 cm), the second for the tank (60 cm), and the first of them is welded to the firebox. After this, make a rectangular hole in a larger section of the pipe with dimensions of 20 × 50 cm for the blower and securely attach the door to it. A grate (grid) is welded onto the resulting product.

Remember! To heat a room of 14 m², it is enough to have a heater with dimensions of 30 × 40 × 30 cm.

To make a heater (that part of the stove that will contain heated stones), they take several more pieces of the plate and make a container out of them, then thick iron rods (thickness - at least ten millimeters) are welded on top of the prepared firebox. Be sure to make a hole for the door and carefully weld it onto the hinges. It is worth paying attention to the fact that the structure must be strong, because these rods or metal plates need to hold a fairly large weight of stones.

Important! To fill the heater, they usually take diabase or soapstone, but refuse to use granite (it crumbles after strong heating) and stones containing mica (it helps release carbon dioxide) or the inclusion of silicon.

A heater on a stove, welded from rods Source hozsektor.ru

Another important structural element of a homemade stove is a water tank. Above the manufactured heater, first of all, another metal plate (thickness - at least 8 mm) with a pre-made hole for the chimney is welded. After this, the pipe prepared for the smoke exit is also carefully welded to the edges of the round hole.

At the final stage, they do one more thing - in the area of the rear wall of the structure, and attach a water tap. A pipe for the tank is then welded to it. It is important to make the water tank small so that you can easily weld it on top of the stove, above the heater or next to it.

In the resulting product, after welding all the structural parts together, each node will perform its functions. So, at the very bottom (above the ash container), that is, in the firebox, fuel (for example, harvested firewood) is burned, then the heat moves through the stove to the stone section, strongly heating the stones. In this case, these stone blocks can be changed or added through the door in the heater (if it is a closed type), and the smoke comes out through the chimney.

One of the options for placing a water tank and heater on a sauna stove Source baniwood.ru

The water tank is equipped with an additional lid or other auxiliary parts that will allow you to periodically fill the container with new cold liquid. Thus, they create the simplest homemade iron sauna stove with a water tank and a heater.

Metal for sauna stove

As for the metal from which a homemade stove is made, cast iron material is usually chosen, because it is much more difficult to fasten (if there are no difficulties with fastenings, cast iron is well suited for the firebox door).

Iron plates are used, but they must take into account that when such a stove operates, the temperature in the combustion chamber rises to four hundred and fifty degrees Celsius. Thin metal under such loads begins to deform and burn through. When choosing a stainless metal with a sheet thickness of 10 mm or more, you can avoid this problem, but another one will appear - the warm-up time will increase significantly, and with it, fuel consumption.

Structural steel for furnace Source steelsukraine.com.ua

If a non-professional nevertheless decides to make a stove with his own hands, be sure to take into account the advice of experts who recommend using stainless high-alloy steel grade 08x17T. It is practically not subject to corrosion and destruction by high temperatures. An example of a product that is made of just such steel is AISI 430. It will not change its shape even when heated to a temperature of + 850 °C.

The furnace compartment, called the firebox, is exposed to the highest temperature and is in direct contact with the flame. That is why steel grade 10 is chosen for this structural part (manufactured according to the GOST 1050-88 standard); for convection parts, 08PS or 08YU is suitable (manufactured according to the rules of GOST 19904-90). Structural sheet steel is considered ideal for the body of a sauna stove.

Water container

Immediately before building the stove, it is important to determine the volume of the tank in which the water will be heated. The volume of the tank will depend on the intensity of visiting the steam room

So, the calculation is made based on one liter of hot water per person. It is best to use an open container. Although there will be evaporation, there are a number of positive aspects:

- Convenient when filling the container.

- The ability to carry out maintenance or repair of the internal part if necessary, for example, remove scale, clean and dry.

- In winter, completely remove water, protecting the tank from freezing the water in it.

How to make a brick stove for a bath

A bath stove can also be made from bricks. Unlike the installation of a metal sauna stove, the brick version requires the construction of a foundation, since the device will be stationary.

Refractory brick for the stove Source prom.st

The fuel combustion chamber is lined with refractory bricks, while the external (visible) parts are decorated with burnt red. Masonry mortar is made from a mixture of sand and clay. It is the clay component that will firmly hold the brickwork. The most common version of a homemade sauna stove is a design with a base of 890 by 1020 mm. To do this, standard brick blocks are laid in a base 3.5 by 4 bricks wide. When choosing a stove with base dimensions of 1020 × 1290 mm, blocks are laid in a stove foundation measuring 4 by 5 bricks. The dimensions of a conventional stove, including the chimney, are usually 168-210 cm.

Important! Cement is not used in the manufacture of sauna stoves, as it crumbles when the masonry is heated.

Masonry of furnace walls

The brick must be wetted before laying. Then apply the required amount of solution.

The brick fits tightly into place. The mortar displaced by the brick is removed.

There is no need to plaster the internal surfaces with clay; excess mortar is unacceptable here. Once dry, it peels off and clogs the chimney duct.

Furnace casting is installed directly during masonry and fixed with wire. To ensure that the doors fit tightly to the masonry, they are wrapped around the perimeter with asbestos cord.

The cord will seal the contact points and will not allow the cast iron door, which expands when heated, to destroy the masonry.

Video description

To see how a 3x3.5 brick stove is laid, see this video:

When choosing a brick for a sauna stove, be sure to pay attention to the absence of cracks and chips, as well as mica film. The standard version is suitable, having the following dimensions: 25 × 250 × 65 mm (permissible deviation - 2 mm). If thin thread-like cracks and very slight grooves are observed on the brick, such a building material is considered to be of high quality and suitable for construction. To make the stove level, the bricks must be the same size.

Before starting the manufacture of a homemade stove, after preparing the bricks, sand mixture and a grinder with a diamond disc for cutting building materials, pre-lay (without mortar) the bottom (zero) layer. After the issue with the size and layout of the furnace base has been resolved, the first layer of bricks is put back, since first of all it is necessary to make waterproofing, securing it to the foundation.

After this, the sand and clay are cleaned of stones and other foreign matter. The clay is soaked for several days. The best material for such work is a clay mass mined in the area of one and a half meters from the surface of the earth.

Mortar of clay and sand Source 2proraba.com

Important! Always choose the clay that is part of the brick that will be strengthened with its help (for example, for fireclay bricks, it would be ideal to use fireclay clay for mortar).

Unlike making an iron stove for a bathhouse, a brick stove requires a bonding agent. To get a good solution, combine clay with water and sand, after which everything is thoroughly mixed. If the clay has a high fat content, it can be diluted in a ratio of 1 to 2, that is, one part clay to two parts sand.

You can check whether the solution came out correctly as follows. Take a wooden stick and dip it into the solution. After this, they carefully look at the sand-clay layer that has stuck to the piece of wood: if its thickness is 2 mm, they begin the intended work.

Prepare for installation:

- bricks;

- emery wheel;

- order;

- pliers;

- broom and dustpan;

- container for soaking bricks and water.

In order to remove unnecessary air bubbles from the brick, as well as to prevent dehydration of the solution and wash away dust, it is pre-soaked, that is, immersed in water for a while immediately before laying begins.

This is how bricks are soaked Source kronotech.ru

Construction of a foundation made of rubble concrete

For laying the base of a sauna stove, the strength of the clay mixture is not enough. A regular mortar based on cement and sand will do. The most common foundation is made of rubble concrete.

Stages of work:

Digging a pit with a depth of 1 - 1.2 cm in dimensions exceeding the dimensions of the stove by 15 - 20 cm. Compaction of the soil with suitable cuttings of timber or logs. A timber measuring 100×100 mm is suitable. Laying crushed stone and compacting it to a layer 15 cm thick. Installing formwork. Waterproofing of its internal surface is required. Laying rubble 20 - 30 cm.

The maximum size of individual rubble stones is no more than 15 cm. Filling small fractions of voids between stones with crushed stone. Laying concrete mortar. Concrete must fill all the voids, for which its consistency is chosen to be similar to sour cream. This stage is repeated the required number of times until the desired height of the foundation. Laying the last layer of stones.

Ensuring a level height of 6 - 7 cm to the finished floor Controlling the horizontality of the surface Drying the concrete covered with a film for 15 - 30 days Dismantling the formwork Isolating the side foundation surfaces from water. You can isolate the foundation from water at the stage of its construction by adding special additives to the solution. Filling the space between the foundation and the edges of the pit with sand. A gap of at least 5 cm is required between the bathhouse and stove foundations. It must be filled with sand.

Features and important nuances of constructing a stove for a bath

In order to properly make a homemade stove for a wood-burning sauna with a water tank or build a brick one, you need to know in advance some rules that should be followed when working on this useful device:

- They think in advance about exactly what plan the stove will be made in order to prepare all the necessary tools and materials in sufficient quantity.

- To produce a metal furnace, you can also use an unnecessary iron barrel, which eliminates the common problem of unsoldering the seams of the product.

- After completing the welding work (if any), be sure to check each seam made for integrity.

- A container for laying stones can be provided for both metal and brick sauna stoves.

- When selecting bricks, clay, sand or metal sheets for making a bathhouse, you should always give preference to high-quality materials. In some cases, the material is improved independently: for example, sand is sifted to include large fractions, and other components are cleared of debris.

Cast iron

The manufacture of cast iron stoves requires casting, so only steelworkers at the factory can make it themselves. Such installations must be purchased from trusted companies with good reviews.

But after purchasing, you can connect this heat source yourself. To do this, it is enough just to place the stove in its permanent place and ensure that combustion products exit into the street. The walls closest to the installation must be finished with non-combustible material. Basalt fabric is used as it. You can mount metal sheets, it will be much cheaper, but the metal near the furnace will certainly heat up and pose a threat to careless people passing by.

Video description

One of the options for assembling a bathhouse using the example of a layout is shown in this video:

- When making a stove, they always remember that the stove is being made for loved ones, relatives, and friends, so they always check the safety of using the selected building materials.

- The quality of steaming in a built sauna depends, among other things, on the regularity and thoroughness of cleaning the stove.

- If an already unnecessary gas cylinder is used for a sauna stove, the doors are carefully cut out from it, then additional money is avoided on these structural elements.

- Homemade sauna stoves can have a vertical or horizontal firebox.

- When purchasing doors for the firebox and ash pans, compare their size in advance with the dimensions of the future stove (they also think about it in advance and purchase fasteners in the required quantity).

- If the stove is made without a heating water tank, you just need to equip the chimney with a steel heat exchanger and run pipes to the water used for showering, then the thermal energy generated in the firebox is used more fully.

Drawings of a metal stove for a bath Source oboiman.ru

- The air flow, when passing through a stove made of a thick pipe, a metal barrel or an unused cylinder, flows around it, thus improving heat transfer.

- A very hot metal stove is additionally separated from the rest of the space by brick walls, then the level of fire safety is acceptable.

Selection of bricks for walls and fireboxes

What kind of brick to line the stove with?

Most of the furnace mass is laid out from ordinary clay (red) bricks. Sand-lime or hollow bricks are not suitable.

Most often, white color is used for plastering. Popular names include whitewashing the stove, or “white stove.” If the stove is left without finishing, you need to use bricks of type M 200 and higher.

High-quality red brick measuring 25 × 12 × 6.5 cm has no cracks. It has even corners and weighs 3.2 - 3.5 kg. When tapped with a hammer, the brick produces an almost metallic sound, clear and sonorous.

Attention! The characteristics of a brick are most stable in one batch, so you need to buy all the bricks at the same time, without relying on subsequent purchases. For the lining (protective internal lining) of the firebox, use fireclay bricks of the brands SHA, SHAK, ShB, SHUSim similar

It is heat resistant and has good thermal conductivity

For the lining (protective internal lining) of the firebox, use fireclay bricks of the brands SHA, SHAK, SHB, SHUSim similar. It is resistant to heat and has good thermal conductivity.

Purchasing bricks from a manufacturer will eliminate the risk of purchasing low-quality material.

Briefly about the main thing

Brick and iron stoves for baths bring even more benefits if they are carried out after appropriate calculations and drawing up a diagram.

Bath stoves can have different volumes, which depend on the size of the steam room and the type of bath.

Metal stoves are good for their mobility, simplicity and ease of manufacture, while brick stoves are good for their aesthetic appeal, softness of steam and safety.

Each of the sauna stove options has its own negative aspects: brick products are heavy, emit infrared radiation and require additional fire safety measures, while brick products require cleaning and heat up unevenly.

A metal sauna stove is made from thick sheets, but for brick stoves you need to purchase a certain amount of refractory bricks.

A device for heating water and steam for bathing procedures can be combined and include several different materials in its design.

Typically, a sauna stove design includes a firebox, a heater, a place for ash and a heating tank with water.

Thin metal used for a sauna stove may burn out after several uses, and non-combustible brick in the firebox may burst or crack.

Doors are one of the most important elements of a sauna stove, therefore they must be selected with special attention or made independently.

Since there are a lot of designs for sauna stoves, each master designs his own unique version for his home or cottage.

To choose a suitable stove for a bath, consider the manufacturing features of each of them.

Ratings 0

Steel

Installing a steel stove is the simplest. To do this, you don’t even have to ask the movers to deliver it to the place. Steel models weigh little and therefore can be installed without outside help. As is the case with cast iron installations, steel ones require a chimney device and protection made of non-combustible material.

The choice of stove depends on the requirements of the home owners. steel options are chosen by lovers of summer holidays in the country. The equipment can be installed independently, it does not require maintenance and, if necessary, heats the room very quickly.

Cast iron stoves can be used year-round, are durable, and appeal to weekend getaways year-round.

A stone stove is an ideal option for people who permanently live outside the city or come to their dacha with enviable regularity.

Useful properties of steam

It is impossible to imagine a real Russian bathhouse without steam. Steam expands skin pores and removes harmful toxins from the body. The skin becomes more elastic and firm.

Heat dilates blood vessels, stimulating metabolism. The human brain is freed from mental and emotional stress, bringing the entire body into a peaceful state.

The heat of a steam room is an excellent cure for joint disease. It was not for nothing that our ancestors loved going to the bathhouse, mercilessly whipping themselves there with brooms, and to get steam, you would need a sauna heater. Let's figure out how to choose a heater for a bath or make it yourself. Most often, a traditional wood stove is used, although an electric one can be installed.

Safety rules for use

To make the structure fireproof, consider protecting all surfaces that are located in the same room with the unit. Walls that are almost in contact with it or are at a distance of 10 centimeters must be covered with thermal insulation material.

[email protected] _masters

Do not forget to pay attention to the arrangement of the pipe passage through the roof. The chimney outlet must be sealed with heat-resistant sealant.

Calculations, diagrams, drawings

Some craftsmen prefer to build a sauna stove “by eye,” arguing for the simplicity and undemanding nature of the structure. But the thermal regime and quality of the steam depend on how correctly it is designed (if desired, you can always install a steam generator in the bathhouse). For example, with excess power, the air in the steam room will heat up very quickly, but the stones will remain cold for a long time. If the performance of the heating device is not enough, then it will constantly overheat, which will quickly disable it.

The parameters of a sauna stove are calculated based on the actual cubic capacity of the room. To determine the volume of a steam room, three quantities are multiplied - its length, height and width. After this, adjustments are made related to the characteristics of a particular structure. So, for bathhouses with a bare frame, the obtained value must be increased by 1.5 times, and for each uninsulated square meter of surface (windows, doors, etc.) 1.2 m3 is added to the volume of the room. For example, the actual volume of an unclad building measuring 2x2x3 m with a window (1x1 m9 and a glass door (1x2 m) is taken equal to V= 2x2x3x1.5+1.2+2.4=21.6 m3.

Experienced stove makers calculate the power of the stove based on the fact that for each cubic meter of the actual volume of the steam room, 1 kW of energy will be required. So, in our case, a 20 kW heating device is suitable. To calculate the size of its firebox, the resulting power is multiplied by 2. For example, in the example discussed above, a firebox with a volume of 40 liters will be required. As for the linear dimensions, the height of the combustion chamber should be no more than 2/3, and the depth should be no less than 2.5 of its width.

Arrangement of the base

A large stove must be installed on a solid foundation

A heavy brick oven is placed on the foundation, and not on the floor of the structure. The foundation of a heavy stove is built separately from the foundation of the house. The foundation is similar to creating a strip foundation. Stages of work:

- marking the foundation and driving in pegs along the edges;

- stretching a rope between pegs for orientation;

- digging a pit: 0.6 m deep with the last 10 cm widening by 15 cm, the width and length must correspond to the dimensions of the furnace;

- the bottom of the foundation is covered 10-15 cm with sand and compacted;

- the sand is covered with broken bricks or crushed stone and compacted;

- lay out a waterproofing layer and construct formwork;

- the pit is filled with concrete reinforced with mesh or tied reinforcement;

- When pouring, leave 15 cm for the starting row of the oven.

A waterproofing layer is laid on top:

- coating with melted bitumen;

- roofing felt coating;

- another layer of bitumen and roofing felt.

The waterproofing layer will protect against the ingress of groundwater.